0409-TOFE-ElGuebaly-IFE-Activation

advertisement

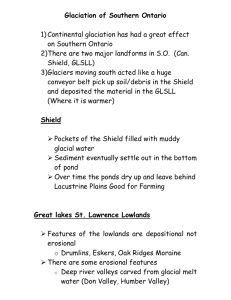

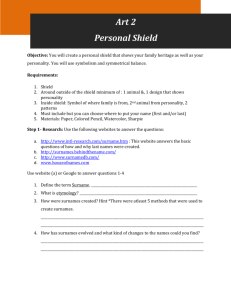

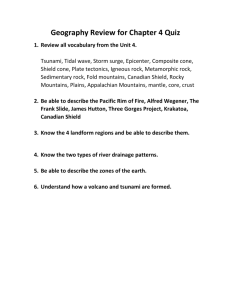

VIEWS ON NEUTRONICS AND ACTIVATION ISSUES FACING LIQUID-PROTECTED IFE CHAMBERS L. El-Guebaly and the ARIES Team University of Wisconsin, Fusion Technology Institute, 1500 Engineering Dr., Madison, WI elguebaly@engr.wisc.edu 0.5 m Target | Nozzles | Shield During the early 2000s, the ARIES team defined the design space and operational windows for both laser and heavy ion driven inertial IFE concepts from the viewpoint of a viable power plant system, rather than developing a point design1. One of the ARIES tasks addressed the nuclear-related issues for thick-liquid protected chambers with heavy ion (HI) drivers. The outcome of the nuclear study2 is the subject of this paper. Previous publications have assessed the radiological issues for the thin liquid wall concept3 and the HI target debris4. 3 m Radius | Gap I. INTRODUCTION rewelding the structure and flow nozzles during operation for component replacement or maintenance. Moreover, the activation of the steel-based chamber structure could be severe. Another concern is related to the IFE pulsed nature. The high instantaneous damage rate and deposition of the neutron energy can change the microstructure and cause isochoric heating problems. The following sections cover in more detail all these issues and highlight the main findings of our nuclear assessment for the ARIES-IFE thick-liquid-protected chamber. Liquid Jets Thin and thick liquid walls provide an attractive solution to the challenging material issues facing the heavy-ion applications of the inertial fusion energy (IFE) concept. Given the many advantages of liquid-protected chambers, there are several nuclear-related concerns that are discussed in detail for the thick liquid wall option in particular. These are the ability to protect the steel-based structure from radiation damage and high activation, the feasibility of rewelding the structure, and the pulserelated problems. These issues have a profound impact on the ARIES-IFE thick-liquid protected chamber design. Chamber Wall A representative radial build for the near-spherical thick-liquid protected chamber is given in Fig. 1, showing a thick-liquid wall surrounded by the shield. The innermost layer of the shield represents the location of the chamber wall and flow nozzles. Two candidate liquid metal breeders have been considered for this study: Flibe (BeF2,[LiF]2) and Flinabe (NaF, LiF, BeF2). The latter has a substantially lower melting point5 compared to Flibe (459 oC), offering lower operating temperature and vapor pressure6. Here, we are concerned with the feasibility of protecting the steel-based structure of the chamber with a thick liquid wall. Specifically, the concern is the ability of the liquid wall to protect the structure during the entire plant life while providing an adequate tritium supply for machine operation and satisfying the ARIES top-level requirement of generating only low-level waste. In addition, the helium production level at the chamber structure is a concern if the design mandates cutting and Fig. 1. Schematic of ARIES-IFE-HIB radial build. II. MODEL, DESIGN CRITERIA, AND LIMITS The 460 MJ yield HIB targets are repetitively injected into the chamber at a rep rate of 4 Hz. Following target injection, multiple HI beams focus on the target, emitting intense x-rays that compress the DT capsule and initiate the fusion process, generating energetic neutrons and ions. During burn, the 14.1 MeV neutrons experience several collisions with the dense capsule materials and lose a fraction of their energy. The average neutron energy is 11.8 MeV. After burn, the x-rays, neutrons, ions and target debris travel through the cavity, reaching the liquid wall in less than a microsecond. The chamber clearing system pumps out the liquid along with the target debris and reconditions the chamber in time for the next shot. Our computational