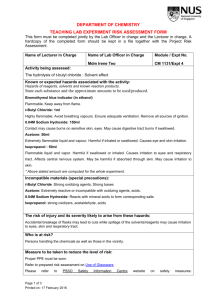

DEPARTMENT OF CHEMISTRY TEACHING LAB EXPERIMENT

advertisement

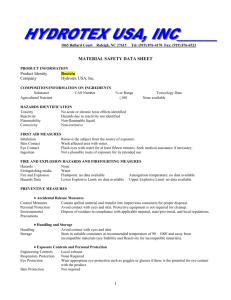

DEPARTMENT OF CHEMISTRY TEACHING LAB EXPERIMENT RISK ASSESSMENT FORM This form must be completed jointly by the Lab Officer in charge and the Lecturer in charge. A hardcopy of the completed form should be kept in a file together with the Project Risk Assessment. Name of Lecturer in Charge Name of Lab Officer in Charge Module / Expt No. A/P Chuah Gaik Khuan Activity being assessed: Toh Soh Lian CM3193/3194 Chemical Engineering Project Known or expected hazards associated with the activity: Hazards of reagents, solvents and known reaction products. State each substance and the approximate amounts to be used/produced. List of activities involved in this experiment which inevitably entail risks. The following are the activities being use: 1) Glass Apparatus. Refer to prepared risk assessment on Use of Glassware 2) 3 Phase Electricity, Refer to prepared risk assessment on Use of Standard Electrical Equipment 3) 18KW Sussman Electric Steam Generator: Risk of inadvertent escape of steam, causing scalding or burns injury to operator. Steam at 100oC will cause a worse burn than water at the same temperature 4) Steam Pressure Reducing Station: Hot surface: Personal injury and burns from hot surfaces. Incompatible materials (special precautions): Steam: Avoid in contact with electricity. The risk of injury and its severity likely to arise from these hazards: Contact burns are likely and may range from trivial to severe but most likely will affect only the user. Who is at risk? Persons handling the materials and as well as those present in the vicinity. Measure to be taken to reduce the level of risk: Proper laboratory attire and safety measures must always be used in order to reduce the level or risk. Eye protection: Chemical safety goggles. Hand protection: Kelklave Autoclave Gloves (Heat resistant terrycloth protects from 200°F to 450°F). Please refer to PSSO Safety Information http://www.chemistry.nus.edu.sg/PSSO/Safety.htm. Page 1 of 3 Printed on: 16 February 2016 Centre website on safety measures: 18KW Sussman Electric Steam Generator The boiler pressure parts, safety equipment, joints and seals are inspected annually by a MOM OSD inspection for the approval use (Licence included – Visual examination & running test). Licences label must paste onto casing of boiler. Training prerequisites: This assessment should be read by everyone who will be doing the above mentioned activity. Please refer to Completed Risk Assessment forms on Common Activities: http://www.chemistry.nus.edu.sg/PSSO/Safety/Risk/risk.htm#Common. Level of risk remaining: Constant vigilance is required by the users. Emergency action if : Spill: Water: Use a mop to dry up. Fire: Water must never be used on an electrical fire. Burn: Douse the burn with copious amounts of cold water e.g. under a running tap (not cold). (do not use ice, as it may cause the burn to take longer to heal). Do not attempt to remove anything sticking to the burn. Seek medical attention. Is the experiment suitable for out-of-hours operation ? Yes No References if any: http://www.chemistry.nus.edu.sg/PSSO/Safety/FirstAid.htm#FirstAid Signature of Lab Officer in Charge:……………………………………………………………….. Date:………………………… Signature of Lecturer in Charge:………… …………………………………….. Date:… …………………….. Prepared Risks Assessments for standard equipment and operation are with the kind permission of Dr. Ken MacNeil, School of Chemistry, University of Bristol. Page 2 of 3 Printed on: 16 February 2016 Activity being assessed: Note any activity to be used which entail risk (e.g. use of glass vacuum apparatus, high pressures, high voltage, radiation, high temperatures). Give reference to any special protocols to be followed, and if appropriate attach copies to the risk assessment form. State any additional precautions taken to minimise risk. Known or expected hazards associated with the activity: FOR EACH CHEMICAL, read the MSDS and note:a) Particular hazards (e.g. highly toxic, carcinogenic, corrosive, flammable, pyrophoric, explosive, volatile, dust hazard). Note any dangerous combinations of properties (e.g. volatile and toxic). b) Requirements for safe handling (e.g. fume cupboard, inert atmosphere, low temperature). c) How to dispose of residuals Dispose to drain, with water dilution Neutralise, then to drain with suitable dilution To flammable liquid waste receptacle To non-flammable liquid waste receptacle Keep for recovery/recycling Keep for special disposal later (e.g. heavy metals) Double bag and dispose to dry waste Special procedure (specify) Incompatible materials (special precautions) Note any dangerously incompatible materials and hazards arising from contact of any reagents and substances used with common materials such as paper, benches, hoses, etc. Measures to be taken to reduce the level of risk Include hazards of previously unknown products. Location of work – laboratory, open bench, fume cupboard Level of risk remaining: Likelihood and consequences of any accident or unforeseen events whilst carrying out the activity. When this has been done, choose the appropriate procedure:a) Close supervision and/or attendance of trained first-aider needed. b) Specific approval of supervisor needed. c) Training is needed prior-to or during the operations specified. d) Training is complete and only general laboratory competence required. e) No risk perceived. Emergency action: a) Any special requirements to deal with accidental spillage or leakage. b) What to do in the event of accidental exposure (skin contact, inhalation, etc.). Page 3 of 3 Printed on: 16 February 2016