DEVELOPMENT OF CAPILLARY ELECTROPHORESIS

advertisement

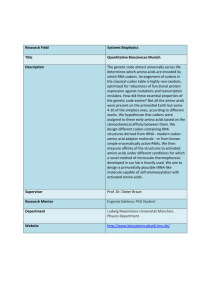

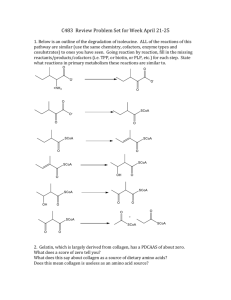

DEVELOPMENT OF CAPILLARY ELECTROPHORESIS-FLUORESCENCE METHOD FOR DETERMINATION OF AMINO ACIDS IN HEALTH DRINK SAMPLES Natta Wiriyakun1,*, Ajala Praneedsuranon1, Duangjai Nacapricha1,2, Rattikan Chantiwas1,# 1 Department of Chemistry and Center of Excellence for Innovation in Chemistry, Faculty of Science, Mahidol University, Rama VI Rd, Rachathewi, Bangkok 10400, Thailand 2 Flow Innovation-Research for Science and Technology Laboratories (FIRST Labs), Thailand *e-mail: n.wiriyakun@gmail.com, #e-mail: rattikan.cha@mahidol.ac.th Abstract Development of a simple capillary electrophoresis has been investigated to determine amino acids (Lysine; Lys, Tyrosine; Tyr, Phenylalanine; Phe, Isoleucine; Ile and Glycine; Gly) in health drink samples. An in-house capillary electrophoresis system with fluorescence detection was set up and the capillary electrophoresis separation method was investigated. The optimum capillary electrophoresis separation conditions such as buffer system; buffer concentration, addition of hydroxyl propyl(methyl) cellulose, injection volume (siphoning injection time) are presented. Electrophoretic separation conditions were borate buffer (40.0 mM, pH 9.00) containing SDS (20.0 mM) and HPMC (0.1%, w/v) and applied electrical field strength of 270 V/cm. The linear calibration curves of Lys-FITC, Phe-FITC and Ile-FITC were 30-250 μM, while Tyr-FITC was linear in range of 20-250 μM, and Gly-FITC was obtained in range of 50-250 μM. Percentage of relative standard deviation (%RSD) of migration times and peak area were less than 3.2% and 4.9%, (n=3), respectively. Limit of detection (LOD) and limit of quantification (LOQ) for all amino acids were less than 29 µM and 95 µM, respectively. Determination of amino acids in health drink samples was carried out by developed method. The labeled amount of amino acids contained in the samples and the measured amounts by CE-FL method were compared. Percentage of difference was acceptable, it was less than 15%. The reasonable accuracy based on recovery study for Lys, Ile and Phe was in ranges of 80-115% (n=3). Keywords: amino acids, capillary electrophoresis, fluorescence, health drink samples, spectrofluorometer Introduction Amino acids play important role in structural formation of protein that necessary for the growth and repairing of tissue, red blood cells, enzymes, and other materials in the body (1). Amino acids have been taken from diets, however, the variety of diets in these day affects unhealthy human-eating behaviors and consequence the insufficient consumption of amino acids (2). Therefore, the amino acids were added in several health drink samples in order to help people consume enough nutrients and increase their market values. Nowadays, there is no standard method to monitor amino acids in health drink samples. Analysis of amino acids is challenging because of the lack of UV absorbing, electroactive groups or fluorescent groups in their native structures. Fluorescence is the most typically used to detect amino acids due to high sensitivity of detection. Fluorescein isothiocyanate (FITC) is one of the most commonly used fluorophore that has been applied to derivatize amino acids for fluorescence detection (3). Due to various amino acids containing in health drink samples, separation techniques are required to use for measurement of amino acids. Gas chromatography (GC), high performance liquid chromatography (HPLC) and capillary electrophoresis (CE) are methods that have been utilized for separation of amino acids. Among of these techniques, CE has been interested as an effective