Alticor Supplier Segmentation Model: Classifying Suppliers

advertisement

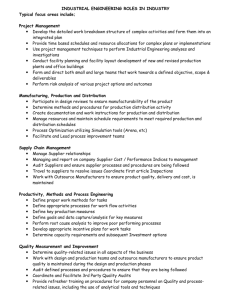

Alticor Supplier / Commodity Segmentation Model The Supplier Segmentation Model has been developed to provide guidelines for Sourcing Strategy Teams (SST’s) and buyers to classify our supply base. It provides structure to our business relationship with suppliers thereby enabling: Alignment within Alticor regarding the commodity strategy and classification of suppliers within the commodity Alignment with our suppliers regarding our requirements, direction, and expectations Sourcing activities that are focused on developing high-performing, well-aligned relationships that can drive innovation and product development. The five supplier classifications Alliance Partner, Preferred, Approved, Conditional and Eliminate are summarized in the graphic to the right, and are described in detail in matrix on the following pages. Alliance Partner • Supplier relationship critical to Alticor's long-term success. Fully integrated activities. • Target: <1% of supply base. Preferred Supplier • Supplier relationship important to Alticor's success and difficult to replace. •Integrated involvement in each parties' activities. The Model is comprised of two categories – Business Relationship, and Performance: The Business Relationship Category describes guidelines on how we intend to award business, establish contracts, review and communicate with our suppliers. The corresponding supplier responsibilities are also outlined. The Performance Category defines the requirements that suppliers should maintain to achieve the classification. Revision Date: July 22, 2005 Approved Supplier • Supplier relationship considered “standard.” • Activities coordinated on a limited basis. Conditional Supplier • Supplier relationship is ”arm’s length” and replaceable when/if necessary. • Supplier can provide existing items, but no new items without SST approval. Eliminate • Actively seeking to eliminate supplier. Page 1 of 4 Supplier Supplier / Commodity Segmentation Model ALTICOR Supplier Classifications Preferred ALTICOR is recognized as a “Top” customer and considered strategic or important. New technology & items offered to ALTICOR at same time as all other “top” customers. Approved Show new technology or items soon after market introduction during scheduled visits. Conditional No responsibility to show new technology or items. The 1st choice for new business, development projects, and long-term relationship development. Alliance Partners are qualified, whenever possible, to supply existing and new items within a given commodity without review by appropriate SST or Strategic Procurement (if no SST exists). SST should be notified of award of new items. Alliance Partners comprise a very small percentage of Alticor’s total supply base. The 2nd choice for new business, development projects, and long-term relationship development. Preferred suppliers should be utilized in a given commodity when an Alliance Partner is unable to supply the required item. Preferred suppliers are qualified, whenever possible, to supply existing and new items within a given commodity without review by SST or Strategic Procurement (if no SST exists). SST should be notified of award of new items. The 3rd choice for new business or development projects. Approved suppliers should be utilized in a given commodity when an Alliance Partner or Preferred supplier is unable to supply the required item. Approved suppliers are qualified to supply existing items within a given commodity. For new items SST should be engaged. May supply existing items. No new items may be sourced from a Conditional supplier without approval from a SST or Procurement. Conditional suppliers are qualified to supply only existing items within a given commodity. All new suppliers in a given commodity will be considered "Conditional" until a review of actual performance (minimum of 180 days history). Long Term with Statement of Work (SOW) – Preferably 3 year minimum. Agreement in place to monitor tie between costs drivers and prices. Process Improvement Team(s) in place Short term contract may be in place – 1 year minimum. Agreement in place to monitor tie between costs drivers and prices. Process Improvement Team(s) in place Contract may be in place (PO). Lock in best pricing. If agreeable, monitor tie between cost drivers and prices. Contract may be in place (PO). No new contracts awarded until supplier moves to “Approved” status. Monitor contract for compliance annually. If applicable, monitor contract for compliance semi-annually. If applicable, monitor contract quarterly for compliance. If applicable, monitor contract quarterly for compliance. Annual review – Supplier will initiate information sharing (10(k), Annual Report, etc.). Cost Drivers identified and shared. Agreement to Terms (2/10 net 30 for example). Total Cost Reduction goals established (quality, inventory, lead time, etc.). Annual review – Supplier will initiate information sharing. Cost Drivers may be identified and shared. Agreement to Terms (2/10 net 30 for example). Total Cost Reduction goals established (quality, inventory, lead time, etc.). Annual review. Cost Drivers may be identified and shared. Agreement to Terms (2/10 net 30 for example). Optional Review Cost Drivers may be identified and shared Agreement to Terms (2/10 net 30 for example). Financial “health” reviewed annually. Tracking of Escalators & Cost Drivers. Tracking of discounts. Financial “health” reviewed annually. Tracking of Escalators & Cost Drivers. Tracking of discounts. Financial “health” reviewed annually. Tracking of Escalators & Cost Drivers. Tracking of discounts. In depth for new suppliers. Financial “health” reviewed annually. Tracking of Escalators & Cost Drivers. Tracking of discounts. ALTICOR Contracts Supplier Business Relationship Awarding New Business Alliance Partner ALTICOR is recognized as a “Top 5 Strategic” customer. New technology & items discussed in technology development phase and offered to ALTICOR first with a useful head start prior to official launch to other customers. ALTICOR Financial Review Revision Date: June 23, 2005 Page 2 of 4 Supplier / Commodity Segmentation Model Conditional Share new ideas, technology, materials at scheduled visits via appointments with product development staff. Presentations to technical staff not appropriate unless on an exception basis and approved by SST. Share technology plans (general). Share new product plans (general). Limited technology plan sharing as appropriate in support of ALTICOR’s interests. N/A Quarterly / Semi-annual presentations on performance, technology, market conditions. Key personnel available when requested. Invitation