Lesson Five Plans - Michigan Technological University

advertisement

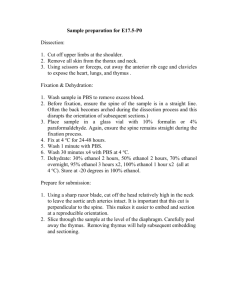

Wood to Wheels- Inquiry Lesson Plan Lesson Introduction ● Title:How can a solution of ethanol and water be separated? ● Subject/ target grade: 10 ● Duration: 1 45 minute period ● Setting: science lab ● Learning Objectives: Student will be able to perform a distillation and separate water and ethanol. They will be able to describe the process and how it occurs. ● Wisconsin Standards: G.12.2 Design, build, evaluate, and revise models and explanations related to the earth and space, life and environmental, and physical sciences C.12.3 Evaluate* the data collected during an investigation*, critique the datacollection procedures and results, and suggest ways to make any needed improvements C.12.4 During investigations*, choose the best data-collection procedures and materials available, use them competently, and calculate the degree of precision of the resulting data C.12.5 Use the explanations* and models* found in the earth and space, life and environmental, and physical sciences to develop likely explanations* for the results of their investigations* C.12.6 Present the results of investigations* to groups concerned with the issues, explaining* the meaning and implications of the results, and answering questions in terms the audience can understand ● Lesson Overview: Students will perform a distillation using the products of their fermentation reaction in the previous lesson. Students will produce a small amount of purified ethanol after their distillation which can be burned in a watch glass or alcohol burner. Lesson Core ● The Guiding Question: How can a solution of ethanol and water be separated? ● Materials and Equipment Needed: Equipment Distillation apparatus-glass elbow, condenser, glass beads. shaped flask, distillation column, Heating mantle or hot plate Boiling chips Graduated cylinder or other container for collection of ethanol Rubber tubing 2 thermometers 2 ring stands with clamps Reagents Fermentation media from previous lab or solution of water and ethanol. ● Safety precautions: Appropriate lab attire, safety glasses, use caution with heating mantle or hot plate, beware of hot glass, keep ethanol away from open flame(flammable). ● Advanced Preparation: See previous lab for fermentation of glucose to produce ethanol. Distillation apparatus should be set up. Students will place their fermentation product into the collective distillation pot. ● Background Information for Teachers: Distillation is a physical process to separate mixtures which have different boiling points. The vapor of the ethanol will evaporate first. The thermometer measuring the gas temperature should read 75-80oC when the ethanol is evaporating. When the ethanol has completed its evaporation the water will start to boil at a higher temperature and the temperature of the vapor will start to increase. ● Engage: How can we separate two liquids that are miscible? Where can we find the boiling points of water and ethanol? How will we know what is boiling? Have students complete research and write the boiling points of both ethanol and water in their lab journals. What is the temperature of water and ethanol vapor? Write this in your lab journal. How does knowing the boiling points help us? ● Building on prior knowledge: What are other ways that we have separated mixtures? What makes separating a solution different? Why would we want to separate a solution? ● Pre-teaching: What were the products of your fermentation? Can the solution in your flask be used as a fuel? Why or why not? How can we remove the ethanol from the water so it may be used as a fuel? ● Explore: 1. Place fermentation media from lab the previous day into the distillation pot. Be careful not to mix or swirl the flask before pouring it in so the cell mass remains at the bottom of the flask and is not poured into the pot. 2. Place the pot on the heating mantle or got plate and turn heat up to the point of boiling. Watch thermometers in the pot and vapor. When the thermometer measuring the vapor is reading 75-80oC ethanol is being condensed in the condenser. 3. Make sure the is a graduated cylinder to catch condensate. 4. When temperature of the vapor starts to rise and exceeds 80oC remove the collection container. After this point water will start being distilled and will dilute the ethanol in the collection container. 5. Measure a small amount of the ethanol and calculate the density. Using the density curve attached calculate the percent ethanol captured. 6. Have the teacher either burn the ethanol in a watch glass or alcohol burner. Make a note of how much water is left behind when the sample is burned. ● Explain: Students should record their ethanol percent in their lab journals. Have students list their ethanol percent on the board and record the percent from other groups into their lab journals. ● Elaboration: Discuss with students: Why did some groups have a greater amount of ethanol in their sample? How did measuring the density tell you the purity of the ethanol? Is their any way that we could produce ethanol with a greater purity? What other applications of distillation are used in every day production? ● Evaluate and Lesson Closure: Students will be evaluated based on their lab notebooks and data and results. Students should write a short paragraph in their lab journals discussing the process of distillation. If we could increase the purity of ethanol would it run better in our engines? How does all of this relate to alternative fuels and our lives? What research should be done to help this problem? Lesson Extension ● Additional Resources: See picture of distillation apparatus used at MTU JSA - distillation http://swc2.hccs.edu/pahlavan/2423L7.pdf http://awsnabeel.xanga.com/540284105/item/ http://www.chem.wisc.edu/courses/342/Fall2006/Experiment_2.pdf Ethanol Data Boiling point: Density: 78.5°C 0.785 g ethanol / cm3 ethanol Density of Ethanol – Water Mixtures at 25° C Volume % of ethanol Mass % Density (g/ cm3) 0 10 0 7.98 1.00 0.9835 20 16.16 0.9717 30 24.54 0.9596 40 33.24 0.9448 50 42.37 0.9265 60 52.03 0.9053 70 62.34 0.8815 80 73.45 0.8551 90 100 85.65 100 0.8249 0.787 David R. Shonnard, Department of Chemical Engineering, Michigan Technological University