model included the liquid wall and shield as arranged in Fig. 1 and explicitly considered the projected 85% system availability. Approximately 126 million pulses per full power year (FPY) have been modeled to estimate the activation level of the structure using the ALARA pulsed activation code7. The neutron flux throughout the chamber was calculated with the DANTSYS8 discrete ordinates transport code and the FENDL-2 175-neutron 42-gamma group coupled crosssection library9. Table I summarizes the design criteria and limits. A tritium breeding ratio (TBR) of 1.08 assures tritium self-sufficiency for ARIES-IFE-HIB. Higher breeding should be avoided as the regulatory agency may not license fusion devices with excess tritium production. Besides breeding tritium and recovering the energy, the liquid wall has an important shielding function. It provides a lifetime protection for the shield. The lifelimiting criterion for steel-based shielding components has traditionally been the displacement of atoms, ranging between 25 dpa for austenitic steel to 200 dpa for advanced ferritic steel (FS). Another design criterion relates to the reweldability of the structure and flow nozzles. There is always a need to cut and reweld these components for maintenance and replacement reasons. The helium production at the innermost surface of the shield should remain below the reweldability limit of 1 appm at any time during plant operation. As a top-level requirement for ARIES power plants, all components should generate only low-level waste (LLW) and meet both Fetter’s10 and 10CFR61 NRC11 waste disposal limits for Class C wastes. A computed volumetric average waste disposal rating (WDR) < 1 at the end of a 100-year institutional control period at the disposal site means the component qualifies for shallow land burial as LLW. We evaluated the WDR for both Fetter’s and NRC limits and reported the highest value. 1.3 Overall TBR 1.2 1.1 1.0 Required TBR Flibe Flinabe 0.9 0.8 50 100 150 200 Liquid Wall Thickness (cm) Fig. 2. Sensitivity of TBR to liquid wall thickness. TABLE I. Design Criteria and Limits Criteria Overall TBR dpa to advanced FS structure dpa to 304-SS structure He production at structure WDR Limit 1.08 200 dpa 25 dpa 1 He appm 1 III. RESULTS III.A. Tritium Breeding We started the analysis by examining the breeding capacity of the candidate breeders using natural lithium, then defined the breeder parameters in terms of thickness and Li enrichment. The homogenized liquid wall consists of 58% breeder and 42% void. It is found that Flibe is a better breeder than Flinabe, thus a wall thickness of 85 cm is required for Flibe and 150 cm for Flinabe for a breeding ratio of 1.08 (refer to Fig. 2). The reported overall TBR takes into account the 3% FW coverage for penetrations and the tritium bred in the shield. The Li enrichment did not enhance the breeding potential of the relatively thick Flinabe wall. Most of the neutron power is deposited in the liquid wall. The heat leakage to the shield is 10% for the Flibe system and 1% for the Flinabe system. The overall neutron energy multiplication amounts to ~1.25 for both systems. III.B. Radiation Damage to Shield The ARIES team has assessed two structural materials for the thick liquid protected chamber: austenitic steel and low-activation FS12. Over the past 10 years, 304-SS has been the material of choice for the HYLIFE design13 for being highly corrosion-resistant to Flibe. The new class of low-activation FS alloys (such as ODS-MF82H14) offer higher tolerance for radiation damage, lower neutron-induced swelling, lower thermal expansion coefficient, and higher range of operating temperatures. The shield protects the externals, operates hot to recover the leaked energy from the liquid wall, and contains 10% Flibe/Flinabe coolant. Figure 3 illustrates the drop of the damage at the shield with the liquid wall thickness. The 200 dpa level at the shield indicates both breeders (85 cm thick Flibe jets and 150 cm thick Flinabe jets) could protect the