method. It provides high separation efficiency, low chemical volume consumption in the level of nanoliter and the variety in separation mode by modification of buffer system (4). Capillary electrophoresis is widely applied to biochemical samples such as protein, enzyme and amino acids (5). In this work, we present the development of capillary electrophoresis-fluorescence method for determination of amino acids in health drink samples. The CE system was an inhouse set up with fluorescence detection using a spectrofluorometer. The spectrofluorometer assembled with a fiber optic to probe excitation and emission beams onto capillary window for detection. Capillary electrophoretic separation conditions such as running buffer systems and injection method have been investigated for the developed CE method for amino acids separation. The developed capillary electrophoresis-fluorescence detection (CE-FL) method was applied to determination of amino acids in health drink samples. Methodology Chemicals and materials Borate buffer solution was prepared from boric acid and sodium hydroxide (Fluka, Switzerland). Standard solutions of L-Lys, L-Tyr, L-Phe, L-Ile and L-Gly (Fluka, Switzerland) were prepared in borate buffer. Standard solution of FITC (Acros organics, USA) was prepared in borate buffer. Sodium dodecyl sulfate (SDS) and hydroxyl propyl(methyl) cellulose (HPMC) were from Sigma-Aldrich (Germany). All solutions were prepared using ultra purified water (EZ pure 2 model system, USA) prior to filter through 0.45 µm cellulose acetate filter (Steritech, USA). Amino acids derivatization Derivatization of individual standard amino acid using FITC was prepared by mixing each standard amino acid (1.0 mM) and FITC solution (1.25 mM) in ratio of 1:1. The mixture solution was gently mixed for 12 hours under a dark room (Temperature = 25°C). Then, the solution was filtered through 0.45 µm cellulose acetate membrane. All solutions were degassed by ultrasonication for 5 min before the CE analysis. Capillary electrophoresis with a fluorescence detection system The in-house CE instrument with FL detection system is shown in Figure 1. Figure 1. Schematic of in-house capillary electrophoresis with fluorescence detection system. Fused-silica capillary (50 µm i.d., 360 µm o.d., Polymicro, USA) was 56.0 cm total length with effective length of 41.0 cm (inlet end to detection end). A high voltage power supply (model SL30, Spellman, USA) was used for applying electrical voltage of 15 kV. A spectrofluorometer (LS55 model PerkinElmer, USA) was used as a fluorescent detector for CE detection system. The FL detector assembled with an optical fiber with excitation wavelength and emission wavelength of 488 nm and 520 nm. Results Investigation of buffer systems Borate buffer (pH 9.00) containing 20.0 mM SDS has been typically used as a CE running buffer for amino acids in CE separation (6), therefore, this buffer condition was chosen as an initial conditions. Investigation of borate buffer concentrations and an addition of HPMC concentrations to obtain optimal buffer system is presented as shown in Figure 2 and Table 1. - Effect of borate buffer concentration Figure 2. Electrophorograms of amino acid mixture solutions (150 M of Lys, 75 µM of Tyr, Phe and Gly): (1) Lys-FITC, (2) Tyr-FITC, (3) Phe-FITC, (4) Gly-FITC and (*) residual FITC. Conditions: hydrodynamic injection (10 cm height for 30 s), separation electrical field strength of 270 V/cm, borate buffer (pH 9.00) containing SDS (20.0 mM) with (A) borate buffer of 20.0 mM and (B) borate buffer of 40.0 mM. Figure 2A and 2B show electrophorograms of amino acids separation (Lys-FITC, TyrFITC, Phe-FITC and Gly-FITC) using borate buffer concentrations, 