- Purdue University

advertisement

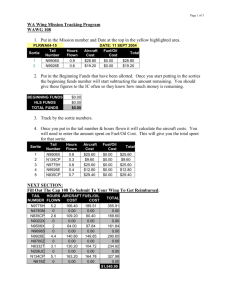

AAE 451 Spring 2006

Preliminary Design Review

(Group II)

Mike Dumas

Adam Naramore

Ben Scott

Gaetano Settineri

Tim Sparks

David Wilson

TABLE OF CONTENTS

1

2

3

4

Executive Summary .................................................................................................... 3

Introduction ................................................................................................................. 5

Concept Justification................................................................................................... 6

Final Design ................................................................................................................ 7

4.1

Aircraft Specifications ........................................................................................ 7

4.2

Design Mission & Flight Envelope..................................................................... 9

5 Cabin Layout ............................................................................................................. 10

6 Flops Analysis ........................................................................................................... 13

7 Aerodynamics ........................................................................................................... 18

7.1

Airfoil Selection ................................................................................................ 18

7.2

Raymer Analysis ............................................................................................... 21

7.3

FLOPS Comparison .......................................................................................... 24

8 Structural Design and Analysis ................................................................................. 25

8.1

Material Selection ............................................................................................. 26

8.2

Load factors ...................................................................................................... 27

8.3

Forward Wing Structure ................................................................................... 28

8.4

Aft Wing Structure ............................................................................................ 28

8.5

Wing connection ............................................................................................... 29

8.6

Rib Spacing ....................................................................................................... 29

8.7

Fuselage Structure ............................................................................................. 30

8.8

Landing Gear .................................................................................................... 31

9 Propulsion ................................................................................................................. 31

9.1

Fuel Selection.................................................................................................... 31

9.2

Emissions .......................................................................................................... 33

9.3

ONX Analysis ................................................................................................... 35

10

Stability ................................................................................................................. 38

10.1 Control Surface Sizing ...................................................................................... 38

10.2 CG, Static Margin and Fuel Burn ..................................................................... 41

11

Weight Estimation ................................................................................................ 43

12

Cost Analysis ........................................................................................................ 46

12.1 Direct Operating Cost ....................................................................................... 46

12.2 Acquisition Cost................................................................................................ 49

13

Conclusion ............................................................................................................ 50

14

References ............................................................................................................. 52

15

Appendix .............................................................................................................. 54

15.1 Aerodynamics ................................................................................................... 54

15.1.1

Airfoil Selection ........................................................................................ 54

15.1.2

Raymer Analysis ....................................................................................... 64

15.2 Structures .......................................................................................................... 71

15.2.1

Composite material properties calculation code ....................................... 71

15.3 Propulsion ......................................................................................................... 73

15.4 Cost Analysis .................................................................................................... 77

15.4.1

Direct Operating Cost ............................................................................... 77

1

Executive Summary

EcoJet has designed a joined wing aircraft that runs on 100% bio-diesel fuel. An

isometric view of the designed aircraft can be seen in Figure 1. This aircraft was designed

to target fractional ownership operators such as NetJets or FlexJets. Over the next 5

years, EcoJet has projected to capture 2.5% of the total business jet market through the

sales of 25 aircraft. As the cost of aviation fuel increases, EcoJet plans to become a strong

competitor in the alternative fuel market for business jets. By 2022, EcoJet projects to

have captured 7% of the light-medium business jet market which is 260 aircraft.

Figure 1: Isometric View of Concept Aircraft

The aircraft fuselage is 50 ft in length and has a wing span of 55 ft. The sweep of

both wings is 30 degrees and the dihedral/anhedral is 10 degrees. Fuel will be stored in

both the forward and aft wing eliminating the need for external fuel tanks. During flight

fuel will be drawn from both wings in junction with a designed fuel schedule in order to

ensure aircraft stability. The two aft mounted engines generate a combine take off thrust

of approximately 10,600 lbs.

Table 1

below shows the target design parameters and the actual parameters of the final

design. From this table, it can be shown that EcoJet met all of its design targets except the

gross take-off weight and acquisition cost. The aircraft was designed to have a

particularly spacious cabin layout that focused on the comfort of its passengers.

Table 1: Target and Actual Design Parameters

Parameters:

Targets:

Actual

GTOW (lbs)

20,000

26,144*

Cruise Mach

0.85

0.85

TO Field Length

3500ft

3400ft

Passenger Cap:

6

6

Range

1700 nm

1700 nm

Acquisition Cost

$10 million

$14.5 million

Operating Cost

$1,000/hr

$1,062/hr

While the final acquisition cost did not meet the target value is still remained

within the established threshold of $15 M. The gross take of weight of the aircraft

exceeded the establish threshold of 25,000 lbs. This was deemed acceptable due to the

aircraft meeting all other critical performance requirements.

2 Introduction

The goal of this project was to design a business aviation (BA) or a general

aviation (GA) aircraft that uses a non-petroleum based fuel in its power plant. This

mandated market research into the future of BA and GA aircraft sales. Research was also

required to determine which alternative fuels would be most applicable to BA or GA

aircraft power plants currently in existence and would be FAA approved for use. The

selected market for this design project was the BA market, specifically fractional

ownership operators, and the fuel selected was B100 bio-diesel. The final concept was a

light-medium business jet that employed a joined wing design. The design requirements

for this concept are listed below in Table 2.

Table 2: Concept Design Requirements

Parameters:

Targets:

Thresholds:

GTOW (lbs)

20,000

< 25,000

Cruise Mach

.85

> .77

TO Field Length

3500ft

< 4000ft

Passenger Cap:

6

≥4

Range

1700 nm

≥ 1500 nm

Acquisition Cost

$10 million

≤ $15 million

Operating Cost

$1,000/hr

≤ $1,500/hr

These design requirements were compiled after a comparative analysis of current

BA aircraft on the market and consultation from representatives from fractional

ownership companies such as NetJets and FlexJets. The market selection also required

this design to conform to IFR requirements. This was critical in the estimation of the

necessary fuel needed for a nominal mission.

3 Concept Justification

With the predicted limited supply of petroleum based fuels the introduction of bio

fuels in aviation is soon expected. It was judged that the time of introduction of new bio

fuels would also be an opportunity to introduce new aircraft concepts that have been

researched but yet to be pursued for full scale design and construction. Of the concepts

researched, the joined wing concept had the most potential benefits over a traditional

aircraft design.