advanced FS structure for 40 FPY. Switching from FS to 304-SS structure would require a substantial increase in the Flibe jet thickness (from 85 cm to 130 cm). If so, the system breeds excess tritium that raises safety and licensing concerns. A potential solution would be to deplete the lithium of the Flibe at an extra cost. III.D. Activation and WDR of Shield 4 Peak dpa to Structure (dpa @ 40 FPY) 10 3 10 FS Limit 2 10 Flibe Flinabe 304-SS Limit 1 10 0 10 50 100 150 200 Liquid Wall Thickness (cm) Fig. 3. Variation of radiation damage at the shield inner surface with liquid wall thickness. III.C. Helium Production Level at Shield Even though the 200 dpa damage limit can be met, the reweldability limit (1 He appm) is greatly exceeded, meaning the chamber structure and flow nozzles cannot be rewelded if there is a need to cut and reweld the structure at any time during operation. Figure 4 illustrates the severity of the problem. The alternate option of replacing the shield and nozzles with new components in case of a failure must be carefully examined as replacement could be a prohibitive expense and require extended shutdown of the machine. The welds should be hidden and located away from the high-radiation zones. Peak Helium Production at Structure (appm @ 40 FPY) 4 10 3 10 2 10 Flibe Flinabe 1 10 0 10 Reweldability Limit -1 10 50 100 150 200 Liquid Wall Thickness (cm) Fig. 4. Sensitivity of He production at front layer of shield to thickness of liquid wall. We examined the two candidate steel alloys: advanced low-activation M-F82H FS and austenitic 304SS. The alloying elements and main impurities from References 14 and 15 are given in Table II. Both alloys generate high-level waste, particularly the inner shield surface and flow nozzles. 304-SS generates very high level waste as Figures 5 and 6 indicate for both Flibe and Flinabe systems. The HLW violates the ARIES top-level waste requirement that calls for only LLW (WDR < 1). The main contributors to the WDR are 94Nb (from Nb), 99 Tc (from Mo), and to a lesser extent, 192nIr (from W). One would expect to solve the FS waste problem by averaging the WDR over a thicker shield or controlling the Nb and Mo impurities. The ODS-MF82H-FS (the leading candidate for the ARIES-IFE-HIB chamber) can meet the Class C limit with at least 50 cm thick shield. Nb and Mo impurity control is a “must” requirement for the ODS-MF82H-FS structure of the Flibe system. Even though tailoring the FS materials to reduce the Nb and Mo concentrations helps reduce the WDR, practically and economically, complete removal of these materials can never be accomplished, requiring shield thicker than 50 cm. Two solutions have been identified to solve the nozzle waste problem: thickening the blanket, or preferably, mixing the nozzles with the shield (if acceptable by the regulatory agency) and disposing them as a single unit after plant decommissioning. The former solution could be prohibitively costly as it calls for a larger chamber with depleted Flibe/Flinabe. TABLE II. Composition of Steel Alloys (in wt%) Elements Fe C N O Si P S Ti V Cr Mn Co Ni Cu Nb Mo Ta W Y ODS M-F82H-FS* 87.981 0.04 0.005 0.13 0.24 0.005 0.002 0.09 0.29 8.7 0.45 0.0028 0.0474 0.01 0.00033 0.0021 0.08 2 0.7 304-SS 70.578 0.046 0.038 -0.47 0.026 0.012 0.03 -17.7 1.17 0.1 9.3 0.2 -0.33 ---- * M-F82H-FS + 0.25wt% Y2O3. Other impurities include B, Al, As, Pd, Ag, Cd, Sn, Sb, Os, Ir, Bi, Eu, Tb, Dy, Ho, Er, U. The heating diminishes in microseconds. 