Electrical Apparatus Design: Solved Problems

advertisement

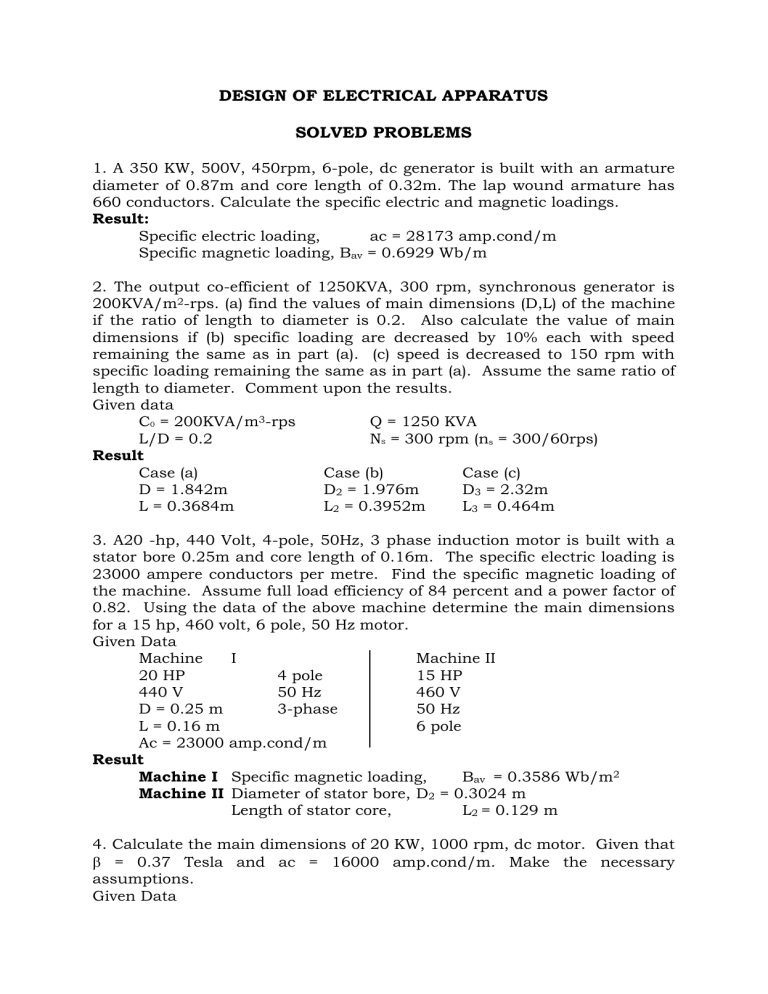

DESIGN OF ELECTRICAL APPARATUS SOLVED PROBLEMS 1. A 350 KW, 500V, 450rpm, 6-pole, dc generator is built with an armature diameter of 0.87m and core length of 0.32m. The lap wound armature has 660 conductors. Calculate the specific electric and magnetic loadings. Result: Specific electric loading, ac = 28173 amp.cond/m Specific magnetic loading, Bav = 0.6929 Wb/m 2. The output co-efficient of 1250KVA, 300 rpm, synchronous generator is 200KVA/m2-rps. (a) find the values of main dimensions (D,L) of the machine if the ratio of length to diameter is 0.2. Also calculate the value of main dimensions if (b) specific loading are decreased by 10% each with speed remaining the same as in part (a). (c) speed is decreased to 150 rpm with specific loading remaining the same as in part (a). Assume the same ratio of length to diameter. Comment upon the results. Given data C0 = 200KVA/m3-rps Q = 1250 KVA L/D = 0.2 NS = 300 rpm (ns = 300/60rps) Result Case (a) Case (b) Case (c) D = 1.842m D2 = 1.976m D3 = 2.32m L = 0.3684m L2 = 0.3952m L3 = 0.464m 3. A20 -hp, 440 Volt, 4-pole, 50Hz, 3 phase induction motor is built with a stator bore 0.25m and core length of 0.16m. The specific electric loading is 23000 ampere conductors per metre. Find the specific magnetic loading of the machine. Assume full load efficiency of 84 percent and a power factor of 0.82. Using the data of the above machine determine the main dimensions for a 15 hp, 460 volt, 6 pole, 50 Hz motor. Given Data Machine I Machine II 20 HP 4 pole 15 HP 440 V 50 Hz 460 V D = 0.25 m 3-phase 50 Hz L = 0.16 m 6 pole Ac = 23000 amp.cond/m Result Machine I Specific magnetic loading, Bav = 0.3586 Wb/m2 Machine II Diameter of stator bore, D2 = 0.3024 m Length of stator core, L2 = 0.129 m 4. Calculate the main dimensions of 20 KW, 1000 rpm, dc motor. Given that = 0.37 Tesla and ac = 16000 amp.cond/m. Make the necessary assumptions. Given Data P = 20 KW N = 1000 rpm ac = 16000 amp.cond/m 2 = 0.37 Tesla Bav = 0.37 Wb/m Result The Diameter of the armature, D = 0.3824 m The length of the armature, L = 0.1401 m 5. Determine suitable values for the number of poles, D and L for a 1000 KW, 500V, 300 rpm dc shunt generator. Assume average gap density = 1 Tesla and specific electric loading as 400 amp.cond/cm. Given Data P = 1000 KW Bav = 1 Tesla = 1 Wb/m2 V = 500 V ac = 400 amp.cond/cm = 40000 amp.cond/m N = 300 rpm Result The main dimensions are D and L The diameter of armature, D = 1.32 m The length of armature, L = 0.29 m 6. Calculate the specific electric and magnetic loading of 100 HP, 300V, 3 phase, 50 Hz, 8 pole star connected, flame proof induction motor having stator core length = 0.5 and stator bore = 0.66m. Turns/phase = 286. Assume full load efficiency as 0.938 and pf as 0.86. Given Data 100 Hp = 0.938 star connected 3000 V L = 0.5 m pf = 0.86 3 phase D = 0.66 m Tph = 286 50 Hz Result Specific electric loading, ac = 14710 amp.cond./m. Specific magnetic loading, Bav = 0.22 Wb/m2 7. A 600 rpm, 50 Hz, 10000 V, 3 phase, synchoronous generator