Credited to Julian Wolkovitch, the proposed benefits of the joined wing design

are listed as follows:

1. Light weight

2. High stiffness

3. Low induced drag

4. Good transonic area distribution

5. High trim CLmax

6. Reduced wetted area and parasite drag

7. Direct lift control capability

8. Direct sideforce capability

9. Good stability and control

Based on the proposed benefits along with the use of bio fuels in this aircraft, the

joined wing design has the potential to transform the image of business aviation.

4 Final Design

4.1 Aircraft Specifications

The final design of the aircraft was a bio-diesel powered BA jet employing a

joined wing configuration. The aircraft carries 6 passengers and has a 2 person flight

crew. The fuselage length was set at 50 ft with an outside diameter of 7 ft. The wing

span is 55 ft with the aft and forward sweep of the wings being 30 degrees. The dihedral

of the forward wing is equal to the anhedral of the aft wing at 10 degrees. The root chord

of the forward wing is 6ft and the root chord of the aft wing is 5 ft. Both wings have a

taper ratio of 0.32, and the aspect ratio is 8.5 which is calculated with the total planform

area of both the forward and aft wing. The vertical tail is 13 ft tall from the center line of

the fuselage with a root chord of 9.3 ft and has a taper ratio of 0.45 and an aspect ratio of

2. A 3-view drawing of the aircraft can be seen on the next page in Figure 2.

Cabin Door

55ft

7 ft

300

300

13ft

50ft

100

100

Figure 2: 3-view of aircraft

The aircraft uses two turbofan engines that are mounted on the side of the aft

section of the fuselage. Each engine produces approximately 5,300 lbs of thrust at take

off using B100 bio-diesel. The aircraft range is 1,700 nmi with a standard IFR reserve

capability. The cruise altitude is 41,000 ft with a maximum service ceiling of 45,000 ft.

The cruise Mach number at cruise altitude is 0.85.

The final gross take off weight is 26,144 lbs with 10,000 lbs of fuel and 1,500 lbs

of payload. The estimated acquisition cost is $14.5M and the direct operating cost is

$1,062/hr.

4.2 Design Mission & Flight Envelope

A representation of a typical mission for the aircraft is shown below. This

mission also includes a missed landing and reserve fuel flight and landing at an alternate

airport, in order to meet the reserve flight requirements. The mission profile is shown

below in Figure 3.

Figure 3: Mission Profile

The flight performance envelope for the aircraft was developed based off of

equations from the Dan Raymer Aircraft Design textbook. Equation 5.6 was used to

calculate the stall velocity at certain intervals in flight. Estimates for the wing loading

were used along with a Matlab program that decreases the CL value as the aircraft climbs

higher during take off and decreases the density of air at the correct intervals. Equation

5.6 was used along with these other constraints to produce Figure 4 below. The same

process was used to produce the cruise portion of the envelope. This figure represents the

slowest possible speed that the aircraft can maintain at certain points in the design

mission.

Figure 4: Flight Performance Envelope

5 Cabin Layout

The cabin was designed to luxury in mind. The designed aircraft has a spacious

fuselage layout for the comfort of its passengers. The length of the cabin is a long 27.5

feet. The width of cabin is 6.5 ft window to window and an aisle to ceiling height of 6 ft.

This has given the passengers plenty of room to stand up and walk around during the

flight.

Figure 5 shows the layout of the cabin. The door is located at the back of the

cabin. A full lavatory with a closing door is located directly across from the cabin entry

door. The cockpit can be seen at the front of the cabin. A large refreshment center,

serving drinks, snacks, and possibly even full meals, is located next to the cockpit. A

large closet for coats and baggage is across the aisle from the refreshment center. Both

the closet and the refreshment center measure 5 feet by 2.2 feet.

The useable floor width of the cabin including the seats and the aisle is 5.6 feet.

The width of the aisle is 1.27 feet. The aisle is sunk approximately 6 inches below the

main floor which allows for 6 ft of clearance from floor to ceiling in the aisle of the

aircraft.

Figure 5: Cabin and Cockpit Layout

There are 6 passenger seats in the cabin. The 4 seats in the rear of the cabin are

arranged for conference style seating with one row of seats facing the other. The

dimensions of the seats are 2.5 feet long and 2.167 feet wide as seen in Figure 6. In

addition to the spacious dimensions of the seats, there is also 3 feet between seats. This

provides passengers with plenty of leg room for comfort. Figure 6 below shows the

dimensions of the aft cabin seats with the spacing between the seats.

Figure 6: Close-up of the geometry of the 4 aft passenger seats in the cabin

Another benefit to the spacious cabin of the designed aircraft is that a conference

table is installed in the cabin. The table folds out in two pieces from the sides of the cabin

in between the passenger seats. The pieces extend to connect in the middle of the aisle.

The seats can also swivel to allow passengers to better face each other during

conversation.

The two front passenger seats are sleeper seats. When upright, these seats sit the

same as the 4 aft passenger seats. These seats have the ability to fold down into sleeper

seats with 6 feet of sleeping room as seen in Figure 7. This feature of the cabin adds to

the comfort of the aircraft. Passengers can comfortably sleep during cross-country flights

if they choose.

Figure 7: Close-up of the two forward passenger sleeper seats

6 Flops Analysis

After conducting the initial trade studies based on the most important design

attributes, and historical aircraft data; using tools like the QFD matrix, and Pugh’s

method, provided good benchmarks for beginning the design process. This also gave

insight into the competition and market into which the product will enter, providing

information to make the aircraft as competitive as possible. Once the design goals and

thresholds had been established using more rudimentary design tools a more detailed

sizing code, FLOPS (Flight Optimization System), was employed to analyze more

specific design configurations. FLOPS utilizes a combination of set design requirements

and thresholds such as gross takeoff weight, wing loading, aspect ratio, thrust to weight

ratio, and a detailed mission, etc. With better estimates of the ranges in which the basic

design requirements fall, FLOPS can make more detailed predictions of the performance

characteristics and critical sizing values such as gross take off weight and fuel weight,

which make up the defining characteristics of an aircraft. FLOPS can also make

predictions for costs of development, acquisition, and operation; however the cost

prediction in FLOPS proved to be unreliable as it was designed for sizing larger

commercial transport aircraft.

