Supplementary material Control and monitoring of oxygen fugacity

advertisement

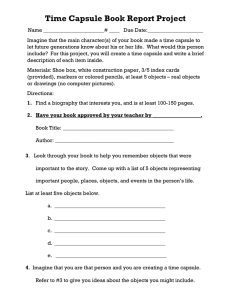

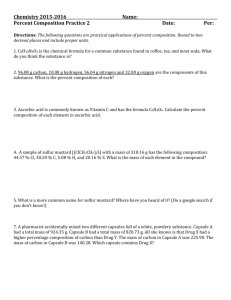

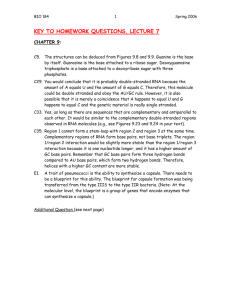

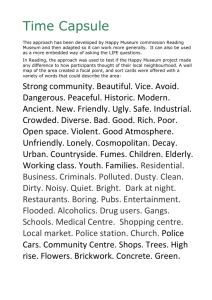

Supplementary material Control and monitoring of oxygen fugacity in piston cylinder experiments Vladimir Matjuschkin1*, Richard A. Brooker1, Brian Tattitch1, Jon D. Blundy1 and Charlotte C. Stamper1 1 School of Earth Sciences, University of Bristol, Wills Memorial Building, Queen's Road, Bristol BS8 1RJ, United Kingdom * vladimir.matjuschkin@bristol.ac.uk Details of the various series of preliminary experiments to evaluate different components of piston cylinder cell assemblies are provided here. Information on the piston cylinder apparatus (with the exception of “JG” experiments) and analytical methods are those given in the paper itself. “CNP” experiments The “CNP” experiments (abbreviation for “Co-Ni-Pd”) were conducted in order to examine the ability of packing/spacer materials (Pyrex and MgO) to retain constant hydrogen fugacity (ƒH2) in experimental capsule assemblies. The test assembly consisted of a single Au80Pd20 capsule in which 3 different solid oxygen fugacity sensors were placed and separated by Al2O3 powder. Water (8µl) was added to the outer capsule in order to activate the ƒO2 sensors. The experimental hypothesis was that consistency of ƒO2 values obtained from sensors will indicate constant hydrogen pressure in the Au80Pd20 capsule, whereas discordant values will point out hydrogen mobility or ƒH2 disequilibrium. Experimental procedure Single Au80Pd20 alloy capsules of ø=3mm were filled with three different ƒO2 sensors, separated by crushable Al2O3 powder. i) Ni64Pd36 sensor was prepared by mixing Ni and Pd metals powders, in a proportion corresponding to logƒO2=NNO+0.36 log units. ii) The second oxygen sensor was mixed in the same proportion, however, Ni(OH)2 was used instead of Ni metal; at high temperatures conditions Ni(OH)2 decomposes to NiO and H2O. iii) The Co28Pd72 sensor was mixed from Co- and Pdmetal powders in a proportion corresponding to NNO+0.04. 10±2µg of each sensor and 8µl water were placed in each capsule, welded shut, pressed and weighed. After storage at 200°C for at least 5 hours, capsules were reweighed to ensure that no water loss had taken place. Experiments were carried out at 1GPa and 1000°C using the usual procedure described in the main document. Run durations varied from 12 to 33 hours (see table S1). Experimental results The compositions of sensors from runs and evaluated values of ƒO2 are presented in the table S1 and Fig. 1 in the main text. The MgO-lined experiments demonstrate discordant ƒO2 values in 13, 15 and 24 hours runs, which we attribute to progressive hydrogen loss. Large ƒO2 variations between sensors correspond to disequilibrium and delayed reaction of the sensor. Only the 33-hour run “CNP-MgO-33” produced consistent ƒO2 values across all sensors signifying full equilibration. In contrast, the agreement of ƒO2 values between all sensors when using Pyrex confirms the maintenance of constant ƒH2. Knowing the exact amount of added starting materials it was possible to make an estimate of ƒO2-equilibrium in the Pyrex experiments, assuming that no hydrogen loss took place. The carefully weighed amount of Ni(OH)2 is the only available source of oxygen in the 3 sensors and this is released by the reactions: Ni(OH)2=NiO+H2O NiO+Pd=NiPd+O The other 2 sensors can only decrease their Ni or Co by access to this oxygen which increases the activity of Pd. Measuring the Ni:Pd ratio in the Ni(OH)2 sensor as it breaks down gives a constrain on the O available for redistribution. In a closed system with O mass is fixed there can be only one unique answer for the Ni in the two NiPd sensors and the Co in CoPd sensor at equilibrium which can be calculated by simple mass balance. If hydrogen is lost from the system, more H2O is converted to O2 and the new oxygen allows more Ni or Co into the sensors equivalent to increasing the O2 mass budget. It is clear from measuring the Ni