59_RA_Yeast 2-Hybrid_SP

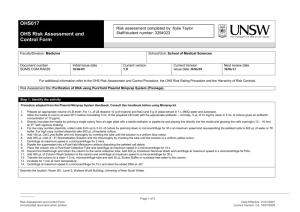

OHS017

OHS Risk Assessment and

Control Form

Risk assessment completed by:Dr S. Palmer

Staff/student number: 3283213

Faculty/Division: Medicine

Document number

SOMS.CGM.RA059

Initial Issue date

30/06/09

Current version

1.0

School/Unit: School of Medical Science, Neuromuscular and Regenerative Medicine

Research Unit

Current Version

Issue date 30/06/09

Next review date

30/06/12

For additional information refer to the OHS Risk Assessment and Control Procedure, the OHS Risk Rating Procedure and the Hierarchy of Risk Controls.

Risk Assessment title:: Yeast 2-Hybrid analysis

Step 1: Identify the activity

Describe the activity:

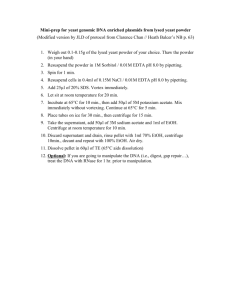

Yeast transformation Geitz lab protocol

Day 1

Inoculate the yeast strain into 5 ml of liquid medium (2x YPD or SD selection medium) and incubate overnight on a rotary shaker at 200 rpm and 30°C. Place a bottle of double strength

YPD broth (2x YPD) and a 250 ml culture flask in the incubator as well.

Day 2

1.

Determine the titer of the yeast culture by pipetting 10 ml of cells into 1.0 ml of water in a spectrophotometer cuvette and measuring the OD at 600 nm. Calculate the cell titer

2.

Transfer 50 ml of the pre-warmed 2x YPD to the pre-warmed culture flask and add 2.5 x 10 8 cells to give 5 x 10 6 cells/ml.

3.

Incubate the flask on a rotary or reciprocating shaker at 30°C and 200 rpm

4.

After about 4 hours, harvest the cells by centrifugation at 3000 g for 5 min, wash the cells in 25 ml of sterile water and resuspend in 1 ml of sterile water.

5.

Heat a 1.0 ml sample of salmon sperm carrier DNA for 5 min @ 100 o C and chill in an ice/water bath while harvesting the cells.

6.

Transfer the cell suspension to a 1.5 ml microcentrifuge tube, centrifuge for 30 sec and discard the supernatant.

6.

Transfer the cell suspension to a 1.5 ml microcentrifuge tube, centrifuge for 30 sec and discard the supernatant.

7. Add water to a final volume of 1.0 ml and vortex mix vigorously to resuspend the cells.

8.

Pipette 100 µl samples (ca. 10 8 cells) into 1.5 ml microfuge tubes, one for each transformation, centrifuge at top speed for 30 sec and remove the supernatant.

9.

Make up sufficient Transformation Mix for the planned number of transformations plus one extra. Keep the Transformation Mix in ice/water.

__________________________________________________________________________________________________________________________________________________________________________

_________

Page 1 of 6

Risk Assessment and Control Form

Uncontrolled document when printed

Date Effective: 01/01/2007

Current Version: 2.6, 16/07/2008

Number of Transformations

Reagents

PEG 3500 50% w/v

1

240 µl

5 (6X)

1440 µl

10 (11X)

2640 µl

LiAc 1.0 M

Boiled SS-carrier DNA

Plasmid DNA plus Water

36 µl

50 µl

34 µl

216 µl

300 µl

204 µl

396 µl

550 µl

374 µl

Total 360 µl 2160 µl 3960 µl

10. Add 360 µl of Transformation Mix to each transformation tube and resuspend the cells by vortex mixing vigorously.

11. Incubate the tubes in a 42°C water bath for 40 min.

12. Microcentrifuge at top speed for 30 sec and remove the Transformation Mix with a micropipettor.

13. Pipette 1.0 ml of sterile water into each tube; stir the pellet by with a micropipette tip and vortex .

14. Plate appropriate dilutions of the cell suspension onto SC selection medium. For transformation with an integrating plasmid (YIp), linear construct or oligonucleotide, plate 200 µl onto each of 5 plates; for a YEp, YRp or YCp library plasmid dilute 10 µl of the suspension into 1.0 ml of water and plate 10 and 100 µl samples onto two plates each. The 10 µl samples should be pipetted directly into 100 µl puddles of sterile water on the SC selection medium.

15. Incubate the plates at 30°C for 3 to 4 days and count the number of transformants.

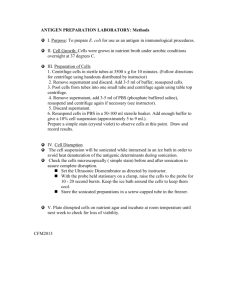

Yeast Media and Plates

YPD medium

20 g/L Difco peptone

10 g/L Yeast extract

20 g/L Agar (for plates only)

• [Optional] For adenine-supplemented YPD (YPDA or YPAD), add 15 ml of a 0.2% adenine hemisulfate solution per liter of medium (final concentration is 0.003%, in addition to the trace amount of Ade that is naturally present in YPD). Adenine hemisulfate tolerates autoclaving.

