Anesthetic Gas Use and Scavenging System in Animal Research

advertisement

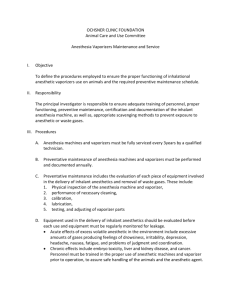

SAN DIEGO STATE UNIVERSITY ENVIRONMENTAL HEALTH AND SAFETY DEPARTMENT ANESTHETIC GAS USE AND SCAVENGING SYSTEM IN ANIMAL RESEARCH STANDARD OPERATING PROCEDURES Purpose: San Diego State University is committed to limiting all exposures to hazardous materials below statutory or recommended levels, or otherwise as low as reasonably as achievable. Scope: This Standard Operating Procedure (SOP) describes the use anesthetic gases such as isoflurane. This SOP applies to all investigators, animal research technicians, and animal care staff using anesthetic gases for anesthesia of their research animals, with or without a delivery system such as a precision vaporizer and oxygen flow meter. Standard: The Occupational Safety and Health Administration (OSHA) has not established a permissible exposure limit (PEL) for anesthetic gases. Regardless, the National Institute for Occupational Safety and Health (NIOSH) has proposed a recommended exposure limit (REL) for halogenated anesthetic gases of <2ppm/hr. Note: If you can smell isoflurane, then waste anesthetic gas (WAG) levels are above acceptable thresholds. The control procedures you are using are inadequate and must be re-evaluated. Safety Consideration: Under no circumstances shall isoflurane be used without the benefit of a ventilating or scavenging mechanism that eliminates inhalation exposure to the user. These mechanisms are: A certified chemical fumehood when not using a precision vaporizer such as when using a bell jar or chamber. Connection of an exhaust hose to a certified fume hood. Connection of the exhaust hose to a scavenging canister when using a precision vaporizer. The use of canister requires tracking of canister weight. Absorption canisters can only be used with systems which actively move the gas, e.g. from a pressurized tanks or vacuum system. Isoflurane must be used in a well ventilated room (10-15 air changes/hour) from which there is no recirculation of exhaust air to supply fans or other indoor spaces. The oxygen concentration delivered will be ~98% (room air is 20-21%), increasing the combustibility of any material this oxygen-rich atmosphere contacts. Exercise care with any nearby heat or ignition sources e.g. cauterizing device. Personnel must use the proper personal protective equipment consisting of proper selection of gloves, lab coat, and safety glasses when pouring or filling liquid anesthetic agents. When in ABSL 2 facility, PPE use must be consistent with the facility policy. Use of Open-Drop Method Open-drop anesthetic procedures are not recommended, but if necessary, must be conducted within a fumehood. All bell jars or chambers used for inhalation anesthetic induction must be used in a fumehood vented to the outside or in a specially equipped gas scavenging hood to prevent exposure to personnel during the opening and closing of the jar or charged chamber. All bell jars or chambers must be aired in the hood to remove all anesthetic vapors prior to removal for disinfection. Purge induction chamber with oxygen prior to opening chamber and retrieving anesthetized animal. The anesthetic must be added to the absorbent material only inside the fumehood. A chamber with a tight-fitting cover must be used. The cover must stay on the chamber except when the animal is being place into or removed from the chamber. Use of Precision Vaporizer Pre Procedure (Preparing for Anesthetic Gas Use) 1. Upon receipt, the scavenging canister must be labeled with the date received and its initial weight. 2. Upon initial use and prior to subsequent use, check expiration date of canister (if expired, dispose through EHS). 3. Upon initial use and prior to subsequent use, weigh and label the scavenge canister with date and current weight (if it weighs 50 grams more than its initial weight, dispose through EHS) to evaluate the remaining absorption capacity. If the total increase is close to 50 g, it should be replaced. Immediately following the use of an anesthesia machine, weigh the canister and record the weight on the canister. Canisters that exceed 50 grams of accumulated weight must be removed and placed in a sealed plastic bag and disposed of as a hazardous waste through EHS. 4. Connect a new canister to scavenger line. The charcoal canister should always be upright and below the vaporizer of the anesthesia machine so that the heaviness of the waste gases is exploited. The holes on the bottom of the carbon canister must not be blocked. The charcoal canister should be as far removed from the administering anesthetist as possible. 5. Verify equipment used (i.e. fumehood and vaporizer) are currently certified and in proper working condition. 6. Fill vaporizer using anti-spill bottle adapter or conduct filling in fumehood, closing bottle and reservoir as quickly as possible. Do not permit containers to remain open. Use agent specific, keyed filler system for refilling vaporizers. 7. If using a compressed gas cylinder, ensure that there is adequate oxygen to last the entire procedure. 8. Tighten all tubing connections. Visually inspect hoses, valves, and connections for leaks, defects, and damage in anesthesia equipment and scavenging system. Note: Leaks can occur from missing, worn, or damaged “O” rings, washers or other seals, loose flutter valve caps, poorly sealed carbon dioxide canisters, loose hose connections, holes in hoses or reservoir bags, or vaporizer caps not completely tightened. Check by pressure testing or running oxygen through machine and then spraying suspected leaks with soapy water. 