Reconstruction and Interpretation of 3D Whole

advertisement

A Model-Based Procedure for Fitting a Surface to Scans of

Clothed People

Maria Consuelo Ruiz

Bernard Buxton

Department of Computer Science

University College London

Gower Street

London WC1E 6BT

United Kingdom

Tel: ++44 20 7679 7329

Fax: ++44 20 7387 1397

e-mail: {m.ruiz, b.buxton,}@cs.ucl.ac.uk

A Model-Based Procedure for Fitting a Surface to Scans of Clothed People

We present a procedure for reconstructing the surface of 3D scans of clothed people. The

method is model-based and is designed to cope with an un-organised cloud of 3D data points,

which may be noisy, irregularly sampled, and suffer from missing data owing to the scanner

geometry, data pre-processing, and, in particular, creases and folds in the clothing. The

method utilises techniques developed for clothing simulation to deal with the fabric’s

deformation and drape and a procedure based on the principles of robust statistics to fit a

simulated cloth surface to point-cloud data obtained from a whole-body 3D scanner. It

produces results for reconstructing the surface of a lady’s blouse that are both quantitatively a

good fit and visually pleasing with realistic looking creases and folds in the fabric. A number

of experiments were carried out to show convergence of the procedure which is initiated from

a simulation of the garment on a scan of the subject in underwear. Additional experiments

were performed to illustrate how the method copes with missing data, how clothing pieces

may be assembled to produce the whole garment, and to include the effect of gravity on the

garment drape.

Une Procédure à Base de Modèle pour Adapter une Surface à des Scans de

Personnes Habillées

Nous présentons une procedure pour reconstruire la surface d’acquisitions 3D de personnes

habillées. La méthode s’appuie sur un modèle et est élaborée de tell sorte qu’elle puisse

prendre en compte une nuage de points (3D) non-organisés, parfois bruités, échantillonés de

manière irrégulière, avec des données manquantes. Ce dernier point est dû à la géométrie du

scanner, au pré-traitement des données, et en particulier au plis et arêtes des vêtements. La

méthode utilise des techniques développées pour les simulations de vêtements, afin de

pouvoir prendre en compte la déformation des tissus, et une procédure utilisant les principes

des statistiques robustes pour adapter une surface de vêtement simulée á un nuage de points

issu d’un scanner 3D corps-entier. La méthode produit des résultats pour la reconstruction de

la surface d’un chemisier de femme qui sont à la fois bon quantitativement et satisfaisant

visuellement, avec des plis réalistes du tissu. Un certain nombre d’expériences ont été

effectuées pour montrer la convergence de la procédure, initialisée à partir de la simulation

d’un vêtement sur le scan d’un sujet en sous-vêtements. D’autres expériences furent

effectuées pour illustrer de quelle manière la méthode fait face à des données manquantes, de

quelle manière plusieurs habits peuvent être assemblés pour former un ensemble, ainsi que

pour introduire les effets de la gravité dans l’habillage du vêtement.

2

1. Introduction

As a wide range of human whole-body scanners has become available over the past few years

(eg from: Cyberware, Hamamatsu, TC2, TCT International, Wicks and Wilson, Vitronics,

etc), a great deal of research has been carried out on developing techniques for the

description, processing and analysis of the data obtained [see for example, 2-5,14,15,21].

Simultaneously, there has also been a great deal of interest in creating, manipulating and

animating life-like models of human beings, for applications in the entertainment, film,

games, and fashion industries, as well as on the web and in virtual environments [9,16,17].

Such simulations usually necessarily include not only simulation of the human body and its

movement, but also of clothing [1,16,20,24]. In this paper, we exploit the existence of good

models of the properties of fabric, in particular that implemented by Vassilev et al [22] which

is known to produce good simulations of clothing drape, to develop a model-based technique

to fit a surface, corresponding to a particular type of garment, to an unorganised set of 3D

points obtained from a scan of a person wearing an example of such a garment. The results

obtained show that the procedure works well, giving accurate results with a realistic

appearance and capable of reconstructing the creases and folds of fabric drape and of solving

a number of common problems for this type of fitting, such as: presence of high levels of

noise, irregular sampling of the surface, and missing data.

