Study of Oxidation and Nitridation characteristics of Superalloy

advertisement

2004 ME Graduate Student Conference

April 17, 2004

STUDY OF OXIDATION AND IPAP NITRIDING CHARACTERISTICS OF

SUPERALLOY IN738LC

Mary Shanti Pampana

M.S. Candidate

Faculty Advisor: Aravamudhan Raman

Abstract

Machine components, which have to

withstand severe environment and high

temperatures, must be made of suitable material.

Inconel alloys have good oxidation and creep

resistance [1]. Power Generation industries use

Inconel alloys extensively in Gas turbines parts.

The physical metallurgy is sophisticated, yet the

relationship of properties to structures in these

alloys is certainly the best known of all materials

for use in temperature range of 650-1100°C

[1].This paper focuses on the oxidation and

Intensified

plasma

assisted

nitriding

characteristics of Inconel 738LC.

Oxidation

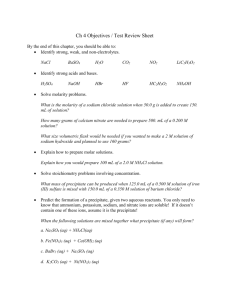

Oxidation kinetics, microstructural changes,

phases present in Superalloy IN738LC at

1000C, 1090C, 1140C and 1190C in air have

been investigated. It was observed that the

oxidation of IN738LC follows the parabolic rate

law and it losses weight at very high

temperatures like 1140C and 1190C after

certain interval of time. Volatilization of certain

oxides at higher temperatures can explain this

behavioral change of the alloy. The volatile

oxide forming elements present in the alloy are

Cr, Ta and Nb. Above 1140 C it is observed that

Cr2O3 gets converted to CrO3 which is volatile.

The XRD analysis of the oxidized

samples as given in the following figures showed

preferred orientation [2] of the matrix and the

precipitate of the metal below the oxide layer. At

1000C it was observed that the alloy below the

oxide is rich in solute having {131} orientation

and all the γ’ precipitate is dissolved in the

matrix forming a no precipitate region called the

precipitate depleted zone as shown in Fig 1.At

1090C it showed that fine γ’ precipitate is

formed. It is interesting to find coarse γ’

precipitate along with solute rich matrix at

1140C, while at 1190C the matrix changed its

orientation as that of γ’ precipitate .It was

indicated that the matrix and precipitate are

having {220} orientation. Using XPS, the

surface composition as a function of depth was

studied.

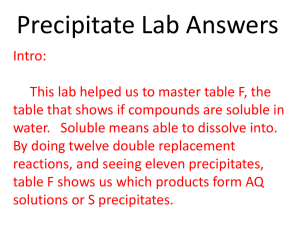

IPAP Nitriding

Many surface modification methods are

available in recent years for enhancing properties

like wear, fatigue and corrosion resistance [3].

Plasma vapor deposition and plasma assisted

chemical vapor deposition are thermo chemical

processes widely used in industrial applications.

Intensified plasma assisted nitriding process is

the one of the most advanced case hardening

technique and was used in the present study to

modify the surface morphology of IN738LC to

improve the reliability and performance in

service and in environmental conditions [3].

The Wear test of the nitrided samples

shows that the friction coefficient is

approximately 1.0.The microhardness tests on

the 3 nitrided samples showed that as the current

density was increased the hardness value of the

surface layer increased indicating the

improvement in mechanical properties. The

nitrogen content in sample 1, sample 2 and

sample 3 with current densities 0.75, 1.0 and

1.5mA/cm2 respectively was studied using XPS.

From the XRD analysis as shown in the

following figures, it was observed that the

nitrided samples have preferred orientation.

The nitrided sample 1 shows that the

fine precipitates were formed in solute rich

matrix, Nitrided sample 2 shows only the fine

precipitate and both matrix and the γ’ precipitate

have {220} orientation. The nitrided sample 3

showed that the precipitates grew and became

coarse due the higher current density.

Figures

1190'C

1200

intensity

1000

800

600

400

200

0

30

Fig.1 showing The oxide scale and precipitate

γ’ depleted region

35

40

45

50

55

60

65

70

75

80

85

90

95 100 105

Theta/2Theta

XRD pictures of As-receiced, oxided and nitided

samples

References:

1. Superalloys II, Chester T.Sims,

Norman S.S., W.S.Hagel.

2. Ercan Balikci, PhD Dissertation, p. 51,

LSU, Baton Rouge, LA, May 1998.

3. V.Singh, K.Marchev, C.V.Cooper,

E.I.Meletis, Surface and Coatings

Technology, Vol. 160,2002,p.249.