Before sizing a bio-diesel powered aircraft, FLOPS was calibrated with a similar

size benchmark aircraft in order to gage the accuracy of the results. The Citation XLS is

a competing aircraft in the medium business jet market. The important design values

characterizing the XLS and the FLOPS subsequent performance predictions are shown

below in Table 3:

Table 3: FLOPS results - Cessna Citation XLS Calibration

Citation XLS, input

GTOW

Aircraft values

20200

Design Range

Cruise Mach #

Wing loading

1798

0.75

54.6

lb

nm

lb/ft^2

fuselage length

51

ft.

width fuselage

PAX capacity

AR

Number of crew

Max cruise alt.

Take off field

length

6

8

8.3

2

41,000

ft.

3560

ft.

Engine/fuel Values

Thrust/engine

3991 Lbf

Overall pres.

Ratio

15.7

Fan pres. Ratio

1.59

Bypass ratio

4.12

Fuel heating

value

18400

lb/(hrSFC max

0.5 lbf)

Fuel price

2.57 $/gal

ft.

Citation XLS, output

Aircraft values

GTOW

19,144

Design Range

1885

Cruise Mach #

0.761

Fuel Weight

4179

lb

nm

Acquisition

DOC

Costs

8.073

1423

$million

$/hr

The most noticeable discrepancy is in the cost of the aircraft. A Citation XLS

today would cost $10.5 million given by reference 2. Therefore, the $8.073 million

FLOPS prediction is an obvious under-estimate. The gross take off weight prediction

from FLOPS appears to be accurate within a few percent of the given specification as

does the design range and cruise Mach #. This calibration proved FLOPS to be reliable

for performance predictions of the aircraft, but significantly inaccurate for cost

estimations.

With initial design parameters determined, entering these values into FLOPS

yielded a detailed description of the aircraft’s size, performance and costs. The design

mission had a large effect on the output of the results, especially with the aggressive

design goal of the aircraft being able to fly 1700 nmi at 0.85 Mach, including IFR range

of 200 nmi. At cruise, a fixed-altitude, fixed-Mach number analysis was used. To adhere

to the design goals this type of analysis was a necessity. Trade studies were performed

varying thrust to weight ratio (T/W) and wing loading (W/S), to verify FLOPS provided

expected trends. A sample of the results from the FLOPS analyses can be seen below in

Table 4:

Table 4: FLOPS Results from Varying Wing Loading and Thrust-to-Weight Ratio

W/S = 65

W/S = 70

W/S =

Wto=

26182 Lb

Wto=

25071.3 lb

Wto=

Takeoff =

3006 ft.

Takeoff =

3602 ft.

Takeoff =

T/W = .4

Oper cost =

2351.3 $/hr

Oper cost =

2262.93 $/hr Oper cost =

Price =

9.681 $M

Price =

9.487 $M

Price =

Wto= 26334.4 Lb

Wto=

25541.5 lb

Wto=

Takeoff =

3177 ft.

Takeoff =

3360 ft.

Takeoff =

T/W = .45

Oper cost = 2315.96 $/hr

Oper cost =

2258.6 $/hr Oper cost =

Price =

9.775 $M

Price =

9.613 $M

Price =

Wto= 27434.2 Lb

Wto=

26504.1 lb

Wto=

Takeoff =

3000 ft.

Takeoff =

3170 ft.

Takeoff =

T/W = .5

Oper cost = 2363.09 $/hr

Oper cost =

2300.44 $/hr Oper cost =

Price =

9.972 $M

Price =

9.789 $M

Price =

75

24226.5

3805

2200.4

9.335

24950.2

3544

2216.63

9.483

25815.2

3338

2254.2

9.646

lb

ft.

$/hr

$M

lb

ft.

$/hr

$M

lb

ft.

$/hr

$M

. The predictions for the current design follow the expected trend in that the

acquisition cost increases (with respect to the XLS); due to the aircrafts significantly

higher cruise speed and larger cabin. The acquisition cost, however, is still grossly

under-estimated considering this is new technology. As expected the GTOW in the

current design is also larger due to the need for more fuel (flying faster and using and

alternative fuel) and the larger fuselage. This information was also used to establish the

Plot

design space with a carpet plot in FigureCarpet

8:

28000

27500

T/W = .4

27000

Takeoff Weight (lb)

T/W = .45

T/W = .5

26500

Takeoff

Constraint

26000

25500

25000

24500

24000

63

65

67

69

71

73

75

77

W/S (lb/ft^2)

Figure 8: Carpet Plot

The final design iteration through FLOPS was a combination of all the previous

analysis mentioned. Wing loading was determined from the carpet plot and aerodynamic

analysis of required wing area. GTOW was determined from FLOPS making sure to

account for the required fuel taking into consideration a bio-fuel powered engine. Not

accounted for in the FLOPS analysis was an actual joined wing analysis as shown below

in Table 5 (engine values were obtained from ONX analysis).

Table 5: FLOPS Results for Current Design

Current Design, input

GTOW

Aircraft values

30,000

Design Range

Cruise Mach #

Wing loading

1700

0.85

73

Lb

nm

Lb/ft^2

fuselage length

50

ft.

width fuselage

PAX capacity

Wing sweep

AR

Number of crew

Max cruise alt.

Take off field

length

7

6

30

8.5

2

41,000

ft.

4000

ft.

Engine/fuel Values

Thrust/engine

5000 lbf

Overall pres.

Ratio

20

Fan pres. Ratio

2.9

Bypass ratio

3.2

Fuel heating

value

16108

lb/(hrSFC max

0.65 lbf)

Fuel price

3.63 $/gal

deg

ft.

Current Design, output

Aircraft values

GTOW

26144.3

Design Range

1802.2

Cruise Mach #

0.85

Takeoff Length

3405

Fuel Weight

9885.6

Costs

Lb

nm

Acquisition

DOC

Airframe R&D

9.486

2194.95

41.211

$million

$/hr

$million

Lb

GTOW has exceeded design threshold, but there has been a welcome increase in

range. All other output values held to the design goals. The block of time in which the

aircraft will perform its design mission is quite good, at 4.06 hrs. Speedy and

comfortable travel was a key design requirement and FLOPS verified that this goal was

met with our high cruise speed and large cabin. Several scaling factors had to be

implemented for the Joined wing concept that could not be taken into account in the

FLOPS analysis, due to not being familiar enough with the FLOPS code and were taken

into consideration by other analyses. FLOPS has shown significant inaccuracies in

predicting the acquisition and operating costs from the calibration model due to the fact

that the FLOPS cost model was designed for commercial transport as mentioned above.

