1 Crandall Bio-Polymers in Construction Kelly Crandall University of

advertisement

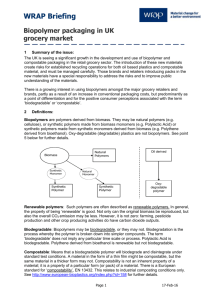

Crandall Bio-Polymers in Construction Kelly Crandall University of Florida 1 Crandall 2 Although humans have long used natural polymers, the twentieth century brought a myriad of synthetic options that were cheaper, more durable, and more versatile than their natural counterparts. Horn and shell were replaced by petroleum and natural gas-derived plastics, such as polystyrene, polyvinyl chloride (PVC), nylon, neoprene, and polyethylene (Wilson & Yost, 2001, n.p.). However, concerns about global climate change, pollution, dwindling stocks of petroleum, and other factors have led materials scientists to reconsider the virtues of bio-based materials. These biopolymers attempt to provide simple but elegant solutions to materials issues. Biopolymers are widely varied, giving them numerous properties and applications. A polymer is a long molecule containing numerous repeated units in covalent bonds. A biopolymer is a “polymer of natural origin” and can include such diverse materials as wood, cellulose, and chitin (Chiellini et al., 2001, p. 64). They are generated from renewable sources and are easily biodegradable because of the oxygen and nitrogen atoms found in their structural backbone (Stevens, 2002, p. 83). Biopolymers are classified differently by different experts; however, the United States Congress Office of Technology Assessment separates them into nucleic acids, proteins, polysaccharides, polyhydroxyalkanoates, and polyphenols (U.S. Office of Technology Assessment [U.S. OTA], 1993, p. 11). The divisions are based on the chemical organization of basic monomers within the biopolymers. Proteins, polysaccharides, polyhydroxyalkanoates, and polyphenols are of special interest as the most applicable to industrial, medical, construction, and other uses. Proteins are created by polymerization reactions between sets of the twenty amino acids found in all living organisms (Stevens, 2002, p. 91). They form enzymes, structural material, hormones, antibodies, and other components of cells (U.S. OTA, 1993, p. 11). Proteins come mainly from oilseeds such as soybeans, and grains like wheat and corn (Wool & Sun, 2005, p. 2). Crandall 3 They include collagen, keratin, casein, fibrin, and enzymes (Chiellini et al., 2001, p. 72). Collagen is the most common protein found in mammals, composing one-third of total protein, and forms triple helices which provide strength and flexibility for bones (Stevens, 2002, p. 92). Gelatin, commercially used in desserts and pharmaceuticals, is a denatured collagen (Stevens, 2002, p. 92-3). Milk contains casein, another protein, which is used to adhere bottle labels, and in protective coatings and finishes (Stevens, 2002, p. 93). 40% of corn kernels and 30-45% of soybeans are proteins usable for adhesives, printing inks, and shellac (Stevens, 2002, p. 93). The corn protein, zein, can be converted into “tough, glossy, and scuff resistant” films (Stevens, p. 93). Proteins have widely variable functions because of the vast possibilities of amino acid combination. They are also extensively cultivated: the potential for production in the U.S. is 120 billion pounds of soybean meal (50% protein), 20 billion pounds of wheat gluten (70% protein), and 40 billion pounds of corn gluten (65% protein) (Wool & Sun, 2005, p. 3). This makes their potential industrial application profound. Polysaccharides are carbohydrates, sugar polymers which function in cells as structural components or sources of activity energy. Carbohydrates also include agricultural fiber, made of cellulose, hemicellulose, and lignin, which compose straw, kenaf, and jute (Wool & Sun, 2005, p. 2). Cellulose and starch are the two major types of polysaccharide biopolymer, although the category includes alginates and chitin (Chiellini et al., 2001, p. 69). Polysaccharides make up 75% of all organic matter, and 40% of that is composed of cellulose (Stevens, 2002, p. 84). 