has the following design data. Bav = 0.48 Wb/m2, = 2.7 amp/mm2, slot space factor = 0.35, number of slots = 144, slot size = 120 x 20 mm, D = 1.92 m and L = 0.4 m. determine the KVA rating of the machine. Given data Bav = 0.48 Wb/m2 D= 1.92 m slot space factor = 0.35 = 2.7 A/mm2 L = 0.4 m phase, slots = 144 slot size = 120x20 600 rpm 10000 V Result KVA rating of the machine = 4025 KVA 8. A 40 HP, 1000 rpm dc motor has ac = 30000 amp.cond/m and Bav=0.44 Wb/m2. Estimate the HP of an 800 rpm dc motor which has Bav = 0.5 Wb/m2, the second machine has a current density 10% greater than that of 40 HP machine and the linear dimensions including those of slots are 20% greater than 40 HP machine. Assume that both the motors has same efficiency. Given Data Machine I Machine II HP1 = 40 N2 = 800 rpm N1 = 1000 rpm Bav2 = 0.5 Wb/m2 Ac1 = 30000 amp.cond./m 2 = 10% greater than 1. Bav1 = 0.44 Wb/m2 Linear dimensions including slots are 20% Greater Result The HP rating of machine II = 83 HP 9. Prove that the output of a dc machine with single turn coil is given by 3a E v ac KW, Where a, E, v, ac, p and N denote respectively the pair of pN armature paths, average voltage between adjacent commutator segment, peripheral speed of the armature in m/sec., armature. Conductor/cm of periphery, pair of poles and RPM. 2.1. Calculate the mmf required for one air gap of a dc machine with an axial length of 20 cm (no ducts) and a pole are 18 cm. The slot pitch is 27 mm, slot opening 12 mm, air gap 6 mm and the useful flux per pole 25 mWb. Take carter's coefficient for slot as 0.3. Given Data L = 20 cm bs = 18 cm lg = 6 mm ys = 27 mm wo = 12 mm Kcs = 0.3 = 25 mWb Result MMF required for air-gap = 3846 AT. 2.2. A 15 KW, 230 V, 4- pole dc machine has the following data: armature diameter = 0.25 m, armature core length = 0.125 m, length of air gap at pole center = 2.5 mm, flux per pole = 11.7 x 10-3 Wb, (pole arc/pole pitch) = 0.66. Calculate the mmf required for air gap(i) if the armature surface is treated as smooth (ii) if the armature is slotted and the gap contraction factor is 1.18. Given Data 15 KW D = 0.25 m = 11.7 x 10-3 Wb lg = 2.5 mm 230 V L = 0.125 m = 0.66 4 - pole Kg = 1.18 Result MMF for air gap with smooth armature = 1444 AT MMF for air gap with slotted armature = 1704 AT 2.3. Determine the air-gap length of a dc machine from particulars: gross-length of core = 0.12m, number of ducts = mm wide, slot pitch = 25 mm, slot width = 10 mm, carter's slots and ducts = 0.32, gap density at pole center = 0.7 the following one and is 10 coefficient for Wb/m2; field mmf/pole = 3900 AT, mmf required for iron parts of magnetic circuit = 800AT, Given Data L = 0.12 m ys = 25 mm Bg = 0.7 Wb/m2 nd = 1 wt = 10 mm mmf/pole = 3900 AT wd = 10 mm Kcs = Kcd = 0.32 mmf for iron = 800 AT Result Length of air gap = 4.7 mm 2.4. Find the permeability at the root of the teeth of a dc machine armature from the following data: slot pitch = 2.1 cm, tooth width at the root = 1.07 cm, gross length = 32 cm, stacking factor = 0.9, real flux density at the root of the teeth = 2.25 tesla, apparent flux density at the