3 Nozzles 2 | 10 2 304-SS 10 1 10 ODS-MF82H-FS 0 10 Class C Limit ODS-MF82H-FS without Nb and Mo -1 10 0 20 40 60 80 Shield Thickness (cm) 100 Fig. 5. WDR of structure as a function of shield thickness behind 85 cm thick Flibe liquid wall. III.E. Isochoric Heating WDR of Shield Structure WDR of Shield Structure 10 | 1 10 304-SS Nozzles ODS-MF82H-FS Class C Limit 0 10 -1 10 ODS-MF82H-FS without Nb and Mo -2 10 0 20 40 60 80 Shield Thickness (cm) 100 Fig. 6. WDR of structure as a function of shield thickness behind 150 cm thick Flinabe liquid wall. To understand the isochoric heating problem, it is essential to identify the evolution of the liquid wall with time following the target implosion. When the x-rays rapidly deposit their energy in the liquid, they vaporize a few microns and drive strong shock waves into the liquid. The neutrons deposit their energy volumetrically in the liquid and the underlying structure. The geometry of the liquid hardly changes before the arrival of the neutrons. The neutron heating causes pressurization and rapid expansion of the liquid. The hydromotion leads to splashing of the liquid and breakup of the entire liquid wall or jets. The disassembly of the liquid wall/jets is allowed only in free-jet systems, like the HYLIFE-II thick liquid wall design13. In thin-liquid wall designs16, there is no splashing as the liquid is contained in a porous structure and the pressure is lower because the first wall radius is placed at much larger radius than 0.5 m. The survivability of the structure over millions of shots is still an open question. The instantaneous deposition of the neutron energy can cause isochoric heating problems with significant pressure waves that could impact the fatigue life of the structure. The structure will be heated and cooled at the same rate as the target rep rate (4 Hz). This means the structure temperature fluctuates four times per second with internal pressure reaching 100 atm. The sudden deposition of the nuclear heating and the fluctuation of the structure temperature can induce high stress/strain in the FS structure. Fatigue from cycling and repetitive shock waves could shorten the structure lifetime and cause internal cracks. When combined with the neutron-induced radiation damage (such as displacement of atoms), the fatigue life of the steel becomes a concern particularly for designs with high nuclear heat loads. The fusion reactions occur during a very short burn time (10-100 ps). Most of the high-energy neutrons reach the liquid surface in 10-150 ns, depending on the surface radius. The lower energy neutrons arrive over a longer period of time. The neutrons spend tens of nanoseconds slowing down within the liquid blanket. Over the past 30 years, only the HIBALL study16 has performed rigorous time-dependent nuclear heating analysis for the liquid and structure17. By inspecting the results, several broad trends can be described: The heating has a sharp peak, then quickly decays IV. CONCLUDING REMARKS The peak is several orders of magnitude above the timeaveraged power density The temporal distribution has a narrow width of ~20 ns No breeding problem has been found for the ARIESIFE thick-liquid protected concept. However, we identified several serious nuclear problems that need further consideration. These relate to waste level, structural integrity of the chamber, and economics. The activation of the chamber structure is severe. The proposed design generates high-level wastes that violate the ARIES top-level waste requirement. Note that this waste problem is generic to the thick-liquid concept as a similar problem has been identified for the HYLIFE design in the mid-1990s18. The apparent best solution to the waste problem is a combination of protecting the shield with thicker Flibe (or Flinabe) liquid walls with depleted lithium, adjusting the size of the shield itself, and more importantly, controlling the Nb and Mo impurities of the FS structure. Thus, consideration of advanced FS for ARIES-IFE-HIB rests heavily on the assumption that Nb and Mo impurities can be drastically controlled for the M-F82H structural material. The high cost of impurity control must be factored in the unit cost of the modified FS structure. Moreover, the cost-of-electricity should reflect the economic penalty associated with the larger chamber and depleted Flibe/Flinabe breeders. Besides the economic concerns, the formation and stability of the sizable liquid jets (> 85 cm thick) are feasibility issues under debate in the fusion community. With regard to the radiation damage issue, while