Impacts Affecting ECCFWSD

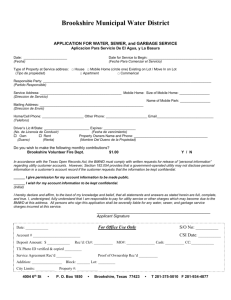

advertisement

East Cedar Creek FWSD Quarterly News Letter June 2012 Major Projects Completed and or in Progress ECCFWSD / Mabank Acquisition is now a success The City of Mabank now has additional capacity for their future growth since the approximately 700 water meter customers have been transferred from their water system to East Cedar Creek FWSD. Our District benefits from the additional meter count which increases our revenues and slightly increased our expenses. Below are some of the key benefits of the project: Water meter customers in the Subdivisions of Loon Bay, Timber Trails, Pleasure Land and Thunderbird Shores and water meter customers that were not on ECCFWSD on Luther Lane, commercial sections and rural customers along Hwy 334 to Railroad Road now are under one water and sewer provider. ECCFWSD and the City of Mabank have two inter connection locations that can be utilized if one or the other need additional water during an emergency. ECCFWSD has installed a water main between Loon Bay and Harbor Point to improve water flows. Water main extensions have been installed to improve capacity for growth in the north east section of Gun Barrel City’s commercial district. Included in the project were additional large flush units known to cities as fire hydrants to insure water quality is maintained as well as a benefit to the Gun Barrel City Fire Department to assist in fire protection. As General Manager I would like to take this opportunity to thank all who worked so hard to make this a reality. Brookshire Water Treatment Clarifier Refurbished Between 2006 and 2008 a second clarifier tank and two additional filter tanks were added to the Brookshire Water Treatment Facility in anticipation of growth within the city limits of Gun Barrel City and the surrounding development areas. Once the new treatment equipment were in operation this allowed time to set aside funds and plan for the refurbishing of the original treatment clarifier and two filter tanks. In 2009 the original two filter tanks were refurbished and as of June 1, 2012 the original Clarifier has been refurbished and placed back into service. Prior to the refurbishing projects the Brookshire Water Treatment Facility was capable of producing 2 million gallons per day. Today the facility is capable of producing 3.4 million gallons per day. Our highest demand day this year so far has been 1.4 million gallons which includes all the additional Mabank Transferred water customers. This equates to only 41 percent of the Brookshire Treatment capabilities. Project in Progress There are two major projects coming up that is projected to reduce annual expenses. Reduced expenses equates to less risk of rate increases sooner than necessary. Bulk Chemical Tanks This project is about 80% completed. Once these large bulk tanks are operational we will be able to purchase water treatment chemicals at a much lower price per pound due to volume purchasing power. Wastewater Sludge Belt Press The wastewater treatment facilities must haul unwanted sludge from the treatment process every week. Currently we haul concentrated sludge to a compost facility and at times must pay for a contractor to haul liquid sludge miles from here for land application. The most economical way to haul sludge is by a concentrated method meaning the sludge is thickened so a lot less water is hauled. ECCFWSD is planning to purchase a Sludge Belt Press to eliminate the liquid hauling and haul all our concentrated sludge with company transportation to the compost facility. It has been projected that these two projects in progress will save approximately $90,000 to $100,000 annually once fully operational. See back of page for additional Customer Information Reduce the Risk of Unwanted Fees and Charges -- Please call for line locates. 1. Call our office and request a line locate 72-hours prior to digging and trenching. Failure to have water and sewer lines located before digging and trenching you take the chance of damaging our mains and having to pay for un-necessary expenses due to the failure to take the time to schedule your project and provide ECCFWSD the 72-hours to schedule in time to mark our water and sewer line locations. 2 Do not flush unwanted waste such as plastic products into sanitary sewer plumbing. The following narrative comes directly from our Water & Wastewater Service Agreement that each customer executes prior to obtaining service: “Damage will include stoppage caused by user flushing items into the sewer that cannot be conveyed by the system. Examples of these items are plastic bags, wash rags, towels, cat litter, personal hygiene products, excess grease and other type of solid waste that normally would be disposed of through garbage collection. Should user damage district equipment or fail to provide adequate protection. All cost of repairs will be at the expense of the user.” Who do you call? ECCFWSD still responds to sewer concerns. If your toilet appears to be backing up or sewer water is ponding somewhere in the yard call our office before you call a plumber. This will provide us with the opportunity to identify if the problem is on our side of the sewer system. There have been several times that this has been the case. If you call a plumber first the plumber will bill you even if it is our problem. Drought / Conservation Concerns If you have replaced shrubbery, sod or trees due to the impact of the devastating drought of 2011-12, ECCFWSD is not under any water stage restrictions at this time. The news releases we have received from Tarrant Regional Water District in April stated that they are not anticipating any water restriction through 2012. Commercial Customers Fats, Oil and Grease (FOG) For commercial clients who provide food service please continue an active grease disposal program. Monitor and maintain grease traps in a manner to prevent possible fees for discharging excessive grease and please have your contractor who hauls this product away provide to you a manifest for each time they come to empty and dispose of excess grease and provide ECCFWSD with a copy so we can keep compliance records up to date. Fats, Oil and Grease (FOG) can settle in the collection lines and in manholes causing blockages and sewer backups to occur. Crews must be called out to resolve these issues causing your utility provider to absorb additional costs for labor and equipment hours. Your utility management team works hard to keep costs to a minimum, please do not allow FOG to enter our sewer collection system by maintaining your responsibility. Residential home owners can do their part by draining and collecting grease from cooking and place in a throw away container such empty coffee containers or similar plastic containers and let the grease solidify, place lid on container and dispose in the sanitary hopper for pick-up.. ECCFWSD Back Flow Prevention Program --This program is an un-funded, mandated law Under the TCEQ 209 Rule, section 290.44 Water Distribution, subsection (h) clearly defines that all water systems must have a backflow prevention program in place. If your business is required to have a testable backflow prevention device, please review your backflow assembly inspection records. Testing of this device annually by an Approved Backflow Prevention Assembly Tester (BPAT) is required. If you need assistance locating a Certified BPAT, contact our office. Backflow prevention devices (BFD’s) assist in the prevention of possible contamination to our drinking water system and to the public as well as to the internal water system of the commercial customer. These BFD’s that are required by law are designed to prevent water used inside businesses from back flowing into our water mains during ECCFWSD reduced pressures during water main repairs or if water pressure inside the business for some reason exceeds the normal water pressures in the water mains. The selected type of BFD installed is due to the degree of hazard. Some high degree of hazard examples would be hospitals, medical clinics, veterinaries and mortuaries and even carbonated soda fountains. The most common medium degree of hazard example in our area is the typical irrigation (sprinkler) system that does not apply chemicals during irrigation and outside hose bibs. For more information regarding BFD’s contact our office.