title - World Journal of Engineering

advertisement

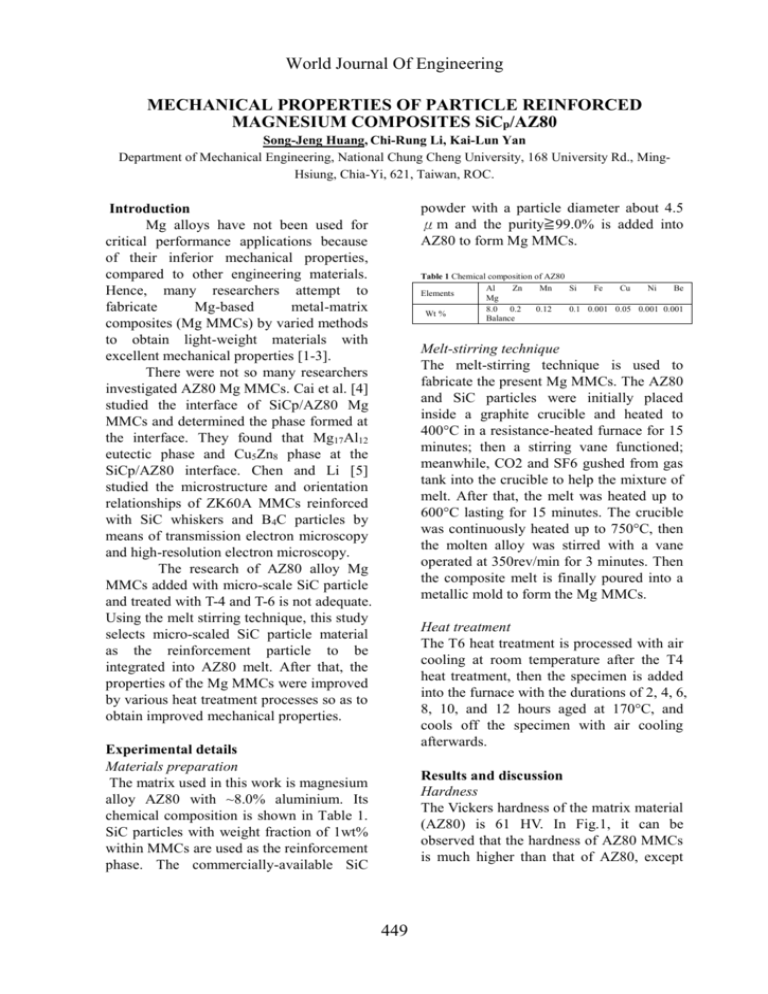

World Journal Of Engineering MECHANICAL PROPERTIES OF PARTICLE REINFORCED MAGNESIUM COMPOSITES SiCp/AZ80 Song-Jeng Huang, Chi-Rung Li, Kai-Lun Yan Department of Mechanical Engineering, National Chung Cheng University, 168 University Rd., MingHsiung, Chia-Yi, 621, Taiwan, ROC. powder with a particle diameter about 4.5 μm and the purity≧99.0% is added into AZ80 to form Mg MMCs. Introduction Mg alloys have not been used for critical performance applications because of their inferior mechanical properties, compared to other engineering materials. Hence, many researchers attempt to fabricate Mg-based metal-matrix composites (Mg MMCs) by varied methods to obtain light-weight materials with excellent mechanical properties [1-3]. There were not so many researchers investigated AZ80 Mg MMCs. Cai et al. [4] studied the interface of SiCp/AZ80 Mg MMCs and determined the phase formed at the interface. They found that Mg17Al12 eutectic phase and Cu5Zn8 phase at the SiCp/AZ80 interface. Chen and Li [5] studied the microstructure and orientation relationships of ZK60A MMCs reinforced with SiC whiskers and B4C particles by means of transmission electron microscopy and high-resolution electron microscopy. The research of AZ80 alloy Mg MMCs added with micro-scale SiC particle and treated with T-4 and T-6 is not adequate. Using the melt stirring technique, this study selects micro-scaled SiC particle material as the reinforcement particle to be integrated into AZ80 melt. After that, the properties of the Mg MMCs were improved by various heat treatment processes so as to obtain improved mechanical properties. Table 1 Chemical composition of AZ80 Al Zn Mn Si Fe Cu Ni Be Elements Mg 8.0 0.2 0.12 0.1 0.001 0.05 0.001 0.001 Wt % Balance Melt-stirring technique The melt-stirring technique is used to fabricate the present Mg MMCs. The AZ80 and SiC particles were initially placed inside a graphite crucible and heated to 400°C in a resistance-heated furnace for 15 minutes; then a stirring vane functioned; meanwhile, CO2 and SF6 gushed from gas tank into the crucible to help the mixture of melt. After that, the melt was heated up to 600°C lasting for 15 minutes. The crucible was continuously heated up to 750°C, then the molten alloy was stirred with a vane operated at 350rev/min for 3 minutes. Then the composite melt is finally poured into a metallic mold to form the Mg MMCs. Heat treatment The T6 heat treatment is processed with air cooling at room temperature after the T4 heat treatment, then the specimen is added into the furnace with the durations of 2, 4, 6, 8, 10, and 12 hours aged at 170°C, and cools off the specimen with air cooling