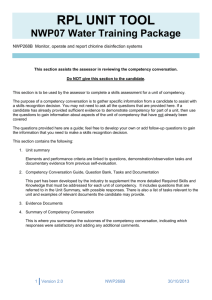

Assessors Guide to RPL – Water Operations NWP07

advertisement

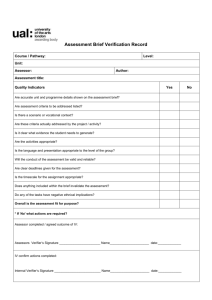

Assessors Guide to RPL – Water Operations NWP07 Unit summary NWP268B Monitor, operate and report chlorine disinfection systems Interview (Key knowledge and Question Bank reference) Demonstration/ observation Documentary evidence (Task number) (Document number) Element Performance Criteria Question number Key Knowledge 1. Plan and prepare for work. 1.1 Determine work requirements according to legislative and organisational requirements. 1,2,3 K1K2,K3, K4 1,2 1,2 1.2 Select and check equipment required to meet safety requirements of task and site. 1.3 Select, fit and use personal protective equipment. 2.1 Monitor chlorine disinfection systems according to agreed schedule and procedures. 2,4,5,6, 7 K4,K5,K6 1,2 1,2 2.2 Collect process samples and conduct standard tests. 2.3 Maintain and monitor relevant OHS requirements. 2.4 Collect and report process data according to organisational and disinfection system requirements. 2.5 Make system adjustments as required to maintain effectiveness of chlorine disinfection. 3.1 Handle, use and store chemicals according to environmental and organisational requirements. 3,4,7 K2,K4,K6 1,2 1,2 3.2 Prepare chemical dosing according to system specifications and organisational requirements and apply using appropriate chlorine dosing equipment. 3.3 Maintain information related to chlorine supply and usage according to statutory requirements. 4.1 Compile records from plant and system data to meet organisational requirements. K5,K6 1,2 1,2 4.2 Report observations outside defined parameters for further action. 2. Monitor systems performance. 3. Prepare and apply chemical dosing. 4. Complete documentation. 1 Version no Date Document name file path Author 6,7 Assessors Guide to RPL – Water Operations NWP07 Evidence Documents Candidate’s name NWP268B Monitor, operate and report chlorine disinfection systems Qualification Date of submission Tasks relevant to the unit Task numbers (chosen by assessor) Doc number SATISFACTORY Assessor’s comment Y N This shows evidence related to: The document is: (relating to documents noted in or relevant to this unit) (Add which part of the unit(s) this evidence relates to) Assessor will provide further information here or refer to the assessment mapping tool. All documents listed above have been sighted and authenticity confirmed on this date / Assessor’s name: .............................................................................................. Assessor’s signature: .............................................................................................. 2 Version no Date Document name file path Author / Assessors Guide to RPL – Water Operations NWP07 Summary of Competency Conversation Unit code and name NWP268B Monitor, operate and report chlorine disinfection systems Candidate’s name Element Performance Criteria Question Numbers Y N Assessor’s comments (drawn from question bank) 1.1, 1.2, 1.3 1 2 2.1, 2.2, 2.3, 2.4, 2.5 3.1, 3.2, 3.3 3 4.1, 4.2 4 Additional questions posed by assessor if required. (relating to key knowledge noted in or relevant to this unit) The participant’s overall responses to the questions was SATISFACTORY Feedback to participant Participant’s signature & date Observers signature & date 3 Version no Date Document name file path Author NOT SATISFACTORY Assessors Guide to RPL – Water Operations NWP07 Key Knowledge, Question Bank, Tasks and Documentation Unit NWP268B Key Knowledge (The Assessor may choose to develop additional questions for this unit assisted from Key Knowledge points noted below) Question Bank Exemplar of Responses 1 Describe the components of a chlorine dosing system 2 What determines prescibed treatment levels 3 What routine maintenance is done. 4 What safety measures are taken in a chlorine dosing plant 5 What tests are done to monitor treatment efficiency 6 What adjustments can be made on results of test results 7 What system data would be recorded and reported Chlorine gas cylinders, calcium hypochlorite, sodium hypochlorite, gas dosing unit , mixing unit, pH monitor, chlorine residual monitor, cylinder bay, leak detectors, alarms, ammonia (chloramination plant), evacuation alert system Drinking water-ADWG, wastewater-SOP”s and licence discharge limits or reuse requirements Plant is always kept clean by washing down and cleaning spills, alarms are tested daily, and cylinder changeover is regular and recorded, leak detection with ammonia is done Use of personal protection equipment, gloves, face mask, SCBA,c lean tools and equipment, alarm tests, leak testing, Bunding of bulk corrosive liquids, safe disposal of empty containers, storage complies with environmental limits. Plant mechanical and electrical isolations. Samples are taken and tested for pH, chlorine residual and microbiological content and results logged and compared to operational limits Dosing limits can be recalculated, dosing pump controls of speed or stoke can be refined, flow rates can be altered. All adjustments are logged and reported. On-line monitors store data and can be down loaded, all test results are recorded and any retesting is also recorded, any parameters outside operational limits are recorded and flagged as attention required. (1) Components of chlorine dosing equipment K (2) Prescribed treatment limits (3) Trouble-shooting and cleaning of chlorine dosing equipment (4) Personal safety and equipment protection (5) Sampling and testing for microbiological content (6) Reporting processes for test results and plant performance Tasks 1 2 Documentation Show and explain plant report initiated by candidate 1 Show and explain lab testing results performed by candidate 4 Version no Date Document name 2 file path Supervisor’s report on candidate Relevant PD report on candidate Author Assessors Guide to RPL – Water Operations NWP07 5 Version no Date Document name file path Author