Chapter 4 Imperfections in solids HW2: 3, 4, 6, 8, 9, 15, 16, 21 Due

advertisement

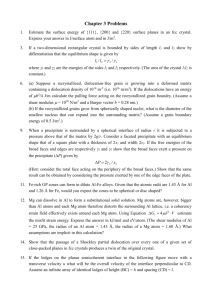

Chapter 4 Imperfections in solids HW2: 3, 4, 6, 8, 9, 15, 16, 21 Due Wensday 13/10/2010 Why study imperfections in solids? Properties of materials are affected by the presence of imperfections Crystalline defect: a lattice irregularity having one or more of its dimensions in the order of an atomic diameter Classification of imperfections is made according to geometry or dimensionality of the defect. 3 basic types of imperfections: 1. Point defects (PD). 2. Line defects (dislocations). 3. Surface defects, SD. Point Defects (PD) Localized disruptions in otherwise perfect atomic or ionic arrangement in a crystal structure. These imperfections may be introduced by movement of atoms or ions when they gain energy: 1 1. by heating, 2. during processing, 3. by introduction of impurities, 4. doping Impurities: elements or compounds that is present from raw materials or processing. Dopants: elements or compound that is deliberately added, in known concentrations, at specific location in the microstructure, with an intended beneficial effect on properties or processing. Vacancies and self-interstitials Produced when an atom or an ion is missing from its normal site in the crystal structure (Figure 1). Are introduced into metals & alloys during solidification at high temperatures. 2 Figure 1: Point Defects: (a) Vacancy (b) Interstitial (c) small substititional atom (d) large substititional atom (e) Frenkel defect (f) Schottky defect Concentration of vacancies increases exponentially with T: Qv N v N exp( ) kT Nv = total no. of vacancies per cm3 N = no. of atoms per cm3 Qv = energy required for the formation of a vacancy 3 k = Gas constant = 1.38×10-23J/atom.K = 8.62×10-5 eV/atom.K T = absolute temp in K N A N A For most metals, the fraction Nv/N just below the melting point is on the order of 10-4 A self-interstitial: an atom from the crystal that is crowded into an interstital site, a small void space that under ordinary circumestances is not occupied Example 4.1 Impurities in solids The addition of impurity atoms to a metal will result in the formation of a solid solution and/or a new 2nd phase depending on: 1. Kinds of impurity 2. Their concentrations 3. Temperature Solvent (host): element or compound that is present in the greatest amount Solute: element or compound present in a minor concentration 4 Solid solutions A solid solution forms as the solute atoms are added to the host material, the crystal structure is maintained and no new structures are formed. A solid solution is also compositionally homegenous, the impurity atoms are randomly and uniformly dispersed within the solid. Substitutional Defects Introduced when one atom or ion is replaced by a different type of atom or ion (Figure 1). Can be introduced either as an impurity or as a deliberate addition. No. of defects is relatively independent of T. Examples: dopants such as P or B into Si. If we add Cu to Ni, Cu atoms will occupy crystallographic sites where Ni atoms would normally be present. Rules for Substitutional solid solution: 1. Atomic size factor: difference in atomic radii between the two atom types is less than 15%. Otherwise, the solute atoms will create substantial lattice distorsions and a new phase will form. 2. Same Crystal structure for both solvent and solute 5 3. Electronegativity: the more electropositive one element and the more electronegative the other, the greater is the likelihood that they will form an intermetallic compound instead of a substituional solid solution 4. Valences: a metal will have more of a tendency to disolve another metal of higher valence than one of a lower valence Interstitial Defects Formed when an extra atom or ion is inserted into the crystal structure at a normally unoccupied position (Figure 1). C atoms occupy interstitial sites in Fe crystal structure, introducing a stress in the localized region of the crystal in their vicinity. If there are DLs in the crystals trying to move around these types of defects, they face a resistance to their motion, making it difficult to create permanent deformation in metals & alloys. This is one important way of increasing strength of metallic materials. No. of interstitial atoms or ions in structure remain nearly constant with T. Specification of composition Weight % basis 6 m1 C1 100 m1 m 2 Atom % basis m1' nm1 A1 nm1 1 C1 100 nm1 nm 2 Composition Conversions: Eq. 4.6 and 4.7 Concentration in terms of mass of one component per unit volume of material: Eq 4.9 Average density and average atomic weight: Eq4.10 and 4.11 Example 4.2 Example 4.3 7 Dislocations (DLs) DLs are line imperfections in an otherwise perfect crystal. 3 types of DLs: screw, edge, & mixed. DLs are useful in increasing strength of metals & alloys. Edge DL (EDL) Slicing partway through a perfect crystal, spreading the crystal apart, & partly filling the cut with an extra plane of atoms. The bottom edge of this inserted plane represents the EDL. BV is perpendicular to the EDL. Screw DLs (SDL) F4.4: Cut partway through a perfect crystal and then skew the crystal one atom spacing. 8 Following a crystallographic plane one rev around axis on which crystal was skewed, starting at a point x & traveling equal atom spacing in each direction, we finish one atom spacing below our starting point (y). The vector required to complete the loop & return us to our starting point is the Burgers vector (BV) b. The axis, around which we trace this path, is the screw DL. BV is parallel to the SDL. Mixed DLs 9 When a shear force acting in direction of BV is applied to a crystal containing a DL, the DL can move by breaking the bonds between the atoms in one plane. The cut plane is shifted slightly to establish bonds with the original partial plane of atoms. This shift causes DL to move one atom spacing to the side (F4.8a). If this process continues, DL moves through the crystal until a step is produced on the exterior of the crystal; the crystal has then been deformed. The speed with which DLs move in materials is close to or greater than the speed of sound. 10 Surface defects (SD) SDs are the boundaries, or planes, that separate a material into regions, each region having the same crystal structure but different orientations. Grains and grain boundaries. By reducing the grain size, we increase the no. of grains, and hence increase the amount of grain boundary area. Any DL moves only a short distance before encountering a GB and being stopped, and strength of metallic material is increased. Small angle grain boundaries (SAGB): an array of DLs that produces a small mis-orientation between the adjoining crystals (F4.19). Because the energy of surface is less than that of a regular GB, the SAGB are not effective in blocking slip. 11 SAGB formed by EDL are called tilt boundaries, and those caused by SDL are called twist boundaries. Stacking Faults: which occur in FCC metals, represent an error in the stacking sequence of CPP. Normally a stacking sequence of ABCABCABC is produced in a perfect FCC crystal. Suppose the following sequence is produced: o ABC ABABC ABC This small region, which has HCP stacking sequence instead of FCC stacking sequence, represents a stacking fault. Stacking faults interfere with the slip process. Twin Boundaries (TB): is a plane across which there is a special mirror image mis-orientation of the crystal structure (F4.20). Twins can be produced when a shear force, acting along the twin boundary, causes the atoms to shift out of position. Twinning occurs during deformation or HT of certain metals. TB interferes with the slip process and increase the strength 12 of metal. The movement of TB can also cause a metal to deform. The effectiveness of surface defects in interfering with slip process can be judged from surface energies. Microscopic Examination Grain size and shape are only two features of what is termed the microstructure. Applications of microstructural examination: 1. Understand the relation between properties and structure 13 2. Predict properties of materials once these relationships have been established. 3. Design alloys with new property combinations 4. Monitor and control results of heat treatment 5. Study the mode of mechanical fracture Microscopic techniques 1. Optical microscopy 2. Electron microscope o Transmission Electron microscope o Scanning Electron microscope 3. Scanning probe microscopy Optical microscopy Used in a reflecting mode Contrasts in the image produced result from differences in reflectivity of the various regions of the microstructure Specimen surface must be ground and polished to a smooth and mirrorlike finish Microstructure is revealed using chemical etching Chemical reactivity of the grains of some single phase materials depends on crystalographic orientation In a polycrystalline specimen, etching char vary from grain to grain F4-11 Small grooves form along grain boundaries as a result of etching. Since atoms along GB regions are more chemically active, they dissolve at a greater rate than those within the grains. GBs reflect light at an angle different from that of the grains themselves (F4-12) 2000X Electron microscopy An image is formed using beams of electrons 14 A high velocity electron will become wave like with a wave length that is inversely proportional to its velocity The electron beam is focused and the image formed with magnetic lenses Transmission Electron microscope (TEM) Image seen with TEM is formed by an electron beam that passes through specimen Transmitted beam is projected onto a fluorscent screen or a photographic film 1000,000X Scanning Electron microscope (SEM) Surface of specimen to be examined is scanned with a beam of electrons and the reflected beam of electrons is collected then displayed at the same scanning rate on a cathode ray tube. The surface may or may not be polished and etched but it must be electrically conductive Very thin metallic surface coating must be applied to nonconductive materials Up to 50,000X Scanning probe microscopy (SPM) Neither light nor electrons is used to form image Microscope generate a topographical map on an atomic scale 109X 3-D magnified images Variety of enviroments SPM employ a tiny probe with a very sharp tip that it brought into close proximty of specimen surface Probe is raster scanned across the plane of the surface 15 During scanning, probe experiences deflections perpendicular to this plane in response to electronic or other interactions between the probe and the specimen surface The in surface plane and out of plane motions of the probe are controlled by piezoelectric ceramic components. Grain Size determination Intercept method ASTM method Standard comparison charts Each is assigned a number ranging from 1 to 10 (grain size number) at 100X N =2n-1 n =grain size number N = average number of grains per square inch at 100X 16