Such effects may also, of course, be present in scans of naked or nearly naked subjects (see

for example [32]), but they are usually less severe than for scans of clothed people. For

example: the colour and texture of clothing can be highly variable and lead to increased noise

in the sensor data; the cut and drape of clothing leads to a less regular surface with the result

that, whatever the scanner geometry, data points will sample the surface less uniformly;

whilst the higher noise level and creasing and folding of the clothing surface mean that data

points are more likely to be missing, either because they are too unreliable and therefore

removed by pre-processing [10,11], or obscured. It is thus difficult to apply methods

developed for reconstructing the skin surface of scans of naked or nearly naked subjects [see

for example 2-5], to scans of clothed people.

Previous work on the fitting of surfaces to 3D whole-body scans have usually been based on

standard surface reconstruction techniques such as triangulation, development of a quad mesh

[2-4], the fitting of spline patches [5,6,28], or on the deformation of a computer graphics

avatar comprised for example of metaballs [33]. Many of these techniques (see for example,

[2-5]) require scanner 3D point data to be pre-processed to segment body parts, such as the

limbs, head and torso, or to organise the data into a regular mesh. However, such preprocessing cannot reliably be carried out for scans of clothed people.

In addition, it is difficult to reconstruct a surface that may be creased and folded. Many

techniques rely on the existence of a smooth underlying surface, for example, either to fit

spline patches [5,6,28] or to allow the introduction of regularisation terms to reduce the effect

of noise. Although it may be possible, for example with conventional image data that can be

treated as a height function of two variables, to detect features and discontinuities (see for

example [34]) and thus to lift these smoothness constraints at such locations, or to carry out

the two processes simultaneously by use of Markov random fields [35,36] or weak constraints

[37], such schemes are more difficult to formulate and implement in 3D. Furthermore, a

surface reconstructed by such techniques would still not behave correctly at creases and folds

where there was self-obscuration.

We thus instead use a fabric model and notions derived from robust statistics [7,13] combined

with a physical force model and geometrical analysis to fit a surface directly to the scanner

data. This model-based approach ensures that the cloth surface is correctly continuous, and

3

behaves in the way expected from the material’s properties at creases and folds or where data

is missing. The only pre-processing operations used are independent of the scanned object,

such as for example, using a threshold to remove unreliable, very low-intensity data points

according to the scanner design [10].

In the following, we commence in section 2 by very briefly reviewing some previous

approaches to surface reconstruction and by showing some examples of human body surface

models obtained from 3D scanner data. Such models are used in simulations of the drape of

garments, in particular, in the calculations of Vassiliev et al [22,38] that are used as the

starting point for our fitting procedure. We then describe our model-based fitting procedure

(section 3), including in particular discussion of the data-fitting force used (section 3.2).

Section 4 contains results illustrating convergence of the procedure, and some additional

experiments in which data points were deliberately removed, a whole garment assembled

from pieces of cloth, and the effects of gravity included. In section 5, we give our conclusions

and discuss, very briefly, areas for future work.

2. Surface Reconstruction Techniques

In general, a range image of an arbitrary object consists of a cloud of 3D points that, because

of the unknown nature of the surface of the object being scanned, does not have any specific

organization or structure, and points correspond to an irregular sampling of the surface.

Several techniques for reconstruction of surfaces from range images have thus been proposed.

Hoppe [12] for example, developed a technique in which very little knowledge about the

original surface is needed. It attempts to infer the surface connectivity by use of a signed

distance function from the data points to tangent planes, which are local, linear

approximations to the underlying real surface, estimated from neighboring points. In order to

obtain a good approximation to the topology and topography of the object’s surface, a fairly

uniform sampling density on the surface is required and noise levels need to be known quite

accurately. Although the shape of the human body is not arbitrary and subjects are usually

scanned in a standard pose [32], the technique does not work well on body scan data such as

that obtained in our work from the Hamamatsu Body Lines scanner [10,11]. In such scans, the

data density varies considerably over the body area, so that, for example, the density is lower

on the neck than on the chest and legs, and there may be very little data available on the inside

of the arms and between the legs, in particular close to the armpits and crotch where the body

is self occluding.

A rather different technique, based on the use of the medial axis transform, Voronoi diagrams

and Delaunay triangulation, has been proposed by Amenta et al [26], and they have shown

that an accurate reconstruction can be obtained from a set of unorganized vertices as long as

there is a “good sampling” of the surface of the object and, in particular, a dense sampling and

low noise levels where there are small features. Though these are obviously reasonable

restrictions in principle, in practice, even when scanning a well-known object such as the

human body, these conditions are not met and, given the wide variation of human body sizes

and shapes, it would seem impractical to develop a scanner capable of doing so. In addition,

the medial axis transform of a whole human body scan is complicated and sensitive to noise.