root = 2.36 tesla. Given Data Ys = 2.1 c.m Breal = 2.25 tesla Sf = 0.9 Wt = 1.07 cm Bapp = 2.36 tesla L = 32 cm Result The permeability at the root of the tooth at real flux density = 30.356 x 10-6 H/m. 2.5. Calculate the apparent flux density at a section of the teeth of an armature of a dc machine from the following data at that section : slot pitch= 24 mm, slot width = tooth width = 12 mm, length of armature core including 5 ducts of 10 mm each = 0.38 m, iron stacking factor = 0.92. True flux density in teeth at that section is 2.2 Wb/m2 for which the mmf is 70000 AT/m. Given Data ys = 24 mm L = 0.38 m Breal = 2.2 wb/m2 ws = 12 mm ducts = 5 nos. at = 70000 AT/m wt = 12 mm wd = 10 mm Sf = 0.92 Result Apparent flux density = 2.332 Wb/m2 3.1. Find the main dimensions of a 200KW, 250V, 6 pole, 1000 rpm generator. The maximum value of flux density in the gap is 0.87 Wb/m2 and the ampere conductors per metre of armature periphery are 31000. The ratio of pole arc to pole pitch is 0.67 and the efficiency is 91 percent. Assume the ratio of length of core to pole pitch = 0.75 Given Data 200 KW N = 1000 rpm = 0.67 2 250 V Bg = 0.887 Wb/m L/ = 0.75 6 pole ac = 31000 amp.cond./m = 0.91 Result The diameter of the armature, D = 0.57 m The length of the armature, L = 0.22 m 3.2. Find the main dimensions and the number of poles of a 37 KW, 230V, 1400 rpm shunt motor so that a square pole face is obtained. The average gap density is 0.5 Wb/m2 and the ampere conductors per metre are 22000. The ratio of pole arc to pole pitch is 0.7 and the full load efficiency is 90 percent. Given Data 37 KW Square pole face = 0.7 230 V Bav = 0.5 Wb/m2 = 90% 1400 rpm ac = 22000 Result Number of poles, p = 4 Diameter of armature, D = 0.3 m Length of armature, L = 0.165 m 3.3. Calculate the main dimensions of a 20Hp, Given that bav = 0.37 Wb/m2 and ac = 16000 efficiency of 90%. Given Data 20 Hp Bav = 0.37 Wb/m2 400 V ac = 16000 amp.cond./m Result Diameter of armature, D = 0.35 m Length of armature, L = 0.128 m 1000 rpm, 400V, dc motor. amp.cond./m. Assume an N = 1000 rpm = 90% 3.4. Determine the diameter and length of armature core for a 55 KW, 110V, 1000 rpm, 4 pole shunt generator, assuming specific electric and magnetic loadings of 26000 amp.cond./m and 05 Wb/m2 respectively. The pole arc should be about 70% of pole pitch and length of core about 1.1 times the pole arc. Allow 10 ampere for the field current and assume a voltage drop of 4 volts for the armature circuit. Specify the winding used and also determine suitable values of the number of armature conductors and number of slots. Given Data 55 KW Bav = 0.5 Wb/m2 N = 1000 rpm 110 V ac = 26000 amp.cond./m If = 10A 4 pole b = 0.7 IaRa = 4 Volts Shunt generator L = 1.1 b Result Diameter of armature, D = 0.355 m Length of armature, L = 0.215 m Number of slots, S = 38 Number of coils, C = 38 Total armature conductors, Z = 228 Conductors per slot =6 Turns per coil =3 3.5. A 4 pole, 25 Hp, 500V, 600 rpm series motor has an efficiency of 82%. The pole faces are square and the ratio of pole arc to pole pitch is 0.67. Tak Bav= 0.55 Wb/m2 and ac = 17000 