to Supplier Conference Semi-Annual presentations on performance, technology, market conditions. Key personnel available when requested. Invitation to Supplier Conference Annual summary report on performance, technology, market conditions made available upon request. Key personnel available when requested. Plan, organize and communicate. Full SST participation along with appropriate business area(s). Plan, organize and communicate. SST involvement along with appropriate business area(s). Annual presentations on performance, technology, market conditions. Key personnel available when requested. Possible invitation to Supplier Conference Plan, organize and communicate. Appropriate business area(s) participation with SST notification Communication with Ada Executive Management with SST integration. Executive Team helps to foster relationship. Communication with Management in Procurement, & other functional areas as necessary, with SST integration. Sales Rep. to Team / Buyer communication. Sales Rep. to Team / Buyer communication. Communication with Supplier Executive Management with SST integration. Executive Team helps to foster relationship. Communication with Supplier Middle Management with SST integration. Team / Buyer to Sales Rep communication. Team / Buyer to Sales Rep communication. Supplier ALTICOR On-Site Visits & Presentations Supplier ALTICOR Management Interaction Revision Date: June 23, 2005 ALTICOR Supplier Business Relationship Product Development / Technology Classifications Preferred Proactively initiate technology updates and new product ideas when they become available. Presentations to technical staff encouraged. Include PD SST member on presentation invite. Willing to assist ALTICOR with product testing and registration needs (i.e. EPA, FTC, etc…) when justified. Share market research. Approved Share new ideas at scheduled visits. Provide data necessary for product registration. Presentations to technical staff acceptable. Notify SST of pending presentation. Alliance Partner Proactively initiate technology updates and new product ideas – Inform ALTICOR of developmental status and ask for assistance where applicable. Presentations to technical staff encouraged. Include PD SST member on presentation invite. Exclusivity is always encouraged. Always willing to assist ALTICOR with product testing and registration (i.e. EPA, FDA, etc…) needs. Share market research. Share technology plans (detail). Share new product plans (detail). Assist in new product/application development and testing where applicable. Plan, organize and communicate. Page 3 of 4 Supplier / Commodity Segmentation Model Supplier (Supply Based Continuous Improvement) ALTICOR Supplier Quality Development Supplier Recognition Program ALTICOR Supplier Performance Supplier ALTICOR Performance Evaluation ALTICOR Portal Revision Date: June 23, 2005 Alliance Partner Must maintain minimum requirements by commodity to retain Alliance Partner classification. Formal response required if rating falls or if requested. Sets yearly targets and presents progress at presentations. Establishes performance targets. Generate Performance Scorecard SST Review of Performance against objectives on a quarterly basis or more frequently, as required. Classifications Preferred Must maintain minimum requirements by commodity to satisfy classification. Formal response required if rating falls or if requested. Sets yearly targets and monitors progress. Establishes performance targets. Generate Performance Scorecard SST Review of Performance against objectives a quarterly basis or more frequently, as required. Approved Must maintain minimum requirements by commodity to satisfy classification. Formal response required if rating falls or if requested. If requested, sets yearly targets and monitors progress. Establishes performance targets. Generate Performance Scorecard Buyer Review of Performance against objectives. Conditional Formal response required if rating falls or if requested. If requested, sets yearly targets and monitors progress. Establishes performance targets. Generate Supplier Performance Scorecard Maintain quality rating of 98% or greater based upon: Incoming quality Quality systems evaluation Customer service on issues CAPA Responsiveness Share best practices to help ABG achieve goals. Monitor and improve quality performance Perform quarterly quality performance evaluation. Jointly develop targets and action plans for continued progress towards total lowest cost. Apply shared best practices to drive prevention. Audit supplier facilities and data. Eligible for recognition program. Recognized as Alliance Partner. Maintain quality rating of 95% or greater based upon: Incoming quality Quality systems evaluation Customer service on issues CAPA Responsiveness Share best practices to help ABG achieve goals. Monitor and improve quality performance Perform quarterly quality performance evaluation. Jointly develop targets and action plans for continued progress towards total lowest cost. Apply shared best practices to drive prevention. Audit supplier facilities and data. Eligible for recognition program. Recognized as Preferred Supplier. Maintain quality rating of 90% or greater based upon: Incoming quality Quality systems evaluation Customer service on issues CAPA Responsiveness Maintain quality rating of 80% or greater based upon: Incoming quality Quality systems evaluation Customer service on issues CAPA Responsiveness Focus on identified issues. Monitor and improve quality performance levels. Perform quarterly quality performance evaluation. Set targets and develop action plans to drive towards total lowest cost (reduced appraisal, TAT, etc.). Audit supplier facilities and data. Eligible for recognition program based on SST request. Monitor and improve quality performance levels. Perform quarterly quality performance evaluation. Set targets and develop action plans to drive towards more reliable supply. Audit supplier facilities and data. Manage recognition program. Manage recognition program. Manage recognition program. N/A 100% use of Supplier Portal features – Scorecard, Open Orders, Forecast, Frictionless, VMI, DMDO’s. 100% use of Supplier Portal features – Scorecard, Open Orders, Forecast, Frictionless, VMI, DMDO’s. 100% use of Supplier Portal features – Scorecard, Open Orders, Forecast, Frictionless, VMI, DMDO’s. 100% use of Supplier Portal features – Scorecard, Open Orders, Forecast, Frictionless, VMI, DMDO’s. 100% support of Supplier Portal requirements / Frictionless. 100% support of Supplier Portal requirements / Frictionless. 100% support of Supplier Portal requirements / Frictionless. 100% support of Supplier Portal requirements / Frictionless. Not Eligible Page 4 of 4