Nevertheless, much use can be made of the general shape of the normal, healthy human

subject, especially when scanned in a standard pose or stance, as in the work of Dekker et al

[2-4]. In this case, methods based on known aspects of human anthropometry are used to

detect key landmark points on the body and an interpolation procedure is used to turn the

unorganized cloud of 3D points into a regular mesh from which a surface may be created by

triangulation, meshing or by using polynomial spline curves. For example, Douros [5,6] used

4

such techniques to obtain a regular mesh to which B-spline surface patches were finally fitted.

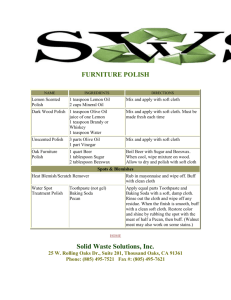

Examples of these are shown in Figure 1, reproduced from Dekker et al [32].

(a)

(b)

(c)

(d)

Figure 1. Surface reconstruction using various geometrical primitives: a) Initial cleaned point

cloud, b) Points interpolated and rearranged with their connectivity established so as to form a

wireframe mesh, c) a set of smooth contour curves used to define the boundaries of smooth Bspline surface patches, d) the final smooth surface composed of B-spline patches.

These techniques have two main characteristics. First, there is prior knowledge of the surface

to be reconstructed, in this case, a typical, healthy human body. A number of assumptions can

therefore be made that make segmentation of the torso and limbs, for example, easy and

reliable and therefore lead to a successful surface reconstruction. Second, the reconstruction is

carried out after several pre-processing steps have been performed on the raw data, which lead

to loss of noisy data, missing data in areas of difficult geometry, and the possibility of

unwanted artifacts where data is sparse. Although, the results can, as illustrated in figure 1, be

visually pleasing, issues such as unnecessary smoothing of the surface, completeness of the

surface, and reconstruction of the surface in areas of missing data need to be further

addressed.

3. Model-based surface fitting

We first follow the traditional formulation for fitting surfaces to noisy data by means of

minimising a fitting functional or energy, E , composed of two terms:

min E E data E model

.

(1)

The first term expresses the closeness of fit of the model to the data and is usually represented

by a least squares term derived from the distance of model point x(m) in 3-space1 from its

corresponding data point x(i ) . If the weight, or confidence of the i th data point is w(i ) , the

data energy is, on summing over all the corresponding model and data points, m i :

E data 1

N

2 m

i

w(i )x(m) x(i )

2

.

(2)

It is well known that such least squares approximations are efficient, but very sensitive to the

presence of outliers in the data, and it is for exactly this reason that pre-processing steps are

often carried out to clean the data by removing such points. Removal of data points in this

1

That is, x (m) denotes a position vector describing the location of model node

5

m in ordinary, Euclidean space.

way is formally equivalent to setting their weight w(i ) to zero. It can only strictly be carried

out if the data point is not part of the model since, if the one-to-one correspondence between

model and data points is to be preserved, points removed in this way from the data also have

to be removed from the model. Alternatively, a soft weighting factor can be used which

reduces the effect of an erroneous point and allows it to remain part of the model. It is

important that the confidence used in such a thresholding or down-weighting procedure is

derived solely from the data, independently of the model to be fitted. Down-weighting of

points which it turns out do not agree well with the model is better accommodated by use of a

2

robust statistic [7,13] that reduces the influence of the term x(m) x(i ) at large values of

x(m) x(i) by replacing the x 2 function in (2) by a function (x) that increases less rapidly

at large x . A variety of such functions have been suggested in the literature; see for example

Huber [13] and Geman and Belhumeur [7] for examples based on statistical considerations.

We shall return, in section 3.2 to choice of a function well-suited to our fitting problem, in

particular one that allows us to relax the constraint that there should be a one-to-one

correspondence between model and data points, after consideration of the second, model term

in (1).

The traditional approach for the model energy is to use a regularization term that balances

accurate fitting to the data with, for example, smoothness of the surface, but such measures

are not appropriate here as, for fitting a clothing surface, we specifically want to allow the

surface to fold and crease. As noted in section 1, more sophisticated models such as Markov

random fields with hidden variables [35] and weak constraint methods [37] could enable us to

allow the surface to be discontinuous or to have a discontinuous gradient. However, in order

to preserve the required topological equivalence of all three cartesian co-ordinates, such

models would be complicated2 and still fail to address the other issues of importance here, in

particular that we should obtain a continuous surface capable of folding and creasing like real

cloth. Since they are available, the obvious solution is to use one of the models developed for

realistic clothing simulation [20,24,25]. The essential ingredients of the model we used, that

developed by Vassilev [22,38] are described next.

3.1

The Cloth Model

The locations of the model points used in our fitting procedure are thus constrained by forces

that have been used to model cloth properties. In addition, since energy minimisation

problems such as (1) usually have to be solved iteratively it is convenient to adopt the

complete dynamics of such simulations via the appropriate Newtonian equations of motion

and to introduce the data fitting via a set of “data-fitting forces” or “data forces” for short.

In the cloth and garment simulations, the cloth surface is represented by a quad mesh, where

each node m 1...M of the mesh model has a mass3 with a position x(m) , velocity x (m) ,

and acceleration x(m) at time t whose motion is governed by Newton’s law of dynamics:

x(m) x (m) F (m)

,

(3)

2

Formulating a smoothness measure, for example, from the trace of the square of the curvature tensor over the

surface, that has the required topological invariance, is easy, but the equations that have to be solved in

implementing the resulting model are complicated.

3

We shall treat all model nodes, springs etc as equivalent. It is easy however to relax this constraint, provided

that care is taken appropriately to adjust the Euler time step used in numerical solution of Newton’s equations of

motion. See [22] for details.

6

in which we have included a damping term proportional to the velocity. In clothing

simulations, such terms may be used to mimic the effects of air resistance. Here, they are

particularly useful to ensure that, in principle, our garment evolves to an equilibrium position

at rest in which the total force F (m) on each node is zero. In general, the total force F (m) on

each node is comprised of three components

F (m) F model (m) F data (m) F ext (m)

,

(4)

where:

(i)

F model (m) is the net force on node m of the cloth model due to other nodes n in the

model;

(ii)

F data (m) is the net force on node m of the cloth model due to the data;

(iii)

F ext (m) represents any external forces that may be acting on the cloth.

External forces are usually used to allow for the effects of gravity and may also be used to

take account of frictional forces between layers of clothing and between clothing and the skin

or, more simply, to anchor a garment to the body at important drape points [22]. Since our

garments will be anchored to the body by the data fitting forces which are much stronger than

gravity, and since we are not interested in movement of the cloth, we shall, for the most part,

ignore the external forces in what follows (but see section 4.2).

The important term in the cloth model for our fitting procedure is the force F model (m) which

is characteristic of the material from which the garment has been made. These internal forces

are simulated by an arrangement of non-linear, massless springs that connect the masses in

three different ways as illustrated in Figure 2, each simulating a different fabric property.

Structural

Shear

Bend

Figure 2. Spring arrangement in the cloth model.

The structural springs maintain the integrity of the cloth by constraining it under tension or

compression and preventing tearing. These springs are strongly non-linear, it being relatively

easy, for example, to stretch the material against the bending moduli of the threads until the

threads are straight and taught, at which point the much higher elastic moduli of the threads

become important. This may be approximately modelled as a cut-off beyond which the

material will not stretch without tearing. Similarly, since cloth behaves differently along the

warp and weft directions, these springs are anisotropic and, finally since cloth behaves

differently under compression than it does under tension, the springs are directional and, in

particular, have no limit on the extent to which they can be compressed. The shear springs

connect nodes diagonally across the quad mesh and reflect the way the shear resistance of the

cloth depends on the twisting of the interwoven threads one over the other. These are also in

general non-linear and anisotropic. Finally, the springs connecting nodes to next nearest

neighbours in the warp and weft directions are used to model the cloth’s resistance to

bending. These springs obey a linear Hooke’s Law.

The properties of threads and fabrics have themselves been studied and measured, and we are

fortunate to be able to use a model in which the spring elasticity laws and parameters are

7

consistent, within the above approximations, with the properties of the cloth material as

determined by experimental work at DeMontford University [31].

Since only one spring connects any two nodes in the model, the internal model forces are thus

calculated from:

x(m) x(n)

F mod el (m) k (m, n) x(m) x(n) l (0)

n

x(m) x(n)

,

(5)

where, x(m) and x (n) , are the positions of nodes m and n , x(m) x(n) is the vector from node

n to m , l (0) is the natural length of the spring that joins m and n , and k (m, n) its stiffness.

The linear law, (5) is, as mentioned above, applied only up to a maximum extension of about

15-20%.

For further details of this clothing model, see [22,38]. These also describe the method used to

solve the Netwonian equations of motion by an Euler integration procedure which, when

applied to each of the co-ordinate axes in turn, turns out to be more efficient than RungeKutta methods and, if care is taken with the non-linearities and, if present, any

inhomogeneities, appears to be stable provided a sufficiently small time step is used. This

model has been shown [22,32] (and see Figure 3(a)) to generate realistic cloth simulations and

to be able to simulate the drape of garments on a scanned body model of a naked or nearly

naked person. As described further below, this model is used in exactly the same way to

initialize our fitting procedure. It is also used, as indicated at the beginning of this section, as

the dynamical model from whose final, equilibrium state; we obtain the fit of the clothing

model to our scanner data. For this last calculation, we need now to specify the data

force, F data (m) , that defines how a 3D scan of the clothed person is used in the fitting.

3.2

The Data-Fitting Force

As indicated at the beginning of section 3, we replace the squared term in the data energy by a

function (x) that increases less rapidly at large x . The force between model node m and

data point i obtained from the gradient of the energy with respect to x(m) ,

E data

w(i) x(m) x(i)

,

(6)

,

(7)

m i

is thus

F data (m) m E data w(i) x(m) x(i) xˆ(m, i)

where (x ) denotes the derivative of the function (x) with respect to its argument, x , and

xˆ (m, i) is the unit vector,to

xˆ(m, i) x(m) x(i) x(m) x(i)

.

(8)

Since, in equilibrium, the fitting and model forces balance, it is important to choose a

function (x) that generates a data force (7) that, via the influence function (x ) , has the

appropriate properties. A number of possible influence functions are listed in table 1 below. In

particular, since, in the absence of outliers, a least-squares error metric is efficient, the force

F data (m) should be proportional to x(m) x(i ) whenever a model point is close to a data

point and x(m) x(i) is small. All the models derived from the functions listed in table 1

below behave in this manner, but they differ in their behavior at large distances. Some, like

the force derived from a smooth Huber norm, tend to a constant (first row) and, like those

derived from the Geman-McClure norm (second row) and from the Lorentz norm (third row)

8

which decay slowly at large distance, may be regarded as long-ranged, whilst others, like

those derived from an exponential function (fourth row) and a Gaussian (fifth row), may be

regarded as short-ranged. The final two rows, derived from second and third order piecewise

continuous polynomials respectively, as described below, are finite ranged.

To see what behavior is appropriate at large distances, we note that, when fitting a model to a

scan of a clothed person, we do not know which data point corresponds to which model node.

In fact, since the clothing model and scanner data will usually be at different resolutions and

the latter is sampled at varying densities on different parts of the surface, it is impossible to

establish such a one-to-one correspondence. One way to proceed which overcomes this

difficulty, is to allow each model node to interact with every data point in its vicinity:

E data w(i ) x(m) x(i )

,

(9)

F data (m) w(i ) x(m) x(i ) xˆ (m, i )

,

(10)

M

N

m 1 i 1

M

=>

i 1

but to ensure that this interaction falls to zero over a distance comparable to the spacing of the

nodes in the cloth model. This strongly suggests that we use one of the short or finite ranged

models in the last four rows of table 1.

Name

smooth Huber

Geman-McClure

Lorentz

(Cauchy)

exponential

Gaussian

spline

Influence function

( x)

ax

Surface force

long

infinite

(divergent)

long

infinite

(divergent)

a2 x2

a2x

( x) 2

a x2

( x)

Range

long

a4x

(a 2 x 2 ) 2

1

( x) sech( bx) tanh( bx)

b

( x) xeb

short

short

2 2

x /2

( x) x( x m x) x m

finite

x , z xm

smooth spline

( x) x( x m x) 2 x m2

finite

x , z xm

z

3x m

a 4 z

2 a2 z2

z

b2

sec h(bz )

2 b 2 z 2 / 2

ze

b2

( x m 2 z )( x m z ) 2

z

6 x m2

( x m 3z )( x m z ) 3

Table 1. Influence functions, force type and resulting force from a flat surface sampled at

density .

In fact, the long-ranged models can immediately be ruled out since, if we have a large number

of scanned data points uniformly sampled with density , say, on a plane at z 0 , the force

on each model point becomes infinite. The Lorentz model leads to a long-range force

attracting each model point to the plane, which, as shown in the last column of table 1, is of

similar form to the force between the model and data points. It too can be ruled out. The

9

exponential and Gaussian models lead to short ranged forces attracting the model point to

such a plane, whilst the two polynomial models lead to finite ranged forces that vanish

beyond a distance x m . In principle, we could thus use any of the last four models for the datafitting force. Since, in practice, it is computationally much simpler to use a fitting-force that is

finite ranged and strictly vanishes beyond a distance x m the polynomial forces are preferred.

We thus used the smooth spline force model as it vanishes smoothly at x x m whilst the

corresponding surface force vanishes very smoothly (ie, as a cubic factor) at the limit of its

range, which is also x m .

The influence function for the smooth spline force is sketched in Figure 2 below. As noted

above, we chose its range xm D, the distance between neighboring model nodes, so as to

ensure that there is little or no overlap in the sets of data points influencing the position of

each model node, and that each data point affects a model point, ie. that there is an

approximate many to one correspondence of data points to model nodes.

(x )

xm/3

xm

x

Figure 3. Sketch of the influence function for the smooth spline data force.

4. Fitting to a scan of a clothed person

A female subject was scanned in underwear and then, in the same pose, wearing a blouse. The

shape and design of the blouse was modelled on a CAD system and fitting initialised by using

the system developed by Vassilev [22,38] to simulate the blouse on the unclothed subject. The

cloth was constructed as a quad mesh with 700 model points set a distance of (on average)

24.6 mm in the horizontal direction and 26.4 mm in the vertical direction. The scan of the

clothed subject was segmented by hand to approximately delineate the blouse so that points

on other garments or parts of the body would not interfere with the fitting. Finally, the

range, x m of the data-fitting force was taken to be the diagonal distance between model points,

approximately 36.0 mm.

4.1

Convergence

The initial clothing simulation [22] brings the garment to within a few cm of the body,

ensuring that the blouse model nodes are close enough to the data points from the clothed

scan for the attractive fitting force to be effective. The appearance of the simulated blouse is

shown in Figure 4(a). At this stage, 73% of the 700 garment nodes were within distance x m of

a data point as indicated by the histogram above the simulation in Figure 4(a). Snapshots of

the fitting procedure are shown in Figure 4(b-f), together with histograms of the distance of

each data point from its closest model node. The attractive data-fitting force pulls the model

to the data points, usually commencing at the sides (Figure 4(b)) and progressively pulling

more of the garment to the data points (Figures 4(c) & (d)) until, after 80 iterations,

integration may be stopped as almost all the data points have a model point closer than the

distance of around 13.0 mm at which the data fitting force is a maximum. After 80 iterations

there is very little further change as shown in Figure 5.

10

10 Iterations

0

100

200

300

400

20

60

15

10

5

0

100

200

20

10

400

500

0

600

100

300

400

500

600

72% of model points within force range

(c)

400

distance mm x 10 -1

99% of model points within force range

80 Iterations

40

Number of poi nts

30

25

20

15

10

5

0

300

200

distance mm x 10 -1

60 Iterations

Number o f p oin ts

Number of poi nts

30

(b)

40 Iterations

(d)

300

78% of model points within force range

(a)

200

40

distance mm x 10 -1

73% of model points within force range

100

50

0

0

500

Distance mm x 10 -1

0

20 Iterations

Number of points

Number of points

Number of model points

Initial State

10

9

8

7

6

5

4

3

2

1

0

30

20

10

0

0

50

100

150

distance mm x 10-1

100% of model points within force range

(e)

35

30

25

20

15

10

5

0

0

50

100

150

200

distance mm x 10-1

100% of model points within force range

(f)

Figure 4. Stages in the fitting procedure. (a) initial simulation, (b)-(f) after 10, 20, 40 60 and 80

iterations respectively.

As can be seen from Figure 4, creases and folds are created in the cloth as model nodes are

progressively attracted to the data points. This is particularly noticeable at the sides of the

blouse and under the armpits as shown in Figure 6. The cloth is also folded down the centre of

the blouse where, in the real garment, there was a row of buttons. There is a higher density of

scanned points in the vicinity of the buttons and the scanned surface is uneven. Both effects

tend to cause the cloth to fold and crumple and, in addition, the fitting force has pulled excess

cloth into this area.

11

s

100% model points within the force range

Figure 5. Fitted blouse after 100 iterations.

4.2

Experiments

In order to see how the procedure copes with missing data, we deliberately removed data

points from a strip down the centre of the scan, between the vertical lines in Figure 6(a). The

model interpolates across the area of missing data, but the cloth is crumpled because, as noted

above, there is again excess material in this region.

(a)

(b)

(c)

(d)

Figure 6. Effect of deliberately removing data points (a). Details from the fitted blouse of Figure

5 to show creases near the armpits (b) and a fold (c), and crumpling down the front (d) where

the real garment had buttons.

(a)

(b)

(c)

(d)

Figure 7. Results obtained when the front of the garment (a) was joined to the back (b) along

the seams down the sides, and a similar experiment in which the effect of gravity was also

included (c) and (d).

In a second experiment, we used two pieces of material, joined along seams down the side, to

model the whole blouse as in [22]. The results are shown in Figure 7 (a) and (b). Again there

12

are realistic folds and creases under the armpits. Finally, we included the effect of gravity on

the drape via an appropriate external force in (4). The results are shown in Figure 7 (c) and

(d). They are very similar to Figures 7 (a) and (b) because gravity is very weak in comparison

to the data-fitting force.

5. Conclusions and Further Work

A model-based procedure for fitting a surface to scans of clothed people has been developed

by utilising an existing model for clothing simulation in combination with a finite-ranged,

attractive force for the data-fitting. Experiments on several scans indicate that the modelbased fitting procedure is quite robust, and that it allows the surface to deform, crease and

fold where necessary. The resulting garment, fitted to the scan data thus has a very realistic

appearance. In addition, it was shown that the model can interpolate over areas where data is

sparse or missing, that a whole garment surface could be fitted by joining pieces of cloth at

seams and, since it is weak in comparison to the fitting force, that gravity has little effect on

the appearance.

The success of this work suggests that, if a suitable skin or flesh model were available, similar

techniques could be very effective in reconstructing the skin surface of scans of naked or

nearly naked subjects.

6. References

[1]

D. Baraff and A. Witkin. “Large Steps in Cloth Simulation”. Computer Graphics Proceedings, Annual

Conference Series: 43-54, SIGGRAPH 1998.

[2]

Dekker L, Khan S, West E, Buxton B, Treleaven P, “Models for Understanding the 3D Human Body

Form”, IEEE International Workshop on Model-Based 3D Image Analysis, IEEE, 1998.

[3]

Dekker L., “3D Human Body Modelling from Range Data”, Thesis for a degree of Doctor of

Philosophy in Computer Science at UCL, 2000.

[4]

Dekker L., Douros, B.F. Buxton, Treleaven P, “Bulding Symbolic Information for 3D Human Body

Modelling from Range Data”, 1999.

[5]

Douros I., “B-Spline surface reconstruction of the human body from 3D scanner data”, Master Research

in CVIPGS at UCL, 1998.

[6]

Douros I, L. Dekker, B.F. Buxton, “An improved Algorithm for reconstruction of the surface of the

Human Body from 3D Scanner data using local B-Spline patches”, Proceedings of the Second International

Conference on 3D Digital Imagining and Modelling, IEEE Computer Society, 1999

[7]

Geman G, Belhumeur P, “Statistical methods for tomographic image reconstruction”, Bull. Int. Statis.

Inst, 1987.

[8]

Hilton A, Stoddart A, Illingworth J, and Windeatt T, "Implicit surface-based geometric fusion",

Computer Vision and Image Understanding, Vol. 69, pp 273-291, 1998.

[9]

Hilton A. ”Towards Model-Based Capture of Persons Shape, Appearance and Motion”, Centre for

Vision, speech and Signal Processing, University of Surrey, UK, IEEE International Workshop on Modeling

People, Greece, 1999.

[10]

Horiguchi C, “BL ( Body Line) Scanner”, International Archives of Photogrammetry and Remote

Sensing, Vol XXXII, Part 5, Hakodate 1998.

[11]

Horiguchi C, "Sensors that Detect Shape", J. Adv. AutomationTechnology Vol. 7 No. 3, 1995, pp. 210216.

[12]

Hoppe H, DeRose T, Duchamp T, McDonald J, Stuetzle W,”Surface Reconstruction from Unorganised

Points”, SIGGRAPH ’92,.

[13]

Huber P, “Robust statics”, John Wiley and Sons, 1981.

[14]

Li P, and Jones P, "Anthropometry-Based Surface Modelling of the Human Torso", Computers in

Engineering, Amer. Soc. Mech. Eng., Minneapolis, 1994, pp. 469-474.

[15]

Li P, Corner B.D., Paquette S.,” Extracting surface area coverage by superimposing 3D scan data”,

GEO-Centers, Inc., Newton, U.S. Army Natick Research, Development & Engineering Center, Natick, Three

Dimensional Image Capture and Applications, Proceedings of Spie, San Jose California, 1999.

13

[16]

Magnenat Thalmann N, Yang Y, Thalman D, “The problematic of Cloth Modelling and Animation”,

Proceeding of the 2nd Conference on CAD on Computer Graphics”, International Academic Publishers, 1998.