amp.cond./m. Obtain the main dimensions of the core and particulars of a suitable armature winding. Given Data 4 pole b/ = 0.67 25 HP Bav = 0.55 Wb/m2 500 V ac = 17000 amp.cond./m Result Diameter of armature, D = 0.337 m Length of armature, L = 0.177 m Type of armature winding = Wave Number of slots, S = 33 Number of coils, C = 165 Conductors per slot = 30 Number of turns per coil =3 600 rpm Series motor Square pole face 3.6. A 4-pole, 400 V, 960 rpm, shunt motor has an armature of 0.3 m in diameter and 0.2 m in length. The Commutator diameter is 0.22 m. Give full details of a suitable winding including the number of slots, number of commutator segments and number of conductors in each slot for an average flux density of approximately 0.55 Wb/m2 in the air-gap. Given Data 4 pole D=0.3 m L = 0.2 m 400 V 960 rpm Dc = 0.22 m Shunt motor Bav = 0.55 Wb/m2 Result Number of slots = 30 Total armature conductors = 960 Number of coils = 120 Turns per coil =4 Conductors per slot = 32 Number of commutator segment = 120 Commutator segment pitch = 5.75 mm. 3.7. Draw the winding diagram in the developed form for a 4-pole, 12 slots simplex lap connected dc generator with commutator having 12 segments. Indicate the position of brushes. 3.8. Draw the winding diagram in developed form for a simplex lap wound 24 slots, 4 pole dc armature with 24 commutator segments. Show the position of brushes. 3.9. Draw the winding diagram for a 4-pole, 13 slots, simplex wave connected dc generator with a commutator having 13 segments. The number of coil sides per slot is 2. Indicate the position of brushes. 3.10. A 4 pole simplex wave wound armature has 25 slots and 25 coils. The commutator has 25 segments. Work out its winding details. 3.11. Design the shunt field winding of a 6 pole, 440 V, dc generator allowing a drop of 15% in the regulator. The following diesign data are available. MMF per pole = 7200; mean length of turn = 1.2 m; winding depth = 3.5 cm; Watts per sq.m. of cooling surface = 650 Given Data ATfl = 7200 d1 = d + 0.4 mm Lmt = 1.2 m = 2 - cm = 2 x 10-8 - m df = 3.5 cm = 0.035 m p = 6; V = 440 V 2 qf = 650 W/m drop in field regulator = 15 % Result Area of cross-section of field conductor, af = 2.772 mm2 Diameter of bare conductor, d = 1.88 mm Diameter of insulated conductor, d1 = 2.28 mm Number of turns in field coil, Tf = 1256 turns Height of field coil, hf = 0.195 m Inner cooling surface of a field coil = 0.2126 m2 Outer cooling surface of a field coil = 0.255 m2 End cooling surface of a field coil = 0.0143 m2 3.12. Calculate the size of the conductor and number of turns for the field coil of a o6 poles, 460 V dc shunt motor. The coil is to supply 4000 AT at the working temperature, where = 0.02 micro - ohm - m. The length of the inside turn is 0.74 m, the space factor of the winding is 0.52 and the permissible dissipation per sq.m. of external surface (excluding the two ends) is 1200 watts. Solution should not be attempted by assuming a numerical value for the winding depth. Given Data ATfl = 4000 p=6 Li = 0.74 m Hf = 0.13 m Sf = 0.52 = 0.02 - cm = 2 x 10-8 - m 2 qf = 1200 W/m V = 460 