Add H2O to 950 ml. Adjust the pH to 6.5 if necessary, then autoclave. Allow medium to cool to ~ 55°C and then add dextrose (glucose) to 2% (50 ml of a sterile 40% stock solution). Adjust the final volume to 1 L if necessary.

SD medium

6.7 g Yeast nitrogen base without amino acids

20 g Agar (for plates only)

850 ml H2O

__________________________________________________________________________________________________________________________________________________________________________

_________

Page 2 of 6

Risk Assessment and Control Form

Uncontrolled document when printed

Date Effective: 01/01/2007

Current Version: 2.6, 16/07/2008

100 ml of the appropriate sterile 10X Dropout Solution

• Adjust the pH to 5.8 if necessary, and autoclave. Allow medium to cool to ~ 55°C before adding 3-AT, cycloheximide, additional adenine, or X-gal (see below).

• Add the appropriate sterile carbon source, usually dextrose (glucose) to 2%, unless specified otherwise for your application. Adjust the final volume to 1 L if necessary.

Describe the location:

Laboratory Rm 501, Fume hood Rm 525, Yeast shaking incubator Rm 525

Step 2: Identify who may be at risk by the activity

A number of people may be at risk from any activity. This may affect the risk controls needed. These people may include fellow workers, visitors, contractors and the public. The location of the activity may affect the number of people at risk.

Operator and those exposed to heating block at 100 o C or near Bunsen flame.

Steps 3 to 7: Identify the hazards, risks, and rate the risks

1. An activity may be divided into tasks. For each task identify the hazards and associated risks.

2. List existing risk controls and determine a risk rating using the UNSW Risk Rating Procedure.

3. Additional risk controls may be required to achieve an acceptable level of risk. Re-rate the risk if additional risk controls used.

Tasks

Hazards

(Step 3)

Associated risks

(Step 4)

Existing risk controls

C

Risk rating with existing controls *

(Step 5)

L R

Additional risk controls required

(Step 6)

(Apply the hierarchy of risk controls)

Risk Rating with additional controls *

(Step 7)

C L R

Make solutions, media and plates

Chemical Hazards

Exposure to:

Lithium Acetate 1M

3-amino-1,2,4-triazole

Lithium Acetate 1M –

Slightly hazardous in case of skin/eye contact

(irritant) or inhalation/ingestion

3-amino-1,2,4-triazole -

Slightly hazardous in case of skin/eye contact

(irritant) or inhalation/ingestion

Standard PPE lab coat, goggles and gloves.

Training

Irritant and toxic chemicals – weigh out and make solutions in fume hood

3 D M

__________________________________________________________________________________________________________________________________________________________________________

_________

Page 3 of 6

Risk Assessment and Control Form

Uncontrolled document when printed

Date Effective: 01/01/2007

Current Version: 2.6, 16/07/2008

Grow Yeast culture to the appropriate density(steps 1-4)

Physical Hazard

Shaking Incubator

Benchtop centrifuge

Spectrophotometer

Electrical appliance

– electrocution hazard

2 E L

Heat salmon sperm DNA for 5 mins at 100oC on hot block then place on ice.

(Every3-4 experiments)

T

ransfer the cell suspension to a

1.5 ml microcentrifuge tube, centrifuge for

30 sec, wash once in water, centrifuge again

Resuspend cells in fresh transformation mix

(table in point 9) and vortex

Heat samples in water bath at

42oC, centrifuge, resuspend in water and plate with glass spreaders, incubate at 30

o

C

Physical Hazard

Electrical equipment

Physical Hazard

Electrical equipment

Physical Hazard

Electrical equipment

Chemical Hazards

Exposure to:

Lithium Acetate 1M

Physical Hazard

Electrical equipment

Glass pipettes bent in

Bunsen flame

Electrocution

Burns

Electrocution

Rotor spin injury

Electrocution

Lithium Acetate 1M –

Slightly hazardous in case of skin/eye contact

(irritant) or inhalation/ingestion

Electrocution

Rotor spin injury

Burns from Bunsen

Stick injury from glass pipettes

* C = consequence L = likelihood

Standard PPE lab coat, goggles and gloves.

Electrical equipment testing

Training

Standard PPE lab coat, goggles and double gloves.

Training

Standard PPE lab coat, goggles and gloves.

Training

Standard PPE lab coat, goggles and gloves.

Electrical equipment testing

Training

R = risk rating

2 E

2 E

2 E

2 E

L

L

L

L from the UNSW Risk Rating Procedure

Standard PPE lab coat, goggles and gloves.