150 billions pounds of cellulose are cultivated each year through wood and cotton, which are 50% and 90% cellulose on average (Stevens, 2002, p. 84-5). Starch, another major type of polysaccharide, contains amylase and amylopectin polymers of varying proportions depending on the plant. It can be found in corn, potatoes, wheat, cassava, rice, sorghum, barley, and peas Crandall 4 (Stevens, 2002, p. 85). Over 70 billion pounds of starch are produced each year, of which 35 billion pounds are grown in the U.S. (Steven, 2002, p. 85). Chitin, which is best known as a component of the crustacean exoskeleton, is also a common polysaccharide. It is found in the skeletal tissue of crustaceans and insects, and in certain kinds of fungi (Stevens, 2002, p. 88). Chitin is currently used in cosmetics, agriculture, and food additives, although scientists are seeking new industrial uses. Alginates, as well as agar and carrageenan, are polysaccharides found in seaweeds and bacteria. They can be used as food additives, as well as microbiology culture media, adhesives, dye thickeners, emulsifiers, corrosion inhibitors, and hygiene products (Stevens, 2002, p. 88). There are two other major categories of biopolymers, polyhydroxyalkanoates and polyphenols. Polyhydroxyalkanoates are lipid biopolymers, water-soluble hydrocarbons (Stevens, 2002, p. 98). They are oils (liquid) and fats (solid). The oils are divided into drying, used in paints and varnishes, semidrying, used for cooking, and nondrying, which maintain their greasy properties. Soybean, flax, and rapeseed are the primary origins of the 16 billion pounds of vegetable oils produced in the U.S. each year (Stevens, 2002, p. 98). These oils function in plasticizers, emulsifiers, lubricants, inks, coatings, greases, and other industrial applications. Polyphenols are largely structural plant materials, particularly lignin. Lignin is “the second most abundant component of woody material,” and after cellulose, makes up 20% of organic matter (Stevens, 2002, p. 90). In the U.S. alone, 100 billion pounds a year are isolated, most burned as fuel (Stevens, 2002, p. 90). However, it has applications in gypsum wallboard, adhesives, and concrete mixtures. In addition to these major categories, Stevens adds another, the “honorary biopolymers,” which are synthetically generated, biodegradable biopolymers created from naturally-occurring monomers (2002, p. 95). This includes lactic and amino acids, among others. Crandall 5 Biopolymers have many properties and are either used as materials for new applications, or as models for new synthetic polymers (Stevens & Verhe, 2004, p. 192). They can be produced primarily in three ways: direct isolation from plants or animals, intra- or extracellularly, in cell-free systems such as in vitro enzyme synthesis, and through transgenic plants geared for specific production (Stevens & Verhe, 2004, p. 191). There are many uses for biopolymers. Because one of their chief attributes is their biodegradability, they have a unique function in packaging. Plastic packaging waste composes one-third of all waste sent to landfills in the U.S. (Comstock, Farrell, Godwin, & Xi, n.d., Slide 2). This can include “loose-fill” packaging materials (such as packing peanuts) and bags. The University of Florida has experimented with biodegradable PLA (corn-based) plastic cutlery and plates at alumni and football functions as part of its Zero Waste Initiative (Gouz, 2004, n.p.). Biopolymers may be important for green construction because of their wide functionality as plastics, resins, adhesives, paints, anticorrosion coatings, emulsifiers, concrete and gypsum mix-ins, and perhaps eventually structural components (Wilson & Yost, 2001, n.p.). In Biomimicry, Janine Benyus describes several original uses for animal-based biopolymers. Abalones have an extremely tough nacre shell, which absorbs stress with the aid of a thin, stretchy polymer (1997, p. 99). The edulis, a bivalve, excretes a waterproof adhesive protein that could have diverse applications not just in paints and glues, but also in surgical sealants (1997, p. 119-20). Spider silk is a composite with crystallites in an organic polymer mix (1997, p. 131). It has a breaking point similar to steel but is five times lighter and is extremely elastic. It stretches 30 percent more than the stretchiest nylon, and can absorb five times the force of Kevlar (1997, p. 132). Spider silk has myriad applications, including artificial tendons Crandall 6 and ligaments, microsurgery sutures, lightweight body armor, and plane-stopping cables on aircraft carriers (Trivedi, 2002, n.p.). Polymers derived from petroleum and natural gas can have marked environmental consequences. 