Glossary of Terms - Rowan University

advertisement

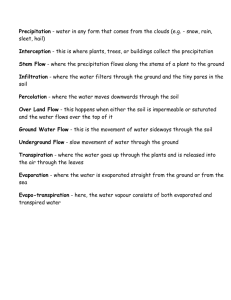

Senior Clinic II Soil Monitoring SOIL MONITORING FOR EDUCATIONAL APPLICATIONS: SENIOR CLINIC II TINA CONROY DREW DEFINIS MAY 4, 2000 Final Report Page 0 of 9 Senior Clinic II Soil Monitoring ABSTRACT The soil monitoring Senior Engineering Clinic project for the Spring 2000 semester focuses on the development and understanding of geotechnical field and laboratory equipment. The main objective is to incorporate various laboratory and field soil analysis techniques into Freshmen and Sophomore Clinics, as well as into standard undergraduate Geotechnical Engineering courses. The currently available laboratory equipment includes the direct shear, flexible wall permeameter, and the consolidation apparatus. Field equipment to be utilized includes soil augers, soil sampling equipment, infiltrometer, and a soil moisture meter. All of the above will be assembled and appropriate operations manuals developed. A second project deliverable involves the selection of a suitable instrument to measure soil pH and moisture content. The final objective of the project is to construct a web page, which will document progress and display work. To date, the project team has recommended a soil pH and moisture content meter; assembled, documented and tested the soil consolidation apparatus; assembled, documented and ran a needed deaerator; assembled and prepared the Little Beaver auger; and composed a project web page. Final Report Page 1 of 9 Senior Clinic II Soil Monitoring PROJECT OBJECTIVES The soil monitoring Senior Engineering Clinic project for the Spring 2000 semester focuses on the development and understanding of geotechnical field and laboratory equipment. This task is in preparation for the broader objective of incorporating this equipment into Freshmen and Sophomore Clinics, as well as standard courses in Geotechnical Engineering. The direct shear, flexible wall permeameter, and the consolidation apparatus are the laboratory equipment to be utilized. A user’s manual is to be developed. Soil augers, soil sampling equipment, infiltrometer, and a soil moisture meter are to be assembled along with development of a user’s manual. The determination of a suitable instrument to measure soil pH and moisture content is another deliverable of the project. With the understanding of their operation, field activities and laboratory experiments using such equipment will be devised for the Freshmen and Sophomore Clinics. A final objective is the construction of a web page to document progress and display work. COMPLETED WORK The project began with a thorough review of possible soil moisture content devices. Based on our findings, a recommendation was made for a specific moisture meter. A web page has been constructed and updated weekly. The following objective was to develop procedures for the direct shear, flexible wall permeameter, and the consolidation apparatus. The consolidation apparatus is the only one of the three testing machines utilized thus far. A procedure has been developed and three test runs have been conducted. To date, all trials have been unsuccessful in collecting data. In using the Final Report Page 2 of 9 Senior Clinic II Soil Monitoring consolidation apparatus, it is imperative to use deaerated water. Therefore, a short procedure was developed for operating the Nold Deaerator. In regards to the field equipment, testing of the soil auger has been successfully completed. We have also begun to incorporate the laboratory work with applications for Freshman and Sophomore clinics. Projects and procedures that introduce geotechnical engineering on an understandable level have been developed. The following sections of the report will expand upon these topics. MOISTURE METER The desired instrument to measure the moisture content of soils in the field must be both accurate and economical. The most accurate method involves the use of a nuclear moisture gauge. This technique offers reliable data, however it is expensive and a license is required to operate it. This method is therefore both uneconomical, and impractical for the use of students. Many inexpensive moisture meters were researched. These devices are mainly suited for agricultural purposes. They do not provide the accuracy needed for geotechnical analysis, nor feature digital data recording capabilities in the field. The method recommended is Time Domain Reflectometry (TDR). TDR was originally developed as a method to detect faults in electronic systems. This technique is currently applied to soil analysis