ARC FLASH SAFETY REGULATIONS AND WORK - Dot

advertisement

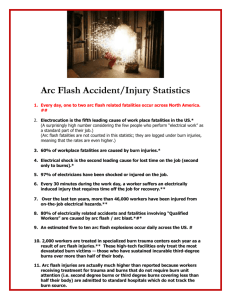

ARC FLASH SAFETY REGULATIONS AND WORK PRACTICES: A FLASH REHASH An electrician screws a circuit breaker onto a mounting plate, working under no tag-out restrictions. One of the screws makes contact with the line-side wiring behind the circuit breaker, penetrating the wire insulation. The resulting short circuit vaporizes metal and ionizes the air--an arc flash-causing a phase-to-phase fault. The electrician receives second-degree burns from the arc flash. Because there is no prejob analysis, neither the worker's proximity to potential danger nor the necessity for appropriate Personal Protective Equipment (PPE) is established. Such an arc-flash explosion in and around electrical equipment that requires burn treatment is said to occur five to 10 times per day in the U.S., costing as much as $15.75 million per case in direct and indirect outlays. The basic distinction to be made between arc flash and ordinary shortcircuit, or bolted, contact is the heat and force, or incident energy, generated by the arc. Temperatures as high as 35,000 degrees Fahrenheit -- four times hotter than the sun's surface -- can be achieved. Vaporized metal can expand 40,000 to 1, producing a shattering blast. The physical conditions that produce arc faults -- voltage x current x time -- along with distance from the arc, which can be reduced by protective clothing, are the basic quantities that are controlled and regulated to better insure protection from an arc flash. Most regulations for improving worker safety change over time as requirements become more familiar and economic conditions rise and fall. Thus, safety regulations governing arc flash are in a state of transition with regard to applying effective protection. THE REGULATIONS Here's the bottom line: According to Occupational Safety and Health Administration (OSHA) Standards 29-CFR, Part 1910 -- the electrical industry's defining set of rules for dealing with arc flash -- equipment must be de-energized, that is, put in an electrically safe condition, whenever possible before work begins. That includes disconnecting every power source over 50 volts as well as all control power; application of lockout/tag-out procedures; discharge of all stored energy sources; and testing for safe conditions by qualified personnel wearing appropriate PPE. This means, practically speaking, that de-energization must occur when the bus voltage is greater than 120 volts, since arc faults generally need in excess of 120 volts to be sustained. Some energy sources or live lines are not obvious, as in the case of the worker described above. Potential danger should be identified beforehand as part of a flash hazard analysis that uses one-line drawings and nameplate specifications to determine all areas where de-energization must occur. Deenergization is not always possible. However, for example, life support systems at some facilities could shut down with an outage, and functional testing of energized systems must, of course, be done with at least part of the system online. Further, the need to maintain a high level of production increasingly demands that systems be worked hot. Those needs are countered by expenses incurred through accidents, including worker injury and unplanned outages from equipment damage, as well as the industry's desire to keep its electricians safe. OSHA requires system calculations based on the one-lines mentioned above as well as details of the line sizes involved, along with minimum and maximum fault currents supplied by the provider utility, to determine estimated short-circuit energy and the flash protection boundary, or approach distance, throughout the system. Those results then determine the extent of PPE -- specifically, protective clothing -- that must be used. The equations needed for those calculations are found in either National Fire Protection Agency (NFPA) regulation 70E-2000 or IEEE Standard 15842002. These calculations are not simple and are usually achieved by a software program. Once the necessary values have been established, OSHA requires labeling, that is, field markers placed prominently on equipment that warn electrical workers of potential arc flash hazards. PROTECTIVE MEASURES What follows next in the flash protection process is different from place to place, depending on the nature of the equipment involved and the governing facility policy. This is the coordination of plant protective equipment -- breakers, disconnects, relays, fuses -- with the energy situation at hand. How quickly and efficiently this protective equipment responds to a short circuit to shut the energy down can greatly minimize harm to personnel and damage to equipment. Note that the proper selection and adjustment of protective devices won't, as is often thought, prevent an arc flash from occurring. But the process of defining the appropriate time and current-limiting response of protective devices can provide distinct advantages. It can limit an outage to the portion of the system downstream from the protective device, preventing the main breaker from tripping. Further, and most critical to worker protection, it can better assure that the necessary NFPA 70E category of protective clothing is chosen. Overly conservative flash-hazard analyses that emphasize preserving system reliability have traditionally established protective equipment settings on the high side, with slower response times tolerated and higher currents allowed. But slower reacting breakers and fuses allow more arc energy to be produced before they trip. That dictates using the most protective as well as cumbersome gear, corresponding to NFPA Category 4. More recent coordination studies have considered that arc fault current is usually less than bolted fault current, allowing faster equipment response and reducing the potential heat and force that protective clothing must withstand. Such an evaluation might allow electricians to wear a lower category of PPE that is also much more comfortable and work friendly. Current-limiting circuit breakers and lower rated fuses, coupled with other protective measures like long-handled tools and infrared inspection windows on cabinets for closed door inspection, can provide significantly improved protection for electricians who must work with live equipment. Thoughtful preventive measures -- de-energization when possible, equipment selection and settings to minimize accidental arc exposure -- can make a big difference in providing a more effective measure of electrical worker safety.