the liquid jets control the FS atomic displacements below the 200 dpa limit needed for structural integrity, the neutroninduced helium production level is excessive and precludes the reweldability of the chamber FS stucture and flow nozzles during plant operation. No viable solution has been found for the reweldability problem. We hope, however, that the materials community can develop a more forgiving FS with three orders of magnitude higher reweldibility limit to avoid the economic penalty of shutting down the machine for extended periods to replace the chamber structure and flow nozzles. In relation to the pulsed nature of the concept, the high instantaneous damage rate can lead to significant changes in the microstructure of the structure. The repetitive shock waves, the instantaneous deposition of the neutron energy, and the fluctuation of structure temperatures will certainly impact the fatigue life and produce significant stress/strain and internal cracks. This could shorten structure lifetime making the structure fatigue an important life-limiting factor as the 200 dpa limit. In future thick liquid wall studies, it is essential to address the combined effect of radiation damage and fatigue on the lifetime of the chamber structure. ACKNOWLEDGMENTS This work was performed under the auspices of the US DOE (contract # DE-FG02-98ER 54462). [1] [2] [3] REFERENCES F. NAJMABADI, R. RAFFRAY et al., “Operational Windows for Dry-Wall and Wetted-Wall IFE Chambers,” Fusion Science & Technology, 46, No. 3, 401 (2004). L. EL-GUEBALY, “Ferritic Steel Assessment and Self-Consistent Nuclear Parameters for ARIES-IFE-HIB,” Presentation given at ARIES Project Meeting (October 2002). Available at: http://aries.ucsd.edu/ARIES/. L. EL-GUEBALY, P. WILSON, D. HENDERSON, L. WAGANER, and R. RAFFRAY, “Radiological Issues for Thin [4] [5] [6] [7] [8] [9] [10] [11] [12] [13] [14] [15] [16] [17] Liquid Walls of ARIES-IFE Study”, Fusion Science & Technology, 44, 405 (2003). L. EL-GUEBALY, P. WILSON, D. HENDERSON, and A. VARUTTAMASENI, “Feasibility of Target Materials Recycling as Waste Management Alternative”, Fusion Science & Technology, 46, No. 3, 506 (2004). P. PETERSON, University of CaliforniaBerkeley, Private Communications (September 2002). T. LUTZ, “Measurement of the Melting Point Temperature of Several Lithium-SodiumBeryllium Fluoride Salt (FLiNaBe) Mixtures,” These proceedings. P. WILSON and D. HENDERSON, “ALARA: Analytic and Laplacian Adaptive Radioactivity Analysis Code Technical Manual,” University of Wisconsin Fusion Technology Institute, UWFDM-1070 (January 1998). DANTSYS: A Diffusion Accelerated Neutral Particle Transport Code System, Los Alamos National Laboratory Report, LA-12969-M (1995). Available at: http://www.iaea.org/. S. FETTER, E. T. CHENG, and F. M. MANN, “Long Term Radioactive Waste from Fusion Reactors: Part II,” Fusion Engineering and Design, 13, 239 (1990). Nuclear Regulatory Commission, 10CFR61, Licensing Requirements for Land Disposal of Radioactive Waste, Federal Register, FR47, 57446 (1982). M. BILLONE, R. RAFFRAY, D.K. SZE, and L. EL-GUEBALY, “ARIES Assessment of IFE Structural Material,” University of California San Diego Report UCSD-ENG-101 (2002). R. MOIR, R. BIERI, X. CHEN et al., “HYLIFEII: a Molten-salt Inertial Fusion Energy Power Plant Design - Final Report,” Fusion Technology, 25, 5 (1994). M. BILLONE, Argonne National Laboratory, Private Communications (September 2002). C. BAKER et al., “Starfire-A Commercial Tokamak Fusion Power Plant Study,” Argonne National Laboratory Report, ANL/FPP-80-1 (1980). B. BADGER, F. ARENDT, K. BECKER et al., “HIBALL - A Conceptual Heavy Ion Beam Driven Fusion Reactor Study,” University of Wisconsin Fusion Technology Institute Report, UWFDM-450 (September 1981). M. SAWAN, G. MOSES, and G. KULCINSKI, “Time Dependent Neutronics Analysis for the HIBALL Heavy Ion Beam Fusion Reactor,” Nuclear Technology/Fusion, 2, 215 (1982). [18] J.D. LEE, “Waste Disposal Assessment of HYLIFE-II Structure,” Fusion Technology, 26, 74 (1994).