V Result Number of turns in field coil, Tf = 1043 turns Area of cross-section of field conductor, af = 0.982 mm2 3.13. Calculate the reactance voltage induced per coil a single turn two layer winding with two conductors/slot, of a 250 KW, 6 pole lap wound dc generator driven at 220 rpm. The number of armature conductors is 600. The inductance per coil is 0.0057 mH. The brush covers one commutator segment. If the armature diameter is 1.6 m and core length is 0.3 m, determine the flux density under the interpole. The length of interpole is 0.18 m. Given Data 250 KW N = 220 rpm Z = 600 525 V Lcoil = 0.0057 mH L = 0.3 m 6 pole tb = c D = 1.6 m Lap wound Lip= 0.18 m Tc = 1 Double layer winding Two cond./slot Result Average reactance voltage = 0.9952 Volts Flux density under interpole = 0.15 Wb/m2 3.14. Determine the total commutator losses for a 1000 KW, 500V, 800 rpm, 10 pole generator. Given that commutator diameter = 1.0 m, current density at brush contact = 75 x 10-3 A.mm2, brush pressure = 14.7 KN/m2, coefficient of friction = 0.28, brush contact drop = 2.2 V. Given Data P = 1000 KW Dc = 1.0 m V = 500 V -3 2 b = 75 x 10 A/mm N = 800 rpm Pb = 14.7 KN/m2 p = 10 = 0.28 Vb = 2.2 v Result Total commutator loss = 13.596 KW. 3.15. Design a suitable commutator for a 350 KW, 600 rpm, 440 V, 6 pole dc generator having an armature diameter of 0.75 m. The number of coils is 288. Assume suitable values wherever necessary. Given Data P = 350 KW D = 0.75 m p=6 V = 440 V Nc = 288 N = 600 rpm Result Number of commutator segments = 288 Diameter of commutator = 0.48 m Width of commutator segment = 5.2 mm Number of brushes = 6 Thickness of brush = 15.6 mm Width of brush = 38 mm Length of commutator = 0.3 m 4.1. Calculate the core and window areas required for a 1000 KVA, 6600/400 V, 50 Hz, single phase core type transformer. Assume a 2 maximum flux density of 1.25 Wb/m and a current density of 2.5 A/mm2. Voltage/turn = 30 V. Window space factor = 0.32 Given Data KVAn = 1000 f = 50 Hz Bm= 1.25 Wb/m2 V1 = 6600V V2 = 400 V = 2.5 A/mm2 Et = 30 V Kw = 0.32 1-phase Core type Result Net core Area, Ai = 0.108 m2 = 0.108 x 106 mm2 Window Area, Aw = 0.0834 m2 = 0.0834 x 106 mm2 4.2. Estimate the main dimensions including winding conductor area of a 3=phase, -y core type transformer rated at 300 KVA, 6600/440 V, 50 Hz. A suitable core with 3-steps having a circumscribing circle of 0.25 m diameter and a leg spacing of 0.4 m is available. Emf/turn = 8.5V, =2.5 A/mm2 Kw=0.28, Sf=0.9 (stacking factor). Given Data S=phase, - y 50 Hz Et = 8.5 V 2 3-stepped core = 2.5 A/mm Core type 300 KVA d = 0.25 Kw = 0.28 leg spacing = 0.4 m Sf = 0.9 6600/440V Result Number of primary turns/phase, Tp= 776 Number of secondary turns/phase Ts= 30 Area of cross-section of primary conductor, ap= 6.06 mm2 Area of cross-section of secondary conductor, as= 157.5 mm2 Net core area, Ai= 0.0369 m2 Window area, Aw= 0.067 m2 Height of window, Hw= 0.15 m Width of window, Ww= 0.45 m 4.3. A-3phase, 50 Hz oil cooled core type transformer has the following dimensions : Distance between core centers = 0.2 m. Height of window = 0.24 m