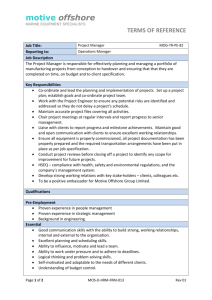

oil & gas offshore & onshore client qa/qc representative

advertisement

Curriculum Vitae OIL & GAS OFFSHORE & ONSHORE CLIENT QA/QC REPRESENTATIVE House No. A/9, 1st. Main Road, Thiruvenkata Nagar, Ambattur, Chennai – 600 053. Tamil Nadu, India. Mobile No.: +91 995 2025570 Mobile No.: +91 944 4744702 E-mail : nssqaqc@gmail.com E-mail : nssqaqc@yahoo.co.in E-mail : nssqaqc@hotmail.com N.Sadhasivam Personal Details Name : N S SIVAM (NATANASABAPATHY SADHASIVAM) Date of Birth : 15th November 1967 Marital Status : Married Nationality : Indian Passport No : G 1505846 Valid until : 18/01/2017 Technical Qualification : Diploma in Mechanical Engineering. Professional Qualifications : 1) CSWIP Level 2 Automated Ultrasonic Testing (AUT) PHASED ARRAY (PipeWIZARD) DATA INTERPRETER (as per EN 473 & ISO 9712 Certification for NDT Personnel) CSWIP CERT NO 43626. Date of Expiry 19 November 2014. Course & Exam Done at TWI, MIDDLESBROUGH, UK. 2) HANDS ON Training in “Advanced Phased Array UT Using Omni Scan PA” & TOFED Inspection and Data Acquisition & Data Analysis Using “Tomoview” Software. Done at Limited,Chennai, India. In Association with M/s. Olympus NDT Training Academy – CANADA. In Dec. 2008. 3) Senior Welding Inspection with Radiographic Interpretation (CSWIP 3.2.2) Certificate #: 38415, Date of Expiry: 18 October 2013. 4) BGAS-CSWIP Painting Inspection Grade 2 (BGAS Gr. 2) BGAS ID 533171 And Certificate No.: 37643., Date of Expiry: 22 Jan. 2014. 5) ASNT (SNT.TC. 1A, 1996 Edition) Level – II in RT, UT, MT, PT. Sadhasivam CV nssqaqc@gmail.com Page 1 of 5 SAFETY Training Programs: 1) H.U.E.T. / SEA SURVIVAL CERTIFICATE – Validity Until 11/05/2012 done at Emirates Technical & Safety Development Center, Abu Dhabi, UAE. Certificate No. : 07479 / 2009. 2) Holding Panama Seaman Book No. : 380373 Validity until 16 April 2012. 3) Holding Valid Offshore Medial Certificate. 4) Holding International Certificate of Vaccination for Yellow Fever. Validity until 17/10/2016. Summary of Work Experience Total of Around 20 years experience in Inspection, Quality Control and Non Destructive Testing of Pressure Vessels, Heat Exchangers, Plant Piping and Structures for Petrochemical Plants, Thermal Power Stations, Refineries, Oxygen Plant & Steel Plant, Cross country Pipelines, Oil & Gas Pipeline (Offshore & Onshore) Projects and Storage Tanks. Leading the inspection personnel to achieve the targets and plan to maintain the integrity of piping and equipments by allocating appropriate personnel to suit the requirement. Review / Preparation of Quality Assurance Plan (QAP) to meet ISO 9000 standards. Follow up a corrective action to improve the Quality system. Review / Preparation of Quality Control Procedures, WPS, PQR and Welders Qualification Test. Review / Interpretation of Radiographic films of weld as per the applicable codes. Witness of all Destructive testing, Chemical testing, Painting / Coating, Holiday test, Hydrostatic test. Co-ordination with third party inspection / client as per the contractual requirement. And also Worked as Client/Owner Representative, Project Management Consultant (PMC) & Third Party Inspection (TPI). Summary of Offshore Experience Total of Around 5 Years Continuously Working in Offshore - Quality Control & Inspection of Welding, Non Destructive Testing and Painting / Coating of Pipe Lay Installation, Jacket Installation, Top side and Hookup Projects. Inspection Activities includes but not limited to in Offshore as Follows Automated Ultrasonic Testing (AUT) Review / Verify AUT System Verification Documents and Inspection Personal Qualifications. Verify all documentation to execute the work such as approved AUT procedures. Check the AUT Calibrations (Cal. IN & Cal. OUT). Online Monitoring the Scan result of Girth Welds Using Tomo Viewer. Witness & inspection of AUT, MUT activities, Review of AUT, MUT Documents & Has the authority to reject defective work. Automated Ultrasonic Testing (AUT) System Familiar With: OLYMPUS-RD TECH-PHASED ARRAYPipeWIZARD. Welding Review the WPS & PQR. Vitness the WPQT & Mechanical Test. Check that all onshore/offshore-related QA/QC work is carried out in accordance with the approved PQP and Inspection & Test plan. Check all documentation to execute the work such as approved welding procedures, Quality Control procedures, NDT procedures, Codes; standards are available at work site. Sadhasivam CV nssqaqc@gmail.com Page 2 of 5 Check that all applicable equipment is calibrated and has valid certification. Check installation processes are carried out in accordance with approved procedures & specification & Inspection and confirmation of welding consumables as per the specifications. Witness & inspection of all Welding activity, Review of Inspection Documents & Has the authority to reject defective work. Automatic Welding System Familiar With: Saipem - Passo, STT Presto, McDermott–AWS, Allseas - Phoenix, Serimer dasa, Vermaat and SAW for double joints. Painting / Coating Review the Painting / Coating Procedure. Verify / Review all onshore/offshore-related Painting / Coating work is carried out in accordance with the approved PQP and Inspection & Test plan. Ensure all documentation to execute the work such as approved Painting / Coating procedures, Quality Control Codes & standards are available at work site. Verify that all applicable equipment is calibrated and has valid certification. Check Painting / Coating Application processes are carried out in accordance with approved procedures & specification. Inspection and confirmation of Painting / Coating, Blasting Materials as per the specifications. Check and Witness of Profile, Salt Test, Wet Film Thk.,Dry Film Thk., Adhesive Test, Peel Test & Holiday Test. Witness & inspection of all Painting / Coating activities, Review of Inspection Documents & Has the authority to reject defective work. Current Employment Detail Period : April 2009 to October 2009 Employer : Abu Dhabi Gas Industries Ltd. (GASCO), Abu Dhabi., UAE. Seconded by MOODY International (TPI)., Abu Dhabi. UAE. Position : Company / Owner (GASCO) QC Representative for AUT Project : Project No. 5241- Offshore Associated Gases (OAG) Package - 2. 30” Dia. Offshore Pipeline Project from Das Island to Ras Al-Qilla. Pipe Lay Vessel : NPCC – D.L.B. - 1000 Project Location : Arabian Sea, Abu Dhabi., UAE. Activities : Monitor for AUT activities of NPCC / Oceaneering - Inspection International Ltd. (CONTROCTOR) in Offshore and reports directly to the GASCO Construction Superintendent. Previous Employment Details Period : October. 2007 to Jan. 2009 Employer : Reliance Industries Ltd., India., Seconded by Bechtel (Project Management Consultant)., USA. Position : Company / Owner (Reliance) QC Representative (Welding & Coating) Project : DHIRUBHAI 1 & 3 Field Development Project, KG-D6 (KG-DWN-98/3) Deep Water Block. Pipe Lay Vessel : Allseas – D.L.B. - Lorelay, Audacia & Tog Mor. Project Location : Krishna Godavari Basin on the East Coast of India in Bay of Bengal., INDIA. Activities : Monitor for all QA/QC Welding & Coating activities of Allseas (CONTROCTOR) in Offshore and reports directly to the Senior Representative of Reliance Industries Ltd. --------------------------------------------------------------------------------------------------------------------------Period : April. 