270 million tons of fossil fuel are used each year to produce the world’s plastics (Slater, Glassner, Vink, & Gerngross, n.d., p. 475). The 200 billion pounds of plastics produced each year in the U.S. alone use 4 percent of the country’s total energy sources (Comstock, Farrell, Godwin, & Xi, n.d., Slide 15). Currently, plastics have a long lifespan and do not degrade easily in landfills. This is coupled with decreasing landfill space. Plastics deposited in landfills also create hazards for wildlife, which ingest them or may be entrapped by them. Rather than landfill waste plastics, many organizations have chosen to incinerate them, which causes hazardous emissions and leads to other forms of pollution. PVC, which contains up to 40% chlorine, can develop into the persistent organic pollutant dioxin in uncontrolled fires (Wilson & Yost, 2001, n.p.). Recycling techniques for plastic polymers, such as drink bottles, have improved over time. Thermoplastics can be recycled, but are generally downgraded. The presence of food contamination can sometimes make recycling difficult (Comstock, Farrell, Godwin, & Xi, n.d., Slide 3). The plastics industry only recycles about 7% of waste plastics, and construction plastics are recycled even less because of the prevalence of cheap construction and disposal landfills (Wilson & Yost, 2001, n.p.). Despite this context, a major contributor to the development of biopolymers has been the negative environmental image of synthetic, petroleumbased polymers in the public eye (Patel, Bastioli, Marini, & Wurdinger, n.d., p. 5). This has led to increasing market share: in the European Union, biopolymer consumption was estimated to have risen from 20,000 to 40,000 tons a year between 2001 and 2003 (National Non-Foods Crop Center, 2004, p. 3). Crandall 7 In contrast to petroleum-based polymers, biopolymers address many facets of sustainability by being biologically-based and biodegradable. Of disposal methods for biopolymers, composting is the most frequently cited. This may replace degraded soil and reduce the need for fertilizers (Patel, Bastioli, Marini, & Wurdinger, n.d., p. 10). Although the composting process effectively “downgrades” biopolymers into soil, because they are made from renewable sources they do not face the same circulation problems that synthesized plastics (and recycled metals) may face. When biodegradable plastics are landfilled rather than composted, their breakdown produces large quantities of methane and CO2, with implications for global climate change. Another issue is that the sheer quantity of plastics produced each year would demand a steep increase in the amount of a polymer crop under cultivation. In addition to scale, one study, which analyzed corn plants modified to produce plastics inside their chloroplasts, reported that it took 300% more energy to harvest corn, extract and refine its PHA, and blend it to produce a resin than the 29 MJ necessary to produce an equivalent amount of polyethylene (Gerngross & Slater, 2000, n.p.). This puts the sustainability of biopolymers, at least for now, into question. Of special concern is the use of genetic engineering to mass-produce biopolymers. Soy and corn are two common crops which have been genetically modified to increase yield or improve the quality or content of their proteins or oils (Wool & Sun, 2005, p. 30-31). Bacteria and other microorganisms, such as E. coli, are capable of generating biopolymers like PHA (Chiellini et al., 2001, p. 71). However, transgenic plants can contaminate wild plants, compromising the species’ evolution, or nearby organic farms. Genetic engineering can have unpredictable results, such as the Brazil nut allergens which piggybacked other genes inserted into soybeans (Mellon & Rissler, 2003, n.p.). There are also ethical questions raised by the Crandall 8 concept of altering life, such as whether it can be patented, or whether it devalues the wild version of a plant or animal to engineer a “better” version. These questions should be addressed in large-scale biopolymer generation projects. Life cycle analyses have been attempted for only a few kinds of biopolymers, and many LCAs are incomplete. Starch polymers, the most widely used variety, are also the most comprehensively studied. A study commissioned in 1996 by the Swiss Federal Agency for the Environment, Forests and Landscape studied the production process and waste management for