III. Supervisory Genetic Evolution Control

advertisement

Supervisory Genetic Evolution Control for Induction Machine

Using Fuzzy Design Technique

Rong-Jong Wai*, Jeng-Dao Lee, and Li-Jung Chang

Department of Electrical Engineering, Yuan Ze University, Chung Li 320, Taiwan, R.O.C.

*E-mail: rjwai@saturn.yzu.edu.tw

AbstractThis study presents a supervisory genetic

evolution control (SGEC) system for achieving highprecision position tracking performance of an indirect

field-oriented induction motor (IM) drive. Based on

fuzzy inference and genetic algorithm (GA)

methodologies, a newly design GA control law is

developed first for dominating the main control task.

However, the stability of the GA control can not be

ensured when huge unpredictable uncertainties occur in

practical applications. Thus, a supervisory control is

designed within the GA control so that the states of the

control system are stabilized around a predetermined

bound region. In addition, the effectiveness of the

proposed control scheme is verified by numerical

simulation and experimental results, and its advantages

are indicated in comparison with a feedback control

system.

I. INTRODUCTION

Nowadays, the field-oriented control technique has been

widely used in industry for high-performance IM drive [1,

2], where the knowledge of synchronous angular velocity is

often required in the phase transformation for achieving the

favorable decoupling control. However, the performance is

sensitive to the variations of motor parameters, especially

the rotor time-constant, which varies with the temperature

and the saturation of the magnetizing inductance. Recently,

much attention has been given to the possibility of

identifying the changes in motor parameters of an IM while

the drive is in normal operation. Some researchers have

proposed various IM drives with rotor-resistance or rotor

time-constant identification to produce better control

performance [3-5]. However, the control performance of the

IM is still influenced by the uncertainties, such as

mechanical parameter variation, external disturbance,

unstructured uncertainty due to nonideal field orientation in

transient state, and unmodelled dynamics, etc. In the control

fields, the acquirement of the uncertainty information is an

important research topic. From a practical point of view,

however, it is usually very difficult to get the complete

information of uncertainties. Therefore, the motivation of

this study is to design a suitable control scheme to confront

the uncertainties existing in practical applications of an

indirect field-oriented IM drive.

To deal with the mentioned uncertainties, much research

has been done in recent years to apply various approaches

to attenuate the effect of uncertainties. On the basic aspect,

the conventional proportional-integral-derivative (PID)-type

controllers are widely used in industry due to their simple

control structure, ease of design, and inexpensive cost.

However, the PID-type controller can not provide perfect

control performance if the controlled plant is highly

nonlinear and uncertain [6, 7]. On the other hand, computed

torque or inverse dynamics technique is a special

application of feedback linearization of nonlinear systems

[8, 9]. The computed torque controller is utilized to

linearize the nonlinear equation by cancellation of some, or

all, nonlinear terms such that a linear feedback controller is

designed to achieve the desired closed-loop performance.

However, since the computed torque approach is based on

perfect cancellation of the nonlinear dynamics, the

objection to the real-time use of such control scheme is the

lack of knowledge of uncertainties.

Genetic algorithm (GA), which uses the concept of

Darwin’s theory, has been widely introduced to deal with

nonlinear control difficulties and to solve complicated

optimization problems [10-17]. Darwin’s theory basically

stressed the fact that the existence of all living things is

based on the rule of “survival of the fittest”. In the theory of

evolution, different possible solutions to a problem are

selected first to a population of binary strings encoding the

parameter space. The selected solutions undergo a parallel

global search process of reproduction, crossover, and

mutation to create a new generation with highest fitness

function [10]. This process of production of a new

generation and its evaluation is repeated until there is

satisfactory convergence within a predefined fitness grade.

Since the GA simultaneously evaluates many points in the

parameter space, it is more likely to converge toward the

global solution [16]. Recently, this underlying GA-based

global optimization technique has been applied in several

fuzzy logic control applications [18-22]. In view of the

previous research results, the favorable control or

optimization performance can reach their destination owing

to the powerful global searching capability of GA. However,

the role of GA control is usually used as a minor

compensatory tuner in the open literatures because the

stability of the GA-based control scheme can not be

guaranteed until now. The aim of this study is to design an

on-line GA control scheme as a major controller, moreover,

the stability of this strategy can be ensured with the aid of

supervisory control during the whole control process.