20.0 mM and 40.0 mM, respectively. Borate buffer concentration was studied to control the electroosmotic flow (EOF) by increasing of borate buffer concentration from 20.0 mM to 40.0 mM, the EOF increased (7). The resulting electrophorograms illustrated that these standard amino acids were well-separated except Tyr-FITC (peak 2) and Phe-FITC (peak 3). It can be seen that peak 2 (Tyr-FITC) and peak 3 (Phe-FITC) overlapped (see Figure 2A). Resolving of these two peaks slightly improved when using 40.0 mM borate buffer (see Figure 2B). Higher borate buffer concentrations than 40.0 mM may improve peaks resolution, however, this has not been carried out due to electrophoretic current issue. Since the joule heating in the capillary possibly occur when electrophoretic current is higher than 30 µA (4),(8). Resulting electrophoretic current obtained when utilizing borate buffer of 40.0 mM containing 20.0 mM SDS was 34 µA which is very close to tolerate limit electrophoretic current for CE. In this experiment, 40.0 mM borate buffer concentration was then chosen. - Addition of hydroxyl propyl(methyl) cellulose (HPMC) Hydroxyl propyl(methyl) cellulose (HPMC) has been generally added into running buffer for using in CE separation to suppress the electroosmotic flow (9). To improve peak separation between Tyr-FITC and Phe-FITC, HPMC was added into borate buffer (40.0 mM containing 20.0 mM SDS) to improve peaks separation, especially between peak 2 and peak 3. Resolution (Rs) between Tyr-FITC and Phe-FITC was calculated from electrophorograms in order to illustrate the improvement of separation. Table 1 shows Rs between Tyr-FITC and Phe-FITC from the electrophorograms obtaining of running buffer without HPMC (0%, w/v) and with HPMC (0.1%, w/v). Table 1 shows Rs between Tyr-FITC and Phe-FITC was 0.5 when running buffer without HPMC (0.0%, w/v), whereas Rs between Tyr-FITC and PheFITC was 0.8 when running buffer with adding HPMC (0.1%, w/v). Further improvement in Rs between Tyr-FITC and Phe-FITC was limited when adding HPMC (0.2%, w/v), besides the irreproducibility in migration times of Tyr-FITC and Phe-FITC peaks were experienced (data are not shown). Therefore, the HPMC concentration (0.1%, w/v) was selected to add into borate buffer (40.0 mM, pH 9.00) for higher resolution of separation of separating peaks. Table 1. Resolution (Rs) between Tyr-FITC and Phe-FITC from the electrophorograms obtaining of running buffer without HPMC (0%, w/v) and with HPMC (0.1%, w/v). HPMC concentration, %(w/v) Resolution (Rs*) between Tyr-FITC and Phe-FITC, n=3 0.0 0.5 ± 0.1 0.1 0.8 ± 0.1 0.2 - *Rs was calculated from [1.7(tm2 – tm1)/(w1/21+ w1/22)], where tm = migration time and w1/2 = peak width at half height. Effect of siphoning injection time Due to the fact that injection volume contributes peak broadening in electrophoresis separation, injection volume of standard amino acids was investigated. This injection method based-on siphoning method, it was done by elevating the inlet capillary end (10 cm) while keeping the outlet end at the same position. (A) Injection time = 5 s Rs = 1. 2±0.2 (B) Injection time = 10 s Rs = 1.2±0.1 (C) Injection time = 30 s Rs = 0.8±0.1 Figure 3. Electrophorograms of amino acid mixture solutions (150 M of Lys, 125 µM of Tyr, Phe and Gly): (1) LysFITC, (2) Tyr-FITC, (3) Phe-FITC, (4) Gly-FITC, (*) residual FITC and (**) unknown when using the different hydrodynamic injection times of (A) 5 s, (B) 10 s and (C) 30 s. Separation conditions: borate buffer (40.0 mM, pH 9.00) containing SDS (20.0 mM) and HPMC (0.1% (w/v)) and applied electrical field strength of 270 V/cm. Note: Unknown peaks (**) were observed in the electrophorograms, these may be due to impurities from prepared