Additional cost models were developed to take into account the use of new technology

and the development of the Joined wing design.

7 Aerodynamics

7.1 Airfoil Selection

Over forty-five airfoils were looked at from Dr. Michael Selig’s airfoil database at

the University of Illinois. The airfoils listed in Table 16 are in the NACA 63-Series,

NACA 64-Series, NACA 66-Series, Sikorsky Rotorcraft Series, and the NASA

Supercritical Series. Figure 19-Figure 23 show examples of the airfoils analyzed. The

NACA 6-Series airfoils are used frequently on business aircraft for their high

performance in the low transonic Mach range and their ease of manufacturing. The

Sikorsky Rotorcraft Series was looked at for their ability to have high lift coefficient

values in the transonic range. The NASA Supercritical Series is used on transonic

aircraft, because the airfoils minimize the transonic wave drag by reducing the shock

magnitude along the upper surface.

A cambered airfoil is needed for all of the forward wing and the aft wing after the

elevators to the tip. A symmetrical airfoil is needed for the vertical stabilizer and the

elevator region of the aft wing to create some downwash for stability. For a look at

current production aircraft, airfoil selections were obtained from Mr. David Lednicer’s

“Incomplete Guide to Airfoil Usage.” The majority of the early Cessna Citation Jets used

NACA 5-Series airfoils; however, these aircraft do not meet our required cruise Mach

number. The Bombardier Learjet’s in our class use NACA 64-Series airfoils while also

having similar cruise Mach numbers.

The airfoils selected were run through Dr. Mark Drela’s X-FOIL code developed

at the Massachusetts Institute of Technology. This analysis was run at a Reynolds

Number of 1 million to account for the maximum possible root chords of the wings at

lower than cruise altitudes. The actual Reynolds Number for the forward wing is 274,000

and 219,000 for the aft wing at 41,000 feet and at 480 knots. The fuselage Reynolds

Number is 75.9 million at these same conditions, but was factored into the airfoil

analysis. The airfoils that converged fully in X-FOIL over a specified angle of attack

range of -10° to 20° had their data compiled in MATLAB and further analysis was done.

The goal in the airfoil selection was to obtain the lowest drag at low angles of

attack while obtaining a high CLmax at an angle of attack of at least 15° with soft stall

characteristics. Also, the airfoils selected had to be structurally capable to fit around a

wing box and encompass a flap/aileron/elevator section. With these parameters set,

several airfoils were eliminated from the database.

Figure 9 shows the drag polar for the 4 best airfoils that met all of the specified

parameters. The NACA 64212, shown in Figure 10, was chosen due to its very low drag

at small CL values for the forward wing and the aft wing without the elevator section.

The SC 20010, shown in Figure 11, was chosen for the elevator section of the aft wing

and the vertical stabilizer, because it had the lowest drag for a symmetrical airfoil.

Comparison of CD vs. CL for 4 best airfoils

0.025

0.02

CD

0.015

0.01

0.005

NACA 64212

NACA 64012A

SC 20010

SC 20614

0

-2.5

-2

-1.5

-1

-0.5

0

CL

0.5

1

1.5

2

2.5

Figure 9: CD vs. CL Plot for 4 Best Airfoils

Figure 10: NACA 64212 Airfoil chosen for the forward wing and the aft wing without the elevator

section

Figure 11: NASA SC 20010 Airfoil chosen for vertical stabilizer and the elevator section of the aft

wing

Section 15.1.1 in the Appendix shows plots of some of the airfoils analyzed and

then just the top 4 airfoils with their lift, drag, and transition characteristics.

7.2 Raymer Analysis

Chapter 4 “Airfoil and Geometry Selection,” Chapter 12 “Aerodynamics,” and

Chapter 21 “Conceptual Design Examples” from the Raymer textbook were used in the

aerodynamic sizing of the joined wing aircraft. The MATLAB code used to do this

analysis along with the code that generated the V-N diagram found in the Structures

Analysis section of this paper can be found in the Appendix section 15.1.2.

The aircraft was sized for a traditional mono-wing design initially. To transform

the design to the joined wing, we took the required planform area output from the code

and split the wing. The forward wing was sized to produce 60% of the required lift,

while the aft wing was sized to produce the other 40% of the required lift without the

elevator section that will produce significantly less lift. The actual wing area is larger

than the required area. In later design phases the wing areas could be optimized for best

structural and aerodynamic performance, however, at this stage no optimization was

done. The airfoil inputs for the Raymer analysis code are listed on the next page in Table

6. The mission inputs were the same for the design mission (i.e. Mach Cruise Number of

0.85).

Table 6: Airfoil / Wing Inputs into Raymer Aerodynamic Analysis Code

Aspect Ratio

Airfoil Efficiency

Wing Sweep @ Quarter Chord

Hinge-Line Angle of Flaps

Wing Sweep @ Max Thickness

Wing Loading

Taper Ratio

CLmax (airfoil)

Thickness to Chord Ratio

dy ~ Leading Edge Sharpness Ratio (Raymer p329)

CLmax/Clmax (aircraft/airfoil) (Raymer p330)

ΔCL for Cruise Mach of 0.8 at dy=2.3

Slotted Flap Additional Lift CL

Cfe ~ estimated (Raymer p341)

Flap Angle at Takeoff

Flap Angle at Landing

Estimated Oswald Span Efficiency Factor

Mean chord location of Maximum Thickness

Flap Coverage Reference Area

8

95%

30°

30°

28°

7

0.32

2.0

10%

20.3*t/c

0.89

-0.5

1.3

0.0030

30°

70°

1.05

0.4

30%

An elliptical lift distribution was assumed for this initial analysis of the aircraft.

Normally, the Oswald Span Efficiency Factor for traditional mono-wing aircraft ranges

from 60% to 80% with a fully elliptical lift distribution. However, the out-of-plane

effects felt by the joined wing, winglets, a bi-wing, or a c-wing aircraft have the ability to

push the span efficiency above 100%. The calculated span efficiency for our aircraft for

a mono-wing is 60%. The same airfoil and wing inputs for a bi-wing give a span

efficiency of 160%. The average span efficiency then is 110%. From Dr. John

Sullivan’s course notes of AAE 415 “Aerodynamic Design,” the span efficiency for a

joined wing aircraft with a wing spread height to span ratio of 0.2 is 105%. Thus, this

number was used in our analysis.