II. INDIRECT FIELD-ORIENTATION INDUCTION MOTOR

DRIVE

The IM used in this drive system is a three-phase Yconnected four-pole 800W 60Hz 130V/5.6A type.

Moreover, the drive system is a ramp comparison currentcontrolled pulse width modulated (PWM) voltage source

inverter (VSI). The current-controlled VSI is implemented

by isolated gate bipolar transistor (IGBT) switching

components with a switching frequency of 15kHz. For the

position control system, the braking machine is driven by a

current source drive to provide braking torque. An inertia

varying mechanism is coupled to the rotor of the IM. The

mechanical equation of an IM drive can be represented as

(1)

Jr Br TL Te

where J is the moment of inertia; B is the damping

coefficient; r is the rotor position; TL represents the

external load disturbance; Te denotes the electric torque.

With the implementation of field-oriented control [1, 2], the

electric torque can be simplified as

(2)

Te Kt iqs*

with the torque constant K t is defined as

(3)

Kt (3n p 2)(L2m Lr )ids*

Substituting (2) into (1) as follows can represent the

mechanical dynamic of the IM drive system:

K

B

1

r ( t ) r ( t ) t iqs* ( t ) TL

(4)

J

J

J

Apr ( t ) B p U ( t ) D p TL

where Ap B J ; B p K t J 0 ; D p 1 J , and

U (t ) iqs* (t ) is the control effort. Dynamic modeling based

on measurements [23] is applied to find the drive model offline at the nominal condition. The results are (on a scale of

50(rad/s)/V)

K t 0.4851 N m/A

J 4.78 10 3 N m s 2 / rad

(5)

B 5.34 10 N m s/rad

The overbar symbol represents the system parameters in

nominal conditions.

3

unpredicted uncertainties for the actual IM drive system

r (t ) ( Ap A) r (t ) ( B p B) U (t ) D p TL

A pr (t ) B p U (t ) L(t )

(7)

where A and B denote the uncertainties introduced by

system parameters J and B; represents the unstructured

uncertainty due to nonideal field orientation in transient

state, and the unmodelled dynamics in practical applications;

L(t ) is called the lumped uncertainty and is defined as

(8)

L(t ) A (t ) BU (t ) D T

r

p

L

Here the bound of the lumped uncertainty is assumed to be

given; that is,

(9)

L(t )

where is a given positive constant. The control problem

is to find a control law so that the rotor position can track

any desired commands. To achieve this control objective,

define a tracking error as e m r and its derivative

e , in which represents a reference trajectory

m

r

m

specified by a reference model. The control law for a SGEC

system is assumed to take the following form:

U U GA U S

(10)

