System Vulnerability Review Report

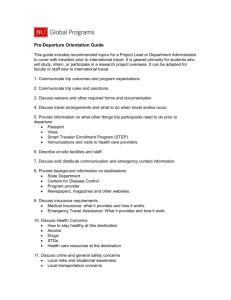

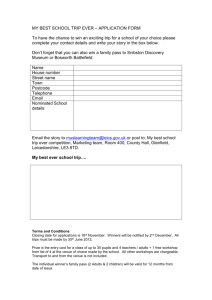

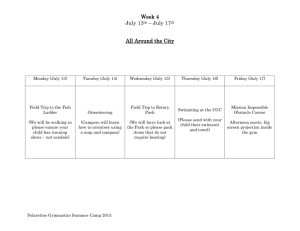

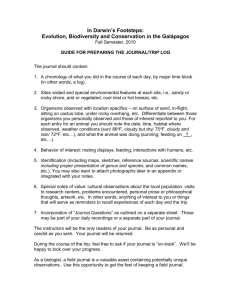

advertisement