D & T RESISTANT MATERIALS

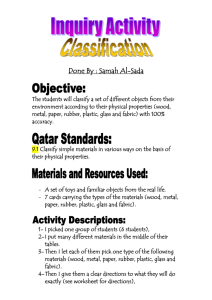

advertisement