Figure 12 on the next page shows a plot of the coefficient of lift versus the angle of

attack required from the Raymer Analysis. The horizontal lines between CL values of

1.5-2.0 are the maximum lift coefficient values for this aircraft based on Raymer’s

correlations. It was stated in class that the average flight angle of attack for climb is 3°,

so for this values, the CL required is 0.45 at takeoff. The CLmax value for cruise is 1.75.

2

1.5

Cruise

Takeoff

Landing

1

0.5

CL

Cruise

0

Takeoff

-0.5

Landing

-1

-1.5

-2

-25

-20

-15

-10

-5

0

5

10

15

20

(deg)

Figure 12: CL and CLmax versus Angle of Attack from Raymer Analysis with Cruise, Takeoff, and

Landing Requirements

Figure 13 on the next page shows the drag polar determined from the Raymer

analysis for cruise, takeoff, and landing. This plot correlates well with the airfoils chosen

for the design aircraft.

2

Cruise

Takeoff

Landing

1.5

1

CL

0.5

0

-0.5

-1

-1.5

-2

0

0.01

0.02

0.03

0.04

0.05

CD

0.06

0.07

0.08

0.09

0.1

Figure 13: Drag Polar from Raymer Analysis showing Cruise, Takeoff, and Landing Requirements

7.3 FLOPS Comparison

The drag polar received from the FLOPS analysis in section 6 was compared with

the data received from the Raymer analysis done above section 7.2. Figure 14 on the

next page shows the comparison between these separate analyses.

The drag found from Raymer is lower than the drag found in FLOPS for a few

reasons. First, the FLOPS code does not have an input to change the Oswald span

efficiency factor. This value is calculated from aspect ratio and taper ratio, and for the

same lift, the total drag will be higher in the FLOPS analysis. The second reason for the

drag differential is the fact that transonic wave drag was not included in the Raymer

analysis. The design cruise Mach number is at the bottom threshold for transonic flow.

Thus, even though some flow over the top of the wings will be supersonic, the majority

of the aircraft will be at a cruise Mach number of 0.85. The understanding that the

Raymer analysis will consistently under predict the drag was utilized throughout the

aerodynamic analysis and sizing.

Drag Polar

1

0.9

0.8

0.7

CD

0.6

0.5

0.4

0.3

0.2

0.1

0

0

0.01

0.02

0.04

0.03

0.05

0.06

0.07

CL

Raymer - M=.84

Flops M=.825

Flops M=.850

Figure 14: Drag Polar Comparison between the Raymer and FLOPS Analysis

8 Structural Design and Analysis

One of the proposed benefits of the joined wing design is a reduction in the

structural weight of the wings compared to a traditional mono-wing and horizontal tail

configuration. This reduction in weight involves significant optimization of the wing

structure based on the aerodynamic loading. Due to the limited time frame for analysis

this optimization could not be performed. The forward wing and aft wing structure were

designed separately for different loading conditions. The forward wing structure was

sized similar to a mono-wing designed for bending due to lift. The aft wing was sized for

column buckling due to compression. This is due to the lift and torsion loads on the

forward wing being transferred into the aft wing at the wing tip. The fuselage structure

was sized for shear loading at trim and cabin pressurization. The basic equations for the

structural analysis were found in chapter 14 of reference 1.

8.1 Material Selection

For the internal wing box structure and ribs Aluminum 2017 was chosen.

Aluminum 2017 is a widely used material in aircraft structures and allows for a low

fabrication cost. For the wing skin AS4/3501-6 Graphite Epoxy was used. The use of

composites allows for a reduction of weight while maintaining high strength in the

structure. For ease of analysis a symmetric ply lay-up was used. This results in the

composite having quasi-isotropic material properties. The ply stack orientation was

[±45/0/90]s2 for a total of 16 plies. Each ply is 5 mils thick resulting in a total skin

thickness of 0.08 inches. Fiber orientations at ±45 degrees provide torsional stiffness in

the skin alleviating part of the torsion stress in the wing box. This same composite lay-up

was also used for the fuselage skin. The overall material properties for the composite

were calculated using a Matlab code developed in AAE 555: Mechanics of Composites

Materials and Laminates taught by Professor C.T. Sun at Purdue University. This code

can be found in Appendix 15.2. A summary of the material properties is given in Table 7

below.

Table 7: Material Properties

Material

Ex

Ey

Gxy

υxy

Al 2017

10.4 Msi

--

3.95 Msi

0.33

AS4/3501-6

[±45/0/90]s2

16.2 Msi

16.2 Msi

6.27 Msi

0.29

8.2 Load factors

The load factors that the aircraft structure is required to withstand are mandated

by the FAA. For this class of aircraft the limit load factors are 3 positive gs and -1.5

negative gs. A V-N diagram was constructed for this aircraft to determine the load

factors during different segments of the flight. The diagram can be seen on the next page

in Figure 15.

Stall Speed

Figure 15: V-N Diagram

The aircraft structure was sized for an ultimate load factor which is 1.5 times the

limit load factor. This was done to increase survivability of the aircraft in a worst case

scenario.

8.3 Forward Wing Structure

From the aerodynamic analysis, the total lift was distributed between the forward

and aft wing 60/40 (60% of the lift on the forward wing 40% on the aft). For a final

design GTOW of 26,144 lbs this results in a nominal lift of 15,686 lbs generated by the

front wing. For an ultimate load factor of 4.5 the forward wing would have to withstand

70,588 lbs of lift. For a simple, conservative design of the wing box structure, the lift

was split in half and placed as a point load at both tips. This was used to size the cross

section of the wing box at the root. Based on analysis from reference 19, the wing box

spanned from 7% of the chord length to 70% of the chord length which left 30% of the

chord for control surfaces on the trailing edge. With the root chord of the forward wing

being 6 ft in length this resulted in a wing box height of 5 inches and a span of 44 inches

at the root. The web thickness was set at 0.25 inches and the resulting flange thickness

was 0.5 inches using the ultimate stress of Al 2017 as the failure criteria for sizing the

cross section. The wing box carries through at the bottom of the fuselage below the cabin

deck. This was done to minimize stress concentrations at load path intersections.

