Tannery_Process_Phot..

advertisement

FactSheet # 1: Tannery Process Description

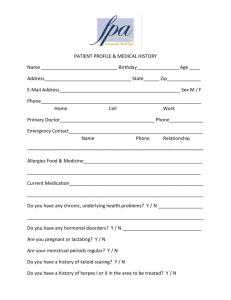

1.

Hide and skin curing

Hide and skin curing

a. Air drying, used in warm, dry climates such as India and Africa, consists of either

stretching the hides and skins on bamboo frames or by pegs or spreading on the ground

in mild sun. Dried hides are called “flints.” Arsenication of dried skins intended for

export takes place to prevent hide beetles. Naphthalene powder or flakes, DDT, zinc

chloride, chlorophenols and dichlorobenzenes are also used as insecticides, mostly for

goat and sheepskins before export.

b. Dry-salting involves rubbing the fleshing side with a solution of salt. This is performed

prior to exporting hides.

c. Wet-salting is used for short-term preservation.

d. Brine curing, introduced in the US and South America, is replacing salt curing. The

process involves submerging flayed, washed, cleaned, defatted, and trimmed hides in

brine (a saturated solution of sodium chloride usually with some naphthalene) for 12-24

hours.

e. Pickle curing is used for dewooled sheepskins in New Zealand and Australia to prepare

the skins for export. The process involves immersing the skin in a bath of sodium

chloride and mineral acid

Beamhouse

2. Receiving and storing

Receiving and storage

3. Cutting and trimming

Trimming hides

4. Stamping

5. Washing occurs in drums, soaking pits, baths, or vats with paddle stirrers. Soaking softens

the dry-salted and/or flint-dried hides and skins. Disinfectants such as bleaching powder,

chlorine, and sodium acid fluoride prevent putrefaction of hides. Caustic soda, sodium

sulfide, and wetting agents are added to accelerate soaking.

6. Liming involves immersing the hide in a milk of lime (calcium hydroxide) to loosen the

epidermis, hair roots, and to remove other unwanted soluble proteins and fats. Sodium

sulfide, sodium hydrogen sulfide, and dimethylamine are used to enhance and accelerate

the unhairing process. {Another method uses a depilatory paste of lime, sulfide and salt on

the fleshside of skins in order to save hair and wool}

Placing hides in lime pits

7. Washing involves cleaning the hides with warm water combined with wetting agents and

bactericides.

Washing the dehaired

hides

8. Unhairing and defleshing usually is completed by machines where fresh and limed hides pass

between several rollers while being pressed against a cylinder with spiral knives. This

operation can also be completed using hand tools.

9. Scudding is the removal of fine hair roots.

Tanning

10. Deliming and bating is the process where all lime is removed using weak acids or ammonium

salts (carbon dioxide ammonium sulfate and sodium bisulfate). Enzymes may be added to

digest residues of hair roots and non-structural proteins.

11. Pickling is performed prior to chrome tanning. The hides are soaked in a dilute solution of

sulfuric or hydrochloric acid and common salt. 2-naphthol or p-nitrophenol are sometimes

added to prevent mold growth.

12. Tanning converts the hides and skins to non-putrescible leather by stabilization of the

intermediate layer (derma) between epidermis and subcutaneous tissue. Tanning takes

place in rotating drums and may be followed by retanning. There are two general tanning

processes.

Chrome tanning is used for lighter leathers and can be performed in one bath containing

chromium III (chrome sulfate) as a bulk liquid. This process has largely replaced

the two-bath method that uses chromium VI. Chromium VI is now used only for

special purpose leathers.

Vegetable tanning is used for heavier leathers and involves the use of certain barks

(mimosa, acacia, quebracho and sumac) and nuts (myrobolam nuts used in India).

Synthetic tannery liquids (used mainly for retanning) include amino resins and

phenol and naphthalene derivatives.

Preparing vegetable tanning liquor

Vegetable Tanning Pits

Chrome tanning drums

Tanning drums

Finishing

13. Pressing is performed to remove excess water.

Tanning drums

14. Splitting divides the hide into two sheets.

15. Shaving removes excess thickness on the flesh side of the leather.

Shaving

16. Retanning may involve subsequent or simultaneously retanning, dyeing, and fat liquoring of

the hide. These processes define the properties of the finished leather.

17. Samming is used to remove excess water and oils and involves machine smoothing and

stretching of the hides

Pressing the hides

18. Drying is performed in one of three ways, vacuum drying, air-drying, and hot air circulation

drying.

19. Softening is performed to improve certain properties of the leather and involves sliding the

leather through a combination of folds, bumps, and stretches.

20. Dyeing is performed by soaking in vats or drums, or, more commonly, by color-spraying.

Dyeing and dressing

Hot Air Drying

http://billsmachinery.com.au/featured/tannery/tannery%20041.jpg

Packing

References

1.

Encyclopaedia of Occupational Health and Safety, Third Edition, Volume 2. L.

Parmeggiani, ed. Geneva: International Labor Organization (1983).

2.

Burgess WA: Recognition of Health Hazards in Industry. New York, John Wiley &

Sons

Photo Credits

Terry Dear, Celtic Leather

Holmes Halls Processors, Ltd.