General Water Chemistry Protocol

advertisement

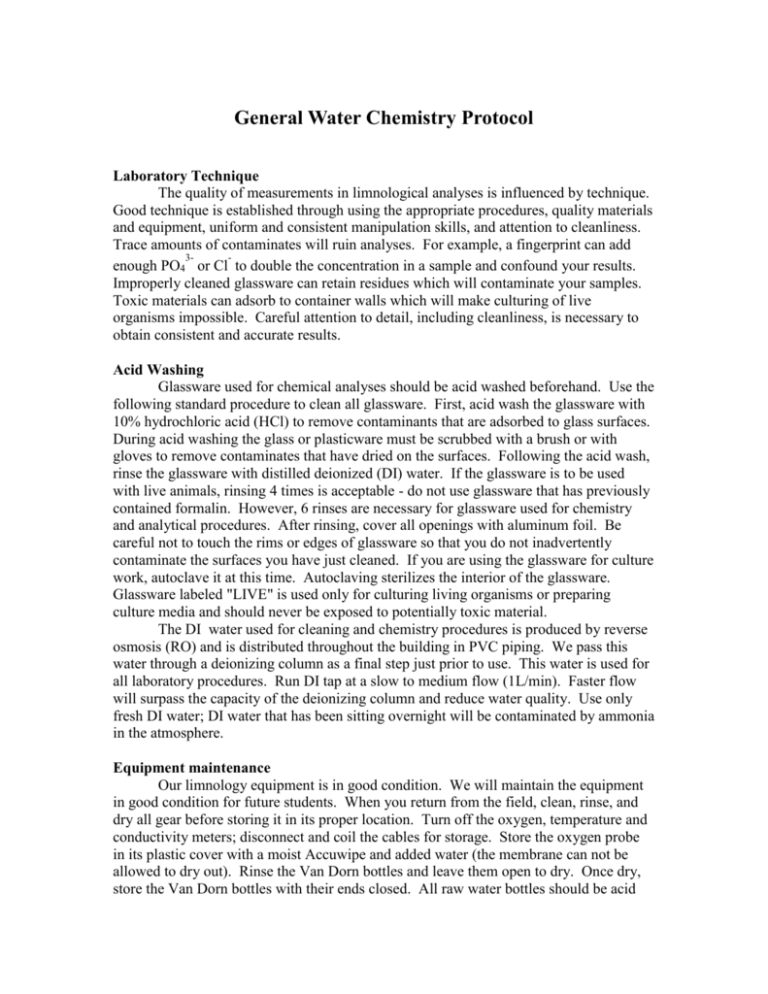

General Water Chemistry Protocol Laboratory Technique The quality of measurements in limnological analyses is influenced by technique. Good technique is established through using the appropriate procedures, quality materials and equipment, uniform and consistent manipulation skills, and attention to cleanliness. Trace amounts of contaminates will ruin analyses. For example, a fingerprint can add 3enough PO4 or Cl to double the concentration in a sample and confound your results. Improperly cleaned glassware can retain residues which will contaminate your samples. Toxic materials can adsorb to container walls which will make culturing of live organisms impossible. Careful attention to detail, including cleanliness, is necessary to obtain consistent and accurate results. Acid Washing Glassware used for chemical analyses should be acid washed beforehand. Use the following standard procedure to clean all glassware. First, acid wash the glassware with 10% hydrochloric acid (HCl) to remove contaminants that are adsorbed to glass surfaces. During acid washing the glass or plasticware must be scrubbed with a brush or with gloves to remove contaminates that have dried on the surfaces. Following the acid wash, rinse the glassware with distilled deionized (DI) water. If the glassware is to be used with live animals, rinsing 4 times is acceptable - do not use glassware that has previously contained formalin. However, 6 rinses are necessary for glassware used for chemistry and analytical procedures. After rinsing, cover all openings with aluminum foil. Be careful not to touch the rims or edges of glassware so that you do not inadvertently contaminate the surfaces you have just cleaned. If you are using the glassware for culture work, autoclave it at this time. Autoclaving sterilizes the interior of the glassware. Glassware labeled "LIVE" is used only for culturing living organisms or preparing culture media and should never be exposed to potentially toxic material. The DI water used for cleaning and chemistry procedures is produced by reverse osmosis (RO) and is distributed throughout the building in PVC piping. We pass this water through a deionizing column as a final step just prior to use. This water is used for all laboratory procedures. Run DI tap at a slow to medium flow (1L/min). Faster flow will surpass the capacity of the deionizing column and reduce water quality. Use only fresh DI water; DI water that has been sitting overnight will be contaminated by ammonia in the atmosphere. Equipment maintenance Our limnology equipment is in good condition. We will maintain the equipment in good condition for future students. When you return from the field, clean, rinse, and dry all gear before storing it in its proper location. Turn off the oxygen, temperature and conductivity meters; disconnect and coil the cables for storage. Store the oxygen probe in its plastic cover with a moist Accuwipe and added water (the membrane can not be allowed to dry out). Rinse the Van Dorn bottles and leave them open to dry. Once dry, store the Van Dorn bottles with their ends closed. All raw water bottles should be acid washed as described above. Nets should be rinsed and hung to dry. Make sure the pH meter is turned off and the probe is stored in buffer solution. Chemicals should be returned to their correct locations: the chemical cabinet, fume hood, or refrigerator. Clean up and rinse all areas you have used. If you spill or splash while you are working, clean it up immediately. If you spill anything on