amino acids. Injection volume was calculated from [ρg∆Hd4πt/128ηL], where ρ = buffer density (1 g/cm3), g = gravitational constant (6.67×10−11 m3/kg s2), ∆H = height differential of capillary inlet and outlet (10 cm), d = capillary inside diameter (50 µm), t = injection time (5 s, 10 s, 30 s), η = buffer viscosity (1 kg/ms) and L = total capillary length (56.0 cm). Siphoning injection times of 5 s, 10 s and 30 s, were carried out in this experiment, the calculated volumes were 1.5 nL, 2.9 nL and 8.7 nL, respectively. Resulting electrophorograms of the separation of standard amino acids are shown in Figure 3A, 3B and 3C when applying siphoning times of 5 s, 10 s and 30 s, respectively. Resolutions between peak 2 and peak 3 were given in each electrophorogram; Rs = 1.2 ± 0.2, 1.2 ± 0.1 and 0.8 ± 0.1 were obtained when injection time of 5 s, 10 s and 30 s were used, respectively. Therefore, siphoning injection time was selected at 10 s throughout this experiment. Summary of CE conditions for the amino acids separation The investigated CE conditions; borate buffer concentration, addition of HPMC and siphoning injection time were summarized as shown in Table 2. Table 2. Summary of CE conditions for amino acids separation Conditions Optimum value Borate buffer concentration 40.0 mM HPMC concentration 0.1% (w/v) Siphoning injection time 10 s The figures of merit of the developed CE-FL method such as linearity range, regression coefficient (r2), limit of detection (LOD), limit of quantification (LOQ) and reproducibility were listed as in Table 3. Linearity range of each amino acid is shown with obtaining of linear coefficient (r2) higher than 0.99. The precision of the method was estimated based on the reproducibility of peak area and migration time. Overall reproducibility (%RSD) was less than 5% (n=3). Limit of detection (LOD) was less than 29 µM and limit of quantification (LOQ) was less than 95 µM for all interested amino acids. Table 3. Linearity, limit of detection (LOD), limit of quantification (LOQ) and reproducibility studies for amino acids separation (n=3). 1 2 Reproducibility (%RSD) Linearity range (µM) Regression coefficient (r2) LOD1 (µM) LOQ2 (µM) Migration time Peak area Lys 30-250 0.9989 29 93 1.7 3.8 Tyr 20-250 0.9994 4 18 1.7 4.7 Phe 30-250 0.9988 28 94 2.8 4.9 Gly 50-250 0.9995 8 27 1.6 3.7 Ile 30-250 0.9924 28 95 3.2 4.4 Amino acid Limit of detection (LOD) was calculated from 3[SD/slope]. Limit of quantification (LOQ) was calculated from 10[SD/slope]. Determinations of amino acids in health drink samples The developed CE method was applied to determine amino acids contents in health drink samples. The samples (S1, S2, S3, and S4) were bought from the supermarkets in Bangkok. From the labeled amount of each sample, it is found that there are two samples (S1 and S2) contained Lys whereas Ile and Phe were contained in all samples. Figure 4. Bar graphs of the amino acid contents in health drink samples determined from the developed CEFL method (n=3), vs from the labeled amounts; (A) Lys (B) Ile (C) Phe. Figure 4 depicts amino acids contents; (A) Lys, (B) Ile, (C) Phe determined by the developed CE-FL method and stated on the sample label. It is found that the measured amount of Ile and Phe were 790 ± 50 µM and 660 ± 60 µM, 800 ± 50 µM and 780 ± 60 µM, 590 ± 30 µM and 900 ± 50 µM, 700 ± 50 µM and 580 ± 30 µM (n=3), for S1, S2, S3, S4, respectively. Whereas, the measured amount of Lys were 610 ± 30 µM and 770 ± 50 µM (n=3), for S1 and S2, respectively. The labeled amount of amino acid contents with the measured amount by CE-FL method was compared with acceptable different percentages of 15%. The recovery of the developed CE-FL method was studied by spiking standard