PREPARATION OF TERT

advertisement

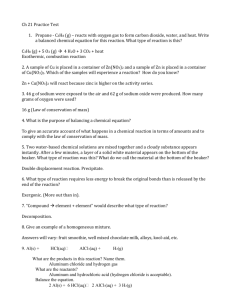

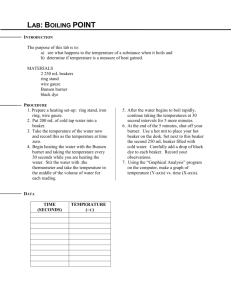

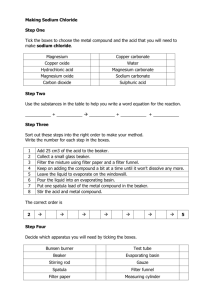

Honors Chemistry II PREPARATION OF TERT-BUTYL CHLORIDE FROM TERT-BUTYL ALCOHOL Purpose: To synthesize 2-chloro-2-methylpropane (tert-butyl chloride) from 2methylpropan-2-ol (tert-butyl alcohol). Discussion: The substitution of a hydroxyl group with a halide follows the SN1 mechanism. Cl H H OH O 1) O H + + C 3) H HCl H 2) + + H2O + C Cl - Cl (1) Protonation of the hydroxyl group creates an excellent leaving group – a water molecule. (2) The water leaves, creating a carbocation, (3) which then bonds with the chloride ion to form the product. Answer the following questions to help expand on the discussion: 1. What is an SN1 mechanism? 2. How does a separatory funnel work? How will it be useful in this lab? 3. How does the simple distillation apparatus work? Why will it be used to find the boiling point of the liquid product instead of a Dennis tube? The following equipment setup diagrams will be used throughout the procedure. Refer to these as needed. Figure 1: Separatory Funnel Figure 2: Gravity Filtration Filter paper Sep funnel Glass funnel Iron ring 50 mL Beaker Ring stand 50 mL Beaker Ring stand Figure 3: Simple Distillation Thermometer with adapter Water out 3-way adapter Condenser Vacuum distilling adapter 50 mL round bottom flask Water in Heating mantle 50 mL beaker Objectives: In this lab, you will... 1. synthesize 2-chloro-2-methylpropane from 2-methylpropan-2-ol. 2. verify the identity of your product by determining its boiling point. 3. calculate the percent yield of 2-chloro-2-methylpropane. Safety: Wear safety goggles at all times while in the lab. Some chlorinated hydrocarbons have been known to be carcinogenic. Do not touch any of the chemicals with your hands. Wash your hands frequently and report any spill immediately. Materials: 50 mL Beaker 400 mL Beaker 125 mL Separatory Funnel 10 mL Graduated Cylinder 125 mL Erlenmeyer Flask Filter Funnel Filter Paper (12.5 cm) Ring Stand Small Iron Ring Simple Distillation Setup Boiling Chips Ice 12.1 M HCl tert-butyl Alcohol Distilled Water 1 M NaHCO3 Anhydrous Na2SO4 Procedure: 1. In the fume hood, pour ~30 mL of concentrated HCl into a 50 mL beaker. 2. Cool the concentrated HCl to 5˚C in an ice bath (400 mL 1/3 full of ice and tap water). 3. Pour the cooled HCl into a 125 mL separatory funnel (see Figure 1). 4. Add 10.00 mL of tert-butyl alcohol and gently shake the mixture. After shaking, invert the sep funnel and open the stopcock to relieve pressure. Be sure to point the bottom of the sep funnel away from yourself. Repeat this every 30 seconds for five minutes. Let the solution stand for another 15 minutes, relieving the pressure every few minutes. 5. After the 20 minutes, allow the mixture to stand undisturbed until the layers have separated. Place the 50 mL beaker under the stopcock on the sep funnel, remove the stopper from the sep funnel, and drain the bottom aqueous layer into the beaker (see Figure 1). Close the stopcock. 6. Add 5 mL of distilled water to the sep funnel. Gently shake, allow to stand and separate, then drain the water layer into the beaker. 7. Repeat step 6 with 1 M NaHCO3, then again with 5 mL of distilled water. 8. Transfer the product to a 125 mL Erlenmeyer flask and add ~2 g of anhydrous Na2SO4. This is called “drying” the product. 9. Gravity filter the “dried” tert-butyl chloride product (see Figure 2). Record the volume of tert-butyl chloride obtained. 10. Determine the boiling point of the product to verify its identity using a simple distillation setup (see Figure 3). This will prevent any open evaporation of tert-butyl chloride. 11. Record today’s atmospheric pressure. Cleanup: Dump aqueous solutions down the drain with plenty of running water. Place t-butyl chloride in the organic waste container. Clean all glassware thoroughly: - For glassware that contained aqueous solutions, clean normally. - For glassware that contained organic substances, clean with acetone with three rinses. Calculations/Analysis: Calculate the % yield of tert-butyl chloride. Error: The accepted boiling point for tert-butyl chloride is 50.9˚C. Calculate Ea and E% between your corrected boiling point and the accepted boiling point.