2007 to August 2007 Employer : Qatar Gas Limited. Seconded by Velosi Certification (TPI)., Qatar. Position : Company / Owner (Qatar Gas) QC Representative. Project : QG II Common Condensate Single Point Mooring Facilities Project – Offshore Installation. Pipe Lay Vessel : McDermott Barge – D.L.B. KP1 Project Location : Arabian Sea, QATAR. Activities : Monitor for all QA/QC activities of McDermott (CONTROCTOR) in Offshore and reports directly to the Senior Representative of Qatar Gas Limited. Sadhasivam CV nssqaqc@gmail.com Page 3 of 5 Period : Oct. 2006 to Jan. 2007 Employer : Oceaneering – Inspection International Ltd / Global Offshore International Ltd., For CHEVRON TEXACO (USA) / CABINDA GULF Oil Company Offshore Oil Pipeline Project in ANGOLA, WEST AFRICA. Position : QA/QC Inspector Project : Involves installation of One 10’’ Water Injection Pipeline from BANZALA Platform A to BANZALA Platform B, One 10’’ Oil Pipeline from BANZALA Platform A to BANZALA Plat form C, One 12’’Oil Pipeline From BANZALA Platform C to 12" Export line Sub Sea Tie-in And 6’’ Oil Pipeline from GSM to Takula FOX. Total Aprox. 26 Kms. Installation of Jackets & Top side. Pipe Lay Vessel : GLOBAL Barge – D.L.B. CHEYENNE & D.L.B COMMANCHE Jacket & Top side Installation Vessel : GLOBAL Barge – D.L.B. HERCULES. Project Location: ANGOLA, WEST AFRICA (Deep Sea) Activities : Responsible for all quality control activities in Offshore and reports directly to the Client. ----------------------------------------------------------------------------------------------------------------------------- ---------------- Period : June 2006 to Aug. 2006 Employer : Saipem UK Ltd., for Sakhalin Energy Investment Company (SEIC). Offshore Oil & Gas Pipelines Project, Russia. Position : QA/QC Inspector Project : Sakhalin II Phase2 Project is development of offshore oil and gas fields on the north-eastern shelf of Sakhalin Island, Russia. Two Production fields associated with the project, Piltun-Astokhshoye (PA) is an oil field with gas and Lunskoye (LUN) is a gas field with condensate. During Phase 2 – four separate Offshore Pipelines and Cables installation have been done. 14” Diameter PILTUN oil and gas pipeline comprises 235 Km long, which will deliver crude oil and dry gas from PA-A and PA-B Platform to onshore pig- traps adjacent to the Piltun shore crossing for Sakhalin Energy Investment Company (SEIC). Thereafter, the gas and oil pipelines will be manifolded and two pipelines will run to the Onshore Processing Facilities. Pipe Lay Vessel : SAIPEM S.S.P.L. Barge – SEMAC – 1. (Double Joint Barge) Jacket & Top side Installation Vessel : SAIPEM Lay Barge – D.L.B. Castoro 8 Project Location : Sakhalin Island, Russia. (Deep Sea) Activities: Responsible for all quality control activities in Offshore and reports directly to the QA/QC Supervisor. --------------------------------------------------------------------------------------------------------------------------Period Employer Position Project : Sep. 2005 to June 2006 : DOLPHIN ENERGY Ltd. Seconded by Germanisher Lloyd (GL) – (TPI), QATAR, For their Offshore Project., QATAR. : Company / Owner (DOLPHIN ENERGY Ltd.,) QC Representative. : 1) Two Pipelines of 36”ØSubmarine (UPSTREAM Sea lines) Gas Pipelines Project (Aprox. 157 Kms) Involves installation of 2 Pipelines of 36”Ø Submarine UPSTREAM GAS Pipelines for transportation of Hydrocarbon Gas from DOL1 Platform & DOL2 Platform (Located in the north felled of Offshore, QATAR) to onshore Gas Plant of Dolphin Energy Ltd,Ras Laffan Industrial City, QATAR. The two Offshore Wellhead platforms located form onshore Aprox. 70.57 Kms & 86.42 Kms. 2) 48”Ø Submarine Export Gas Pipeline Project (Aprox. 361 Kms) Involves installation of 48”Ø Submarine Export Gas Pipeline via sea for Export the processed Gas from Dolphin Energy Ltd Gas Plant onshore of Ras Laffan, QATAR to receiving Plant at Taweelah, UNITED ARAB EMIRATE (UAE). The receiving plant at Taweelah, UAE is Located from onshore of Ras Laffan, QATAR approximately 361 Kms. Single Joint Pipe Lay Vessel – SAIPEM Lay Barge – D.L.B. Castoro 2 Double Joint Pipe Lay Vessel – SAIPEM Lay Barge – D.L.B. Castoro 6 Project Location : Arabian Sea, QATAR & UAE Activities : Monitor for all QA/QC activities of SAIPEM - ITALY (CONTROCTOR) in Offshore and reports directly to the Senior Representative of Dolphin Energy