Cozzone Method: Calculating f0 Stress for Plastic Bending

advertisement

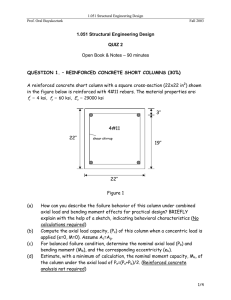

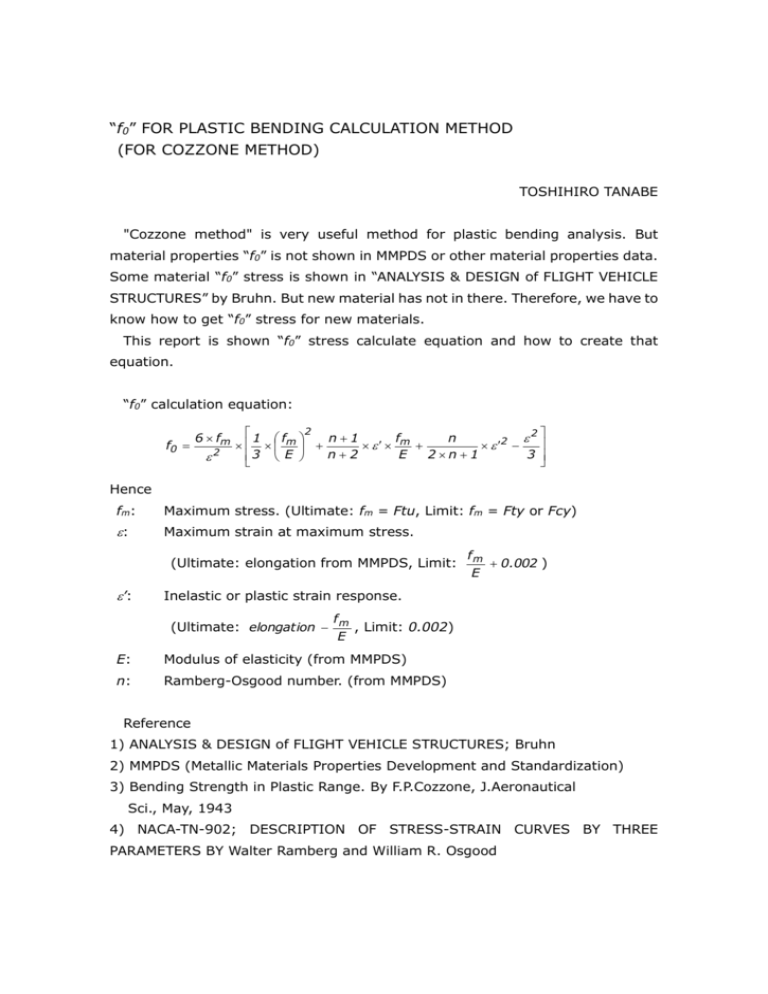

“f0” FOR PLASTIC BENDING CALCULATION METHOD (FOR COZZONE METHOD) TOSHIHIRO TANABE "Cozzone method" is very useful method for plastic bending analysis. But material properties “f0” is not shown in MMPDS or other material properties data. Some material “f0” stress is shown in “ANALYSIS & DESIGN of FLIGHT VEHICLE STRUCTURES” by Bruhn. But new material has not in there. Therefore, we have to know how to get “f0” stress for new materials. This report is shown “f0” stress calculate equation and how to create that equation. “f0” calculation equation: f0 6 fm 2 1 f 2 n 1 f n 2 m m 2 n2 E 2n1 3 3 E Hence fm: Maximum stress. (Ultimate: fm = Ftu, Limit: fm = Fty or Fcy) : Maximum strain at maximum stress. (Ultimate: elongation from MMPDS, Limit: ’: fm 0.002 ) E Inelastic or plastic strain response. (Ultimate: elongation fm , Limit: 0.002) E E: Modulus of elasticity (from MMPDS) n: Ramberg-Osgood number. (from MMPDS) Reference 1) ANALYSIS & DESIGN of FLIGHT VEHICLE STRUCTURES; Bruhn 2) MMPDS (Metallic Materials Properties Development and Standardization) 3) Bending Strength in Plastic Range. By F.P.Cozzone, J.Aeronautical Sci., May, 1943 4) NACA-TN-902; DESCRIPTION OF STRESS-STRAIN CURVES BY THREE PARAMETERS BY Walter Ramberg and William R. Osgood How to create “f0” equation The Cozzone method is replaces the true bending variation curve by a trapezoidal stress variation. The stress “f0” is fictions stress which is assumed exist at the neutral axis or at zero strain. The value of “f0” is determined by making the requirement that the internal moment of the true stress variation must equal the moment of the assumed trapezoidal stress variation. FMAX = fm f0 N.A. f0 FMAX = fm fm fm N.A. 2 0 fm f0 Equation “f0” strain f f E fm f0 2 n fm f0 EQ. (1) 2 2 f d 0 3 (Rectangle area moment) (Triangle area moment) f0 2 2 fm f0 f d 0 2 3 EQ. (2) From equation (1) d 1 n f n 1 df E fmn 1 n f n 1 df d n E fm Therefore f n f n f d df E fmn EQ. (3) From equation (1) & (3) n n f f f f n df f d E fm E fm EQ. (4) 2 3 From equation (3) u 0 n n f f f n f df f E f 0 E m m 2n fm f 2 n 1 f n 1 2 f n df 0 E E fm fm f d fm EQ. (5) fm 1 f3 n1 f n 2 n f 2n 1 2 2 n2 E fmn 2 n 1 fm2n 0 3 E 1 fm3 n 1 f 2 n m 2 fm 2 3 E n2 E 2n1 From equations (2) & (5) 2 f0 2 2 1 n1 f n f fm f0 fm m fm m 2 fm 2 3 3 E n 2 E 2 n 1 1 f 2 n 1 f0 f f n 2 m 2 fm m m 2 6 3 n2 E 2n1 3 E Therefore f0 6 fm 2 1 f 2 n 1 f n 2 m m 2 n2 E 2n1 3 3 E Equation check result Comparison of Reference(1) “f0” values and equation results. Ref.(1) Fig No Material Thickness Ftu in ksi Fty E ×103 e f0u f0y ksi % ksi ksi Calc. value f0u f0y ksi ksi C3.9 2024-T3C SHT 0.01~0.062 59 39 9.5 15 50 18 50 16 C3.11 2024-T4C PLT 0.25~0.50 62 40 10.0 15 55 20 52 17 C3.13 2024-T3 SHT ~0.25 64 42 10.5 15 53 23 54 18 C3.15 7075-T6C SHT ~0.39 70 60 10.0 5 64 24 62 22 C3.17 7075-T6 EXT ~0.25 75 65 10.4 7 70 29 68 24 C3.16 7075-T6 SHT ~0.039 76 65 10.3 7 70 24 69 24 Calculated values are almost same as Reference 1) “f0” values.