Diameter of circumscribing circle = 0.14 m. The flux density in the core = 1.25 Wb/ m2. The current density in the conductor = 2.5 A/mm2. Assume a window space factor of 0.2 and the core area factor = 0.56. The core is 2-stepped. Estimate KVA rating of the transformer. Given Data 3-phase D = 0.2m = 2.5 A/mm2 50 Hz Hw = 0.24 m Kw = 0.2 Core type d = 0.14 m Kc = 0.56 2 2=stepped core Bm = 1.25 Wb/m Result The KVA rating of the transformer = 16.5 KVA 4.4. Determine the dimensions of core and window for a 5 KVA, 50 Hz, 1phase, core type transformer. A rectangular core is used with long side twice as long as short side. The window height is 3 times the width. Voltage per turn = 1.8 V. Space factor = 0.2, = 1.8 A/mm2, Bm = 1 Wb/m2 Given Data Q = 5 KVA Core type = 1.8 A/mm2 F = 50 Hz rectangular core Bm = 1 W/mm2 1-phase Et = 1.8 V long side = 2 x short side Hw = 3 Ww Kw = 0.2 Result The net core area, At = 0.0081 m2 The dimensions of the core, a x b = 0.134 x 0.067 m The window area, Aw, = 0.0154 m2 The dimensions of window, Hw x Ww = 0.2148 x0.0716 m 4.5. Determine the dimension of the core, the number of turns, the crosssection area of conductors in primary and secondary windings of a 100 KVA, 2200/480 V, 1-phase, core type transformer, to operate at a frequency of 50Hz, by assuming the following data. Approximate Volt/turn= 7.5 Volt. Maximum flux density = 1.2 Wb/m2. Ratio of effective cross-sectional area of core to square of diameter of circumscribing circle is 0.6. Ratio of height to width of window is 2. Window space factor = 0.28. Current density = 2.5 A/mm2. Given Data 100 KVA 50 Hz Hw/Ww = 2 2200/480 V Et = 7.5 V 1-phase 2 Kw = 0.28 Ai/d = 0.6 = 2.5 A/mm2 Core type Bm = 1.2 wb/m2 Result Net core area, Ai = 0.0281 m2 Diameter of circumscribing circle, d = 0.2164 m Window Area, Aw = 0.0382 m2 Window dimension, Hw, Ww = 0.2764 x 0.1382 m Number of turns in primary = 294 turns Number of turns in secondary = 64 turns Area of cross-section of primary conductor = 18.18 mm2 Area of cross-section of secondary conductor = 83.33 mm2 4.6. Calculate the dimension of the core, the number of turns and crosssectional area of conductors in the primary and secondary windings of a 100 KVA, 2300/400V, 50hz, 1-phase shell type transformer. Ratio of magnetic and electric loadings equal to 480x10-8 (i.e. flux and secondary mmf at full load). Bm = 1.1 Wb/m2, = 2.2 A/mm2, kw= 0.3, Stacking factor = 0.9 Depth of stacked core = 2.6 Height of window = 2.5 Width of central limb Width of window Given Data 100 KVA 2300/400 V 1-phase Shell type m/AT = 480 x 10-8 Bm = 1.1 Wb/m2 = 2.2 A/mm2 Kw = 0.3 Depth of core/width of central limb = 2.6 50 Hz Hw/Ww = 2.5 Sf = 0.9 Result Area of cross-section of core, Ai = 0.0423 m2 Core cross-section, width x depth = 0.1533 x 0.39859 m Area of window, Aw = 0.0293 m2 Window dimensions, Hw x Ww = 0.2708 x 0.1083 m Number of primary turns, Tp, = 223 turns Number of secondary turn, Ts = 39 turns Area of cross-section of primary conductor, ap = 19.76 mm2 Area of cross-section of secondary conductor, as = 113.636 mm2 4.7. The tank of 1250 KVA, natural oil cooled transformer