and Co content of the alloys (see table S1) if this mass balanced situation has been preserved or not, even before any equilibrium has been reached. However, these change in Ni or Co will reach equilibrium at different rates depending on how far they have to move (i.e. how much Ni or Co they need to loose), so some time is required before all the sensors give the same ƒO2. In the Fig. 1b where MgO allows considerable hydrogen loss the NiPd represents the sensor with the highest Ni content and as a result has to change the least in response to the oxidation caused by hydrogen loss. In contrast, the other two sensors take some time to react. Hence, they show very different behaviors in Fig. 1b. The calculated value of +0.55±0.45 log ƒO2 units relative to NNO buffer was achieved by a mass-balance calculation taking into account a maximum weighing error of 2µg. Thus, the elevated ƒO2 values for Pyrex in the longer duration experiment (26 hrs) demonstrate that slow on-going hydrogen loss resulted in oxidation of about +0.25 logƒO2 units above the nominal value. In comparison, MgO experiments were more oxidized, reaching +0.5 logƒO2 relative to the upper limit of the no hydrogen loss field (Fig. 1a,b). Table S1: Composition of oxygen sensors in run products and their corresponding ƒO2 calculated relative to Ni-NiO oxygen buffer (NNO). The values represent mean values of 20-50 point measurements, and the numbers in brackets refer to 2 reproducibility in the last decimal place. Sample Pressure medium material MgO Sensor Run product Resultant Duration [hours] NiPd CoPd Ni(OH)2-Pd Ni45Pd55 Co13Pd87 Ni15Pd85 +0.84(10) +1.47(16) +2.53(8) 13 13 13 CNP-MgO15 MgO NiPd CoPd Ni(OH)2-Pd Ni62Pd38 Co4Pd96 Ni6P94 +0.40(16) +3.16(63) +3.68(34) 15 15 15 CNP-MgO24 MgO NiPd CoPd Ni(OH)2-Pd Ni66Pd44 Co5Pd95 Ni7P93 +0.33(8) +2.76(16) +3.52(42) 24 24 24 CNP-MgO33 MgO NiPd CoPd Ni(OH)2-Pd Ni31Pd69 Co16Pd84 Ni26Pd74 +1.44(10) +1.12(18) +1.73(13) 33 33 33 CNP-Pyr-12 Pyrex NiPd CoPd Ni(OH)2-Pd Ni42Pd58 Co19Pd81 Ni40Pd60 +0.96(14) +0.75(8) +1.04(6) 12 12 12 CNP-Pyr-26 Pyrex NiPd CoPd Ni(OH)2-Pd Ni32Pd68 Co15Pd85 Ni36Pd64 +1.42(5) +1.18(16) +1.22(13) 26 26 26 CNP-MgO13 Au80Pd20 CoPd Al2O3+ 8µl H2O Ni(OH)2Pd Pressure medium (MgO or Pyrex) NiPd 1mm Fig. S1: Diagrammatic cross-section of the capsule design for “CNP” experiments. Powdered and crushable Al2O3 were used to separate the sensors from each other as well as to prevent from contact with the capsule walls. “C-diff” experiments The carbon diffusion experiments “C-diff” were carried out in order to assess the degree of carbon and boron contamination for a single Au80Pd20 capsule in combination with different packing materials: Al2O3, MgO or Pyrex acting as ‘barriers’. The common source of carbon in experimental runs is elemental graphite from the furnace, which may infiltrate through microfractures in pressure medium material and then into the capsule, oxidizing to CO/CO2 and imposing an ƒO2 on the experimental charge. The diffusion (or permeability) rate of carbon may be linked to the physical properties of packing/sleeve materials such as porosity or plastic behaviour at high-pressure conditions. The obvious source of boron is the packing material itself (BN or Pyrex) and a crucial factor may be the availability of elemental boron as opposed to the oxidized B2O3 species. Experimental procedure Au80Pd20 capsules of ø=3mm were used, filled with 9µg of Bishop Tuff rhyolite powder (Table 2S) and 1µl H2O. Experiments were carried out at 1GPa and 1000°C using different packing materials: crushable Al2O3, MgO or Pyrex. Run durations were 3 and 7 days. Post-run capsules were prepared for analytical procedure using the same technique described in the paper. Polished samples were gold coated for SIMS analyses. Experimental results The C and B contents of glasses are presented in Table 3S. Overall CO2 (C is assumed to be converted to molecular CO2 or carbonate in the glass) contents increased with increasing run duration. On average, experiments run for 7 days contain 2-3 times more CO2 than those run for 3 days. Pyrex was found to be the best material