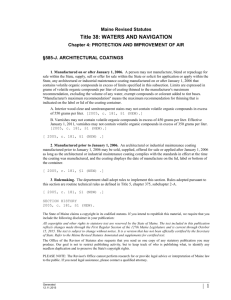

WNCRAQA Code Chapter 4.0900 .0947 MANUFACTURE OF

advertisement