Building SMEs Competitiveness

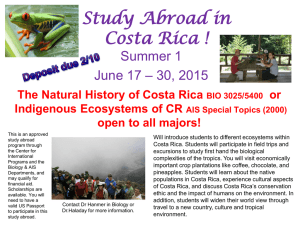

advertisement