has the dimensions length, width and height as 1.55 x 0.65 x 1.85 m respectively. The full load loss = 13.1 KW, loss dissipation due to radiations = 6 W/m2-0C, loss dissipation due to convection = 6.5 W/m2-0C, Improvement in convection due to provision to tubes = 40 %, Temperature rise = 400C, Length of each tube = 1 m, Diameter of tube = 50 mm. Find the number of tubes for this transformer. Neglect the top and bottom surface of the tank as regards the cooling. Given Data KVA = 1250 Lt = 1 m dt = 50 mm Tank dimension = 1.55 x 0.65 x 1.85 m conv = 6.5 w/m2 – 0C rad = 6 W/m2 –0C Improvement in cooling = 40 % Full load loss = 13.1 KW Result Total number of tubes = 160 4.8. A 250 KVA, 6600/400 v, 3-phase core type transformer has a total loss of 4800 watts on full load. The transformer tank is 1.25 m in height and 1m x 0.5 m in plan. Design a suitable scheme for cooling tubes if the average temperature rise is to be limited to 350 C. The diameter of the tube is 50 mm and are spaced 75 mm from each other. The average height of the tube is 1.05 m. 5.1. Determine the approximate diameter and length of stator core, the number of stator slots and the number of conductors for a 11 KW, 400V, 3, 4-pole, 1425 rpm, delta connected induction motor. Bav = 0.45 Wb/m2, ac=23000 amp. Cond/m, full load efficiency = 0.85, pf = 0.88, L/ = 1. The stator employs a double layer winding. Given Data 11 KW 1425 rpm 3 Bav = 0.45 Wb/m2 4-pole ac = 23000 amp.cond/m 400 V = 0.85 delta connected pf = 0.88 double layer winding L/ = 1 Result Diameter of stator = 0.19 m Length of stator = 0.15 m Number of stator slots = 36 Total stator conductor = 1080 or 1152 5.2. Estimate the stator core dimensions, number of stator slots and number of stator conductors per slot for a 100 KW, 300 V, 50 Hz, 12 pole, star connected slip ring induction motor. Bav= 0.4 Wb/m2, ac = 25000 amp.cond/m, = 0.9, pf = 0.9. Choose main dimensions to give best power factor. The slot loading should not exceed 500 amp. Conductors. Given Data 100 KW 3300 v Bav = 0.4 Wb/m2 50 Hz 12 pole ac = 25000 amp.cond/m = 0.9 pf = 0.9 slot loading < 500 amp.cond. star connected 3 phase Result Diameter of stator = 0.78 m Length of stator = 0.23 m Number of stator slots = 144 Total stator conductors = 2880 5.3. Determine the D and L of a 70 Hp, 415V, 3-phase, 5-Hz, star connected, 6 pole induction motor for which ac = 30000 amp.cond/m and Bav = 0.51 wb/m2. Take = 90 % and pf = 0.91. Assume = L. Estimate the number of stator conductors required for a winding in which the conduxtors are connected in 2-parallel paths. Choose a suitable number of conductors/ slots, so that the slot loading does not exceed 750 amp. cond. Given Data 70 HP 415 V Bav = 0.51 Wb/m2 3-phase 50 Hz ac = 30000 amp.cond/m = 0.9 pf = 0.91 star connected 6-pole =L slot loading < 750 amp.cond. conductors are connected in 2-parallel paths. Result Diameter of stator = 0.36 m Length of rotor = 0.19 m Turns / phase = 63 Number of stator slots = 54 Conductors / slot = 14 5.4. Estimate the main dimensions, air-gap length, stator slots, stator turns per phase and cross sectional area