8.4 Aft Wing Structure

The wing box design in the aft wing spanned the same chord percentage as the

forward wing box. With the root chord of the aft wing being 5 ft in length the wing box

span was 36 inches and 4.2 inches tall. The aft wing box was sized for compression and

failure due to buckling. A worst case scenario of a complete transfer of the forward wing

load into compression of the aft wing for a 4.5 ultimate load factor was used as the design

loading condition. Again the ultimate stress of Al 2017 was used as the failure criteria.

The boundary condition used was a fixed-fixed column with riveted or bolted ends

reducing the effecting column length to 82% of the original length. An average inertia of

the root and tip cross sections was taken for calculation of the critical buckling load. The

web thickness was set to 0.25 inches which resulted in a required flange thickness of 0.25

inches. This provided the necessary compression stiffness and also the necessary shear

stiffness to handle the lifting load. There is very little carry through structure for the aft

wing because of the root connections at the mid-span of the vertical tail.

8.5 Wing connection

Reference 25 suggests a connection of the aft wing with the forward wing at 70%

of the semi-span of the forward wing from the center line of the fuselage. This would

ideally minimize the structural weight of the wing. The result of a wing connection at

this point would be reduction in the span efficiency factor and a more complicated

analysis of the loading condition on the wing. For better aerodynamic performance and

ease of structural analysis, the forward and aft wings were connected at the tip resulting

in both wings having an equal span. The leading edge of the aft wing is lined up behind

the trailing edge of the forward wing and a simple wing pod structure is used to connect

the wing tips together.

8.6 Rib Spacing

The rib spacing was determined using sheet buckling of the skin. The boundary

condition employed was simply supported on all sides. The distance between the ribs at

the root of the forward wing was calculated and was then maintained throughout the rest

of the forward wing and the aft wing for uniform rib spacing. The resultant spacing was

30 inches between ribs. The thickness of the ribs was 0.25 inches and the material

selected was Al 2017. The complete wing structure layout is show in Figure 16 on the

next page.

Figure 16: Wing Structure Layout

8.7 Fuselage Structure

The composite lay-up used for the skin of the wings was also used for the

fuselage skin. This lay-up was analyzed to determine if additional structural support such

as longerons would be needed. This was done by calculating the max shear force at trim

conditions for ultimate loading of the aircraft and then calculating the resultant shear

stress in the fuselage cross section. The maximum shear force was estimated to be

130,720 lbs which results in a shear stress of 6.2 ksi at ultimate loading. This was an

acceptable stress level therefore it was determined that no addition support structure was

needed. The fuselage also had to withstand a 9.3 psi pressure differential between the

cabin pressure and the external pressure. The resulting hoop stress was 5.6 ksi, also an

acceptable stress level for the fuselage.

8.8 Landing Gear

A critical component of the overall aircraft is the landing gear system. Based on

the discussion of landing gear from Raymer’s text the nose gear for this aircraft will be

placed 7.5 feet back from the nose along the center line of the aircraft, and the main gear

will be 32.5 feet back from the nose. In order to assure that the tail will not strike the

ground during rotation at take-off the gear will have to be at least 3.25 feet tall. The

horizontal spacing needs to be adequate to prevent the aircraft from tipping over. For this

aircraft configuration this spacing will be 18 feet. The main gear will have two tires per

strut, and the nose gear will also have two tires two provide control of the aircraft in the

event of a flat tire. Tire selection is as follows; main gear: 37 x 14.0-14, nose gear: 21 x

7.25-10. This tire selection was made from the list of landing gear tires provided in

Raymer chapter 11 Table 11.2.

9 Propulsion

9.1 Fuel Selection

The basis for choosing an adequate alternate fuel source was put upon the

maturity, the availability, and the amount of fuel available and any evidence of the wear

effects the fuel might have on certain parts of the aircraft. Three fuels were studied as

possible candidates for this task. These fuels included bio-diesel, liquid methane, and

bio-kerosene.

Through research bio-diesel has shown it is able to meet all the requirements

deemed necessary in an alternate fuel. The use of bio-diesel has been researched in the

science community and test data is readily available for a number of different cases. This

research has shown that bio-diesel is currently the most mature fuel of all the proposed

fuels. Because the proposed market entrance would be in relatively soon five year period,

bio-diesel has a large advantage over the other, less tested fuels. The availability of biodiesel is much greater than that of the other two fuels especially liquid methane. New

government proposals to use mixed diesel fuel instead of standard number 2 diesel fuel

and to offer tax benefits for people using bio-diesel will result in the increased

production. The supply of bio-diesel will begin to rise as the market demand for it also

rises.

During the preliminary analysis of the proposed aircraft the assumption was made

that because bio-diesel has a lower fuel heating value, 16,108 BTU/lbm (National Biodiesel Board), more fuel would be required to fly the same distance as an aircraft using

Jet-A fuel. Jet-A fuel in comparison has a fuel heating value of about 18,300 BTU/lbm.

After research on tests performed to study the fuel flow rate it was found that this

assumption was not entirely accurate. Research by the Purdue Aviation Department has

found just this in Table 8. The aviation facility ran these tests at a ground stationed

engine at about 600ft above sea level with no applied load. If this proves true for 100%

bio-diesel, this will translate into weight savings for the estimated gross takeoff weight of

the aircraft. The density of bio-diesel is greater then that of Jet-A. This translate into a

few things, less volume is needed of bio-diesel for the same mass of fuel which can effect

the CG travel as fuel is consumed from the wing fuel tanks. It should be noted however

that not all studies have found this. A 2nd study from a Baylor University found

inconclusive evidence whither this would hold true while flying at cruise altitude. Further

analysis and research into this area will be necessary considering most of the flight time

will be spent cruising at the proposed 41,000 ft

Table 8: Fuel Consumption of Jet-A versus Bio-Diesel Mixes

9.2 Emissions

A number of studies have also been done on the emissions of bio-diesel fuels.

