Mechanical Systems (part 1)

advertisement

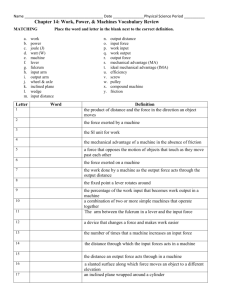

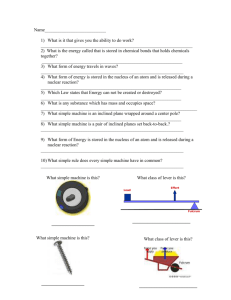

Revised Standard Grade Technological Studies Mechanical Systems Contents Preface Structure Resources Assessment Introduction Motion Rotary Linear Reciprocating Oscillating Forces Static forces Dynamic forces Bending forces Shear forces Torsion forces Compression forces Tension forces Vectors Equilibrium Levers Force multiplier ratio Movement multiplier ratio Efficiency Classes of lever Moments The bell-crank lever Linkages Free-body diagrams Beams Beam reactions Types of beam support Gears Simple gear train Movement multiplier ratio in gears Idler gears Ratchet and pawl Compound gears Worm and wheel Bevel gears Torque and Drive Systems Power transmitted by a belt drive Belt and chain drives Multiplier ratio for belt drives Toothed belts Chain drives Multiplier ratio for chain drives Chain tension Converting motion Cams Cam motion Crank slider Rack and pinion Couplings Bearings Clutches Mechanical Systems – Homework Unit Assessment ii iii iii iv iv 1 2 2 2 2 2 5 5 5 6 6 6 7 7 9 10 15 16 16 17 20 25 32 34 37 38 38 38 44 44 45 46 46 50 51 52 57 58 59 61 65 65 67 67 71 71 71 73 77 81 82 84 89 113 Standard Grade Technological Studies: Mechanical Systems Preface Mechanisms are widely used in industry and are included in a large number of devices and equipment commonly used in society. It is important, therefore, that students have a good understanding of how mechanical systems assist and aid everyday tasks. Throughout the coursework, students should gain knowledge of how mechanical systems operate and how they fit into common everyday devices. It is not only necessary to understand how the mechanical system carries out its task, but also important to know hot the systems can be altered to improve performance and efficiency. It is therefore recommended that this unit of work be completed towards the end of the course to allow students to grasp the requirements and rigour of the mechanisms calculations. Owing to the nature of course modifications, it is not necessary for students to construct mechanical or compound systems. If, however, the class teacher sees a need for construction to assist the learning process, then this can be undertaken. The construction of ‘rigs’ or working models to display and convey important mechanical observations is also acceptable. Structure The material provides the student with natural progression throughout the course. There is, however, flexibility within the material so that the teacher can determine which sections can be taught to suit the classroom needs. The following areas are covered. Introduction Motion Forces Vectors Levers Moments Linkages Free-body diagrams Beams Gears Torque and drive systems Converting motion Rack and pinion Couplings, bearings, clutches, friction The content of the unit fulfils all the requirements of the course and the structured homework exercises can be distributed at the end of a course topic. Some teachers may, however, add additional well-tried and tested worksheets to benefit student learning and understanding of topics. The use of the CD-ROM gives students an interactive way of understanding mechanical devices in real-life situations. This classroom methodology is a very important part of students’ development and their knowledge of how mechanical systems work can assist in everyday situations. The tasks associated with the CDROM allow pupils to search and interact at suitable times within the coursework. There is a variety of suitable CD-ROMs on mechanisms and these could also be used at the discretion of the teacher. The interactive computer simulation associated with the tasks: Standard Grade Technological Studies: Mechanical Systems iii 6 Levers 4 Gears and Belts 12 Gears and Belts 2 Cams and Cranks 2 Friction refers to The New Way Things Work CD-ROM. The ‘Simulation of Gear Systems: Task 1 Simple gear train’ refers to Crocodile Clips Mechanical components. Resources The majority of resources required to assist in the understanding of this unit should be available if Technological Studies has already been undertaken. The resources comprise: examples of classes of levers a balance lever a model of a gear train a model of a compound gear system a computer simulation of gear systems an interactive computer simulation of mechanisms a model of a bevel-gear system a model of belt/chain-drive systems a model of a rack-and-pinion system examples of couplings, bearings and clutches individual components. Assessment