of stator and rotor conductors for a 3phase, 15 HP, 400 V, 6 pole, 50 Hz, 975 rpm, induction motor. The motor is suitable for star delta starting. Bav = 0.45 Wb/m2, ac = 20000 amp.cond/m, L\ = 0.85, = 0.9, pf = 0.85 Result Diameter of stator = 0.275 m Length of stator = 0.12 m Turns / phase = 240 turns Number of stator slots = 36 Number of rotor slots = 33 Area of cross-section of stator conductor = 4.061 mm2 Area of cross-section of rotor bar = 113 mm2 Area of cross-section of end ring = 200 mm2 5.5. Design a cage rotor for a 40 HP, 3-phase, 400V,50 Hz, 6 pole, delta connected induction motor having a full load of 87% and a full load pf of 0.85. Take D = 33 cm and L = 17 cm. Stator slots – 54, conductors/slot = 14. Assume suitable the missing data if any. Result Length of rotor = 0.17 m Diameter of rotor = 0.3286 m Length of air-gap = 0.7 mm 5.6. A 3-phase Induction motor has 54 stator slots with 8 conductors per slot and 72 rotor slots with 4 conductors/slot. Find the number of stator and rotor turns. Find the voltage across the rotor slip rings, when the rotor is open circuited and at rest. Both stator and rotor are star connected and a voltage of 400 volt is applied across the stator terminals. Result Stator turns/phase = 72 Rotor turns/phase = 48 Rotor emf between slip rings at standstill = 266.7 Volts. 5.7. A 90 KW, 500 V, 50 Hz, 3-phase, 8-pole induction motor has a star connected stator winding accommodated in 63 slots with 6 conductors/slot. If the slip ring voltage on open circuit is not to exceed 400 volt, find a suitable rotor winding by estimating number of slots, number of conductors/slot, coil span, slip-ring voltage on open circuit, approximate full load current per phase in rotor. Assume = 0.9 and pf = 0.86. Result Number of stator slots = 63 Number of rotor slots = 48 Emf between slip rings = 381 Volts Rotor turns/phase = 48 Rotor conductor/slot =6 Rotor current/phase = 149.62 a Cross-section of rotor conductor = 30 mm2. 5.8. Determine for a 250 KVA, 1100 V, 12 pole, 500 rpm, 3-phase alternator(1) air gap diameter, (2) core length, (3) Number of stator conductors, (4) Number of stator slots and (5) cross-section of stator conductors. Assuming average gap density as 0.6 Wb/m2 and specific electric loading of 30,000 amp cond/m. L/ = 1.5. Result Diameter of stator = 0.7348 m (Air-gap diameter) Length of stator = 0.293 m (core length) Number of stator conductor = 540 Number of stator slots = 108 Cross-section of stator conductor = 37.48 mm2 5.9. Determine the output coefficient for a 1500 KVA, 2200 volt, 3-phase, 10-pole, 50 Hz, star connected alternator with sinusoidal flux density distribution. The winding has 600 phase spread and full pitch coils. ac = 30000 amp.cond/m, Bav = 0.6 Wb/m2. If the peripheral speed of the rotor must not exceed 100 m/sec and the ratio pole pitch to core length is to be between 0.6 and 1, find D and L. Assume an air gap length of 6 mm. Find also the approximate number of stator conductors. Result Output coefficient = 189 KVA/m2-rps Diameter of stator = 1.285 m Length of stator = 0.48 m Total number of stator conductors = 312.