where U GA is a GA control that is a main tracking controller,

and U S is a supervisory control that is designed so that the

states of the control system are stabilized around a

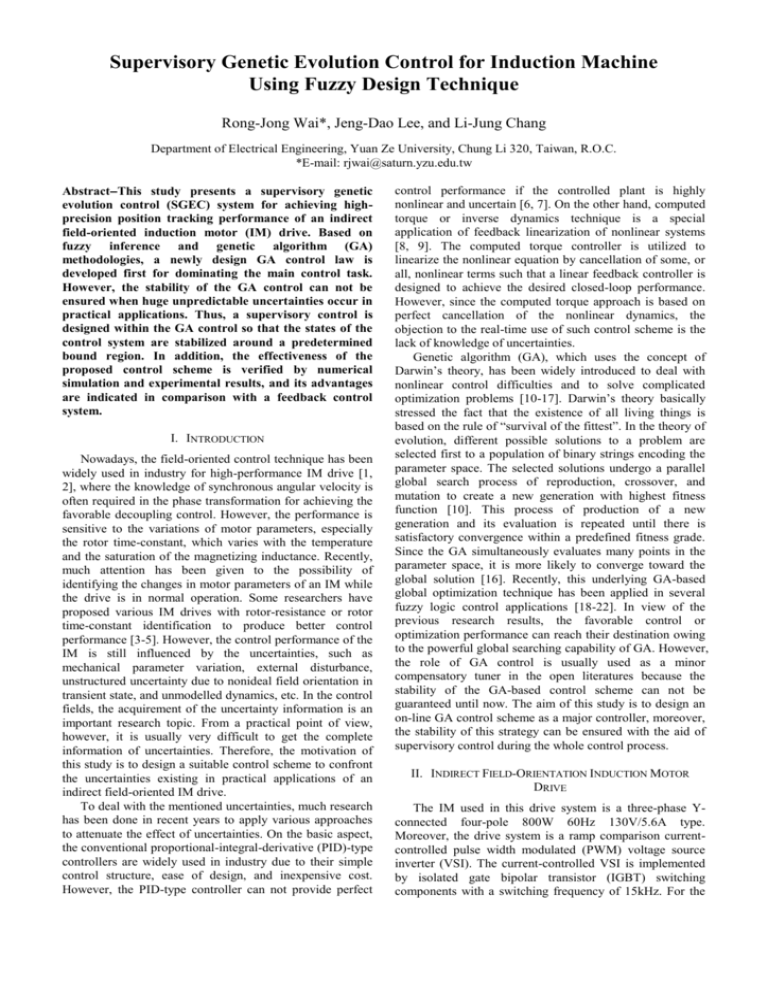

predetermined bound region. The overall scheme of the

SGEC strategy is depicted in Fig. 1 and the detailed

descriptions of each control part are exhibited in the

following subsection.

A. GA Control

III. SUPERVISORY GENETIC EVOLUTION CONTROL

With the field-oriented method, the dynamic behavior of

the IM is rather similar to that of a separately excited dc

motor. The decoupled relationship is obtained by means of

a proper selection of state coordinates under the hypothesis

that the synchronous angular velocity is precise. Therefore,

the rotor speed is asymptotically decoupled from rotor flux,

and the speed is linearly related to torque current after the

slip angular velocity can be obtained precisely. However,

the control performance of the IM is still influenced by the

uncertainties of the plant, such as mechanical parameter

uncertainty, external load disturbance, unstructured

uncertainty due to nonideal field orientation in transient

state, and unmodelled dynamics in practical applications.

Therefore, a SGEC scheme is designed in the sense of fuzzy

inference and GA methodologies to increase the robustness

of the indirect field-oriented IM drive for high-performance

applications.

Consider the parameters in the nominal condition

without external load disturbance, rewriting (4) as follows

can represent the nominal model of the IM drive system:

(6)

r (t ) Apr (t ) B p U (t )

where Ap B J and Bp Kt J 0 are the nominal

values of

Ap

and B p , respectively. Consider (6)

parametric

variation,

external

load

disturbance

and

In the GA controller, the tracking error ( e ) and its

derivative ( e ) are chosen as the input signals, and U GA is

the output signal. In this study, the spirit of fuzzy inference

mechanism is utilized to design this GA controller. It can

divide three main parts: GA membership region,

quantization number/levels and GA lookup table

introducing in the following paragraphs.

GA Membership Region

The membership regions Re and Re denote some area,

where the tracking error and its derivative maybe varied in

practical applications. The selection of membership regions

usually depends on the expert’s experience and various

applications.

Quantization Number/Levels

According to the quantization number ne and ne , the

tracking error and its derivative can be separated into

several different levels. Note that, the selection of ne and

ne has a great influence with higher or lower accuracy of

system performance. If the selection of quantization number

is too large, it will cause heavy computation load, and the

learning speed of the GA controller will be reduced. On the

contrary, if the selection of quantization number is too small,

it may cause the chattering efforts in the controlled system,

even to be unstable. In the study, the quantization functions

are denoted as Qer (e) and Qer (e) , and each of them has

nine levels, which are composed of NE (Negative Extend),

NB (Negative Big), NM (Negative Medium), NS (Negative

Small), ZE (Zero), PS (Positive Small), PM (Positive

Medium), PB (Positive Big), and PE (Positive Extend).

Indirect field-oriented IM drive

TL

_

Kt

Te

1

Js B

+

GA control F

fit

reproduction

crossover

mutation

Cr

Mb

U

wr

r

1

s

_

d

dt

+

m

r

U GA

GA lookup

table

+

US

ne

supervisory

control

V

e

e

Re

membership

regions

e

e

m

quantization

levels

Re

K

+

Q er (e )

Qer (e )

ne

r*

d

dt

_

+

reference

model

supervisory genetic evolution control system

Fig. 1. Block diagram of SGEC system.