yourself, notify the TA. Please note the locations of chemical showers, eyewash stations, and fire extinguishers in the lab. Stock Standard Solutions In our chemical analyses we will dilute a stock standard to prepare several working standards. The accuracy of our analyses depends on having accurate, uncontaminated stock standards. The stock standards have been prepared for your use ahead of time. The reagents for these standards are high purity grade chemicals that have been dried and desiccated prior to precision weighing. These stock standards may last for years if they are not wasted or contaminated. To prevent waste, calculate the approximate amount of stock you will need. To guard against contamination, the following procedure should be adhered to strictly. Never put a pipette into a stock solution container and never pour anything back into a stock solution container! Instead, pour a sufficient quantity of stock solution into a clean, dry beaker (acid washed and well rinsed). Re-stopper the stock container and return it to the refrigerator. Pipette what you need to prepare the working standards from the beaker. Dispose of any extra standard to prevent contamination of the stock standard. Duplicates and Replicates Replicates are two [or more] separate water samples collected in the field from the same site and depth - for example, two separate Van Dorn casts from 10 m depth at Allens Lake taken one right after the other and placed into different sample bottles. Replicates are used to determine the errors involved in sample collection; if there are no errors in the collection and analysis, then the difference between two replicate analyses indicates the natural variability in the water at that location. Duplicates are two [or more] lab analyses on the same water sample - for example, two separate syringes are drawn from one sample bottle marked Third Sister Lake 10 m. Duplicates are used to determine the % difference between two samples in order to estimate the error involved in the analyses. For example, if we report a PO43- number as 5 , we must also report the error of that measurement. If duplicates are within 10%, then the actual value could range from 4.5 to 5.5 . Precision, Accuracy, and Limits of Detection Precision is defined as the deviation around an average value from any particular analysis. Precision is determined by running field replicate and lab duplicate samples (see definitions above). Determine the % difference between two replicates: for example, if the first duplicate PO43- value is 5.0 and the second duplicate value is 5.5 , then the precision is 10%. This means that the actual value could fall between 4.5 and 5.5 . Many duplicates on many samples are used to determine the average % difference for a chemical test. The % difference should be below 10%. Accuracy is defined as the deviation from the true value of a sample. Accuracy must be determined using an independent standard. These standards are supplied by various agencies such as the U.S. EPA or Bureau of Standards. For example, if you analyze a standard with a true value of 5.0 several times and your method results in an average value of 4.5 , then you have underestimated the true value, and your accuracy is within 10%. This underestimation may be the result of incorrect preparation of your stock solution for that analysis, or incorrect preparation of your working standards. The calibration of pipettes and volumetric flasks should be checked first, and if there is no error there then the stock solution must be prepared again. Limit of detection is defined as the minimum value of a