potato and maize polymers compared to polyolefins. The study showed that starch polymers used about a quarter of the energy of their polyethylene equivalent to produce, and released 2575% fewer CO2 emissions (Patel, Bastioli, Marini, & Wurdinger, n.d., p. 10-1). Based on this research Patel et al. suggested three guidelines for biopolymers: “save at least 20 MJ (non-renewable) energy per kg polymer, avoid at least 1 kg CO2 per kg polymer and reduce most other environmental impacts by at least 20%” (p. 44). It is uncertain whether these recommendations are too loose or too conservative. Several concepts related to biopolymers remain unaddressed. If biopolymers are viewed from a systems perspective, it is possible that compared to petroleum-based polymers, they require more emergy input than they offer in return. It is also possible that large-scale agricultural cultivation of biopolymer cash crops could turn into a high-impact industry. Additionally, it is uncertain whether it is possible to increase yields enough to produce fuel, food, feed, and biopolymers from renewable agricultural sources. Further research and the application of life-cycle analysis, coupled with a view toward systems thinking, will hopefully begin to successfully address these issues. Crandall 9 References Benyus, J.M. (1997). Biomimicry. New York: HarperCollins Publishers Inc. Chiellini, E., et al. (Eds.). (2001). Biorelated Polymers: Sustainable Polymer Science and Technology. New York: Kluwer Academic/Plenum Publishers. Comstock, K., Farrell, D., Godwin, C., & Xi, Y. (n.d.). From hydrocarbons to carbohydrates: The future of food packaging. Retrieved on January 30, 2006, from the University of Washington Environmental Management Certificate Program website: http://depts.washington.edu/poeweb/gradprograms/envmgt/index.html. Gerngross, T. & Slater, S. (2000, Aug.) How Green Are Green Plastics? Scientific American 283(2). Retrieved on January 30, 2006, from www.mindfully.org: http://www.mindfully.org/Plastic/Biodegrade/Green-PlasticsAug00.htm. Gouz, K. (2004, Nov. 12). Alumni focus on environment. The Independent Florida Alligator. Retrieved on January 25, 2006, from the Alligator website: http://www.alligator.org/edit/news/issues/stories/041112corn.html. Mellon, M. & Rissler, J. (2003, June 12-3). Environmental Effects of Genetically Modified Food Crops (paper presented at a conference, Genetically Modified Foods—the American Experience, sponsored by the Royal Veterinary and Agricultural University, Copenhagen, Denmark). Retrieved on January 25, 2006, from the Union of Concerned Scientists website: http://www.ucsusa.org/food_and_environment/biotechnology/page.cfm?pageID=1219. National Non-Foods Crop Centre. (2004). Growing EU market for Biopolymers. Newsletter Issue 3. Retrieved on January 30, 2006, from the NNFCC website: www.nnfcc.co.uk. Patel, M., Bastioli, C., Marini, L., & Wurdinger, E. (n.d.). Environmental assessment of biobased polymers and natural fibres. Retrieved on January 25, 2006, from the Universiteit Crandall 10 Utrecht Department of Science, Technology and Society website: http://www.chem.uu.nl/nws/www/general/personal/Biopoly.pdf. Slater, S., Glassner, D., Vink, E., & Gerngross, T. (n.d.). Evaluating the Environmental Impact of Biopolymers. In Biopolymers (chap. 16). Retrieved January 25, 2006, from the Wiley VCH website: http://www.wiley-vch.de/books/biopoly/pdf_v10/vol10_20.pdf. Stevens, C.V. & Verhe, R.G. (2004). Renewable Bioresources. West Sussex, England: John Wiley & Sons Ltd. Stevens, E.S. (2002). Green Plastics. Princeton, NJ: Princeton University Press. Trivedi, B.P. (2002, Jan. 17). Lab Spins Artificial Spider Silk, Paving the Way to New Materials. National Geographic Today. Retrieved on January 30, 2006, from the National Geographic website: http://news.nationalgeographic.com/. U.S. Office of Technology Assessment [U.S. OTA]. (1993, Sept.). Biopolymers: Making Materials Nature’s Way. Retrieved on January 26, 2006, from the University of North Texas Libraries “CyberCemetary” website (OTA-BP-E-102): http://govinfo.library.unt.edu/. Wilson, A. & Yost, P. (2001, July/Aug.). Plastics in Construction: Performance and Affordability at What Cost? Environmental Building News 10(7): Retrieved January 25, 2006, from the EBN Building Green database. Wool, R.P. & Sun, X.S. (2005). Bio-Based Polymers and Composites. London: Elsevier Inc.