Table I. GA Lookup Table

e

PE

PB

PM

PS

ZE

NS

NM

NB

NE

NE

C11

C12

C13

C14

C15

C16

C17

C18

C19

NB

+ C 21

C22

C23

C24

C25

C26

C27

C28

C29

NM

+ C 31

+ C32

C33

C34

C35

C36

C37

C38

C39

NS

+ C 41

+ C42

+ C43

C44

C45

C46

C47

C48

C49

ZE

+ C 51

+ C52

+ C53

+ C54

C55

C56

C57

C58

C59

PS

+ C61

+ C62

+ C63

+ C64

+ C65

C66

C67

C68

C69

PM

+ C71

+ C72

+ C73

+ C74

+ C75

+ C76

C77

C78

C79

PB

+ C81

+ C82

+ C83

+ C84

+ C85

+ C86

+ C87

C88

C89

PE

+ C 91

+ C92

+ C93

+ C94

+ C95

+ C96

+ C97

+ C98

C99

e

GA Lookup Table

When the input signals are passed through the

quantization number/levels step, the GA lookup table shown

in Table I will be constructed on line with the genetic

evolution mechanism: reproduction, crossover and mutation

introduced later. Note that, based on the fuzzy inference

mechanism, the sign of the associated control efforts are

predefined in Table I such that it has more possibility to

search optimal control efforts. In this study, each control

effort in the GA lookup table can be represented as a

chromosome and can be expressed via binary string

representation as

Ci j {g1i j g 2i j g li j }

with i {0, , ne }, j {0, , ne }

(11)

where C i j is one chromosome that has l-bits binary string,

and g i j denotes a gene. On the other words, the values of

the C i j are converted into their binary equivalent values. In

order to evaluate the fitness grade of each chromosome, a

fitness function is chosen as

(12)

Ffit (i, j ) exp{[(Δ (i, j ) (i, j)) 1]2 } [0, 1]

predetermined bound region and guarantee the system

stability.

B. Supervisory Control

where (i, j ) is the evaluated tracking error induced by the

original control effort, and (i, j ) denotes the evaluated

tracking error-change at two continuous iterations via a new

chromosome in (i, j) area of the GA lookup table. During

the on-line searching process, the chromosome with a

highest fitness grade will be saved on the GA lookup table.

The basic genetic operation used in this study is

summarized as follows:

Assume that the lumped uncertainty is available, there

exists an ideal control law as follows such that the favorable

control performance can be ensured:

1

(16)

U * B pn

[ Apnr L m KE ]

Reproduction

This reproduction procedure is used to decide which

chromosomes would be selected into the mating pool for

further genetic operations. First, an initial chromosome,

named as mother chromosome, is taken as a control input of

the IM drive. According to the running result, it will

produce new tracking error and its derivative such that a

corresponding chromosome, named as father chromosome,

can be detected via GA lookup table. Both of them are

selected to the crossover operation.

Crossover

The crossover operation combines the features of two

parent chromosomes to form one offspring by swapping

corresponding segments of the parents. In this study, the

crossover operation is performed with one crossover rate

defined as

(13)

C r ROUND[ F fit (i, j ) l ] {0, , l}

where ROUND( ) denote rounding the element to its

nearest integer. If the selection of the crossover rate C r is

bigger, then the offspring has more characteristics in the

father chromosome. This operation is repeated until there is

satisfactory convergence within a predefined fitness grade.

Mutation

In order to avoid chromosome trapping in local optimal

point, every gene is subject to random change with

probability of the pre-assigned mutation rate, M r , at each

iteration. In the binary string case, mutation operators just

to change the bit form 0 to 1 or vice versa. According to the

corresponding fitness value, the mutation rate M r can be

represented as

(14)

M r ROUND [(l Cr ) M b l ] {0, , M b }

where M b is a given upper bound of mutation number. As

time goes by, the fitness grade will gradually increase, and

the crossover and mutation operators also tend to settle.