Ltd., -------------------------------------------------------------------------------------------------------------------------------------Period : March 2005 to August 2005 Employer : TL Offshore SDN BHD, Malaysia for Shell Offshore Projects, Brunei. Position : Welding Inspector Project : 1) Champion West Phase 3 Development Project (Oil & Gas pipeline) Sadhasivam CV nssqaqc@gmail.com Page 4 of 5 Involves installation of new drilling platform (CWDP-1) situated approximately 10km NW of the existing Champion Main complex CPCB-7; 2 nos of new DN400 10km pipelines transporting HP multiphase fluids from the new platform to the existing facilities on CPCB-07 platform with submarine cable for power supply from CWWJ-2 and riser installations. 2) Egret Oil Acceleration Project Involves installation of 17km, DN400 oil pipeline from an existing offshore facility EGDP-1 to FACP-4. The new pipeline transporting Egret fluid in HP multiphase to FACP-4 Crude Stabilisation facility prior transporting the oil to Seria Crude Oil Terminal (SCOT)AMAP-6 Pipe Lay Vessel – GLOBAL Barge D.L.B. 264. Project Location : South China Sea, BRUNEI ( Deep Sea) Activities : Responsible for all quality control activities in Offshore and reports directly to the Senior Welding Inspector. --------------------------------------------------------------------------------------------------------------------------------Period : August 2004 to Jan. 2005. Employer : BOTAS Petroleum Pipeline Corporation. (Govt. Firm of TURKEY), TURKEY. Position : Client QC Representative. Project : BAKU-TBILISI-CEYHAN (BTC) Crude Oil Pipeline (BP) Project. Activities : Monitor & Inspection for all QA/QC activities of CONTROCTORS in Onshore and Reports directly to the Senior Representative of BOTAS Petroleum Pipeline Corporation. --------------------------------------------------------------------------------------------------------------------------Period Employer Position Project Client Activities : : : : : February 2004 to August 2004. Ahamed Mansoor Al-A’ali. BSC (C), KINGDOM OF BAHRAIN. Senior QA / QC Engineer - Cum-In-charge. Expansion project in Aluminum Bahrain Company of Line – 05 Bechtel, USA. : Responsible for preparation of Quality Assurance plan, WPS, PQR, WQT, stage inspections like fit up, welding, erection, review of non-destructive inspection reports of fabrication structures as per approved drawings. Control of QA/QC personnel, NDT crews to perform the inspection as per the agreed plan. Witnessing of grit blasting and coating on structures, Dossier preparation and handing over to the client. --------------------------------------------------------------------------------------------------------------------------- Employment Details in India Period : April 2003 to January 2004. Employer : M/s. IVRCL Infrastructures & Projects Limited. Chennai. Position : Quality Assurance / Quality Control Engineer Project : Chennai Metro Water Augmentation Project . --------------------------------------------------------------------------------------------------------------Period : April 2002 to April 2003. Employer : M/s. PSL Holding Ltd (Pipe mill division), Gujarat. Position : Quality Assurance / Quality Control Engineer --------------------------------------------------------------------------------------------------------------Period : October 2000 to March 2002. Employer : M/s. Rishi Projects, JPOCL site, Bellary, Karnataka. Position : Quality Assurance / Quality Control Engineer --------------------------------------------------------------------------------------------------------------Period : April 1990 to September 2000. Employer : M/s. Larson & Toubro Ltd., ECC-Construction Group, Chennai. Position : Quality Assurance / Quality Control Engineer --------------------------------------------------------------------------------------------------------------- Sadhasivam CV nssqaqc@gmail.com Page 5 of 5