to impede carbon infiltration. Glasses in experiments carried out with Pyrex contain 2 or 3 times less CO2 than those performed with MgO and Al2O3 packing materials respectively. Carbon distribution within glasses was found to be heterogeneous in Cdiff-A3 and C-diff-A6 experiments; areas close to capsule walls contain about 70 ppm more CO2 than those near the capsule cores. Backscattered electron images of AuPd capsules from 7 day experiments were made in order to evaluate the capsule corrosion. An experiment with a Pyrex sleeve demonstrates minimal capsule degradation, whereby use of MgO led to slightly heavier corrosion with visible blacking of walls caused by carbon infiltration (Fig. 3a,b main document). Crushable alumina showed the highest corrosion with conspicuous blackening of capsule materials (Fig. 3c main document). A significant amount of Au metal is present in the pore spaces of the crushable alumina spacer, possible due to reaction of Pdalloy with C as a catalyst. Boron contamination was measured in experiments employing a Pyrex sleeve. Traces of boron (≤65ppm) were detected in glasses from experiments run for 1 and 3 days, whereas samples run for 7 days showed significantly higher concentrations (≤1100ppm). Table 2S: Composition of Bishop Tuff rhyolite, used as a starting material in “C-diff” experiments. Vales are given in wt.% and numbers in brackets refer to 2 reproducibility based on X analyses. Na2O 2.7 (0.2) MgO 0.06 (0.04) Al2O3 14.1 (1.7) SiO2 72.4 (2.4) K2O 5.6 (0.3) CaO 0.55 (0.05) TiO2 <0.08 MnO <0.01 FeO 0.33 (0.15) Total 95.8 Table 3S: Concentration of CO2 and B2O3 in glasses from C-diff experiments performed at 1000°C and 1GPa in ppm. Sample CO2 [ppm] in glass, rim/core 1259/1294 C-diff-M3 C-diff-M7 C-diff-P3 C-diff-P7 C-diff-P1-WS Pressure medium Crushable Al2O3 Crushable Al2O3 MgO MgO Pyrex Pyrex Pyrex C-diff-P3-F Pyrex C-diff-A3 C-diff-A6 B [ppm], Run duration rim/core [days] 3 1672/1738 6 755 1683 440 1326 820 64 905/1113 48 3 7 3 7 1 926//918 26043/19144 3 “JG” experiments The experimental series “JG” was carried out in order to assess the suitability of Jakobsson’s (2012) setup for controlling ƒO2 in high-temperature H2O-saturated experiments. Experimental method Starting composition The starting composition (GBA307) replicates basaltic andesite 307 (Thirlwall et al., 1996) from Mount Granby-Fedon's Camp on Grenada, Lesser Antilles (see table 4S). The starting material was made in two batches, one high in Fe2+ (added as FeO) and one with high Fe3+ content (added as Fe2O3), from mixtures of synthetic oxides (SiO2, TiO2, Al2O3, FeO, Fe2O3, MnO, MgO, NiO, Cr2O3), carbonates (Na2CO3, K2CO3, CaCO3) and Ca3(PO4)2 in powder form. SiO2, TiO2, Al2O3, and MgO were dried at 1000ºC for 24 hours to drive off any residual moisture, and the carbonates were stored overnight at 200ºC in a drying oven. Initial mixes of SiO2, TiO2, Al2O3, MgO and carbonates were weighed out in the appropriate proportions and homogenised by grinding under ethanol in an agate mortar, before being decarbonated in a vertical furnace at 600 - 1000ºC for four hours in a Pt crucible. MnO, Ca3(PO4)2, NiO, Cr2O3 and Fe2O3 or FeO were added to the decarbonated powder and the mixtures were rehomogenised in an agate mortar. Experimental setup All experiments were run using the double capsule technique of Jakobsson (2012) (see Fig. S2A) in an attempt to impose the ƒO2 of various redox buffers on hydrous samples. Approximately 15mg of starting material was inserted into an Au80Pd20 alloy inner capsule (o.d. 2 mm, wall thickness 0.1 mm), with the two starting powders mixed in proportion so that Fe3+/ Fe2+ was approximately equal to the anticipated ratio in a fully molten melt for the buffer imposed in the experiment, calculated using Kress & Carmichael (1991) (table 2). Distilled H2O was added to the anhydrous starting composition in the inner capsule with a micro-syringe prior to welding. The inner capsule was then pressed and inserted into a Pt outer capsule (o.d. 4 mm, wall thickness 0.15 mm). To obviate the problem of metal alloying between the Au80Pd20 inner capsule and transition metals in the redox buffer at high temperature, the buffer was physically separated from the inner capsule by crushable alumina powder and a Pt capsule. 