Electrical equipment testing

Training

__________________________________________________________________________________________________________________________________________________________________________

_________

Page 4 of 6

Risk Assessment and Control Form

Uncontrolled document when printed

Date Effective: 01/01/2007

Current Version: 2.6, 16/07/2008

Step 8 Documentation and supervisor approval

Completed by: (name) S.Palmer (signature) Authorised by: (name)

Step 9: Implement the additional risk controls identified

Indicate briefly what additional risk controls from Step 6 above were implemented, when and by whom.

Risk control:

Risk control:

Risk control:

Date:

Date:

Date:

(signature)

Implemented by:

Implemented by:

Implemented by:

Date:

Risk control: Date: Implemented by:

Step 10: Monitor and review the risk controls

It is important to monitor risk controls and review risk assessments regularly. Review is required when there is a change in the process, relevant legal changes, and where a cause for concern has arisen. Reviews could be scheduled on an annual basis. If the risk assessment has substantially changed a new risk assessment is warranted.

Review date: Reviewed by: Authorised by:

Review date: Reviewed by: Authorised by:

Review date: Reviewed by: Authorised by:

Review date: Reviewed by: Authorised by:

Documentation

It is a requirement that legal and advisory documentation that supports this risk assessment be listed. Such documentation includes Acts, Regulations, Australian Standards and Codes of Practice, where applicable.

NSW OHS Act 2000

NSW OHS Regulation 2001

Code of Practice for the Labelling of Workplace Substances

AS/NZS 2243.2:2006. Safety in laboratories. Part 2: Chemical aspects

AS/NZS 2243.3:2002 Safety in laboratories Part 3: Microbiological aspects and containment facilities

Australian Standard AS2243.6-1990. Safety in laboratories. Part 6: Mechanical Aspects.

Australian Standard AS2243.7-1991. Safety in laboratories. Part 7: Electrical Aspects.

AS/NZS 2161.1:2000 Occupational Protective Gloves – Selection, Use and Maintenance

__________________________________________________________________________________________________________________________________________________________________________

_________

Page 5 of 6

Risk Assessment and Control Form

Uncontrolled document when printed

Date Effective: 01/01/2007

Current Version: 2.6, 16/07/2008

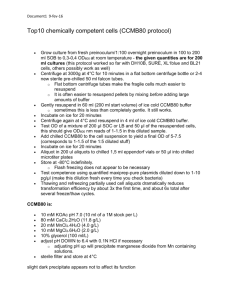

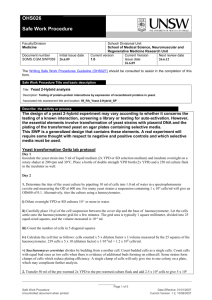

UNSW Concise OHS Risk Rating Table

OHS697

What you need to do

1. Consider what can go wrong that can hurt someone

2. Determine what the most likely outcome would be - Consequences

3. Determine how likely those consequences are - Likelihood

4. Calculate the risk rating

5. Required action

CONSEQUENCES:

Severe

Major

Moderate

Minor

Insignificant

LIKELIHOOD:

Almost certain

Likely

Possible

Unlikely

Rare

LIKELIHOOD

Almost certain

A

Likely

B

Possible

C

Unlikely

D

Rare

E

Risk level

Very high

High

Medium

Low

How severely could someone be hurt death or permanent disability to one or more persons hospital admission required medical treatment required first aid required injuries not requiring first aid

How likely are those consequences? expected to occur in most circumstances will probably occur in most circumstances could occur at some time is not likely to occur in normal circumstances may occur only in exceptional circumstances

Insignificant

1

M

M

L

L

L

Minor

2

H

M

M

L

L

CONSEQUENCES

Moderate

3

H

H

H

M

M

Major

4

VH

H

H

M

M

Severe

5

VH

VH

VH

H

M

Required action

Act immediately:

The proposed task or process activity must not proceed. Steps must be taken to lower the risk level to as low as reasonably practicable using the hierarchy of risk controls.

Act today:

The proposed activity can only proceed, provided that:

(i) the risk level has been reduced to as low as reasonably practicable using the hierarchy of risk controls;

(ii) the risk controls must include those identified in legislation, Australian Standards, Codes of

Practice etc.

(iii) the risk assessment has been reviewed and approved by the Supervisor and

(iv) a Safe Working Procedure or Safe Work Method has been prepared.

(v) The supervisor must review and document the effectiveness of the implemented risk controls.

Act this week:

The proposed task or process can proceed, provided that:

(i) the risk level has been reduced to as low as reasonably practicable using the hierarchy of risk controls;

(ii) the risk assessment has been reviewed and approved by the Supervisor and

(iii) a Safe Working Procedure or Safe Work Method has been prepared.

Act this month:

Managed by local documented routine procedures which must include application of the hierarchy of controls.

_______________________________________________________________________________________________________________

Page 6 of 6

UNSW Concise OHS Risk Rating Table Effective date: 01/01/2007

Uncontrolled document when printed Current Version: 2.6,16/07/2008