amino acids to the sample matrix. The recoveries of Lys-FITC, Ile-FITC and Phe-FITC were in ranges of 90-110%, 81-110% and 80-115%, (n=3), respectively. Discussion and Conclusion The in-house CE system FL detection has been developed for determination of five amino acids (Lys-FITC, Ile-FITC, Tyr-FITC, Phe-FITC, Gly-FITC) in health drink samples. Electrophoretic separation conditions such as buffer system; buffer concentration, addition of hydroxyl propyl(methyl) cellulose; siphoning injection time were investigated to obtain the optimal conditions for amino acid separation. The optimal CE conditions were borate buffer (40.0 mM, pH 9.00) containing SDS (20.0 mM) and HPMC (0.1 %, w/v) with siphoning (by elevating the inlet capillary end (10 cm) while keeping the outlet end at the same position) injection time of 10 s. Linearity range of each amino acid was obtained in ranges of 20-250 µm with acceptable reproducibility (less than 5%, n=3). The developed CE-FL method was applied for determination for amino acids (Lys, Ile, Phe) in health drink samples. The different percentage of labeled amount of amino acid contents compared with the measured amount by CE-FL method was acceptable (%difference ≤15%) for all samples. The recoveries of spiked standard amino acids (Lys-FITC, Ile-FITC and Phe-FITC) were acceptable in ranges of 80-115%. These results indicated that the developed CE-FL system is a promising method for determination of amino acids content in health drink samples with good accuracy and precision. References 1. Poinsot VC, M.; Bouajila, J.; Gavard, P.; Feurer, B.; Couderc, F. Recent advances in amino acid analysis by capillary electrophoresis. Electrophoresis. 2012;33:14-35. 2. Herrero MGa-Ca, V.; Simo, C.; Cifuentes, A. Recent advances in the application of capillary electromigration methods for food analysis and Foodomics. Electrophoresis. 2010;31:205-18. 3. Jin LJR, I.; Li, S. Enantiomeric separation of amino acids derivatized with fluoresceine isothiocyanate isomer I by micellar electrokinetic chromatography using b- and g-cyclodextrins as chiral selectors. Electrophoresis. 1999;20:1538-45. 4. Lagane BT, M.; Couderc, F. Capillary electrophoresis: theory, teaching approach and separation of oligosaccharides using indirest UV detection. Biochemistry and Molecular Biology Education. 2000;28:251-5. 5. MacTaylor CEE, A.G. Critical review of recent developments in fluorescence detection for capillary electrophoresis. Electrophoresis. 1997;18:2279-90. 6. Tezcan FU, S.; Uyar, G.; Öztekin, N.; Erim, F. Determination of amino acids in pomegranate juices and fingerprint for adulteration with apple juices. Food Chemistry. 2013;141:1187-91. 7. Chapman SDGaPJ. Measuring Electroosmotic Flow in Microchips and Capillaries. In: Henry CS, editor. Microchip Capillary Electrophoresis: Methods and Protocols. Totowa, NJ: Humana Press Inc.; 2006. p. 187-201. 8. Weinberge R. Practical Capillary Electrophoresis. New York: Academic Press; 1995. 9. Yasui TM, M.R.; Kaji, N.; Okamoto, Y.; Tokeshi,M.; Baba, Y. Characterization of low viscosity polymer solutions for microchip electrophoresis of non-denatured proteins on plastic chips. Biomicrofluidics. 2011;5:044114. 10. Cooper SF, G.; Brown, S.; Nelson, S.; Hesselberth,J;. MacCoss, M.; Fields, S. High-throughput profiling of amino acids in strains of the Saccharomyces cerevisiae deletion collection. Genome Research. 2010;20:1288-96. Acknowledgements: The authors would like to thank Mahidol University, the Center of Excellence for Innovation in Chemistry (PERCH-CIC) and King Rama VII and Queen Foundation for partial support. Thanks to Center for Instrument Facility (CIF), Faculty of Science, Mahidol University for providing research facilities.