for geotechnical and agricultural purposes. TDR works by determining the time it takes an electronic pulse to travel along rods probing into the soil. The pulse travels through the cable until the probe handle reflects it back to the instrument. These reflections are analyzed by the TDR system to form travel times. The Final Report Page 3 of 9 Senior Clinic II Soil Monitoring travel times are then automatically converted to water content measurements. Data can be extrapolated in the field directly to a lap top computer. This technique is accurate, and more importantly, TDR devices are within our budget. Dr. Sukumaran will make the final selection from the various TDR units. CONSOLIDATION APPARATUS Geotechnical engineering applies principles of soil and rock mechanics to the design of civil engineering structures (Das, 1998). This is why all civil engineering students learn its basic principals and theories. One parameter that is essential to civil engineering is the consolidation settlement. It is the compression of soil layers due to a change in volume of void spaces in a soil and the relocation and deformation of soil particles. It determines whether a soil is capable of supporting a given load without significant deformation. The GEOTest computer controlled back pressure consolidation apparatus measures a given soil’s consolidation settlement rate at varying pressures. The sections below describe the theory behind the consolidation test and analysis of resultant data. Theory of Consolidation Analysis Precise equipment such as the GEOTest computer controlled back pressure consolidation apparatus was not always available. Terzaghi developed the original consolidation testing procedure. This test procedure used an oedometer to measure the increasing pore pressures in a soil. The soil specimen is placed in a cutting shoe similar to that used in our procedure (see Appendix c). Two porous stones are placed on either end of the sample and a specified load is applied to the top with a lever arm. A micrometer dial or Final Report Page 4 of 9 Senior Clinic II Soil Monitoring digital gauge measures compression of the sample. Every 24 hours or so, the load is doubled. At the end of the procedure, the dry weight of the sample is determined. Knowing the initial height of the sample was 1 inch and the change in compression of the soils during the test, a plot of time versus deformation can be created and the change in void ratio with respect to change in pressure can be determined. Application of Consolidation Data Consolidation analysis tests the settlement of a soil under a specified stress. Before a structure can be built on a soil, it is imperative that the settlement of the soil be known, in order that the structure does not “sink” or “tilt” (i.e. Tower of Pisa). Sandy soils will settle almost immediately due to their high hydraulic conductivity where clayey soils have an extended settling time in the primary and secondary consolidation phases. The void ratio versus pressure plots illustrates whether a soil’s normally or overconsolidated. All tests will most likely show some overconsolidation due to release of pressure during sampling. Fortunately, there is a method to reconstruct the laboratory results to simulate the actual field results more closely (Das, 1998). This method is described in Appendix B. Consolidation Analysis Laboratory After assembly of the GEOTest computer controlled back pressure consolidation apparatus, an initial test run was conducted using a loam soil from the laboratory. The soil was passed through a #4 sieve and saturated before analysis. For test procedure, Final Report Page 5 of 9 Senior Clinic II Soil Monitoring refer to Appendix C. The run was inconclusive when the water from the deaerator was not transferred to the consolidation dome. It was later determined that the supply pressure valve had not been opened. The second trial resulted in no data, when the water reservoir was still left dry. In response for trial three, the deaerator was raised above the hieght of the dome to supply an elevation head. This was successful. However, due to an oil leak during trial 2, sufficient pressure was not applied to the sample. For more information on results, refer to the website. DEAERATOR When drinking coffee, tea, or any beverage that needs sweetening, it is common to add sugar and stir the beverage to dissolve the sugar and sweeten the taste of the drink. Similarly, air can be dissolved into water through some form of agitation to occupy approximately 2% of the volume of the liquid at room temperature, or 10,000 parts