substance that you can detect with an analysis. The limit of detection is determined by preparing a standard curve of very low concentrations and comparing the spectrophotometer absorbances of these low standards with the blank. The limit of detection is reached when the standard has the same value as the blank. For example, if your blank absorbance is 0.005 and the absorbances of standards is as follows: 5 = 0.021, 4 = 0.015, 3 = 0.011, 2 = 0.005, 1 = 0.006, 0.5 = 0.005, then your limit of detection is about 2 . Quality control of analyses When first setting up a laboratory or a new technique, replicates and duplicates should be run on every sample. This is required to determine the errors involved and to identify what steps in the analyses are contributing the most to these errors. Errors can be introduced at every step from having a dirty Van Dorn bottle, to a dirty sample bottle, to touching the lip of the sample bottle, to placing the pipette tip on the table, to poor washing of glassware, to carryover of one sample to the next in the spectrophotometer cell, and so on. If the accumulated errors are greater than 10%, a systematic investigation of each step in the analysis must be performed. Once the errors in an analysis are identified fewer replicates and duplicates are needed. Some replicate analyses must always be performed to insure that the quality of the analysis remains good over time. Use of Variable Pipettes (1) Before putting the pipette into the sample liquid, push the plunger down to the first ‘stop’ (you will feel the resistance). (2) Then place the pipette into the liquid and slowly release pressure on the plunger to draw liquid inside. Discard the first aliquot which is used to wet the inside of the tip. If there is a bubble left the tip is dirty and another aliquot should be used to rinse the pipette tip. (3) When expelling the liquid, pushing to the first stop releases most of the liquid. The small amount of leftover liquid is released by applying pressure to the second ‘stop’. This step should be done with the tip against the side of the glass so that all of the remaining aliquot is emptied. (4) Use pipette tips for all of the same stock solution during preparation of standards. Discard tips after standard preparation. 1 0 0 0 0 0 9 0 0 0 0 A 8 0 0 0 0 7 0 0 0 0 6 0 0 0 0 5 0 0 0 0 4 0 0 0 0 3 0 0 0 0 2 0 0 0 0 1 0 0 0 0 0 0 1 0 2 0 3 0 4 0 5 0 3 0 4 0 5 0 3 0 4 0 5 0 3 0 4 0 5 0 1 0 0 0 0 0 9 0 0 0 0 B 8 0 0 0 0 7 0 0 0 0 6 0 0 0 0 5 0 0 0 0 4 0 0 0 0 3 0 0 0 0 2 0 0 0 0 1 0 0 0 0 0 Instrumentreading 0 1 0 2 0 1 0 0 0 0 0 C 9 0 0 0 0 8 0 0 0 0 7 0 0 0 0 6 0 0 0 0 5 0 0 0 0 4 0 0 0 0 3 0 0 0 0 2 0 0 0 0 1 0 0 0 0 0 0 1 0 2 0 1 0 0 0 0 0 D 9 0 0 0 0 8 0 0 0 0 7 0 0 0 0 6 0 0 0 0 5 0 0 0 0 4 0 0 0 0 3 0 0 0 0 2 0 0 0 0 1 0 0 0 0 0 0 1 0 2 0 S t a n d a r d C o n c e n t r a t io n ( u M ) Questions: (1) Which one of the standard curves above (A,B,C, or D) indicates that the instument has reached its limit of detection? What is your reasoning? On that curve, the limit of detection is about uM. (2) Which one of the standard curves would be the most likely result of carelessly handled glassware? What is your reasoning? (3) Which one of the standard curves would be the most likely result of using contaminated reagents in the analysis? What is your reasoning? 1 2 3 4 (4) Given that the center of the targets above represents the true value of a standard and the spots are sample measurements, which pattern (1,2,3 or 4) represents High accuracy and low precision: High accuracy and high precision: Low accuracy and high precision: Low accuracy and low precision: