Hierarchy-Oriented Case-Based Reasoning

advertisement

中華管理學報 第二卷 第一期 第75-87頁

民國九十年

An Application of Hierarchy-Oriented

Case-Based Reasoning in the Pilot Production

Stage

Tzu-Fu Chiu

Department of Industrial Management, Aletheia University

32, Jenli St., Danshuei Jen, Taipei, Taiwan

Tel: 02-26212121 ext 5512

Fax: 02-26212121 ext 5512

email: chiu@email.au.edu.tw

Abstract

In this paper, the problem of organisation and re-use of hierarchical

knowledge in the pilot production stage is described and a proposed architecture

to aid this problem called Hierarchy-Oriented Case-Based Reasoning (HOCBR) is

discussed. HOCBR consists a hierarchical case-based structure, multi-stage

retrieval and hybrid adaptation. The hierarchical case-based structure provides a

knowledge representation format for retaining hierarchical knowledge. Multi-stage

retrieval is used to search through hierarchical case bases for the most similar

cases to the input problem. Hybrid adaptation transforms the information from

these cases into a suggested solution. A new system framework based on this

architecture is put forward. A description of the implementation in the pilot

production stage is also provided. An evaluation of the HOCBR architecture is

provided along with possible future research.

Keywords: HOCBR (Hierarchy-oriented case-based reasoning), Multi-stage

retrieval, Hybrid adaptation, FMEA data, Pilot production.

階層導向案例基礎推理架構於試作生產階段之

應用

邱賜福

真理大學工業管理學系

台北縣淡水鎮真理街 32 號

摘

要

本文描述了在試作階段中階層式知識的組織與再使用問題,並提出了

一個協助解決此問題的階層導向案例基礎推理(HOCBR)架構。HOCBR 架

構包含了:階層式案例庫結構、多階段尋取及混合式轉化等三個方法。階

層式案例庫結構,提供了一個儲存階層式知織的知識表示格式;多階段尋

取,是用來在階層式案例庫中搜尋出一個與輸入問題最相似的案例;混合

75

Tzu-Fu Chiu

An application of hierarchy-oriented case-based reasoning in the pilot production stage

式轉化,是將最相似案例的內涵轉換為適用於輸入問題的建議解答。基於

HOCBR 架構作者建立了一個雛型系統,而此雛型系統即應用於試作階段

,最後對此一 HOCBR 架構進行評估,並提出未來可能研究方向。

關鍵詞:階層導向案例基礎推理,多階段尋取,混合式轉化,FMEA 資,試

作生產

1. Introduction

This paper attempts to organize and re-use the hierarchical knowledge in the

pilot production stage. Hierarchical knowledge is usually complex and great in

volume. Simple representations of knowledge, such as predicate rules, are not rich

enough to efficiently encapsulate all of the factors within this type of information.

Complex knowledge is also difficult to formulate into general models. Case-Based

Reasoning (CBR), a paradigm which solves a new problem by remembering a

previous similar situation and by reusing information and knowledge of that

situation [1], is a particularly useful approach for use in the retrieval and adaptation

of hierarchically complex knowledge. The reason for this is that CBR offers a more

suitable structure for compound knowledge and provides a partial matching

mechanism for searching out similar existing cases [2, 10].

Pilot production is a stage of the production cycle that prepares available

material, existing machines and suitable methods for examining the feasibility of

the planned process. It also finds any possible failures and is usually a complicated

and time-consuming procedure. The essential knowledge items contained in pilot

production are manufacturing data and FMEA 1 data. The relationship between the

data items is hierarchical, as a product may include several parts, each part may

contain a number of processes and every process may hold a set of processing d ata

and a set of FMEA data.

Due to the characteristics of the problem domain and the features of the CBR

approach, the Hierarchy-Oriented Case-Based Reasoning (HOCBR) architecture,

which comprises a hierarchical case-based structure, multi-stage retrieval and

hybrid adaptation, is proposed. Utilizing multi-stage retrieval, HOCBR efficiently

seeks out the most similar cases from the complex knowledge organised in a

hierarchical case-based structure. Using hybrid adaptation, HOCBR also effectively

transforms the similar data into more suitable suggested information for the input

problem.

In the next section the HOCBR architecture is described. This is followed by a

description of the system framework for the HOCBR architecture that facilitates the

building of a prototype system. The prototype system is subsequently discussed. The

discussion continues with an evaluation of the HOCBR architecture. Finally,

conclusions are presented and future work outlined.

2. Proposed Hierarchy-Oriented CBR Architecture

The basic concept behind the HOCBR architecture is derived from the Material

1

Failure Modes and Effects Analysis (FMEA) involves the investigation and assessment of all causes and effects of

all possible failure modes on a system, in the earliest development phases [18].

76

中華管理學報 第二卷 第一期 第75-87頁

民國九十年

Requirements Planning (MRP) procedure used in industry, which obtains the

independent demand from the customer order and then calculates the dependent

demand level-by-level, according to the bill of material [12]. The bill of material, a

structured parts list, shows the hierarchical relationship between the finished

product and its various components [5]. Case-based reasoning is suitable for

problem areas where the knowledge (or data) is complex and not easily organized

into patterns or models [9, 17]. Using the concept of MRP and the capabilities of

CBR, case-based reasoning methods are modified and developed to deal with the

hierarchical data structure. The three main components of HOCBR are presented

below.

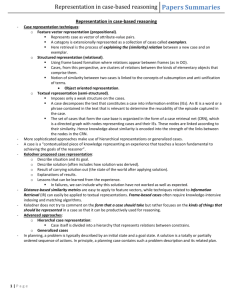

2.1 Hierarchical Case-Based Structure

Hierarchical data can be decomposed into different, but, related types. A car

part product can be broken down into product data (a sub-assembly is called a

product, since it is a finished item from a factory), part data and process data. A

product may contain several parts, with each part fabricated by several processes.

Each process for a part consists of a group of processes and the previously

mentioned FMEA data.

Product

Product_id

Product_description

Constituent_part

Part01

Part02

.

.

Part_n

Figure 1

Part

Part_id

Part_description

Constituent_process

Proc01

Proc02

.

.

Proc_n

Process

Process_id

Process_description

FMEA data

Failure_data

Failure_mode

Cause_of_failure

Effect

Corrective_action

Hierarchical case-based structure with three-level case bases

Thus, it was decided that hierarchical knowledge could be stored in separate

(but related) case bases using the object-attribute-value triplets format [6] and could

also be linked together via a linking function (see Figure 1). A linking function is a

processing procedure in which a seeking operation is employed to connect a field of

a case in one case base onto a case in another case base, then from that case base to

another one and so on. This hierarchical structure also facilitates the retrieval and

adaptation operations. Other benefits of the hierarchical case-based structure are

that redundancy of storage is avoided entirely and the linking function links the

different level case bases together dynamically (starting at any level) and flexibly

(linked and unlinked easily).

2.2 Multi-Stage Retrieval

As stated, data in HOCBR can be organised into a hierarchical case-based

structure. Multi-stage retrieval is proposed to search through multi-level case bases

77

Tzu-Fu Chiu

An application of hierarchy-oriented case-based reasoning in the pilot production stage

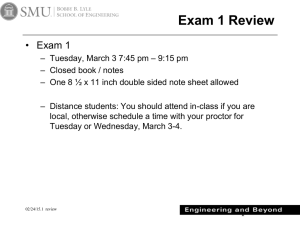

to get a set of related similar cases. The conceptual diagram of multi-stage retrieval

is depicted in Figure 2.

Input

problem

First-stage retrieval

(Product case base, A)

tmp-case

(Retrieval)

case_a2

case_a1

case_a3

.....

case_a4

case_am

(Similar case)

(Linking)

Second-stage retrieval

(Part case base, B)

case_b1

case_b2

case_b7

case_b6

(Edited)

case_b3

case_b8

case_b4

case_b5

(Similar case)

case_b9 . . . . .

case_bn

tmp-case (Retrieval)

(Linking)

(Linking)

Third-stage retrieval

(Process case base, C)

case_c1

case_c2

(Similar case)

case_c6

case_c7

(Retrieval)

tmp-case

case_c4

case_c3

case_c8

(Edited)

case_c9

(Edited)

case_c5

.....

(Similar case)

case_cp

tmp-case (Retrieval)

Hybrid adaptation

Figure 2

A conceptual diagram of multi-stage retrieval

Multi-stage retrieval searches through the hierarchical case bases, from the

highest level case base down to the lowest level case base. Nearest Neighbour

Retrieval (NNR) [9, 13] is employed to search through the three case bases for the

most similar case to the temporary case at each stage. This is shown in Figure 2,

using three-stage retrieval to demonstrate the conceptual logic. Initially first stage

retrieval accepts the input problem from the user and keeps it as a temporary case at

in memory. The case as is found in the top level case base A, such that

Ma (s, t) = max {Ma (x, t)}

for x A, where Ma is the similarity score, associated with the case base A, given

by

n

n

k 1

k 1

Ma (x, t) = ( wk fkxt) / ( wk)

Here fkxt is the value of an appropriate similarity function for feature k of

cases ax, at such that 0 fkxt 1, k = 1, ..., n. The vector of weights w' = (w1, …,

wn) reflects the importance assigned to the features and is called a retrieval view. In

Figure 1, s = 3. Using the constituent parts of as and the linking function, first -stage

78

中華管理學報 第二卷 第一期 第75-87頁

民國九十年

retrieval links the first-level case base A (e.g. in Figure 2, cases a3) to second-level

case base B (e.g. cases b3, b6, and b7).

As there is no editing required for case b3 and case b5 in this example,

second-stage retrieval links to the third-stage directly, using the constituent

processes of case b3 and case b6 and the linking function. The user may wish to edit

a case (to change portions of its fields, or to add a necessary new case) in order to

fit the input problem more closely, as for case b7. Second-stage retrieval then stores

this edited case as a temporary case in memory and utilizes this temporary case to

search out a similar case (e.g. case b9) in the part case base. Using the constituent

processes of the similar case and the linking function, second-stage retrieval links

the second-level case base B (e.g. case b9) to third-level case base C (e.g. case c3,

c4, c5, and c9).

In the third-stage retrieval shown in the example, two cases (i.e. case c8 and c9)

have been edited by the user. Case c8 and case c9 are then stored as temporary cas es

in memory in order to find the most similar cases to them (using NNR). Multi -stage

retrieval (including hybrid adaptation) is performed iteratively on the process and

FMEA data until the search of all of the constituent elements is completed.

The advantages of multi-stage retrieval are: the interactive editing function at

each level for modifying portions of the intermediate data and the dynamic

searching procedure through hierarchical case bases for the most similar cases. Thus

the entire case bases are searched thoroughly and efficiently.

2.3 Hybrid Adaptation

Within multi-stage retrieval, when retrieval proceeds down to the third-stage in

this system, the retrieved case data will be passed onto the next operation, hybrid

adaptation, in order to generate the suggested solutions for the input problem. The

different hybrid adaptation methods which are suitable to the application area of

pilot production and include formula adaptation, rule-based adaptation and

shift-view adaptation, are discussed below.

Formula adaptation: this method uses parameter adjustment [14] to substitute

the processing time and cutting speed for a similar case let us say S (retrieved at

3rd-stage retrieval). The ‘formula field’ is used off-line to calculate the processing

time and cutting speed for each case in the process case base, according to the

relevant data kept in the case fields. The calculation formulae for processing time t

(minutes) and cutting speed V (mm/min) are listed below [8]:

t = L / (fN);

V = DN

where L is the length of the workpiece (mm), f is the feeding speed

(mm/revolution), N is the rotation speed (rpm), and D is the bore diameter (mm).

During system execution, at the editing stage of multi-stage retrieval, if the process

specifications (i.e. the length of a workpiece and/or the rotation speed of a machine)

have been changed and differ from the similar case S, the calculation formula is

employed again to re-calculate a new processing time and cutting speed to reflect

these parameter changes. This will provide adjusted values for the similar case S.

Rule-based adaptation: this method uses domain-specific adaptation [9] to

search out the most suitable machine and tool associated with a specific part and

79

Tzu-Fu Chiu

An application of hierarchy-oriented case-based reasoning in the pilot production stage

process for the similar case S. The machine selection data and tool changing data

collected from the factory is used to generate a knowledge base. During the editing

procedure, if the main specifications of a process are changed, the reasoner passes

this data on onto the rule-based environment. A set of rules for searching out a

suitable machine and tool for the “Body” of an oil pump in the plane milling

process are shown as an example below.

IF Part_name = “Body (OP)” AND

Proc_name = “Plane milling” AND

Hole_distance < 150

THEN

Machine_selected = “MC02; Machine centre”

IF Proc_name = “Plane milling” AND

Machine = “MC02; Machine centre”

THEN

Tool_selected = “T0120110; Milling tool”

Subsequently, the inference engine is activated to seek out a solution which

exactly matches the input condition. The information obtained is sent back to

complete the adaptation procedure. If no exact match exists no value is returned.

Shift-view adaptation: this method applies case-based substitution [7] to replace

FMEA data in the similar case S with a more useful set of FMEA data (or a combination

of two sets of FMEA data), which match the edited case let us say E more closely. A

retrieval view w may be partitioned into subviews w1, w2, wn. Each subview

corresponds to the features in a particular section of the data. For example a process

case contains data of two kinds: process data and FMEA data. Thus, as well as the

general view wg, where w'g = (w'1, w'2), to emphasise the different data types the process

view is defined, wp, where w'p = (w'1, 0') and the FMEA view, wf, where w'f = (0', w'2).

Here w1 and w2 are the subviews corresponding to the process and FMEA data

respectively and 0 is the vector of zeros. The relationships between different kinds of

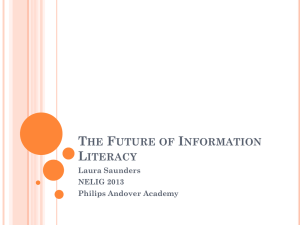

retrieval views is shown below in Figure 3.

Retrieved case

Sp

[retrieval]

Process view, Mp (Sp, E)

(Similarity_score_Sp)

[comparison]

Edited case

E

General view

Similar case

S

FMEA view, Mf (Sf, E)

(Similarity_score_Sf)

[retrieval]

Figure 3

Process view, Mp (Sp, Sf)

(Process_score)

FMEA view, Mf (Sp, Sf)

(FMEA_score)

[comparison]

Retrieved case

Sf

Relationships between different kinds of retrieval views

80

中華管理學報 第二卷 第一期 第75-87頁

民國九十年

Case-based substitution is used to replace FMEA data in the similar case S

(retrieved using wg). A case which is found to be similar using wp may consist of a

process closely related to that of E and may also contain useful FMEA data for E.

Similarly the case retrieved using wf will contain a set of FMEA data closely related to

that in E.

Therefore two cases Sp, Sf are retrieved using wp and wf respectively. These two

cases are then compared using the NNR method (also through the process view and

FMEA view). The aim of the comparison is to measure the degree of similarity of fields

between the two retrieved cases (i.e. Sp and Sf), based on the different views. The

different comparison scores between the two views will facilitate the following selection

procedure for finding a useful set of FMEA data for the similar case S. Essentially, these

two retrieved cases are similar to the edited case E in some aspects, depending on the

view used. If the two retrieved cases are also similar to each other, their two sets of

FMEA data may be useful for predicting possible future FMEA situations in the edited

case E (i.e. the edited process).

The two retrieved cases are retained or discarded as follows. Let Mv (c1, c2) be the

similarity (or comparison) score of cases c1, c2 using view wv. Firstly, the threshold

value is that Mp (Sp, E) 0.5 and Mf (Sf, E) 0.5. Then we retain case Sp if and only if

max {Mp (Sp, Sf), Mf (Sp, Sf)} 0.5 or Mp (Sp, E) 0.75, and similarly we retain case Sf

if and only if max {Mp (Sp, Sf), Mf (Sp, Sf)} 0.5 or Mf (Sf, E) 0.75. These decision

criteria can also be explained as in Table 1.

Table 1

Selection criteria table for the retrieved cases

Criterion

Condition 1

Condition 2

Condition 3

Condition 4

Conclusion

No.

Mp (Sp, Sf)

Mf (Sp, Sf)

Mp (Sp, E)

Mf (Sf, E)

Recommended retrieved case

1

>= 50%

--

--

--

Retrieved case Sp & case Sf

2

< 50%

>= 50%

--

--

Retrieved case Sp & case Sf

< 50%

>= 75%

>= 75%

Retrieved case Sp & case Sf

< 75%

Retrieved case Sp

>= 75%

Retrieved case Sf

< 75%

No case

3

4

5

< 75%

6

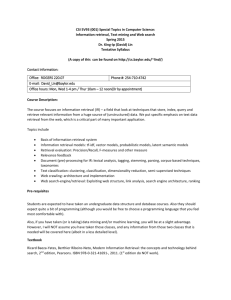

3. System Framework for the HOCBR Architecture

Based on the HOCBR architecture, a system framework has been developed. The

system framework, incorporating the background environment, development tools and

main operations, is shown in Figure 4.

According to the HOCBR system framework, the final prototype system will be

able to perform the following activities. Firstly, the system accepts the manufacturing

and FMEA records as initial data to form the case bases. Process data is then entered as

an input (or current) problem. The multi-stage retrieval (the first shaded operation in

Figure 4) is then activated to do the retrieving operation upon the hierarchical case bases,

by searching for the most similar cases to the input case. Subsequently, the hybrid

adaptation (the second shaded operation in Figure 4) is triggered to do the

81

Tzu-Fu Chiu

An application of hierarchy-oriented case-based reasoning in the pilot production stage

transformation process associated with the case bases and knowledge base, by

transforming the most similar cases into successive temporary solutions. The temporary

solutions are then integrated by the data integration unit into a final suggested solution

for the user. The main functions of the system are: single-stage retrieval, multi-stage

retrieval, formula adaptation, rule-based adaptation, shift-view adaptation and data

integration [3].

Application area: pilot production in the car part industry

Problem: retrieval and adaptation of hierarchical knowledge

Input

problem

Data

entry

Modified

data

Problem

modification

Users

No

Multi-stage

retrieval

Hybrid

adaptation

Down to the

lowest level?

Yes

Case

base

Knowledge

base

(Knowledge Archive)

Successive

solutions

Programming

language:

ReMind API &

Visual Basic

No

More alternatives

needed?

Solution

display

Yes

Suggested

solution

Data

integration

Using: manufacturing & FMEA data

Based on: ReMind development system

Figure 4

HOCBR system framework for the problem domain

Key:

: an operation

: main operations of the system

: logical flow

: data flow related to the knowledge archive

: judgement

: knowledge archive (a set of data structures)

: various types of data used in the operations;

: various types of data structure in the archive.

4. Implementation in Industry

A prototype system for this research has been developed from the HOCBR system

framework and successfully installed in an automobile component factory in Taiwan.