afterwards. Experimental details Materials preparation The matrix used in this work is magnesium alloy AZ80 with ~8.0% aluminium. Its chemical composition is shown in Table 1. SiC particles with weight fraction of 1wt% within MMCs are used as the reinforcement phase. The commercially-available SiC Results and discussion Hardness The Vickers hardness of the matrix material (AZ80) is 61 HV. In Fig.1, it can be observed that the hardness of AZ80 MMCs is much higher than that of AZ80, except 449 World Journal Of Engineering for T6-4hrs and T6-6hrs. In general, the hardness of AZ80 and AZ80/1wt.% SiC increases with increasing time of T6, except for the range between T6-4hrs and T6-6hrs. The hardness of AZ80/1wt.% SiC with T612hrs has 28.9% increase than that of AZ80. Hence, the hardness of Mg alloy can be improved both by adding reinforcement particles and T6 heat treatment. (b) Fig.2 Stress-strain curve of T6 heat treated (a) AZ80, (b) AZ80/1wt.%SiC Conclusion AZ80/1wt.% SiC MMCs were formed by melt-stirring technique. The hardness of Mg alloy can be improved both by adding reinforcement particles and T6 heat treatment. Their yield strength can be increased by T6 heat treatment both for AZ80 alloy and AZ80/1wt.% SiC MMCs Fig.1 Microhardness with time of T6 Tensile strength Fig.2 shows the stress-strain curve of T6 heat treated AZ80 and AZ80/1wt.%SiC. The ultimate tensile strength of the matrix material (AZ80) is 186 MPa. Comparing Fig.2 (a) and (b), the ultimate tensile strength and yield strength of T6 heat treated AZ80/1wt.%SiC are greater than those of T6 heat treated AZ80. The 10 hr T6 heat treated AZ80/1wt.%SiC has biggest ultimate tensile strength of 256 MPa, which is much bigger than that of AZ80. The 10 hr - T6 heat treated AZ80/1wt.%SiC has biggest yield strength of 98 MPa, which is is much bigger than that of AZ80. References [1] Lin, P.-C., Huang, S.-J., and Hong, P.-S. Formation of magnesium metal matrix composites Al2O3p/AZ91D and their mechanical properties after heat treatment. Acta Mellallurgica Slovaca, 16 (2010) 237-245. [2] Huang, S.-J. and Chen, Z.-W. Microstructure of AlN particles reinforced AZ91D Mg-based metalmatrix composites. Acta Mellallurgica Slovaca, 16 (2010) 246-253 [3] Saravanan, R.A., Surappa M.K. Fabrication and characterisation of pure magnesium-30 vol.% SiCp particle composite. Materials Science and Engineering A, 276 (2000) 108-116. [4] Cai, Y., Shen, G. J. and Su, H. Q. The interface characteristics of as-cast SiCp/Mg(AZ80) composite,” Scripta Materialia, 37 (6) (1997) 737-742. [5] Chen, Y.X. and Li, D.X. Microstructure and orientation relationships of Mg alloy matrix composite reinforced with SiC whiskers and B4C particles. Materials Letters, 61 (2007) 4884–4886 (a) 450