Internal assessment Internal assessment can be measured against the tasks that the students complete during the coursework allied with their homework at the end of topics. A twelve-question end-of-unit assessment prepares students to undertake assessable elements in knowledge and understanding and reasoning and numerical analysis. This assessable work can be used to supplement students’ grades in the event of appeals. Marks are awarded for each question and are associated with elements. External assessment This unit of work and the exercises within prepare the students for any mechanisms questions that appear in the 90-minute exam at the end of the course. It will enable all students to gain the knowledge and understanding required and give them suitable practice in reasoning and numerical analysis. iv Standard Grade Technological Studies: Mechanical Systems Introduction Mechanisms are still a large part of modern society. Most of the mechanisms that we use every day are so familiar that we never think twice about them, for example door handles, light switches, scissors, etc. Mechanisms play a vital role in industry. While many industrial processes now have electronic control systems, it is still mechanisms that provide the muscle to do the work. They provided the forces to press steel sheets into the shape of car body panels, to lift large components from place to place and to force power hacksaws to cut through thick metal bars – the list of jobs is endless. It is only by using mechanisms that industry can make products you use every day. Some machines are easy to understand, but many are hidden away from sight behind glossy panels and covers. In the past, machines were much easier to see, as with the old steam engine, for example, but as people became more concerned about safety, it was necessary to fit guards over moving parts. Today, guards are often replaced by styled covers that make it much harder to see what is happening, but whether you can see them or not, mechanisms are still playing a vital part in everyday life. All mechanisms: involve some kind of motion involve some kind of force make a job easier to do need some kind of input to make them work produce some kind of output. Standard Grade Technological Studies: Mechanical Systems 1 Motion There are four basic kinds of motion. Rotary Turning in a circle. This is the most common type of movement, for example wheels, clock hands, compact discs, CD-ROMs. Linear Movement in a straight line, for example movement of a paper trimmer cutting a straight edge on paper or a lift moving between floors. Reciprocating Backwards and forwards movement in a straight line, for example the needle in a sewing machine or the piston in a car engine. Oscillating Swinging backwards and forwards in an arc, for example the pendulum of a clock, a playground swing or a rocking horse. 2 Standard Grade Technological Studies: Mechanical Systems Motion: task 1 What types of motion do the following sports or leisure activities show when they are being used or carried out? Complete a systems diagram for each. Swing 100 metres’ sprint Golfing Bungee jump See-saw Fire button on a computer game Standard Grade Technological Studies: Mechanical Systems 3 Motion: task 2 The machines and tools that are used in your practical rooms in school use all types of motion. The four types of motion are listed; now list as many machines/tools as possible for each type of motion. Rotary Linear Reciprocating Oscillating 4 Standard Grade Technological Studies: Mechanical Systems Forces Forces affect structures in a variety of different ways depending on how they are applied to the structure. Forces can move a structure slightly or cause damage by changing the shape of the structure. Sometimes when forces are applied to a structure, it may be almost impossible to see changes happening. For example, a bridge will sag slightly when a vehicle drives over it, but this is not visible to the human eye. Nevertheless, the vehicle causes downwards movement of the bridge structure. Loads such as vehicles on a bridge can be deemed examples of forces acting on the bridge. Forces can stop an object from moving or they can make it change direction. When a football is kicked, the forces applied from the player cause the dimensions of the ball to change on impact. It happens so quickly that it is not visible. Forces are measured in newtons and the symbol is the letter ‘N’. There are a number of different types of forces that can be applied to and which affect bodies and structures. Static forces When static loads or forces are applied to structures, the structures do not normally move. Normally the total downwards force comprises the weight of the structure plus the load it is carrying. The runner below is in his starting position; his weight is a static or stationary downwards force. Dynamic forces When dynamic loads or forces are applied to a structure, the structure does move and the forces applied can be varied. Dynamic forces are visually more noticeable and are produced by a variety of means and effects: machines, wind directions, people, etc. The picture below shows the sprinter after the starting gun has been fired; he is creating a dynamic impact to gain momentum. Standard Grade Technological Studies: Mechanical Systems 5 Bending forces Structures that carry loads across their length are subject to bending forces. The weightlifter lifting a weighted bar feels the effect of the downward forces of the weights and these cause the bar to bend. A car driving across a bridge will cause bending forces on the structure but often they are not visible. Shear forces Shear forces can be described as tearing or cutting forces affecting structures. Simple examples are a pair of scissors used to cut a ribbon at an opening ceremony and a mower cutting the grass. Torsion forces Torsion or torque forces have the effect of trying to turn or twist a structure or a piece of material. A screwdriver being twisted to apply a force to a screw and a spanner turning a bolt to lock it into place are examples of torque being applied. 6 Standard Grade Technological Studies: Mechanical Systems Compression forces The figure below shows a column with a weight pressing down on it, but the column does not disappear into the ground because the ground exerts an upwards reaction force on the column’s base. The downward pressure of the weight and the upward reaction are external forces trying to squash or shorten the column. Forces that act like this are called compressive forces and the column is said to be in compression. For example, when you sit on a stool in the classroom, your weight acts as a downward force on the chair. However, there must be an upward force on the legs of the chair; therefore the legs are said to be in compression. The same can be said about the weightlifter’s arms and legs. WEIGHT FORCE W (EXTERNAL FORCE ON COLUMN) W COLUMN R GROUND REACTION R (EXTERNAL FORCE ON COLUMN) Figure 1 Tension force We have noted that compression occurs when things are being pushed together. The opposite of compression is ‘tension’ – when a structure is being pulled apart. In a tug of war, the two sides are pulling the rope in opposite directions. The forces applied by the teams are called tensile forces and cause the rope to be in tension. It could also be said that the arms of team members are in tension. Figure 2 The wire rope holding the net in volleyball is also in tension. Figure 3 Standard Grade Technological Studies: Mechanical Systems 7 Force: task 1 Against each of the six forces mentioned make a list of ‘real life’ situations where these types of forces may be found. Ask the teacher if you are unsure which category the situations fit into. (a) Static (b) Dynamic (c) Bending (d) Shear (e) Torsion (f) Compression (g) Tension 8 Standard Grade Technological Studies: Mechanical Systems Vectors Force is a vector quantity and has both magnitude and direction. This means it is often convenient to represent a force by a line, that is, a vector quantity, which is sometimes easier to understand visually. The direction of the force may be indicated by an arrowheaded line, with the length of the line drawn to scale to represent the size of the force. This line is called a vector. Example The cyclist pedalling with a force of 800 N is being assisted by a tail-wind of 400 N, but the friction from the road surface measures 200 N. 800 N 400 N 200 N Figure 1 The overall effect will be 800 N + 400 N – 200 N = 1000 N (or 1 kN). A suitable scale would be selected – possibly 10 mm to represent 20 N – and using this scale each force is drawn in turn, one following on from the other. 800 N + 400 N – 200 N = 1000 N or 1 kN Figure 2: a vector diagram When the three forces are added together, they can be replaced by a single force that has the same effect, called the ‘resultant’. RESULTANT = 1 kN Figure 3 Standard Grade Technological Studies: Mechanical Systems 9 Vectors are also used to find the resultant of two forces that are inclined at an angle to each other. 25 N 60 º 35 N Figure 4 In the example above the resultant of the two forces can be found by drawing two vectors. First choose a suitable scale and draw the two vectors CA and CB. Scale: 10 mm = 10 N 25 mm = 25 N = CA 35 mm = 35 N = CB The bigger the scale the more accurate the vectors. From A draw a line parallel to CB, and from B draw a line parallel to CA. Call the point where the two lines intersect point D. Now draw a line from C to D. A line drawn from C to D is the resultant of the two forces CA and CB. Figure 5 The resultant has a magnitude of 46 N by measurement. Equilibrium Certain conditions must apply within structures in order to create stability. The resultant is made up of the combined forces that are trying to move an object or structure in a set direction. If such a force were applied without an opposing force then major problems could occur. Structures have to remain in a stable or balanced state called ‘equilibrium’, which simply means ‘balanced’. There are three types of balancing that must exist if structures, bodies, objects, etc. are to remain in equilibrium: horizontal, vertical and rotational forces must all balance. 10 Standard Grade Technological Studies: Mechanical Systems The general conditions of equilibrium are as follows. upward forces leftward forces clockwise moments = = = downward forces rightward forces anticlockwise moments Example 1 Consider again the same two forces in figure 5. Are they in equilibrium? It is easily seen that a force must be added acting downwards to the left, but we cannot tell from this exactly how large this force must be or its exact direction (figure 6). Figure 6 The resultant has been drawn and it can be seen that to balance it, the equilibrant CE is required. If the forces F1 and F2 are drawn as in figure 7 then it is much easier to obtain the equilibrant by completing the triangle, as shown in figure 7. Figure 7 Standard Grade Technological Studies: Mechanical Systems 11 Example 2 A crane is fixed against a wall, as shown in figure 8. Find the forces in the compression and tension members. Figure 8 To find the forces created in the tension and compression members by the 1000 N load, draw the triangle from the area circled. Select a suitable scale and then draw the known force first, the 1000 N load (figure 8). A line is drawn through one end of the load line parallel to one of the unknown forces. Another line is drawn through the other end, parallel to the second unknown force. By measuring each line, the size of each force can be found. (Note: the arrowheads must follow round the triangle.) Figure 9 Scale: 10 mm = 200 N The compression member = 2000 N The tension member = 1733 N 12 Standard Grade Technological Studies: Mechanical Systems Equilibrium: task 1 1. Study the following statements and cross out the incorrect answer. A body that is accelerating is in a state of equilibrium. TRUE/FALSE For a body to be in a state of equilibrium it is necessary only for the vector sum of the forces acting on it to be zero. TRUE/FALSE A resultant force is a single force that can replace two or more forces. TRUE/FALSE If two or more forces are replaced by a resultant force, the effect on the body is changed. TRUE/FALSE An equilibrant force is the force that, if applied to a body, will cause the body to be in a state of equilibrium. TRUE/FALSE The equilibrant force is identical to the resultant force. TRUE/FALSE 2. Try to explain two conditions necessary for a structure or body to be in equilibrium. 3. Two forces are acting on a body as shown. (a) Graphically indicate their size and direction. (b) Graphically indicate the resultant of the two forces. 4. Two forces are acting on a body as shown. (a) Graphically indicate their size and direction. (b) Calculate the resultant and direction of the two forces. 5. What are the resultant and equilibrant of the two forces affecting the system below? Standard Grade Technological Studies: Mechanical Systems 13 6. A small crane is used on a fishing trawler to lift cases of fish to the dock. The weight of the lift is 1200 N. Determine the size and direction of the forces in each of the crane members. (Use a scale where 10 mm represents 200 N.) 1200 N 7. A weight of 2000 N is suspended by a rope attached to a hook firmly fixed to a roof joist. A second rope is attached to the vertical rope and pulled horizontally until the rope makes an angle of 30 to the vertical as shown. Determine the horizontal pull on the rope and the force on the hook. 2000 N 8. The figure below shows a cranked lever that is part of a gear-change mechanism. Find the resultant force FR acting on the hinge pivot and the angle . 750 N FR 600 N 14 Standard Grade Technological Studies: Mechanical Systems Levers Figure 1(a) shows an early lever. The large boulder is too heavy to move by pushing it. By using a small boulder as a pivot point and a branch as a lever, it is possible to amplify the force applied to the large rock. The further from the pivot the effort is applied, the easier it is to move the large rock or load. Figure 1(a) Figure 1(b) When a weight is attached to one side of a lever to assist the user, it is known as a counterbalance. A universal systems diagram of a lever is shown in figure 2. A lever system changes an input force and an input motion into an output force and an output motion. INPUT FORCE INPUT MOTION OUTPUT FORCE LEVER SYSTEM OUTPUT MOTION Figure 2 The point that a lever pivots about is called a fulcrum. A line diagram of a lever is shown in figure 3. The input force is called the effort and the input motion is the distance moved by the effort force. The output force is called the load and the output motion is the distance moved by the load. EFFORT DISTANCE MOVED BY EFFORT LOAD DISTANCE MOVED BY LOAD Figure 3 The lever is a force multiplier and is normally used to get a large output force from a Standard Grade Technological Studies: Mechanical Systems 15 small input force. However, it can also be used as a distance multiplier, giving a large output movement for a small input motion; but it cannot do both at the same time. Figure 4 below shows a lever system designed to move heavy machine castings from a lower level to a position of installation. The castings must be lifted 200 mm. EFFORT = 260 N LOAD = 750 N 600 mm Figure 4: machine-loading lever system Force multiplier ratio In the lever system shown in figure 4 above, the load being lifted is about three times more than the effort being applied. The load divided by the effort gives a ratio. This ratio is a force multiplier, or how much more load can be lifted compared to the effort. The lever in figure 4 therefore has a force-multiplier ratio of 2.88 (a ratio has no units of value). Example 1 Find the force-multiplier ratio for the lever in figure 4 above. Force-multiplier ratio = load effort = 750 N 260 N = 2.88 Movement-multiplier ratio The force multiplier ratio appears to give the user something for nothing. The user is only applying about a third of the force to move the load. However, it can be seen from figure 4 that the effort side of the lever has to move much further than the load side. The ratio of the distance moved by the effort, divided by the distance moved by the load, is known as the distance-multiplier ratio. The lever in figure 4 therefore has a distance-multiplier ratio of three (again a ratio has no units of value). 16 Standard Grade Technological Studies: Mechanical Systems Example 2 Find the distance-multiplier ratio for the lever in figure 4 above. Movement-multiplier ratio = distance moved by the effort distance moved by the load = 600 mm 200 mm =3 Efficiency Owing to the effects of friction and inertia associated with the movement of any object, some of the input energy to a machine is converted into heat, and losses occur. Since losses occur, the energy output of a machine is less than the energy input; thus the mechanical efficiency of any machine cannot reach 100 per cent. The efficiency of a lever system is found by dividing the force ratio by the movement ratio, with the efficiency given as a percentage. The result of the above division is multiplied by 100 to give the percentage efficiency value. Example 1 Find the efficiency of the lever system shown in figure 4. Efficiency (η) = Force Ratio Movement Ratio 100 η = 2.88 100 3 η = 96 The system shown in figure 4 has an efficiency of nearly 100 per cent. No system can be 100 per cent efficient; there are always losses. The losses in a lever system consist of energy lost to friction at the fulcrum of the lever and the energy lost in strain as the lever bends slightly. In some cases a small amount of energy will also be lost in the form of sound. Remember, no machine is 100 per cent efficient. Common energy losses include heat energy due to friction, strain energy and sound energy. Standard Grade Technological Studies: Mechanical Systems 17 Levers: task 1 Draw a universal system diagram of a lever system. Label the diagram input, process and output. Complete the line diagram of a lever shown below. You should identify the load, effort and fulcrum. INPUT OUTPUT Levers: task 2 Calculate the force-multiplier ratio of the