These studies have had fairly consistent results. The trends found show that in a

comparison of straight Jet-A versus blends of bio-diesel, emissions are not significantly

different at engine idle, but the emissions from the bio-diesel decrease as the engine is

throttled up. Particle emissions and carbon monoxide emissions are reduced but some

tests have shown that there can be a slight increase in NOx production. Some test results

have shown the opposite, however, which may be due to the manufacturing process of the

bio-diesels themselves. Shown on the next page are two studies on emissions from

turbine engines. Figure 17 was produced through a study done at Baylor University,

while Table 9 was produced through a study done by the American Society of

Mechanical Engineers. In this particular study at 500Hp the more bio-diesel used in the

fuel mixture the lower all of the emissions were measured at, with the exception of CO

which was measured less then Jet-A for the 2% bio-diesel mix, but measured higher for

the 20% mix.

Figure 17: Baylor University Turbine Engine Emission Study

Table 9: American Society of American Engineers Study on Turbine Engine Emission

The largest decrease in hydrocarbons occurs at the higher levels of bio-diesel and

Jet-A mixes. The study by Baylor University was performed using a PT6 engine and used

two types of bio-diesel fuel. One type was produced by NOPEC in Lakeland Florida and

was derived from waste cooking oils. The 2nd was produced by Griffin Industries of Cold

Springs Kentucky. The 2nd oil was derived from rendering plant animal wastes. The other

two studies were done using a soy methyl ester blend with Jet-A.

9.3 ONX Analysis

The heating value of bio-diesel varies slightly depending on the additives mixed

into it along with the Jet-A. The estimate that was used for all of the engine calculations

was a heating value of 16108 Btu/lbm (National Bio-diesel Board). In order to choose a

suitable engine for the proposed alternately fueled aircraft a number of factors were

considered. The required fuel flow was a concern as well as the thrust produced by the

aircraft. In order to determine these values an on-design engine program was used called

ONX. This program was developed by Jack Mattingly (aircraftenginedesign.com). To

calibrate the ONX code baseline data from three engines was used. One of these engines

is the Garrett TFE731-5BR engine which is used on aircraft such as the Hawker 800XP

and the Falcon 900. The engine compressor specifications inputted into the ONX code

was found from www.jetengine.net/civtfspec.html. ONX results on the TFE731-5BR can

be seen in Table 10 and Table 11 along with a comparison of the actual values. The info

on the other two engines can be found in the appendix in Table 19 through Table 22.

There is a small discrepancy between the two, 2.5% for the SFC and 7% for the thrust,

but these values seem very reasonable considering some inputs needed to be estimated

such as the turbine inlet temperature and other more advanced inputs that ONX may not

consider that were not available in the engine database.

Table 10: Baseline Engine TFE731-5BR

Component

Cruise Mach

Cruise Alt

Overall Pressure Ratio (OPR)

Value

.8

40000 ft

15.1

Bypass Ratio (Beta)

3.5

Fan Pressure Ratio (FPR)

3.48

Turbine Inlet Temp (TIT)

Jet-A Heating Value

2600 R

18400 BTU/lbm

Table 11: ONX Comparison for Baseline Engine TFE731-5BR

Parameter

SFC

Cruise Thrust

ONX Value

.7748

1122 lbf

Actual Value

.756

1052 lbf

In order to predict the performance of the new bio-diesel engine the only input

values that were changed was the fuel heating value and the OPR. The higher the OPR

the less fuel is needed to burn therefore an OPR of 20 was used. In new engines an OPR

of 20 is a very obtainable figure due to the new technologies being incorporated into new

engines that increase compressor efficiencies. Two different trade studies were done to

calculate an optimal bypass ratio and fan pressure ratio. These studies can be found in the

appendix in Figure 34. The trade study shows the bypass and fan pressure ratios. At high

bypass ratios less fuel is needed with the cost of more drag and less thrust. A middle

value was chosen that gave a good thrust and a reasonable SFC. The fan pressure ratio

affects the thrust much less then the bypass ratio therefore the value which gave the

lowest SFC was chosen. The results of the ONX code for the alternately fueled engine

can be found in Table 13. A more complete list of the ONX inputs and results can be

found in the appendix.

Table 12: Bio-Diesel Engine Results

Component

Cruise Mach

Cruise Alt

Overall Pressure Ratio (OPR)

Bypass Ratio (Beta)

Fan Pressure Ratio (FPR)

Turbine Inlet Temp (TIT)

Jet-A Heating Value

Value

.85

41000 ft

20

3.2

2.9

2600 R

16108 BTU/lbm

Table 13: Bio-Diesel Design Point and Threshold Point Operation

Output Parameters

Thrust

SFC

f (fuel fraction)

M= .85 Value

1151 lbf (cruise)

.882

.0331

M = .77 Values

1206 lbf (cruise)

.852

.0337

It can be seen in Table 13 that the fuel flow fraction is not significantly higher

than that of the baseline engine using Jet-A, but it is still larger. The SFC value, however,

is much higher in the bio-diesel engine but the same amount of thrust is produced which

is very important for proper cruise speeds.

A number of assumptions were made while using the ONX code due to the

complexity of the code and the limitations of the different requirements of the aircraft at

this point. Efficiencies for each component play a large role in the fuel required and the

amount of thrust that can be produced. Compressor efficiencies are always less than the

turbine efficiencies, which is reflected in the ONX code. Bleed air and cooling air values

are not often published for engines, so the program default values were used. Based on

research a conservative turbine inlet temperature value was set at 2600°R. This has

already been achieved in the marketplace so there would be a possibility that this could

be increased as new technology is introduced into the market. The Cp values also needed

to be estimated for the engine. Finding accurate Cp values after the combustion of the

bio-diesel has occurred yielded no results, so the program default values were used. The

last assumption made was the amount of air flow through the engine. The engine

database used reported static flow rates, but to find the thrust at cruise the air flow at

cruise is needed. These values were found using the baseline data at static conditions and

the thrust at cruise. For the baseline and the bio-diesel engine at mass flow rate of

40 lbm/s was used. All the exact values entered into ONX can be found in Appendix 15.3

in Table 17 and Table 18.

10 Stability

10.1 Control Surface Sizing

Every control surface was sized separately for this design (i.e. no control surface

serves a dual function). The aircraft has ailerons and flaps located on its forward wing. It

has ailerons, flaps, and elevators located on its aft wing. The rudder on the vertical tail

was sized for directional stability during a one engine out scenario.