This evolution procedure progresses until the fitness grade

reaches the desired specification. Thus, the output of the

GA controller can be represented as

(15)

U GA Table( Qer (e), Qer (e))

However, the stability of the GA control can not be ensured

when huge unpredictable uncertainties occur in practical

applications. Therefore, the auxiliary design of a

supervisory control is necessary for the condition of

divergence of states to pull the states back to the

where K [k1

k 2 ] is a given positive constant vector and

E [e e] is a tracking error vector. From (7), (10) and

(16), an error equation is then obtained as follows:

(17)

E E Bm [U * U GA U S ]

T

1

0

is a stable matrix

k

k 2

1

Bm [0 B pn ] . Define a Lyapunov function as

where

and

(18)

VS E T PE / 2

where P is a symmetric positive definite matrix which

satisfies the following Lyapunov equation:

(19)

T P P Q

and Q 0 is selected by the designer. Take the derivative

of the Lyapunov function and use (17) and (19), then

1

VS E T QE E T PBm [U * U GA U S ]

2

1 T

E QE E T PBm ( U * U GA ) E T PBmU S

2

(20)

To satisfy V 0 , the supervisory control U is designed

S

S

as follows [8, 9]:

1

U S I sgn(E T PBm )[ U GA B pn

( Apnr m KE )]

(21)

where sgn() is a sign function; is an absolute function; I

is an index function and is defined as

I 1, if VS V

I

(22)

I 0, if VS V

in which V is a positive constant designed by the user.

Substitute (21) into (20) and consider the I 1 case, then

1

VS E T QE E T PB m ( U * U GA ) E T PB m U S

2

T

E QE / 2 E T PB [ B 1 ( A L KE )

m

U GA U GA

pn

Pn

r

m

B ( A pnr m KE )]

1

pn

1 T

1

1

E QE E T PB m B pn

( L ) E T QE 0

(23)

2

2

Using the designed supervisory control U S as shown in eqn.

28, the inequality V 0 can be obtained for non-zero

S

value of the tracking error vector E when V S V . As a

result, the stability of the SGEC system can be guaranteed.

The effectiveness of the proposed control scheme is verified

by the following simulation and experimental results.

IV. SIMULATION AND EXPERIMENTAL RESULTS

The simulation of the proposed SGEC system is

implemented via the “Matlab” package based on the scheme

B 3 B , TL 1Nm occurring at 5.5s. The control

objective is to make the rotor position follow the periodic

step reference trajectory under the occurrence of

uncertainties.

reference

model

rad

K [100 20 ] (24)

Mb 1,

5,

V 0.3 ,

All the parameters in the proposed control system are

chosen to achieve the best transient control performance in

both simulation and experimentation considering the

requirement of stability. In order to let the GA controller

have the self-organizing property, the initial GA lookup

table in this study is set at a null table. The effect due to the

inaccurate selection of the initialized population can be

retrieved by the on-line searching methodology. The

parameter searching process remains continually active for

the duration of the simulation and experiments runs.

A second-order transfer function with rise time 0.5s is

chosen as the reference model for the periodic step

command:

w n2

57 .8

(25)

s 2 2w n s w n2 s 2 15 .2s 57 .8

where and w n are the damping ratio (set at one for

critical damping) and undamped natural frequency.

Moreover, two simulation cases including parameter

variations and external load disturbance in the shaft due to

periodic commands are addressed as Case 1: J J ,

B B , TL 1Nm occurring at 5.5s; Case 2: J 3 J ,

responses are resulted owing to parameter variations and

external load disturbance. Though a large control gain K

may solve the problem of delay or degenerate tracking

responses, it will result in impractical large control efforts.

Therefore, the control gains are difficult to determine due to

the unknown uncertainties in practical applications, and are

ordinarily chosen as a compromise between the stability and

control performance. Now, the SGEC system is considered

under the same simulated cases as the feedback control

system. The simulated results of SGEC system for periodic

step command at Case 1 and Case 2 are depicted in Fig. 3.

The tracking errors converge quickly, and the robust

tracking performance of the proposed control scheme can

be obtained under the occurrence of uncertainties.

reference

model

rotor

position

time (sec)

(a)

rad

shown in Fig. 1, and its control parameters are given as

follows:

l 3,

Re 0.15 , Re 1.25 ,

i j 9,

reference

model

rotor

position

time (sec)

(b)

Fig. 3. Simulated responses of SGEC system at Case 1 and Case 2.

rad

rotor

position

2 rad

reference

model

0rad rotor

time (sec)

(a)

position

reference

model

1Nm

start

1sec

(a)

rad

rotor

position

reference

model

time (sec)

(b)

Fig. 2. Simulated responses of feedback control system at Case 1 and Case

2.