[17]

Magnenat Thalmannn N, Carion S, Courchesne M., Volino P., Yin w., “ Virtual Clothes, Hair, and

Skin for Beautifil Top Models”, MIRALab, University of Geneva, 1998.

[18]

Volino P, Courchesne M, and Magnenat Thalmann, N, "Versatile and efficient techniques for

simulating cloth and other deformable objects", Computer Graphics (SIGGRAPH), annual Conference Series,

1995, pp137-144.

[19]

Terzopoulos D, J. Platt, A.Barr and K. Fleischer, “Elastically Deformable Models”, Computer

Graphics Procedures SIGGRAPH, Vol.21 No. 4, 1987..

[20]

Provot X, “Deformation Constraints in a Mass-Spring Model to Describe Rigid Cloth Behavior”,

Institut National de Recherche en Informatique et Automatique (INRIA)

[21]

Pargas Roy, Chhatriwala M., Mulfinger D. Deshmukh P_, Vadhiyar S, “Generating animated sequences

from 3D whole body scans”, Department of Computer Science, Clemson University, Three Dimensional Image

Capture and Applications, Proceedings of Spie, San Jose California, 1999.

[22]

Vassilev, T., Spanlang, B., Chrysanthou,Y, “Efficient Cloth Model and Collision Detection for

Dressing Virtual People”, (in CD proc. GeTech Hong Kong), January 2001.

[23]

Stoddart AJ, Hilton A, Illingworth J, “Slime A new deformable surface”, Proceedings of the British

Machine Vision Conference BMVA Press, 1994.

[24]

Ng HN, Grimsdale RL, “Computer Graphics Techniques for Modelling Cloth”, IEEE Computer

Graphics and Applications, Vol. 16 No. 5, 1996.

[25]

Tsopelas N, “Modelling Thin-Walled Objects in Computer Graphics and Animation”, thesis for the

degree of Doctor of Philosophy in Computer Science at Queen Mary and Westfield College, 1993.

[26]

Amenta N, Bern M, Kamvselis M, “ A new Voronoi-Based Surface Reconstruction Algorithm”,

SIGGRAPH ’98, ACM, 1998.

[27]

Daanen HAM, Van de Water GJ, “Whole body scanner”, Displays, Vol 19. Elsevier Science 1998.

[28]

West, E, "B-spline surface skinning for body scanner data", MRes Thesis, Department of Computer

Science, University College London, September 1997.

[29]

Ray Harwood, DeMontford University, private communication, May 2000.

[30]

Nurre JH, “Locating Landmarks on Human Body Scan Data”, International Conference on Recent

Advances in 3D Digital Imaging and Modeling, IEEE, 1997, pp. 289-295.

[31]

Floater S. Michael, “MeshLess Parametrization and B-Spline Surface Approximation”. Proceedings of

the Ninth IMA Conference on the Mathematics of Surfaces. The Mathematics of Surfaces IX, Cambridge, June

2000.

[32]

Csakany P, Wallace M, “Computation of Local Differential Parameters on Irregular Meshes”,

Proceedings of the Ninth IMA Conference on the Mathematics of Surfaces. The Mathematics of Surfaces IX,

Cambridge, June 2000

[32]

Laura Dekker, Bernard Buxton, Ioannis Douros, Tsvetomir Vassilev, “Reconstruction and

Interpretation of 3D Whole Body Surface Images”, Numerisation 3D Scanning 2000 Conference Proceedings.

April 2000.

[33]

N.Thalmann,, P Kalra, “The Simulation of a Virtual TV Presenter”, PG95,Geneva, Switzerland, 1995.

[34]

Canny J F. “A Computational Approach to Edge Detection”, IEEE Transactions on Pattern Analysis

and Machine Intelligence, Vol PAMI-8, No.6, Nov, 1986.

[35]

J E Besag, “Spatial interaction and the statistics of lattice systems”, Journal of the Royal Statistical

Society, series B, 192-236, 1974.

[36]

S Geman and D Geman, “Stochastic relaxation, Gibbs distributions and the Bayesian restoration of

images”, IEEE PAMI 6, 721-741, 1984. Reprinted in Advances in Applied Statistics, 20(5/6), Statistics and

Images: 1, edited by K V Mardia and G K Kanji, pp 25-62, 1993.

[37]

Blake, A, and Zisserman, A, “Visual Reconstruction”, MIT Press, Cambridge, 1987.

[38]

Vassilev T, “Dressing Virtual People”, SCI'2000 Conference, Orlando, July 23-26, 2000.

14