following levers. Show all working. EFFORT 1OO N 18 EFFORT 300 N EFFORT 200 N LOAD 400 N EFFORT 50 N LOAD 100 N Standard Grade Technological Studies: Mechanical Systems Levers: task 3 A diagram of a lever system is shown below. (a) (b) (c) (d) Find the force-multiplier ratio of the lever system. Calculate the movement-multiplier ratio of the lever. Calculate the efficiency of the system. Identify possible efficiency losses in the system. Show all calculations. EFFORT = 150 N LOAD = 450 N 650 mm 200 mm (a) Force ratio = (b) Movement ratio = (c) Efficiency (η) = (d) Possible efficiency losses in a lever system = Standard Grade Technological Studies: Mechanical Systems 19 Classes of levers Levers can be divided into three distinct types (classes) determined by the position of the load, effort and fulcrum. Applications of their use are found almost everywhere, from the home or school to equipment on the space shuttle. The classes of levers are as follows. Class 1 In class 1 levers the effort is on one side of the fulcrum and the load is on the opposite side (figure 5). Class 1 levers are the simplest to understand: the longer the crowbar the easier it is to prise open the lid. LOAD EFFORT FULCRUM OR PIVOT Figure 5 Class 2 In class 2 levers the fulcrum is at one end of the lever and the load and the effort are spaced out on the other end of the bar. The load must be closer to the fulcrum than the effort (figure 6). A wheelbarrow is a good example of a class 2 lever. The wheel is the fulcrum, the load is in the container area and the effort is applied to the handles. Similarly, a door has a hinge (fulcrum), the load can be considered as acting in the door’s centre of gravity and the effort is applied as far from the hinge as possible. LOAD EFFORT FULCRUM Figure 6 Class 3 Class 3 levers are similar to class 2 levers except that now the effort is closer to the fulcrum than the load (figure 7). This means that more effort has to be applied to move the load. This type of lever is used when mechanisms require a large output movement for a small input movement. 20 Standard Grade Technological Studies: Mechanical Systems EFFORT FULCRUM LOAD Figure 7 Examples of various types of lever are shown below; in some cases it is difficult to tell exactly into which class they fit. E E F E F L L C A B F L F E L E E L F L L Standard Grade Technological Studies: Mechanical Systems E 21 Levers: task 4 Complete the following list in a table format. 22 Name the equipment. Draw a line diagram with arrows showing the fulcrum, effort and load. Name the class of lever. Standard Grade Technological Studies: Mechanical Systems Levers: task 5 Calculate the force multiplier ratios for the following levers and state which class of lever each one belongs to. 1.. F.M.R. Class of lever _________ Class of lever _________ 10N Standard Grade Technological Studies: Mechanical Systems 23 Levers: task 6 In the printed version of these materials, issued to Scottish schools in August 2001, this page contained embedded copyright material. For copyright reasons that material has been removed for this website version. In order to see the completed text for this page Scottish schools are advised to refer to their copy of the printed version. For other users the complete pack is available from Learning and Teaching Scotland, priced £24.00. Using your CD-ROM The New Way Things Work, try to answer the following questions from Principles of Science (Levers) in an interactive way. 1. When rotating a lever mechanism what other name can be used when effort is applied? 2. Name two related machines that use levers. 3. Explain in your own words how a lever mechanism is used in a car’s clutch system. 4. What class of lever is a can opener? Sketch a line diagram to show effort, fulcrum and load. 5. How does a lever system work in a fire extinguisher? 6. What class of lever is used in an aneroid barometer? 24 Standard Grade Technological Studies: Mechanical Systems Moments The sketch in figure 8 shows a weight attached to a metal rod, and the rod is free to rotate around a hinge (pivot) P. If the rope holding the weight stationary is cut, what happens to the rod? If the rope is cut, the force on the weight causes the rod to swing or turn around the pivot. This ‘turning effect’ is called a moment. The weight in figure 8 shows a moment of 20 Nm (10 N 2 m). A moment is measured in newton-metres. As long as the rope is not cut, the weight and rod are held in balance by the force in the tie rope. When any system is in a steady state it is said to be in equilibrium. ROPE WEIGHT HINGE P 2m TURNING EFFECT Figure 8 The lever system in figure 9 shows a lever that is in a state of equilibrium (balance). The input force is tending to turn the lever anticlockwise; the load is tending to turn the lever clockwise. The forces on each end of the lever are exerting a moment: one clockwise, the other anticlockwise. If the beam (lever) is in equilibrium, both of these moments must be equal. FORCE (10 N) Figure 9 Standard Grade Technological Studies: Mechanical Systems 25 The principle of moments states that the sum of the moments must equal zero or the sum of the clockwise moments must equal the sum of the anticlockwise moments. The Greek letter stands for ‘the sum of’ and can be used as a shorthand way of writing the principle of moments: CWM = ACWM F1¹ d1 = F2 d2 The force times the distance turning the lever clockwise is equal to the force times the distance turning the lever anticlockwise. As stated, moments are measured in newtonmetres. It can be seen that the moment on one side of the lever is equal to the moment on the other side. (Work done = force distance in the direction of motion.) Example 4 Using the lever system in figure 10, use the principle of moments to show that the lever is in equilibrium. Figure 10 Answer For equilibrium, the CWM = ACWM. A moment is a force multiplied by a distance CWM = ACWM F1¹ d1 = F2 d2 The load is exerting a clockwise moment; that is, it is tending to make the lever turn clockwise. Clockwise moment = 200 N 2 m = 400 Nm The effort is exerting an anticlockwise moment. Anticlockwise moment = 400 N 1 m = 400 Nm CWM = ACWM Therefore the lever is in a state of equilibrium. 26 Standard Grade Technological Studies: Mechanical Systems Moments: task 1 Use a balanced lever similar to the one in the line diagram shown below, which is available from your teacher. Use a set of weights as a load. Use the spring balance to apply the effort to the system for each of the load positions. LOAD PIVOT EFFORT 1 2 3 Suspend the load from position 1 on the load side of the lever. Measure the effort required to balance the lever using a spring balance. Record the effort in the table below. Move the load to positions 2 and 3 and record the effort required for balance each time. Position 1 Position 2 Position 3 Load Effort Calculate the force multiplier ratio for each position. Position 1 Position 2 Position 3 Complete this statement. As the load gets further away from the fulcrum, the effort required to balance it … Standard Grade Technological Studies: Mechanical Systems 27 Example 5 A car footbrake uses a lever action to amplify the force transmitted by the driver to the braking system when the driver’s foot presses the foot-pedal. If the driver’s foot can exert a force of 5000 N, what force will be transmitted to the braking system? 5000 N INPUT 500 mm FORCE TO BRAKING SYSTEM (LOAD) 100 mm FULCRUM Figure 11 This is a class 2 lever. Take moments about the fulcrum to find the force on the braking system. Notice the distance from the fulcrum to the input is 600 mm. The input tends to make the lever turn clockwise; the braking system is opposing the input and so acts to turn the lever anticlockwise. The principle of moments states that CWM = ACWM F1 d1 = F2 d2 5000 N 0.6 m = braking force 0.1 m braking force = 5000 N 0.6 m 0.1 m braking force = 30,000 N or 30 kN 28 Standard Grade Technological Studies: Mechanical Systems Moments: task 2 Use the principle of moments to find the missing force or distance in the following problems. Show all working. E=? L = 5 kN 0.9 m CWM = ACWM 0.3 m FULCRUM E = 50 N L=? 200 mm CWM = ACWM 40 mm FULCRUM E = 480 N L = 960 N 300 mm CWM = ACWM d=? FULCRUM E = 400 N L = 1200 N d=? CWM = ACWM 0.2 m FULCRUM Standard Grade Technological Studies: Mechanical Systems 29 Moments: task 3 The hand-cutters shown are used to cut thin metal with the effort and load shown. (a) Draw a suitable line diagram. (b) What effort will have to be applied if the force required in the hand-cutters to shear metal is 1.5 kN? Moments: task 4 The diagram below shows a tower crane carrying a load of 90,000 N. At the other end a counterbalance load is applied. (a) Explain why the crane would be unstable without the counterbalance. (b) Is it an advantage for the counterbalance to be able to move, either towards the centre of the crane or away from its centre? (c) The crane in the diagram is lifting a load of 90,000 N, which is 6.3 m away from the tower. How far from the tower should a 100,000 N counterbalance be placed so that the crane remains stable? 