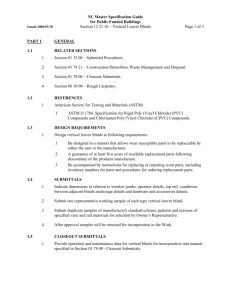

Crown Aluminum Blinds Section 12492 – Horizontal Louver Blinds

advertisement

Crown Aluminum Blinds Section 12492 – Horizontal Louver Blinds Last Revised: 2/2012 Crown Shade Company | PO Box 9689 Baltimore, MD 21237 | 800.445.5557 | www.crownshadeco.com PART 1 GENERAL 1.1 Description A. Horizontal Louver Blinds with Aluminum Slats. 1.2 Submittals A. Manufacturers complete CSI-3 part specification sheet. B. Submit working hand sample or mock-up blind as required. C. Submit two 6” samples of aluminum slat indicating color and dimensions. 1.3 Delivery, Storage & Handling A. Horizontal blinds are not to be delivered to site until building is enclosed and respective rooms are substantially complete. B. Store products in manufacturer’s unopened packaging until ready for installation. 1.4 Project Conditions A. Site environmental limitations: Install horizontal blinds only after finishing work such as painting is complete. 1.5 Extra Stock A. Attic stock to be supplied as required. PART 2 PRODUCTS 2.1 Manufacturers A. Acceptable Manufacturer: Crown Shade Company: PO Box 9689, Baltimore, Maryland 21237. Tel: 800-445-5557 Fax: 410-686-6015 Website: www.crownshadeco.com Email: sales@crownshadeco.com B. Substitutions: Not Permitted. C. Requests for substitutions will be considered in accordance with provisions of Section 01600. 2.2 Horizontal Blinds A. Product: a. Crown ½” Aluminum Micro Blinds b. Crown 1” Aluminum Mini Blinds c. Crown 2” Aluminum Galaxy Blinds B. Color Name: Color Number: C. Headrail shall be U-channel steel. The steel finishing process includes phospate treatment for corrosion resistance, a chrome free sealer, a low HAP urethane primer and a topcoat with low HAP polyester baked enamel a. Crown ½” Micro Blind head rail dimensions – 1” high x 1” wide x .025” thick b. Crown 1” Mini Blind head rail dimensions – 1” high x 1 ½” wide x .025” thick 1 c. Crown 2” Galaxy blind head rail dimensions - 2” high x 2 1/4” wide x .025” thick D. Tilter Mechanism: 1. Mini and Micro Blinds: Shall me made of injection-molded thermoplastics for smooth low-friction operation and will incorporate a clutch mechanism to prevent damage due to over tilting. i. Wand Tilt Control [Std] ii. Cord Tilt Control [Opt] 2. Galaxy Blinds: Shall me made of .0” Tominized steel with gear and pulley for smooth low friction operation and will incorporate a clutch mechanism to prevent damage due to over tilting. i. Cord Tilt Control [Std] ii. Wand Tilt Control [Opt] iii. Motorized Tilt Control [Opt] E. Cord Lock shall be metal of a snap-in design incorporating a floating, shaft-type locking pin and shall incorporate a crash proof safety feature that will lock the blind automatically upon release of cord. Options: a. Top Lock Cord Lock Option; provides only two blind positions; fully down or fully raised. b. Ring Pull Cord Option; provides a single plated steel ring lieu of tassels with a nominal 4” cord length. Select one: F. Braided Ladder shall be made of 100% high tenacity polyester incorporating two extra strength rungs per ladder to support slats. 1. Mini and Micro Blinds: i. 21.5mm (14.17 slats per foot) [Std] ii. 20mm (15.24 slats per foot [Opt] 2. Galaxy Blinds: i. Braided polyester ladder [Std] ii. Plastic 1.5” wide tapes [Opt] iii. Cloth 1” or 1.5” wide tapes [Opt] G. Slats: a. Mini and Micro Blinds: Shall be 5000 series cold-rolled aluminum containing the maximum allowable recycled content to produce a high strength and corrosion resistant flexible product. Slats shall be nominally 1” wide x .006" thick and processed with Advanced Finishing Technology (AFT), providing a smooth, hard, less porous surface. AFT delivers anti-static performance to repel dust. Slats shall be treated with a topcoat of polyester baked enamel. Select One: i. Solid .006" thick (standard) ii. Solid .008" thick b. Galaxy Blinds: Shall be cold-rolled magnesium alloy aluminum containing the maximum allowable recycled content to produce a high strength and corrosion resistant flexible product. Slats shall be nominally 2” wide x .008" thick and processed with Advanced Finishing Technology (AFT), providing a smooth, hard, less porous surface. AFT delivers anti-static performance to repel dust. Slats shall be treated with a topcoat of polyester baked enamel. H. Bottomrail shall be completely enclosed tubular shape made of phosphate treated steel, finished with a polyester baked enamel paint finish and shall measure .025" thick. 2.03 Fabrication A. Blinds shall be fabricated according to specifications and accurate to tolerance 2 established by Crown Shade Company standards. Part 3 Execution 3.1 Examination A. Do not begin installation until substrates have been properly prepared. B. If substrate preparation is the responsibility of another installer, notify Architect of unsatisfactory preparation prior to proceeding. 3.2 Preparation A. Coordinate requirements for blocking and structural supports to ensure adequate means for installation of window shades. B. Surfaces shall be cleaned thoroughly prior to installation. 3.3 Installation A. Install blinds in accordance with manufacturer’s instructions including recommended support brackets and fasteners. B. Install blinds with adequate clearance for a smooth operation. END OF SECTION 3