15 mg H2O was added to 60 mg of redox buffer in the outer capsule using a microsyringe before welding. Both capsules were weighed before and after welding the capsule to check for volatile loss. Piston cylinder experiments were carried out using 1.27 cm (half-inch) end-loaded piston cylinders at the Research School of Earth Sciences at the Australian National University at pressures of 1.0 GPa and 1300ºC with run times of 6 hours. The assembly comprised an NaCl-cell with a Pyrex sleeve, straight graphite furnace and inner spacers of MgO (Fig. S2B). Experiments were performed using the `hot pistonin' method. An initial sample pressure of ~0.2 GPa was applied before the sample was simultaneously pressurized and heated at a rate of 100ºC min-1. Sample pressure was kept constant during runs to ±0.05 GPa with manual adjustment when necessary. Temperatures were measured using a Pt-Rh (B-type) thermocouple inserted axially into the capsule using two-bore, high purity Al2O3 (hot end) and mullite (cold end) tubing (as described in Mallmann and O’Neill, 2007). No allowance was made for the effect of pressure on e.m.f. Experiments were terminated by turning off the power to the apparatus; initial quench rates were typically in the order of 70ºC s-1. All quenched samples were mounted in epoxy before being cut in half on a diamond saw. The sample was polished using abrasive paper, followed by diamond pastes to 1 µm grade. Experiments were H2O saturated with initial H2O-content = 20 wt %, calculated for composition GBA307 using the model of Papale et al. (2006) and run with five different redox buffers chosen to cover a wide spread of ƒO2. Results Glass composition and texture Initial major element composition was consistent for all superliquidus experiments and variation in glass chemistry was confined to FeO. Absolute Fe loss, as determined by mass balance, across all experiments ranged between 0.3 - 3.4 wt % (4 -51 % relative), resulting in Mg# (Mg/[Mg + ∑Fe]= 0.54 - 0.71. H2O content of glasses Experiments contained glasses with two distinct populations of vesicles (Fig. S3B). Larger bubbles (ø<5 µm) are distributed evenly throughout the sample. Interstitial to these are microvesicles of ø<1 µm. Rare experiments have a ø ~ 1 mm void at the base of the Au80Pd20 capsule. The presence of large vesicles suggests experiments were fluid saturated, but the smaller vesicles show that the full water content of the melt was not retained on the quench. As a result it is difficult to measure a meaningful glass water content. There was also evidence of CO2 related FTIR peaks in the glass, so the ‘excess fluid’ composition was almost certainly not pure H2O. Fe3+/∑Fe of glass Fe3+/∑Fe as analysed by µXANES in H2O-saturated experimental glasses varies between 0.41 - 0.86 (see Fig. 5 in main text). For all H2O-saturated experiments, measured Fe3+/∑Fe is higher than the initial ratio set in the starting composition, which was determined by Kress & Carmichael (1991) for each redox buffer, and does not show systematic variation with the intended ƒO2. The most oxidised experiment occurred with an NNO buffer, where there was an Fe3+/∑Fe increase of 0.73 from a starting ratio of 0.13. The formulation of Kress & Carmichael (1991) has been shown to accurately predict Fe3+/∑Fe of anhydrous (Moore et al., 1995; Partzsch et al., 2004; Cottrell et al., 2009, Stamper et al., 2014) and hydrous (Sisson and Grove, 1993; Gaillard et al., 2001, 2003; Botcharnikov et al., 2005) basaltic glass at 1 atm and high pressure for given redox conditions. Therefore, for our experiments, there should also be a tractable and direct relationship between measured Fe3+/∑Fe and ƒO2. Utilising this fact, the range of Fe3+/∑Fe in all experimental glasses analysed by µXANES experiments is 0.41 0.86, which corresponds to an inner capsule ƒO2 = NNO + 3.1 to + 7.7 (using Kress & Carmichael (1991)). This illustrates the failure of this particular cell design to impose