In the simulation, first the ideal control law in (16)

without considering lumped uncertainty ( L 0 ), which is

called a feedback control system, is demonstrated for

comparison. The simulated results of feedback control

system for periodic step command at Case 1 and Case 2 are

depicted in Fig. 2. From the simulation results, favorable

tracking response shown in the beginning of Fig. 2(a) only

can be obtained at the nominal condition, and poor tracking

0rad

rotor

position

2 rad

1Nm

start

1sec

(b)

Fig. 4. Experimental results of feedback control system at external

disturbance condition and parameter variation condition.

Some experimental results are provided here to further

demonstrate the effectiveness of the SGEC system via

“Turbo C” language. Two test conditions are given to verify

the robustness of the proposed control scheme. One is the

external disturbance condition, that is the nominal inertia

with 1Nm braking-load disturbance occurring at 5.5s, and

the other is the parameter variation condition, that is the

increasing of the rotor inertia to approximately three times

the nominal value with 1Nm braking-load disturbance

occurring at 5.5s. First, a feedback control system, which is

the ideal control law shown in (16) with L 0 , is

implemented to control the IM drive for testing the

influence of lumped uncertainty. The experimental results

due to periodic step command at the two test conditions are

depicted in Fig. 4. Though favorable tracking responses

shown in the beginning of Fig. 4(a) can be obtained at the

nominal condition, the degenerated tracking responses are

resulted under the occurrence of parameter variations and

external load disturbance. Then, the SGEC system is

implemented to control the rotor position of the IM drive

system. The experimental results due to periodic step

command at the two test conditions are depicted in Fig. 5.

From the experimental results, the robust tracking

performance of the proposed control scheme can be

obtained under the occurrence of parameter variations and

external load disturbance. Compared these results with the

ones of feedback control system, the proposed SGEC

scheme is more suitable to control the rotor position of an

indirect field-oriented IM drive system under the possible

occurrence of uncertainties.

2 rad

reference

model

0rad

rotor

position

1Nm

start

1sec

(a)

reference

model

0rad

rotor

position

2 rad

1Nm

start

1sec

(b)

Fig. 5. Experimental results of SGEC system at external disturbance

condition and parameter variation condition.

V. CONCLUSIONS

This study has been successfully implemented a SGEC

system for an indirect field-oriented IM drive. This control

scheme contains two parts: one is a GA control that was

utilized to dominate the main control task, and the other is a

supervisory control that was designed to further ensure the

stable control characteristic. The effectiveness of the

proposed control scheme was confirmed by numerical

simulation and experimental results, and its advantages

indicated in comparison with a feedback control system.

The major contribution of this study is: 1) the successful

utilization of the spirit of fuzzy inference mechanism to

design a GA control with self-organizing property, and 2)

the successful confirmation of the stability of SGEC system

at the aid of a supervisory control, and 3) the successful

implementation of a SGEC system to an indirect fieldoriented IM drive for high-precision position tracking under

the occurrence of uncertainties in practice.

ACKNOWLEDGMENTS

The authors would like to acknowledge the financial

support of the National Science Council in Taiwan, R.O.C.

through its grant NSC 90-2213-E-155-003.

REFERENCES

[1] LEONHARD, W.: ‘Control of electrical drives’ (SpringerVerlag, 1996)

[2] KRISHNAN, R.: ‘Electric motor drives: modeling, analysis,

and control’ (Prentice-Hall, 2001)

[3] VUKOSAVIC, S.N., and STOJIC, M.R.: ‘On-line tuning of

the rotor time constant for vector-controlled induction motor

in position control applications’, IEEE Trans. Ind. Electron.,

1993, 40, (1), pp. 130-138

[4] LIN, F.J., SU, H.M., and CHEN, H.P.: ‘Induction motor

servo drive with adaptive rotor time-constant estimation’,

IEEE Trans. Aerosp. and Electron. Syst., 1998, 34, (1), pp.