per billion (ppb) dissolved oxygen. The amount of dissolved air fluctuates with temperature, but for the purpose of testing soil the water utilized will most likely be at standard temperature. The removal of air from a liquid (i.e. water) is a process known as deaeration. Deaerating water for the purpose of measuring consolidation in soil specimens is an important preparation before soil consolidation analysis. Any air introduced into the pressurized consolidation apparatus can adversely influence the results. Air in the water could invoke damage to the apparatus through introduction of air into the system. The air Final Report Page 6 of 9 Senior Clinic II Soil Monitoring supplies oxygen promoting algal growth. The growth in turn disrupts the pressures in the system yielding inaccurate results. The premise behind deaeration involves a process known as nucleation. Air can be removed from water by applying a vacuum, but this method alone is slow and inefficient. The deaerator applies a vacuum while simultaneously breaking apart the water molecules with a rotating impeller. As the water molecules separate, bubbles of vacuum and dissolved gas form and rise to the surface. This method can effectively reduce the quantity of dissolved oxygen to 600 ppb in five to six minutes, producing an acceptable level of deaerated water for the consolidation testing. For operations of the deaerator, refer to Appendix D. FIELD EQUIPMENT The sole field equipment used this semester was the Little Beaver earth drill & auger. All other field equipment tools ordered have not yet arrived in their entirety. A tripod to remove drilled augers was received and assembled. However, due to lack of earth drill & auger runs, it was not needed. The Little Beaver earth drill & auger engine was started and let to run for a period of time in order to test the engine. It was then used to drill a four-foot deep hole into a silty loam soil located on the West side of Rowan Hall. The use of the auger was a success. With the proper safety precautions needed for any gas powered engine the auger is easy yet cumbersome to operate. A procedure for starting and operating the auger is provided in Appendix F. This procedure is a supplement to the operating manuals provided by the manufacturer. It does not replace them. Any person Final Report Page 7 of 9 Senior Clinic II Soil Monitoring attempting to use the auger must read and understand the safety precautions and operating instructions provided by the Little Beaver company. FRESHMEN AND SOPHOMORE CLINIC ACTIVITIES A major objective of this clinic project is to develop geotechnical field and laboratory activities for the freshmen and sophomore clinics. These activities should incorporate the newly purchased field equipment to better illustrate geotechnical-engineering principles. The activities must provide some source of independent learning, but also be elementary enough for the underclassmen to understand without a background in geotechnical engineering. A broad topic with multiple applications is needed to easily integrate the activity into a general clinic project such as the baseball field project from the fall ’99 semester. We have proposed two topics and have made preliminary procedures for the activities. Whose topics are as follow: Water - Content Determination The water-content of soils is an aspect of geotechnical engineering that is derived from basic principles, and is of great importance to all civil engineering. Computing the watercontent of soils is an initial test done for all soil examinations prior to the construction of any structure (building, house, foundation, road, underground tanks, etc.). The results of such tests can warrant more sophisticated laboratory tests like the consolidation or triaxial tests. However, the results can also eliminate future tests, which in turn saves time and money. Computing the water-content is a simple field and lab experiment that can be applied to broad multidiscipline engineering projects. See Appendix E1 for a proposed Final Report Page 8 of 9 Senior Clinic II Soil Monitoring procedure. This procedure is written assuming the instructor will give an introduction to geotechnical engineering, and an explanation of the equipment being used. Soil Permeability In geotechnical engineering, an important soil property is permeability. When selecting a material for a landfill cover and liner, soil permeability is essential in order to prevent seepage of leachate into nearby water bodies. For a sophomore clinic project, students can be split into teams. An introduction to soil permeability and