World Journal Of Engineering Mechanical behavior of metallic

advertisement

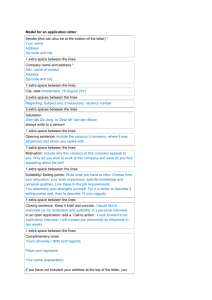

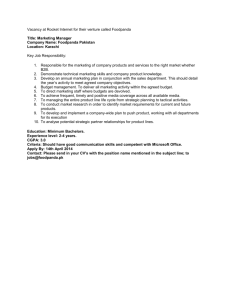

World Journal Of Engineering Mechanical behavior of metallic nanowires containing vacancy cluster defects Pei-Hsing Huang, Lay Gaik Teoh, Yu-Ren Wu, Ming-Yue Huang, Hong-Yi Li Department of Mechanical Engineering, National Pingtung University of Science and Technology, Taiwan. phh@mail.npust.edu.tw mechanical responses of a stretched NW. The detailed simulation domains and mechanical deformations are illustrated in Fig. 1. Introduction Since NWs are often used in complicated mechanical surroundings [1,2,3], a thorough understanding of their mechanical behavior is crucial for the design of functional nanowire-based devices. However, when the dimensions of the system become comparable to or smaller than the critical size, the macroscopic continuum theory is inadequate for predicting the mechanical behavior of NWs due to the coupled effects of the large surface area to volume ratio [4-6], anisotropic orientation dependence [5,7], and particle confinement (including electrons and phonons) [3,8]. Exploring the microscopic mechanisms of the structural evolution of NWs via experimental methods is challenging because the critical stress generally occurs within a very short period, which is within several picoseconds (ps) of the natural vibration of an atom [9,10]. Therefore, molecular dynamics (MD) study of the microscopic deformation and mechanical behavior of NWs is required. The effects of vacancy defects on the mechanical behavior of nanowires are largely unknown. The present study explores the coupled influences of VC defects, operating temperature, and applied stress on the deformation behavior of stretched Cu NWs using molecular dynamics with the embedded-atom method (EAM) [11]. Elastic and plastic behaviors related to the stretching of defective NWs, including investigations of the microscopic mechanisms of incipient yielding, the evolutions of plastic flow and transient structure, stress-strain behavior, Young’s modulus, and eventual fracture patterns, are analyzed. Fig. 1 Schematic illustrations of atomic diagrams of Cu nanowires containing various patterns of cluster defects, including (a) single atomic-vacancy (VC1), (b) octahedral vacancy cluster (VC6), and (c) octahedral vacancy cluster (V19). Atoms are color-coded according to the value of their potential energy in eV. Numerical method In the presented work, the generalized EAM potential developed by Wadley et al. [11] is used because it can well fit the basic material properties (such as the lattice constant, the elastic constant, the bulk modulus, the sublimation energy, and the heat of solution). More importantly, this potential accurately expresses the vacancy formation energy, which is crucial for analyzing the effect of VCs on the mechanical behavior of a defective NW. Cu NWs oriented along the [100] direction with an initial length of 108.1 Å and a square cross-section were studied, as shown in Fig. 2. Three cross-sectional dimensions of the Cu NWs were adopted: (1) 18.1×18.1Å, (2) 25.3×25.3Å, and (3) 36.1×36.1Å. The corresponding FCC unit cells in the x, y, and z directions are (1) 30a0×5a0×5a0, (2) 30a0×7a0×7a0, and (3) 30a0×10a0×10a0, respectively, where a0 (= 3.615 Å) denotes the lattice constant of Cu. Three designated patterns of the vacancy cluster were adopted: (1) single atomic-vacancy (VC1), (2) octahedral vacancy cluster (VC6), and (3) octahedral vacancy cluster (V19), where the subscripts denote the number of atomic vacancies (see insets of Fig. 1). These vacancy clusters were singly embedded inside of wires in order to analyze the effect of vacancy clusters on the The NW was thermally equilibrated at a given operating temperature using Gauss's principle of least constraint [12] for 50 ps. The equilibrium state of a NW was determined by allowing the volumetric contraction to saturate; this process is a function of the thermal relaxation time. After the Cu NW reached the equilibrium state, a uni-axial tensile loading at a constant true-strain rate of 8×108 s-1 along the x-direction was applied to the Cu NW as follows: (1) one end of the Cu NW was fixed; (2) uni-axial loading was applied to the other end of the Cu NW; (3) a ramp stretch profile, which prevented shock waves from being emitted at the fixed end of the Cu NW, was created by assuming that the displacement of atoms linearly increases along the loading direction from zero (at the fixed end) to a maximum value (at the free end). Moreover, to investigate the role of temperature in tensile deformation and mechanical behavior, the system was assumed to experience isothermal loading by idealized heat transfer to a surrounding medium. Moreover, the atomic potential and intermolecular forces of the system were derived in each computational time step of ∆tMD = 5 fs. The neighbor list 447 World Journal Of Engineering trend is consistent with the reports by Liang and Upmanyu [6]. Based on the simulation results, the formalization of Young’s modulus (EY /Ebulk) as a function of cross-sectional area and temperature of NWs can be approximated in the analytic form as follows: method with an appropriate list radius of 2.8 re (where re denotes the equilibrium spacing between nearest neighbors) was employed to decrease computational time. The velocity and acceleration of atoms were accurately estimated and updated using Gear’s fifth-order predictor-corrector algorithm [13]. 2 EY / Ebulk 0.8636e ( C A / S A ) 0.3678 CT T 8.5434 (1) where SA and T are the cross-sectional area and operating temperature of the nanowires. CA denotes the size parameter with a value of 3.267 nm2, and CT = 3.9527×10-4 K-1 is the fitted coefficient of temperature. Results and Discussion Fig. 2(a) and (b) show the plots of stress (ordinate) versus strain (abscissa) of stretched wires containing a VC6 vacancy cluster for various cross-sectional areas and operation temperatures. As shown, for a given wire sectional area, yield strength largely decreased with increasing operation temperature. In elastic deformation ranges, the slope of the linear segment distinctly increases with decreasing operation temperature, indicating that the Young’s modulus greatly depends on operation temperature. Fig. 2(c) show that the stress-strain curves for a perfect wire and wires with various vacancy cluster sizes. The stress-strain curves are overlapped during elastic deformation, indicating that the elastic modulus is independent of the vacancy cluster defects. Fig. 3 Young’s moduli as a function of operating temperature for various wire cross-sectional areas. Conclusion A structural imperfection can increase atomic potential energy and facilitate crystalline slip under critical stress. Extensive atomistic simulations of the mechanical deformation of defective NWs were performed using the embedded-atom molecular dynamics modeling approach. The stress-strain behaviors show that the elastic modulus is independent of the vacancy cluster defects. Quasi-linear decreasing Young’s moduli were observed with increasing operation temperature. For a given operation temperature, NW Young’s modulus increased with increasing NW size. References 1. Z.L. Wang, J. Song, Science 312, 242 (2006) 2. J. Andzane, N. Petkov, A.I. Livshits, J.J. Boland, J.D. Holmes, D. Erts, Nano Lett. 9, 1824 (2009) 3. K. Takayanagi, Y. Kondo, H. Ohnishi, JSAP Int. 70, 3 (2001) 4. J.C. Gonza´lez, V. Rodrigues, J. Bettini, L.G.C. Rego, A.R. Rocha, P.Z. Coura, SO. Dantas, F. Sato, Phys. Rev. Lett. 93, 126103 (2004) 5. P.H. Huang, T.H. Fang, C.S Chou, Current Applied Physics 11, 878 (2011) 6. H. Liang, M. Upmanyu, H. Huang, Phys. Rev. B 71, 241403(R) (2005) 7. C. Ji, H.S. Park, Nanotechnology 18, 305704 (2007) 8. K.W. Adu, H.R. Gutie´rrez, U.J. Kim, G.U. Sumanasekera, P.C. Eklund, Nano Lett. 5, 409 (2005) 9. P.H. Huang, H.Y. Lai, Phys. Rev. B 77, 1254008 (2008) 10. P.H. Huang, H.Y. Lai, Nanotechnology 19, 255701 (2008) 11. H. N. G. Wadley, X. Zhou, R. A. Johnson and M. Neurock, Prog. Mater. Sci. 46, 329 (2001) 12. D.J. Evans, W.G. Hoover, B.H. Failor, B. Moran, A.J.C. Ladd, Phys. Rev. A 28, 1016 (1983) 13. J. M. Haile, Molecular Dynamics Simulation: Elementary Methods (Wiley, NY: Wiley, 1992) Fig. 2 Stress-strain behavior of tensile stretching of defective NWs for various vacancy defect sizes Fig. 3, shows the Young’s moduli as a function of operation temperature for a given NW sectional area. NW Young’s moduli decreased with increasing operation temperature. Simulation results show that NW Young’s moduli are smaller than that of bulk copper (110 GPa) [14], which is mainly due to the de-cohesion effect of the surface atoms; at this size scale, the nanowires consist of about 22-38 % surface atoms. The modulus of elasticity values for [100] Cu nanowires increase with increasing wire area. As the cross-sectional size of the nanowires increases, the Young’s modulus gradually approaches the bulk value. This 14. W. D. Callister, Materials Science and Engineering: An Introduction (John Wiley & Sons, N. Y., 1990). 448