224-234

[5] WAI, R.J., LIU, D.C., and Lin, F.J.: ‘Rotor time-constant

estimation approaches based on energy function and sliding

mode for induction motor drive’, Electr. Power Syst.

Research, 1999, 52, pp. 229-239

[6] HANG, C.C., ASTROM, K.J., and HO, W.K.: ‘Refinements

of the Ziegler-Nichols tuning formula’, IEE Proc. Contr.

Theory Appl., 1991, 138, (2), pp. 111-118

[7] ASTROM, K.J., and HAGGLUND, T.: ‘PID controller:

theory, design and tuning’ (Research Triangle Park, NC: ISA,

1995)

[8] SLOTINE, J.J.E., and LI, W.: ‘Applied nonlinear control’

(Prentice-Hall, 1991)

[9] ASTROM, K.J., and WITTENMARK, B.: ‘Adaptive control’

(Addison-Wesley, 1995)

[10] GOLDBERG, D.: ‘Genetic algorithms’ (Addison-Wesley,

1989)

[11] VARSEK, A., URBANCIC, T., and FILIPIC, B.: ‘Genetic

algorithms in controller design and tuning’, IEEE Trans. Syst.,

Man, Cybern., 1993, 23, (5), pp. 1330-1339

[12] OMATU, S., and DERIS, S.: ‘Stabilization of inverted

pendulum by the genetic algorithm’. IEEE Conf.

Evolutionary Computation, 1996, pp. 700-705

[13] HA, K.J., and KIM, H.M.: ‘A genetic approach to the attitude

control of an inverted pendulum system’. IEEE Conf. Tools

with Artificial Intelligence, 1997, pp. 268-269

[14] CHANG, C.S., and SIM, S.S.: ‘Optimising train movements

through coast control using genetic algorithms’, IEE Proc.

Electr. Power Appl., 1997, 144, (1), pp. 65-73

[15] ALONGE, F., D'IPPOLITO, F., FERRANTE, G., and

RAIMONDI, F.M.: ‘Parameter identification of induction

motor model using genetic algorithms’, IEE Proc. Contr.

Theory Appl., 1998, 145, (6), pp. 587-593

[16] CHEN, B.S., and CHENG, Y.M.: ‘A structure-specified H

optimal control design for practical applications: a genetic

approach’, IEEE Trans. Contr. Syst. Technol., 1998, 6, (6),

pp. 707-718

[17] MIURA, T., and TANIGUCHI, T.: ‘Open-loop control of a

stepping motor using oscillation-suppressive exciting

sequence tuned by genetic algorithm’, IEEE Trans. Ind.

Electron., 1999, 46, (6), pp. 1192-1198

[18] SURMANN, H.: ‘Genetic optimization of a fuzzy system for

charging batteries’, IEEE Trans. Ind. Electron., 1996, 43, (5),

pp. 541-548

[19] TZES, A., PENG, P.Y., and GUTHY, J.: ‘Genetic-based

fuzzy clustering for DC-motor friction identification and

compensation’, IEEE Trans. Contr. Syst. Technol., 1998, 6,

(4), pp. 462-472

[20] MOALLEM, M., MIRZAEIAN, B., MOHAMMED, O.A.,

and LUCAS, C.: ‘Multi-objective genetic-fuzzy optimal

design of PI controller in the indirect field oriented control of

an induction motor’, IEEE Trans. Magnetics: Part 1, 2001,

37, (5), pp. 3608-3612

[21] LEE, S.I., and CHO, S.B.: ‘Emergent behaviors of a fuzzy

sensory-motor controller evolved by genetic algorithm’, IEEE

Trans. Syst., Man, Cybern.: Part B, 2001, 31, (6), pp. 919929

[22] CAO, Y.D., HU, B.G., and GAO, D.J.: ‘Genetic-based robust

optimal design for one-input fuzzy PID controllers’. IEEE

Conf. Syst., Man, Cybern., 2001, pp. 2263-2268

[23] LIAW, C.M., OUYANG, M., and PAN, C.T.: ‘Reduced order

parameter estimation for continuous system from sampled

data’, ASME Trans., J. Dynamic System Measurement and

Control, 1990, 112, pp. 305-308