9. Adjust the stop cock on the y-piece tubing so that the isoflurane/oxygen mixture will flow into the induction chamber, returning to the scavenger canister, and not through the tubing going to the nose cone. 10. When possible, the charcoal canister or the entire anesthesia unit should be placed in a nonrecirculating fumehood during the administration of anesthesia. Procedure (The following techniques should be utilized during anesthetic procedures to reduce the amount of waste gas to be scavenged): 1. Place the animal in the clean induction chamber, making sure to close the chamber securely. Note: The induction chamber is functionally air-tight; do not leave animals in the closed chamber without gas flow. Ensure the chamber is equipped with tow outlets, one for delivery of the inhalant and one for scavenging. 2. Turn on the oxygen so that flow rate is 1 L/min. Adjust dial for isoflurane delivery to 3-4%. Note: Use the lowest anesthetic gas concentration and oxygen flow rates as needed to maintain anesthesia. 3. When animal loses righting reflex, turn off isoflurane flow and flush induction chamber with oxygen for 20 seconds prior to opening chamber and retrieving anesthetized animal. Quickly replace the lid of the chamber, and continue to run oxygen through the chamber for several minutes to help purge the waste anesthetic gas into the scavenger. 4. Remove animal onto a clean procedure surface; snugly attach a nose cone; dial isoflurane concentration to 1.5 – 2.0% and oxygen flow to 0.8 L/min. 5. Adjust stop cocks so that flow is into tubing attached to nose cone and not in to induction chamber. 6. Thoroughly flush all residual gases out of the breathing system and into the scavenging system. 7. If exhaled air is not returned through the scavenger canister through a separate re-breathing line, all subsequent procedures must be performed inside a clean, certified chemical fume hood or with other local ventilation. Mitigating Waste Anesthetic Gas (WAG) Exposure In order to keep waste anesthetic gas levels below threshold, passive scavenging techniques in the animal anesthetic environment should include: 1. Turning off the vaporizer at the end of induction, followed by 2. Purging of the induction chamber with a 1.5 L/min oxygen flush for > 5 seconds, 3. Allowing the animal to breathe oxygen for a few minutes (this scavenges the gas being eliminated from the lungs), 4. Tilting of the induction chamber away from the operator prior to opening (hinged induction chamber: open chamber with hinge facing operator; sliding induction chamber: slide chamber open perpendicular to operator), 5. Briefly opening the induction chamber just enough to remove the anesthetized animal. 6. Thoroughly clean the induction chamber immediately after each use to avoid residual anesthetic waste release into the environment (which can continue to release for up to three hours). Maintenance of Precision Vaporizers 1. Precision vaporizers must be calibrated annually by manufacturer or other authorized party, with verification provided by an attached sticker or other readily accessible documentation. 2. Induction chambers and breathing circuits must be appropriately sanitized after each use. Note: Do not use alcohols for sanitization of induction changers as it will weaken the structure of acrylic and may cause clouding. Exposure/Contact Response If the employee is in need of emergency medical attention, call 911 immediately. Wash hands and arms with soap and water immediately following any skin contact with anesthetic liquids. Flush eyes for 15 minutes following eye contact. Report exposure, contact, signs and symptoms to your supervisor and EHS within 24 hours. Obtain proper medical treatment and follow-up. Complete and submit the Supervisor Injury Report and Incident/Accident Report. Spill Response Spilling only 1ml of a liquid anesthetic can vaporize up to 200 mls of gas, and result in a concentration of 1,000,000 ppm (greatly exceeding NIOSH guidelines). Accidental volume spill will require immediate action. Isolate contaminated areas by closing doors. Clean up spill as much as possible using absorbent materials. Spill materials for anesthetic agents are designed to control the liquid portion of the spill and minimize the production of vapors. Never use paper towels on large spills of anesthetic agents because it exacerbates vapor production. Contaminated articles of clothing and contaminated absorbent materials used to clean up the spill must be removed and placed in airtight containers. Only staff wearing proper protective vinyl or plastic clothing, gloves and respirators are allowed access to the contaminated areas. Waste Disposal Containers of expired or unused liquid anesthetic agents and spent waste anesthetic gas canisters are to be disposed through EHS Hazardous Waste Program by contacting x46778 for proper disposal. Wrap spent charcoal canisters in plastic before disposal. Records: Maintenance logs i.e. inspection and testing should be kept for each anesthetic machine, vaporizer, and ventilator. The precision vaporizer and anesthesia machine should have a label indicating annual service and calibration date, initials of technician, and test results. Each scavenging canister should have a label of the date received and its initial weight. Prior to subsequent use, weigh and label the canister with date and current weight.