30 Standard Grade Technological Studies: Mechanical Systems Moments: task 5 A single-lever monobloc tap is shown below. (a) If the length of the handle is 250 mm and the effort to turn it is 15 N, what moment would close the tap valve? (b) What is the benefit of this type of tap? (c) Where would this type of tap be very useful? Moments: task 6 When a fish has been hooked, the pull from the fish is 22 newtons at right angles to the fishing rod. The pivot is at the end of the rod, which is 2.4 metres long. The angler applies an effort at 0.4 metres from the end of the rod. (a) Draw a line diagram with dimensions, loads, pivots, etc. (b) Calculate the anticlockwise turning moment applied by the fish. Standard Grade Technological Studies: Mechanical Systems 31 (c) Calculate the effort the angler must apply to stop the rod from turning anticlockwise. (d) The angler has to exert a greater effort than the load applied by the fish to maintain equilibrium. Is this an advantage or disadvantage to the angler? The bell-crank lever The bell-crank lever shown in figure 12 is used to transmit the input force and motion through a right angle. It gets its name from part of the bell mechanism used to summon servants in Victorian houses. By varying the lengths of the two arms of the bell crank, it is possible to use it either to magnify an input force or to magnify an input motion. Figure 12 Example 6 Use the principle of moments to determine the length of the output side of the bellcrank lever in figure 12. Calculate the force-multiplier ratio of the lever. Answer This is a class 1 lever with a right-angled bend. To find the distance ‘d’, take moments about the fulcrum. Assume the lever is in equilibrium so that the output force opposes the input force. CWM = ACWM F1 d1 = F2 d2 600 N d = 400 N 0.15 m 32 Standard Grade Technological Studies: Mechanical Systems d = 400 N 0.15 m 600 N d = 0.1 m The force-multiplier ratio = load effort = 600 N 400 N = 1.5 Standard Grade Technological Studies: Mechanical Systems 33 Linkages Levers are often linked together to transmit force or motion. A linkage consists of two or more levers connected together. Linkages are useful for changing the direction of an input or for giving greater force or distance amplifications. Five common linkages found in many machines are shown below. Figure 1 Reverse motion output; distance from fulcrum is the same, therefore, same force. Figure 2 Reverse motion output, but fulcrum is nearer the output so the force is amplified. Figure 3 Input and output motion are the same, but there is a large amplification of force. Figure 4 Reciprocating motion transformed to rotary motion. 34 Figure 5 Lazy tongs linkage for extra reach. Standard Grade Technological Studies: Mechanical Systems Linkages: task 1 A system diagram of a lever mechanism is shown below. The requirements state that when the lever is pushed down, the output should rise. The force-multiplier ratio should be 2:1. INPUT DOWNWARD FORCE OUTPUT LEVER MECHANISM UPWARD FORCE SYSTEM DIAGRAM INPUT OUTPUT MECHANISM Design a suitable linked lever system that will achieve the desired output. A sketched diagram should show: a line diagram the load, effort and fulcrum your notional load and effort indicated in newtons your calculation showing the force ratio. Answer Evaluate your solution by stating whether the solution satisfied the requirements identified from the specification in the question. Standard Grade Technological Studies: Mechanical Systems 35 Linkages: task 2 A counterbalance lever is required for a small city-centre car park. Requirements The car park is a small, one-person business. The operator wants a system that can be opened easily by one person. The system must stay open until closed by the operator and the system must be safe for the operator’s and customers’ cars. The following criteria have been identified from the requirements. The car park barrier must: lift with a small effort be operated initially by hand be able to be locked in an upright position be improved to operate with a simple electronic circuit. Design a suitable system to satisfy the design requirements. State how you would test for the following features. A suitable lever system Manual lift and lower, showing the force-multiplier ratio Lock in raised position Electronic circuit to automate the system Safety Draw a sketch of your solution and state whether your system satisfied the criteria. Write down how you think you could have improved your solution. 36 Standard Grade Technological Studies: Mechanical Systems