Real data from factory has been entered into the system. The system is currently being

used by engineers who work in the interactive manufacturing environment of pilot

production within the factory. The system provides the four main functions for browsing,

multi-stage retrieval, hybrid adaptation (a screen of the shift-view adaptation as an

example shown in Figure 5) and integration.

Feedback about the system has been positive. Summarised questionnaire evaluation

from the engineers states that they found the system useful, improved efficiency and

82

中華管理學報 第二卷 第一期 第75-87頁

民國九十年

would continue to be of use after the initial testing period [4].

Rule-based

Shift-view

Shift-view

S(p)

S(f)

Figure 5

A screen of the shift-view adaptation result

5. Evaluation of the HOCBR Architecture

In order to perform an evaluation of the HOCBR architecture in detail, this section

is divided into three sub-sections. Firstly, the hierarchical case-based structure is

compared to the individual structure (normally used in the flat-record case base), in

order to highlight its advantages with respect to data storage. Multi-stage retrieval is

then compared to other hierarchical systems, in order to show its capability in linking

and editing dynamically. Finally, shift-view adaptation is compared to the CLAVIER

method [7], in order to demonstrate its functionality in data transformation using

different retrieval views.

5.1 Comparison of the Number of Data Units in the

Hierarchical and Individual Case-Based Structures

The individual case-based structure has been employed in many existing CBR

systems (e.g. CHEF, CASEY and HYPO) for data storage [19]. Thus it is used as a basis

for comparison with the hierarchical case-based structure.

Each cluster of product, part, or process data is called a data unit. The number N1

of data units in the individual case-based structure is calculated as in formula (1); and

the number N2 of data units in the hierarchical case-based structure is calculated as in

formula (2).

N1 = 3 mnp,

(1)

N2 = (m + mn + mnp) – c,

(2)

83

Tzu-Fu Chiu

An application of hierarchy-oriented case-based reasoning in the pilot production stage

where m is the number of data units in the product level, n is the average number of

constituent data units in the part level, p is the average number of constituent data units

in the process level and c is the number of common units in the part and process levels.

For c = 0, n > 1 and p 1, it can be said that

p > (1 + n) / 2n;

=> 3np > 1 + n + np;

=> 3mnp > m + mn + mnp; that is

N1 > N 2

therefore, the number (N2) of data units in the hierarchical case-based structure is less

than the number (N1) of data units in the individual case-based structure. The ratio (i.e.

the relative efficiency) for the number of data units between the individual case-based

and hierarchical case-based structures is expressed below.

R = (3mnp) / (m + mn + mnp);

= (3np) / (1 + n + np);

= (3) / ((1 / np) + (1 / p) + 1);

The ratio will approach 3 as p approaches infinity; meanwhile the ratio will

approach (3p) / (p + 1) as n approaches infinity.

In the prototype system, there are 22 data units (i.e. 8 oil pumps, 8 water pumps

and 6 front axle assemblies) in the product base, 54 data units in the part base and 171

data units in the process base. The total number of data units in the hierarchical

case-based structure is:

N1 = 22 (product base) + 54 (part base) + 171 (process base) = 247

However, to keep all of this data in the individual case-based structure, the number

of data units will increase as follows (according to the BOM of products):

((8*1*5), (8*1*2), (8*1*2), (8*1*2)) = 88

(oil pump)

((8*1*4), (8*1*1)) = 40

(water pump)

((6*1*5), (6*1*4), (6*1*3)) = 72

(front axle)

N2 = 3 (88 + 40 + 72) = 600

(data units)

Consequently, the number of data units for keeping the manufacturing and FMEA

data in the hierarchical case-base structure is much less than in the individual case-base

structure. The redundancy of data storage is avoided successfully. Meanwhile, this will

also improve the searching efficiency of the retrieval operation (while the case base size

gets larger and larger).