an application in geotechnical engineering will be presented. Each team will have a different soil to analyze. All the teams will collect the final data and select the best soil type for a landfill application. The procedure for testing can be found in Appendix E2. Final Report Page 9 of 9 Senior Clinic II Soil Monitoring APPENDICES Appendix A: Glossary of Terms Immediate Settlement – settlement of a dry moist or saturated soil due to elastic deformation without a change in the soil’s moisture content. Primary Consolidation Settlement – settlement of a saturated cohesive soil due to drainage of pore water. Secondary Consolidation Settlement – settlement of saturated cohesive soil due to the plastic adjustment of soil fabrics. Hydraulic Conductivity – ability of water to flow through soil Oedometer – consolidationmeter Normally Consolidated Soil – a soil whose current overburden pressure is its preconsolidation pressure. Overconsolidated Soil – a soil whose current overburden pressure is less than its preconsolidation pressure. Final Report Page 10 of 9 Senior Clinic II Soil Monitoring Appendix B1: Laboratory to Field Results of Normally Consolidated Clay 1. Determine preconsolidation pressure, pc a. Select a point a where the e-log p plot has a minimum radius of curvature b. Draw a horizontal line, ab perpendicular to point a c. Draw a line, ac tangent to the curve d. Bisect angle abc with a line, ad e. Draw a line, gh which extends the linear end of the plot up to intersect line ad at point f f. Draw a line from f perpendicular to x-axis. This is the preconsolidation pressure, pc 2. Determine field void ration, eo using the equations below: eo = Hv / Hs Where: H = Initial sample height = 1in. Hs = Height of solids Hv = Height of voids Ws Hs AGs w Where: Ws = Dry weight of sample A = Area of sample Gs = Specific Gravity of soil solids w = Unit weight of water Hv = H - Hs 3. 4. 5. 6. 7. 8. Calculate 0.4eo Draw line ab from pc perbendicular to x-axis Draw horizontal line cd from eo Draw horizontal line ef from 0.4eo where f is the point where line ef intersects curve Draw line fg where g is the point where line ab and line cd intersect Line fg is the virgin/ field consolidation curve. Appendix B2: Laboratory to Field Results of Overconsolidated Clay 1. 2. 3. 4. 5. 6. 7. 8. 9. Determine preconsolidation pressure, pc – refer to Appendix B1 Draw vertical line, ab from pc Determine effective overburden pressure, po – is current applied pressure Draw vertical line, cd from po Determine field void ratio, eo – refer to Appendix B1 Draw horizontal line, fg from eo & label intersection with line cd as point h Draw line, hi & label intersection with line ab as point j Label 0.4eo conjugate point on curve as k & Draw line jk Line jk is the virgin/ field consolidation curve. Final Report Page 11 of 9 Senior Clinic II Soil Monitoring Appendix C: Operations of Consolidation Appartatus 1. Preparing Sample Clean & weigh cutting shoe Fill cutting shoe with soil and shave soil flush to cutting edge side Push soil in with spacer plate as far as spacer plate permits Shave sample even to flat end of cutting shoe and remove spacer plate Determine weight of soil sample which is now exactly 1” high 2. Installation of Sample & Placing of Dome Check that all knobs are turned clockwise to stop. Turn power on. Remove dome from base and place to side. Put selector valve #5 into load position. Put selector valve #28 & selector switch #27 into incremental position. Open vent valve connected to #6. Put selector switch #26 into “manual” position. Let loading disc move into dome as far as it can go. Clean base, pedestal & consolidation ring. Lubricate the “O” rings on the pedestal & consolidation ring. Lay filter paper on pedestal and trim to fit in ring. Install ring on base. Push it down to contact the base. Place cutting shoe flat facedown containing the sample into recess onto of the ring. Open equalizer valve #13 and purge valve #11 a couple of turns. Transfer sample from shoe into consolidation ring. Place the two part (filter paper & stone) spherical blocks into recess on top of the porous plate holder. Push dome down onto consolidation ring. Make sure the loading plate is all the way up. Put selector switch #27 into “off” position. This will allow the load solenoid valve to move into its top most position. Turn selector valve #5 into back pressure position. Leave vent valve on #6 open. Open saturation valve #17. Check that valve #17 is facing you. If not, lift dome up. Orient it so that the valve is toward you. Lower it down in a straight position over the consolidation ring. Push it down to contact the plastic disc under the base. Rotate it counterclockwise about 1/3 revolution to ENGAGE BAYONET LOCKS. Install EDDI onto dome. Plug in power cord and transmission cable to the connectors on the right and left side of the face accordingly. Do not over tighten thumbscrew #24. Connect the tubing from the top of the saturation water reservoir #14 to connector #15 on the dome. Tighten the nut with a wrench using moderate force. Final Report Page 12 of 9 Senior Clinic II Soil Monitoring 3. Filling in Saturation Water – Applying Back Pressure Open equalizer valve #13. Close purge valve #11. Open valve #17 & attach tubing from the Deaerator. Put selector valve #5 into back pressure position. Open Vent valve on #6. Fill until overflow reservoir #14 is about ½ full. This might take a while. When enough saturate is in the reservoir, close valve #17 & disconnect from the Deaerator. Close vent valve on #6 and put selector valve #5 into load position. Check that back pressure supply valve #9 is closed. Check that selector switch #26 is in “manual” position. Turn load pressure control knob #3 to counter clockwise stop. Open load pressure supply valve #2. Supply pressure panel meter #4 should know indicate the available pressure. Record value. Turn load pressure control knob #3 clockwise to obtain 5psi reading on the test gauge. Note that this pressure is not applied to the sample, because load solenoid valve #19 is closed. Look at applied load panel meter #20. It should read “0” +/-1 digit. Open strain rate valve #29 about 6 turns counter clockwise to make the loading disc contact the sample. Turn selector valve #28 & selector switch #27 into “gradient” position. When applied load panel meter #20 indicates 2 or 3-digit rise put selector switch #27 into “off” position. If you wish “zero” readings on the EDDI, press the green button on its face. Put selector valve #5 into back pressure position. Turn back pressure control knob #10 to counter clockwise stop. Open supply valve #9 by turning it clockwise a fraction of a turn to obtain a 2psi reading on both the pore pressure #21 and applied load #20 panel meters. Using purge valve #11 let some saturation water out in quick squirts until no more air is squirted out. (DO NOT use all the water from the reservoir). Let this initial back pressure equalize in the sample. Closing equalizer valve #13 and taking readings on panel meter #21 can check the degree of equalization. The pore pressure will keep dropping, as long as the sample is taking in water. After equilibrium is reached, control may be turned over to the computer. Select “computer” with switch #26. 4. At End of Computer Test When computer completes test, turn switch #26 into “manual” position. Check that the equalizer valve #13 is open. Put selector switch #27 into “off” position. To drain water from the saturation compartment, turn load pressure control valve #3 clockwise to obtain 5psi reading on panel meter #8. This supplies pressure for back pressure regulator. Turn back knob #10 clockwise to obtain 2psu reading on panel meter #16. Final Report Page 13 of 9 Senior Clinic II Soil Monitoring Attach drain tube to saturation valve #17, & drain side of chassis up about 2” from the table momentarily to get all water out. Reduce back pressure to minimum & close valve #9. Reduce load pressure to minimum by turning knob #3 counter clockwise. Close supply valve #2 and put selector switch #27 into “Incremental” position. Remove EDDI. Turn off power. Disconnect saturation tubing from dome (#14 from #15). Rotate dome clockwise to DISENGAGE BAYONET LOCKS. Insert a good size screwdriver into the groove on the mid height of the consolidation ring and pry upward to break static friction of “O” ring seal. Lift off dome and place to side. Be careful NOT to kink any tubing. Remove spacer block and porous plate. Insert screwdriver into recess on bottom of ring. Pry it from pedestal. Push sample out of ring with porous stone. Wipe off dirt & water from the equipment. Place dome on base for safe storage. Check all knobs are turned to clockwise stop position. Spacer Plates Figure 1. Cutting Shoe Pedestal Base Figure 2. Apparatus Platform Plastic Disc Porous Plate Holder O-Ring Figure 3. Consolidation Ring Final Report Page 14 of 9 Senior Clinic II Soil Monitoring EDDI Bayonet Locks Figure 4. Dome Final Report Page 15 of 9 Senior Clinic II Soil Monitoring Appendix D: Operations of Deaerator Operating the deaerator is rather simple. See figure 5 for an illustration of the device. A connection for the vacuum is made at the bottom of the basin where a vertical pipe can be seen rising to the top. Reinforced tubing is used for this connection because the vacuum will collapse weaker tubing. Water enters the unit from the bottom. It is important to note that the deaerator is not designed to DEAERATOR APPARATUS handle water entering from highpressure sources. Remember to apply the vacuum before filling the basin with water. It is recommended to use a rubber tube from the source of the water Basin to the deaerator. In the event that the vacuum is off when the basin is being filled, the rubber tube will expand and burst before any damage is done to the deaerator. Fill the basin roughly six inches high then clamp the rubber tube closed. Before turning the deaerator on, Deaerated Water Supply be sure to turn the valve in the back perpendicular to the tube exiting from the back of the basin to keep water from Water Source Vacuum Source coming out during deaereation. Run the Figure 5: Connections for the deaerator. deaerator for five to six minutes, or Final Report Page 16 of 9 Senior Clinic II Soil Monitoring longer until bubbles have stopped rising to the surface. One or two large bubbles might remain under the circular plate on the bottom of the basin. This is sometimes unavoidable, but as long as no bubbles are rising the process is a success. If bubbles do not stop rising after considerable time, a leak has most likely occurred. To remove the deaerated water, turn the vacuum off and rotate the valve in the back parallel to the exiting tube. Final Report Page 17 of 9 Senior Clinic II Soil Monitoring Appendix E1: Moisture-Content Procedure Objective Determine the amount of water present in a quantity of soil. Compute the watercontent as a ratio of the mass of water present to the total mass of the sample of soil. w Mw 100 Ms w = percent water-content Mw = mass of water Ms = mass of soil sample Equipment In the field: Soil auger (boring tool) Sampling equipment Soil moisture meter Plastic bags In the lab: Sample can with lid Scale Oven Procedure Part 1: (Day 1) In the Field 1. The class will be divided into groups of three. 2. Teacher and/or upperclassmen assistants will operate the soil auger. 3. Samples will be taken at a depth of every foot. To obtain a disturbed sample, fill a plastic bag with the removed soil. Do not collect large rocks in the sample. 4. At each sample depth, a moisture content reading will be recorded using the moisture meter. Each group will take a sample of soil from different depths. The total depth reached will depend upon the number of groups. In the lab 5. Weigh an empty sample can with the lid. Record this mass as Mcan/lid. 6. Fill the sample can with 20 – 40 grams of the sample your group bagged in the field. Weigh the filled sample can with the lid and record this mass as Mcan/lid/soil. 7. Label your can and place the sample in the oven with the lid off. It is good practice to place the lid on the bottom of the can while in the oven so it is not lost. Final Report Page 18 of 9 Senior Clinic II Soil Monitoring Part 2: (Day 2) In the lab 1. The sample should be dry by now. Remove the sample and weigh it with the lid immediately. Record the mass as Mcan/lid/dry soil. 2. Calculate the mass of the soil sample. Ms = Mcan/lid/soil - Mcan/lid 3. Calculate the dry mass of the soil sample. Ms dry = Mcan/lid//dry soil – Mcan/lid. 4. Calculate the mass of the water present. Mw = Ms – Ms dry. 5. With the mass of the soil sample and the mass of the water, compute the percent water content knowing the relationship stated in the objectives. Class Discussion of Results 1. Why do we study the properties and behaviors of soils? 2. Compare the moisture contents calculated by all of the groups. Are they close to each other? Why or why not? 3. Compare the water-contents calculated in the lab to the values recorded in the field with the moisture meter. Are they similar? Why or why not? Final Report Page 19 of 9 Senior Clinic II Soil Monitoring Appendix E2: Soil Permeability Procedure Objective Introduce students to the need for data concerning soil permeability for construction. Equipment Soil Sample Permeability Device Hose Clamp Constant-Head Standpipe Timer (stop watch or stop clock) 500mL to 1000mL Beaker 1000mL Graduated Cylinder Procedure 1. Break up into teams. Each team gets a different soil sample to analyze. 2. Weigh cleaned source container. Then the container with the soil sample. Calculate the sample mass. Msample = Mcont.+ sample - Mcontainer 3. Use calipers determine permeameter volume, Vp. 4. Calculate sample density. P = Ms / Vp = [g/cm3] 5. Place a piece of filter paper on top of sample in the mold. Wipe excess dirt off rim and place a rubber gasket on the rim. Put the now assembled mold onto the cover and attach a 175mm in length tubing to the outlet pipe. 6. Place permeameter in sink, which is filled about 50mm above the cover. Allow the water to soak up through the soil until the water level in the soil is at the same height as the water in the sink. At this equilibrium, the soil is completely saturated with minimal air voids. Final Report Page 20 of 9 Senior Clinic II Soil Monitoring 7. Clamp exit hose. Remove permeameter from sink. Attach clamped water source tubing to the inlet. Place filter paper on inner ring of base. Place mold on base. Tighten fasteners. 8. Fill water source tubing and slowly remove clamp from the hose. As sample fills, slowly remove clamp on outlet tubing to allow trickle. Using the beaker and timer provided, record the time required to collect 500mL of water. 9. Repeat test two more times and average times. 10. Compare results with other teams in class. Select which soil is best for a landfill liner. Compare densities. Diagrams Outlet O-Ring Inlet Source Container Inlet (Planview of Base) O-Ring Outlet (Sideview) (Planview of Inside Cap) Final Report Page 21 of 9 Senior Clinic II Soil Monitoring Appendix F: Operations Supplement for Soil Auger This procedure is a supplement to the operations manual provided by Little Beaver. Refer to the manufacturer’s operation manual prior to operation. Gas & Oil Make sure the gas tank is full and the oil is filled to the overflow level of the oil filler plugs located on either side of the engine. They are labeled in the operations manual as #14 in the engine component diagram. You only have to open one of them to check and fill the oil. The dipstick for the oil level is accurate, but to start the engine it sometimes needs more oil then the dipstick reveals. Hence, it is a recommendation to ignore the dipstick and rely on overflowing the oil filler plug on either side. If oil is low, the engine will not kick-over. Before Starting the Engine 1. Switch the on/off engine switch (red switch) to “ON”. Note: The oil must be filled to the overflow level. If the on/off switch flashes while starting it, this is an indication that there is insufficient oil. 2. Properly attach the torque tube. 3. Make sure there is NO auger attached to the handle. 4. Place the kill switch located on the auger handle in the “ON” position. Final Report Page 22 of 9 Senior Clinic II Soil Monitoring To Start the Engine 1. Set the choke lever to the choke position and put the speed lever to the fast speed (rabbit). 2. Pull the start rope as if you were starting a lawn mower. Starting the engine may need two people. If the engine does not start, have a second person squeeze the throttle located on the handle half way in to give the engine some gas while the other person pulls the start rope. 3. When the engine starts set the choke lever to the run position and allow the engine to warm up for two to three minutes. Drilling the Hole 1. Attach the auger into the drive adapter on the bottom of the handle. Make sure it “snaps” in properly. Operate the auger vertically, not on an angle. When prepared to drill, increase the speed lever to the high (rabbit) position and pull the throttle lever in completely. It is always best to operate the auger at full speed. 2. To attach extensions remove the auger from the handle and snap the extension first to the auger in the ground, and then to the drive adapter on the bottom of the handle. 3. When the desired depth has been reached, stop the auger by releasing the throttle lever and disconnect the handle. If the auger and extensions can not be pulled out by hand, use the tripod to tow them out. When an extension is fully out, disconnect it from the tripod cable and re-attach the cable to the next segment. Continue this process until you have retrieved all extensions and the auger. Final Report Page 23 of 9 Senior Clinic II Soil Monitoring REFERENCES Das, B. Principles of Geotechnical Engineering, Fourth Edition. PWS Publishing Company; Boston, MA: 1998. Instructions Manual: Computer Controlled Back Pressure Consolidation Apparatus, Geotest Instrument Corp., Evanston, IL: 1996. Operations Manual: The Nold Deaerator, Walter Nold Company, Natick, MA: 1994 Bowles, J. Engineering Properties of Soils and their Measurement: Fourth Edition. Irwin McGraw-Hill, Inc., Boston, MA: 1992. Operations Manual with Maintenance and Parts Information: Mechanical Earth Drills, Little Beaver, Inc., Livingston Texas: 1999 Final Report Page 24 of 9