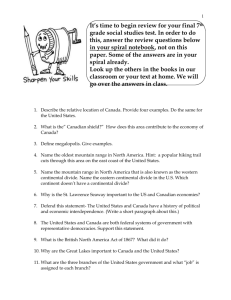

press release (Word, 74 KB)

advertisement

Press Release -1- Smart and Slim: The New Car Keys from Continental A new production method is being employed at Continental to create exceptionally thin and user-friendly car keys. Kia Motors is using these new keys, which are just 3.4 mm thick and allow customers to unlock their doors without even pressing a button. Regensburg (Germany)/Icheon (Korea), June 29, 2012. Downsizing is the defining trend in automotive developments. But not just for "big" assemblies like engines or platforms: International automotive supplier Continental is continuing this development right down to the smallest detail, and has now launched one of the thinnest electronic car keys on the market. While most modern card-shaped car keys are usually more than five mm thick, the new car keys from Continental are just 3.4 mm "thin". Although unlike other downsizing measures, this does not influence the fuel consumption and CO2 emissions of the vehicle, this development from the electronics specialist offers a tremendous boost in terms of userfriendliness. Where previous key cards were sometimes a bit of a struggle to fit into pockets, the new key card from Continental will even fit into some wallets. Even the modern PASE (Passive Start and Entry) system is integrated in the card, despite its slim dimensions. Drivers no longer even need to have the key card in their hand in order to unlock and start their vehicle. The new key has already gone into series production on the new Kia K9 luxury sedan for the Korean market. "For motorists, car keys are something you always take with you. We wanted to produce a key that is not just technically impressive, but also looks and feels good. With our new, thinnest key card we have shown that Continental is firmly committed to the trend toward slim line design. Nonetheless, the key card offers state-of-the-art comfort functions and is highly robust," adds Andreas Wolf, Head of the Continental Body & Security Business Unit. Development and production hold the key to downsizing The more than 20-percent reduction in material thickness has been made possible by combining ongoing refinement and development of the electronics with innovative production techniques. For the first time, Continental is using Resin Transfer Molding (RTM), a .../2 Your contact: Sebastian Fillenberg, +49 6196 87-3709 -2technology borrowed from the field of semiconductor manufacturing. This extremely precise injection molding technique can be used to produce plastic parts that are not only much more delicate, but also extremely durable and resistant. Today, most vehicle keys are injectionmolded from “thermoplastics”. To produce the necessary stability, however, this method requires a minimum material thickness of at least six mm. By contrast, the RTM method uses a special epoxy compound. Not only does this material not compromise the electronic components during the production process, but its excellent flow properties also mean that it can be used to produce high-precision and delicate shapes. Once it has hardened, the material can withstand even very high temperature fluctuations and is resistant to mechanical knocks, scratches and so on. This has made it possible to reduce the amount of material required for production and everyday use. This has delivered a reduction in material thickness of more than 2 mm, making the new key much more comfortable to keep in your wallet. Full range of functions with "keyless" entry Even though the new key card from Continental is thinner than ever before, it still offers electronics with state-of-the-art comfort functions enabling motorists to open, close and start the vehicle without even needing to handle the card. The wireless connection to the vehicle electronics is just as stable as in previous systems, and the new, slimline key card is already perfectly equipped for the future. In the medium term, innovations like the display presented for the first time by Continental on the bi-directional key, which shows information about the current vehicle status, will be just as much a possibility as the integration of NFC chips. Known as Nearfield Communication Technology, this technology is used particularly in contactless payment systems. If a person’s credit card details are saved on the key, he or she can then pay for things simply by touching a sensor field – e.g. on a ticket machine or at a supermarket cash till. This means you can leave your loose change at home, continuing the trend for downsizing right down to your wallet with the aid of Continental. With sales of €30.5 billion in 2011, Continental is among the leading automotive suppliers worldwide. As a supplier of brake systems, systems and components for powertrains and chassis, instrumentation, infotainment solutions, vehicle electronics, tires and technical elastomers, Continental contributes to enhanced driving safety and global climate protection. Continental is also an expert partner in networked automobile communication. Continental currently has approximately 167,000 employees in 46 countries. .../3 Your contact: Sebastian Fillenberg, +49 6196 87-3709 -3The Automotive Group with its three divisions Chassis & Safety (sales of approximately €6.5 billion in 2011, 33,000 employees), Powertrain (sales of approximately €5.8 billion in 2011, 31,000 employees) and Interior (sales of approximately €6.1 billion in 2011, 32,000 employees) achieved sales of approximately €18.4 billion in 2011. The Automotive Group is present in more than 170 locations worldwide. As a partner of the automotive and commercial vehicle industry, it develops and produces innovative products and systems for a modern automotive future in which cars provide individual mobility and driving pleasure consistent with driving safety, environmental responsibility and cost efficiency. The Chassis & Safety division develops and produces electronic and hydraulic brake and chassis control systems, sensors, driver assistance systems, airbag electronics and sensors, windshield washer systems and electronic air suspension systems. Its core competence is the integration of active and passive driving safety into ContiGuard®. The Powertrain division integrates innovative and efficient system solutions for vehicle powertrains. The comprehensive range of products includes gasoline and diesel injection systems, engine management and transmission control, including sensors and actuators, as well as fuel supply systems and components and systems for hybrid and electric drives. Information management is at the very heart of the Interior division, which provides a range of products that includes instrument clusters and multifunctional displays, control units, electronic car-entry systems, tire-monitoring systems, radios, multimedia and navigation systems, climate control systems, telematics solutions and cockpit modules and systems. Sebastian Fillenberg External communications Continental Interior Division Sodener Strasse 9 65824 Schwalbach am Taunus, Germany Tel.: +49 6196 87-3709 Fax: +49 6196 8779-3709 sebastian.fillenberg@continentalcorporation.com www.continental-automotive.de www.continental-corporation.com Your contact: Sebastian Fillenberg, +49 6196 87-3709 Enno Pflug External communications Continental Interior Division Sodener Strasse 9 65824 Schwalbach am Taunus, Germany Tel.: +49 6196 87-2515 Fax: +49 6196 8779-2515 enno.pflug@continental-corporation.com