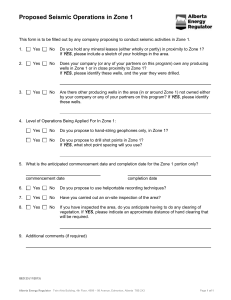

vertical formation

advertisement

5. Inflow deviation for horizontal wells 5.1 Formation damage and skin factor for horizontal wells It takes longer to drill a horizontal well, so the productive intervals are vulnerable to infiltration over a longer period of time. In addition, horizontal bore holes tend to be mechanically unstable, because the horizontal and vertical tensions are different. Therefore, the formation damage is normally higher for horizontal than for vertical wells. Formation damage will usually occur near the well. The influx there is radial, and thus quite similar to that of vertical wells. It is therefore reasonable to represent skin pressure loss similarly as for vertical wells. However, the skin factor for horizontal wells relates to the completed length, Lw; S H p S 2 k Lw qo o Bo (5-1) The definition (5-1) differs from the skin factor for vertical wells (3-2), which relates to the height of the reservoir, h. This difference may lead to paradoxes at the comparison between the skin factors for the vertical and horizontal wells. In the previous chapter, we assumed that the horizontal well was drilled in the middle of the reservoir layer, and derived formulas out of this. Most "horizontal wells" differ from this geometrically. This changes flow patterns and pressure. Change in pressure will be represented through the geometric skin factor, defined in accordance with (5-1) above. 5.2 Well outside the middle of the reservoir During drilling, the well has to be steered after some recordable layer or horizon. It will usually be appropriate to add the well in good distance from the gas or water zone. The well will therefore usually not be in the middle of the reservoir. Figure 5.1 illustrates the influx of a well 2 meters below the hanging wall, in a 10 meters thick reservoir. Figure 5.1 Well beyond the middle of the reservoir Butler / 1994 / presents the mathematical solution for the fluids to flow to a well beyond the middle of the reservoir. From the mathematical solution, the geometric skin factor may be derived 2 2 1 rw b Sb ln sin 2 2h h (5-2) When the well is located in a reasonable distance from the upper/lower walls (b >> rw),(5-2) becomes 1 b Sb ln sin ....... for : b 5rw h (5-3) Figure 5.2 shows how skin factor for the well location varies with well position. Figure 5.2 Skin factor due to the well being placed outside the centre. We see that (5-3) will be sufficient for all purposes, with the exception of wells which lie at the very boudaries. When the path is not far away from the centre, the skin factor, according to Figure 5.2 is very modest. 5.3 Inclined wells 5.3.1 Geometric skin factor Figure 5.3 shows the pressure distribution (and current vectors) around an inclined well Figure 5.3 Beveled set well in starting point b x S ( x ) ln sin h 1 Where the well is close to the lying or hanging wall, this will reduce the inflow. Using (5-3), the average skin factor because of such shielding is estimated to Ŝ 1 1 h 2 Sb db ln 2 0.693... h h 2 (5-5) 5.3.2 The effect of anisotropy on inclined wells Anisotropy can be included by scaling the height (4-15) and permeability (416). For inclined wells, the height scaling causes inclination change. Figure 5.4 illustrates an inclined well in an anisotropic layer. The well trajectory in the real, anisotropic, reservoir is shown by the line Lw. Anisotropy factor for the reservoir: . provides the height scaling factor. The well trajectory equivalent, isotropy system, L̂w is obtained after scaling the height. Inclination angle after scaling is denoted by ̂ . Figure 5.4 Angle change by scaling From the figure 5.4 follows the relationship between the completed length in the real and equivalent systems: w Lw 1 2 1 cos2 L̂w 0.5 (5-7) The relationship between the inclinations can then be expressed as cosˆ w cos (5-8) Thus, the productivity index of an inclined well an anisotropy reservoir is expressed below. This result is obtained using (4-19), and applied arithmetic of (5-5), (5-6) and the geometrid skin factor suggested above S=0.57. J 2 k H h 4 r cos 3 h o Bo ln e w w cos ln 0.57 h 4 rw 1 (5-9) From (5-9) follows that with reduced vertical permeabilities, an inclined well be more favorable than a horizontal, (with same complement length). Figure 5.5 below compares estimates with formulas for the horizontal well (414), scaled to anisotropy, and tilted set well (5-9), for the parameters [h= 10m, Lw=50m, re=200m, rw=0.1m, =1cP, kH=1m2]. Figure 5.5 Productivity index, depending on the anisotropy Figure 5.5 shows that a horizontal well will be marginally more favorable at small anisotropies. At large anisotropies, a tilted set well have far better productivity. In the case in which the vertical permeability approaches zero, as with continuous shale layers, the productivity of a horizontal well becomes very small. An inclined well will cut through the layers and is therefore not much affected. References Cinco-Ley, H., Miller, FG, Ramey, HJJr.: "Well Test Analysis for Slanted Wells" SPE 5131, Annual meeting, Houston, Texas, Oct.6-9, 1974, Cinco-Ley, H., Ramey, HJJr., Miller, FG: "Pseudo-skin Factor for PartiallyPenetrating Directionally-Drilled Wells" SPE 5589, Annual meeting, Dallas, Texas, Sept.. 28 - Oct.1, 1975, JPT, Nov. 1975, p. 1392 Besson, J.: "Performance of Slanted and Horizontal Wells on an Anisotropic Medium" SPE 20965, Europec, The Hague, 22-24 October 1990 1991 Renard, G. & Dupuy, JM: "Formation Damage Effects on Horizontal WellFlow Efficiency" JPT July 1991, 786 Butler, R.: Horizontal Wells for the Recovery of Oil, Gas and Bitumen. Calgary, 1994 1997 Asheim, H. & Oudeman, P.: "Determination of Perforation Schemes to Control Production and injection Profiles along Horrizontal Wells" SPE Drilling & Completion, March 1997, 13