5.2 Comparison of Multi-Stage Retrieval with Other

Hierarchical CBR Systems

Of some other systems organised in a hierarchical way, the more notable ones are

the Deja Vu system [15, 16] and the CBRefurb system [11]. In Deja Vu, complex

problems are stored as hierarchical collections of cases and individual cases describe

part of a more complex solution at some given level of abstraction through the

network-based structure. It then uses ‘adaptation-guided retrieval’ which ensures that

adaptable cases are always retrieved. In CBRefurb, a whole building task is broken

84

中華管理學報 第二卷 第一期 第75-87頁

民國九十年

down into smaller tasks (building items) by organising the refurbishment cases as a

hierarchical structure composed of cases and subcases. It uses ‘multiple case retrieval’

to collate information from several old cases for estimating the cost of refurbishment.

The adaptation-guided retrieval of Deja Vu uses adaptation knowledge during

retrieval to determine the adaptation requirements of cases and the multiple case

retrieval of CBRefurb relies on the indices and the organisation of the memory to direct

the search to potentially useful cases. By contrast, multi-stage retrieval used in the

HOCBR architecture searches through different level case bases to find the required

pieces of a product (i.e. parts and processes) and is accompanied by linking and editing

functions. The advantages of multi-stage retrieval are that the constituent parts of a

product and constituent processes of a part guide the linking function to connect case

bases efficiently, stage-by-stage; the editing function allows the user to add a new

intermediate case or to change portions of an existing one in order to retrieve a more

closely matching similar case.

5.3

Comparison of Shift-view

CLAVIER Method

Adaptation

with

the

Shift-view adaptation, using different retrieval views (i.e. weighted vectors) within

nearest neighbour matching to find the most similar cases within a case base, produces a

more suitable solution for an input problem. The CLAVIER method [7] uses two types

of knowledge to divide cases into two compatibility groups with respect to unmatched

parts: global case compatibility and local spatial compatibility. Global case

compatibility is used to find compatible substitutions for a given part in cases that are

globally similar to the current situation. Local spatial compatibility is utilised to select a

specific part as a substitute according to its relative position in the case piece.

By contrast, three different views (i.e. general view, process view and FMEA view)

are used in shift-view adaptation in order to focus on various attribute groups (i.e. all

attributes of a case, attributes regarding process features and attributes regarding FMEA

features). As a set of failure modes and corrective actions were generated for a specific

process, its similarity can be alternatively measured in three ways: using all attributes,

attributes regarding process features, or attributes regarding FMEA features.

Consequently, based on the various views, all of the potential failure modes and

corrective actions in the case base will be screened out successfully.

6. Conclusions and Future Work

This research has identified the problem as the organisation and re-use of

hierarchical knowledge in the pilot production stage, with particular reference to the car

part industry.

The HOCBR architecture has been proposed to tailor the general CBR

methodology to the selected problem domain. This architecture organises several case

bases into a hierarchical case-based library, searches out the most similar case from the

multi-level case bases and adapts this case (using different adaptation methods) into a

suitable suggested solution for a current problem.

Furthermore, based on the proposed HOCBR architecture, the system framework

has been developed and evaluated in an industrial environment. The full potential of this

approach has not yet been realised in practice. For example, only three levels of retrieval

85

Tzu-Fu Chiu

An application of hierarchy-oriented case-based reasoning in the pilot production stage

have been demonstrated and the number of cases was relatively small. The current

prototype requires that the case bases still need to be created off-line and some processes

within the CBR cycle are not yet fully implemented. Potential research areas suggested

by these limitations are listed below, along with other areas for future investigation:

to strengthen the functions of the HOCBR architecture for the problem domain,

especially the revision and retainment operations;

to develop further application systems based on the HOCBR architecture in other

industries which have similar features to those of the problem domain; and

to collect more real data from the collaborating factory to increase the processing

capacity of the application system.

