CE 428 -DesignActiva..

advertisement

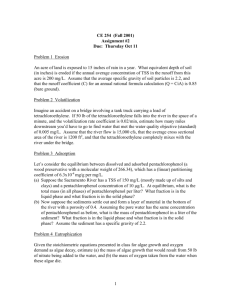

CE 428 Water and Wastewater Treatment Design Dr. S. K. Ong Design of Completely Mixed Activated Sludge System Design a completely mixed activated sludge and secondary settling facility to treat 5.71 mgd (0.25 m3/s) of settled wastewater with 250 mg/L BOD5. The effluent is to have 20 mg/L of BOD5 or less. Assume temperature at 20o C. (i) Influent volatile suspended solids to reactor are negligible (ii) ratio of mixed liquor VSS (MLVSS) and mixed liquid suspended solids (MLSS) = 0.8 (iii) Return sludge concentration = 10,000 mg/L SS (iv) MLVSS = 3,500 mg/L in aeration tank (v) Design mean cell residence time c = 10 d (vi) Effluent contains 22 mg/L of biological solids, 65% is biodegradable (vii) BOD5 = 0.68 BODL (viii) Wastewater contains adequate nitrogen, phosphorus and trace nutrients for biological growth (ix) Peak hourly flow rate is 2.5 times the average flow rate 1. Estimate the concentration of soluble BOD5 in the effluent using the following relationship Effluent BOD5 = soluble BOD5 + BOD5 of effluent suspended solids (a) determine BOD5 of the effluent suspended solids i. Biodegradable portion of effluent biological solids is 0.65(22 mg/L) = 14.3 mg/L ii. Ultimate BODL of the biodegradable effluent solids is (14.3) (1.42 mg O2 consumed/mg cell oxidized) = 20.3 mg/L iii. BOD5 of effluent suspended solids = 20.3 0.68 = 13.8 mg/L (b) Effluent soluble BOD5 escaping treatment is given by: 20 mg/L = S + 13.8 mg/L S = 6.2 mg/L 2. Treatment efficiency, E = (So – S) 100/ So Efficiency of soluble BOD5 is (250 – 6.2) 100/250 = 97.5 % Overall plant efficiency is (250 – 20) 100/250 = 92% 3. Compute reactor volume, use: Y(So S ) X c (1 k d c ) therefore V c QY (So S ) X (1 k d c ) V Q V (10 d) (5.71 mgd )( 0.5)[( 250 6.2)mg / L] (3500 mg / L) (1 0.06 10 d)) V = 1.24 million gallons or 4694 m3 Based on the sizes of aeration tank: select two aeration tanks with depth of 6 m. With a width to depth ratio of 1.0:1 to 2.2:1, select 1.5:1 Width = 6 m 1.5 = 9 m Length = 4694/[2(9 6)] = 43.5 m select 45 m, add freeboard of 1 m Volume of reactor = 4596 = 2430 m3 4. HRT of reactor = (2430 m3) 2(264.17 gal/m3)/5.21 x 106 gal/d = 0.246 days = 5.9 hrs 5. Waste to be wasted each day to maintain sludge age of 10 days c X V Q w X w Qe Xe X V Q w X w (Q Q w )X e Q w X w (Q Q w )X e X V c (3500 )( 45 9 6)2 10 = 170100 x 103 mg of MLVSS/day = 1701 kg of MLVSS/day or QwXw = 1701 – (Q – Qw)Xe then = 1701 – [(0.25 m3/s) 1000 L/m386400 s/d] 22 mg/L0.8 MLVSS/MLSS/106 kg/mg QwXw = 1701 – 380.16 assume Q >> Qw = 1321 kg MLVSS/day Since Xw = 10,000 mg/L MLSS In terms of MLVSS = 10,000 0.8 = 8,000 mg/L MLVSS Therefore Qw = 1321 (kg/day)/[8000 (kg/106 mg) (1000L/m3)] = 165 m3/day or 0.0019 m3/s (Q >> Qw, assumption is ok) 6. Recirculation rate 0.246 1 c 10 0.975 0.76 r Xw 8000 1.286 1 1 3500 X 1 7. Oxygen requirements (no nitrification at 10 days SRT) (a) compute the mass of BODL of the incoming wastewater that is converted to the process, assuming that BOD5 is equal to 0.68 BODL Mass of BODL utilized (lb O2/day) = Q(So – S) 8.34/0.68 In terms of kg/d = Q(So – S)/0.68 = (0.2586,400 s/d)(250 – 6.2) 1000/(106 0.68) = 7,744 kg/d Oxygen requirements (kg/d) = 7744 – 1.42 (1321) = 5868 kg/day Volume of air needed is given by: Assume oxygen transfer efficiency = 8% Safety factor of 2 for actual design volume for sizing blowers Air density is 0.075 lb/ft3 % by weight of oxygen in air = 23.2% in terms of lb/day = 5868 2.2 lb/day/(0.0750.232) = 741,425 ft3/day Air requirement = 741,425/0.08 = 9,267,813 ft3/day or 6,436 ft3/min Design air requirements = 2 6,436 Check: Air volume/flow rate = 12,872 ft3/min = 9,267,816 ft3/d/5,710,000 gal/d = 1.62 ft3/gal Air requirement per lb of BOD5 removed = (9,267,816 ft3/d)/[(250 – 6.2) (5.71) 8.34] = 798 ft3/lb BOD5 removed Check against Ten States Standard Organic loading F/M Ratio (lb BOD5/d/1000 ft3) = 40 (lb BOD5/d/lb MLVSS) = 0.2 – 0.5 Organic Loading = (0.25 m3/s)(250 mg/L) (1000 L/m3)(86,400 s/d) (2.2)/[(106)(64592 m3)(3.28)3] = 0.069 lb BOD5/d/ft3 = 69 lb BOD5/d/1000 ft3 Does not meet Ten States Standard but meets loading rates in notes F/M ratio = (0.25 m3/s)(250 mg/L)(1000 L/m386,400 s/d)/[(3500)(69452 m3)(1000)] = 0.32 within Ten States Standard