an ƒO2 at the desired buffer value in a 6 hours run at 1300°C. Cited references Botcharnikov R, Koepke J, Holtz F, McCammon C, Wilke M (2005) The effect of water activity on the oxidation and structural state of Fe in a ferro-basaltic melt. Geochim Cosmochim Acta 69 (21): 5071–5085 Cottrell E, Kelley K, Lanzirotti A, Fischer R (2009) High-precision determination of iron oxidation state in silicate glasses using XANES. Chem Geol 268 (3-4): 167–179 Gaillard F, Pichavant M, Scaillet B (2003) Experimental determination of activities of FeO and Fe2O3 components in hydrous silicic melts under oxidizing conditions. Geochim Cosmochim Acta 67 (22): 4389–4409 Gaillard F, Scaillet B, Pichavant M, Bény J-M (2001) The effect of water and fO2 on the ferric–ferrous ratio of silicic melts. Chem Geol 174 (1): 255–273 Humphreys M, Kearns S, Blundy J (2006) SIMS investigation of electron-beam damage to hydrous, rhyolitic glasses: Implications for melt inclusion analysis. Am Mineral 91 (4): 667– 679 Kress V, Carmichael I (1991) The compressibility of silicate liquids containing Fe2O3 and the effect of composition, temperature, oxygen fugacity and pressure on their redox states. Contrib Mineral Petrol 108 (1): 82–92. Mallmann G, O’Neill HStC (2007) The effect of oxygen fugacity on the partitioning of Re between crystals and silicate melt during mantle melting. Geochim Cosmochim Acta 71 (11): 2837– 2857 Moore G, Righter K, Carmichael I (1995) The effect of dissolved water on the oxidation state of iron in natural silicate liquids. Contrib Mineral Petrol 120 (2): 170– 179 Papale P, Moretti R, Barbato D (2006) The compositional dependence of the saturation surface of H2O + CO2 fluids in silicate melts. Chem Geol 229 (1): 78–95 Partzsch G, Lattard D, McCammon C (2004) Mössbauer spectroscopic determination of Fe3+/Fe2+ in synthetic basaltic glass: a test of empirical fO2 equations under superliquidus and subliquidus conditions. Contrib Mineral Petrol 147 (5): 565–580 Sisson T, Grove T (1993) Experimental investigations of the role of H2O in calcalkaline differentiation and subduction zone magmatism. Contrib Mineral Petrol 113 (2): 143–166 Stamper C C, Melekhova E, Blundy J D, Arculus R J, Humphreys MCS Brooker RA (2014) Oxidised phase relations of a primitive basalt from Grenada, Lesser Antilles. Contrib Mineral Petrol: 167(1): 1-20 Thirlwall M, Graham A, Arculus R, Harmon R, Macpherson C (1996) Resolution of the effects of crustal assimilation, sediment subduction, and fluid transport in island arc magmas: Pb—Sr—Nd—O isotope geochemistry of Grenada, Lesser Antilles. Geochim Cosmochim Acta 60 (23): 4785–4810. Table 4S: Comparison of experimental glass analyses (anhydrous totals) with whole rock analysis of starting composition. wt.% 307* GBA307 SiO2 57.57 58.49(99) TiO2 0.74 0.73(4) Al2O3 17.34 18.47(56) FeO 6.66 4.93(95) MnO 0.16 0.16(2) MgO 3.92 3.86(13) CaO 7.63 7.95(19) Na2O 4.17 4.21(16) K2O 1.54 0.94(27) P2O5 0.22 0.22(5) Cr2O3 0.01 0.02(1) NiO 0.01 0.02(2) Total 100.0 100.0 * Whole rock major element analysis of basaltic andesite 307 by Thirlwall et al. (1996) Numbers in parentheses are standards deviation of ten experiments (σ) x 100 as measured by electron probe microanalyses (EPMA) A B 4mm Pt-Rh thermocouple MgO spacers Redox buffer Pt cap Graphite furnace 32mm 8mm Au80Pd20 capsule Crushable alumina powder Noble metal capsule NaCl sleeve Starting material Pyrex sleeve 5.9 mm Pt capsule 12.7 mm FIGURE S2: A) Double capsule setup of Jakobsson (2012). B) 1.27 cm (half-inch) salt-pyrex piston cylinder assembly. A B AuPd gl Crushable alumina gl 100 µm C Ni NiO 1 mm 200 µm Figure S3: Back scattered electron SEM images of an H2O-saturated experiment run with a Ni-NiO (NNO) redox buffer. A) Au80Pd20 inner capsule containing vesicular glass and one large (ø = 1 mm) void. Capsule is surrounded by crushable alumina powder. B) Close up of glass texture (position on large image marked by white box). There are two populations of vesicles: larger bubbles are ø < 5µm; microvesicles are ø < 1 µm. C) NNO buffer in outer capsule compartment displaying interlocking texture of Ni and NiO blebs.