The implementation and evaluation of the HOCBR architecture have shown that

the system functions successfully. The author believes the proposed methods and system

architecture to be more efficient, in certain respects, than existing approaches and to

offer considerable practical advantages.

References

1.

Aamodt, A. and E. Plaza, “Case-Based Reasoning: Foundational Issues,

Methodological Variations and System Approaches,” AICOM, 7(1), 39-59(1994).

2.

Bradley, J. and U.G. Gupta, “A Classification Framework for Case-Based

Reasoning Systems,” The New Review of Applied Expert Systems, 1, 35-48(1995).

3.

Chiu, T.F., Hierarchy-Oriented Case-Based Reasoning with an Application to Pilot

Production in the Car Component Industry, Ph.D. Dissertation, School of

Computing and Information Systems, University of Sunderland, UK(1998a).

4.

Chiu, T.F., “An Evaluation of the HOCBR System in the Car Component Industry,”

Tamsui Oxford Journal of Management Sciences, Tamsui Oxford University

College, 13-14, 15-43(1998b).

5.

Evans, J.R., Anderson, D.R., Sweeney, D.J. and T.A. Williams, Applied

Production and Operations Management, West Publishing Company(1990).

6.

Giarratano, J. and G. Riley, Expert Systems: Principles and Programming, PWS

Publishing Company(1994).

7.

Hennessy, D. and D. Hinkle, “Applying Case-Based Reasoning to Autoclave

Loading,” IEEE Expert, 7(5), 21-26(1992).

8.

Kalpakjian S., Manufacturing Engineering and Technology, Addison-Wesley

Publishing Co.(1992).

9.

Kolodner, J., Case-Based Reasoning, Morgan Kaufmann Publishers, Inc.(1993).

10. Kumar, H.S. and C.S. Krishnamoorthy, “A Framework for Case-Based Reasoning

in Engineering Design,” Artificial Intelligence for Engineering Design, Analysis

and Manufacturing, 9, 161-182(1995).

11. Marir, F. and I. Watson, “Representing and Indexing Building Refurbishment

Cases for Multiple Retrieval of Adaptable Pieces of Cases,” Case-Based Reasoning

Research and Development, M. Veloso and A. Aamodt (eds.), 55-66(1995).

12. Martinich, J.S., Production and Operations Management: An Applied Modern

86

中華管理學報 第二卷 第一期 第75-87頁

民國九十年

Approach, John Wiley & Sons, Inc.(1997).

13. Richter, M.M., “Introduction,” Case-Based Reasoning Technology: From

Foundation to Application, M. Lenz, B. Bartsch-Sporl, H. Burkhard & S. Wess

(eds.), 1-15(1998).

14. Riesbeck, C.K. and R.C. Schank, Inside Case-Based Reasoning, Lawrence

Erlbaum Associates, Inc.(1989).

15. Smyth, B. and P. Cunningham, “A Hierarchical Case-Based Reasoning System for

Software Design,” Proceedings of the 10th European Conference on Artificial

Intelligence, Vienna, Austria, 587-589(1992).

16. Smyth, B. and M. Keane, “Experiments on Adaptation-Guided Retrieval in

Case-Based Design,” Case-Based Reasoning Research and Development, First

International Conference, ICCBR-95, M. Velosoand and A. Aamodt (eds.),

313-324(1995).

17. Watson, I. and F. Marir, “Case-Based Reasoning: A Review,” The Knowledge

Engineering Review, 9(4), 327-354(1994).

18. Wirth, R., Berthold, B., Kramer, A. and G. Peter, “Knowledge-Based Support of

System Analysis for the Analysis of Failure Modes and Effects,” Engineering

Applications of Artificial Intelligence, 9(3), 219-229(1996).

19. Zito-Wolf, R.J., Case-Based Representations for Procedural Knowledge, Ph.D.

Dissertation, Brandeis University, USA(1993).

87