The forward wing has 175 ft2 of surface area which does not include the area

through the fuselage. Single slot flaps were used to provide maximum lift during take off

and landing. The surface area of the flaps on the forward wing is 50 ft2 overall or 25 ft2

on each wing. This takes up about 28% of the lifting surface of the forward wing. The

surface area of the ailerons is relatively small with only 6 ft2 total or 3 ft2 per wing. This

results to about 3.5% of the lifting surface of the forward wing.

The aft wing has 178 ft2 of surface area available for lift. The aft wing also has 6

ft2 of aileron surface area, 3 ft2 per wing. The elevators take up 26 ft2 of the aft wing or

13 ft2 per wing. To increase the lift of the aircraft, small flaps were also added to the aft

wing. The flaps are only 12 ft2, but they will enhance the lifting capacities of the aircraft.

The percent used of the total lifting surface of the stability surfaces for the aft wing are

3.4% for the ailerons, 15% for the elevators, and 7% for the flaps.

The tail has a total surface area of 91 ft2. The aircraft has a very large rudder that

is 41 ft2. This is 45% of the total surface area of the tail. A large rudder will establish

better control of the aircraft especially in a one engine out or heavy crosswind situation.

The total surface area of the forward wing, aft wing, and tail is 444 ft2. The total surface

area of the control surfaces is 141 ft2. These control surfaces provide the aircraft with

adequate ability to control itself in a one engine out or 20% of takeoff speed crosswind

situation.

To solve for a one engine out configuration for the designed aircraft, the moment

caused by the one engine was calculated. The engines are located aft of the center of

gravity with a moment arm of 5.5 feet. One engine generates approximately 5300 lbs of

thrust. This generates a moment of 29,150 ft-lbs.

If the aircraft is to be trimmed in this configuration, this moment of 29,150 ft-lbs

must be offset by the rudder. To ensure stability, spin recovery equations were used to

size the rudder. Equation 1 for spin recovery criterion is:

Ixx Iyy

W

b2

g

where:

(1)

b 2WRx2

Ixx

4g

(2)

and:

Iyy

L2WRy2

4g

(3)

The spin recovery criterion for the designed aircraft was determined to be 0.0164.

This is a dimensionless parameter and is a threshold value. The designed aircraft is

above this value. The airplane relative density parameter was determined to be 19.17,

another dimensionless parameter, based on equation 5 below:

W

S

gb

(5)

Based on Figure 16.32 of the reference 1, the TDPF, or minimum allowable taildamping power factor for the designed aircraft is 0.0015. The TDPF is determined by

multiplying the tail damping ratio and the unshielded rudder volume coefficient together.

Based on the minimum value of TDPF, the tail damping ratio will be above 0.05 and the

volume coefficient should be above 0.03.

The designed aircraft will be above these factors for takeoff, landing, and cruise.

This spin recovery criterion was used to determine the amount of rudder area needed to

recover from a one engine out configuration.

10.2 CG, Static Margin and Fuel Burn

The location of the CG of the aircraft is critical to the static stability and the

calculation of the static margin of the aircraft through out the design mission. Equation

(6), shown below, was used to estimate the CG location where W is the weight of each

component and x is the perpendicular distance from the tip of the aircraft to the center of

mass of the component. Locating the CG of the aircraft will help to determine whether

the aircraft is stable or not based on the location of the neutral point. For the aircraft to

be statically stable the CG must be located in front of the neutral point.

The static margin of an aircraft is a value used to describe the stability of the

aircraft. The static margin was determined using Equation (7) shown below. The static

margin calculation was done as a percent of the front wing mean aerodynamic chord

(MAC in the equation). Raymer states that a static margin of 5-10% is typical of

transport aircraft. Based on the estimations made for weight and CG, the minimum static

margin during the design mission is 7 %. This static margin occurs after the descent into

the destination airport before landing maneuvers take place.

CG

W x

W

i i

(6)

i

SM

( x np xcg )

MAC

(7)

One of the most critical factors in determining the static margin travel and the

aircraft stability is the fuel burn schedule. In order to maintain a positive static margin

the fuel consumption must occur on a strict schedule. The schedule that has been used in

the calculations of the static margin throughout the flight is shown in Table 14. Based on

this fuel burn schedule a static margin travel diagram was created to show the location of

the static margin throughout a max passenger, max range mission with the required IFR

alternate. A diagram of the static margin travel is show on the next page in Figure 18.

Table 14: Estimated Fuel Burn Schedule for Design Mission

Fuel Burn Schedule

Mission Segment

Take-off

Climb

Cruise

Descend

Missed Approach

Climb to Alt Cruise

Reserve Cruise

45 Minute Loiter

Descend to Alt

Land at Alt

Total Fuel Burned

Total Fuel

Fuel from Forward

Fuel from Aft

Used

Tanks

Tanks

500

1250

3705

3710

795

800

250

750

750

750

750

450

450

500

110

9700

5820

500

1250

250

750

750

390

3890

Static Margin Travel

27000

Full Fuel, Full

Passengers

Take off

Gross Weight [lbs]

25000

Lower Static

Margin Limit

23000

Climb

Cruise Segment

Upper Static

Margin Limit

21000

Descent

Reserve Cruise

19000

Landing at

Destination

Airport

17000

zero fuel

full payload

15000

0

0.05

0.1

0.15

0.2

0.25

0.3

0.35

0.4

0.45

Static Margin as % of MAC

Figure 18: Static Margin Travel

11 Weight Estimation

In order to assess the accuracy of the FLOPS gross take-off weight estimation a

method developed by Raymer was utilized to develop a 2nd weight estimation. Chapter

15 discusses this method in detail and utilizing Equations 15.25– 15.59 a basic estimation

of the weight of the aircraft was made. The unique design of the aircraft made changes to

Raymer’s structural weight estimations necessary. Both of the wings weights were

calculated with Raymer’s equation as main lifting wings. The dimensions of each wing

were used in the equation to arrive at individual final wing weights. In order to properly

account for the use of advanced composites in the construction of the aircraft structures

the weighting factors shown in Table 15.4 of Raymer’s text were utilized. The low-end

of these factors was used based on the assumption that the aircraft will utilize composites

to the maximum possible extent.

The equations provided in Raymer’s text are given for military aircraft,

cargo/transport aircraft, and general aviation aircraft. A business class aircraft does not

fit into any of these categories, so an average prediction of the weight of each component

was taken from the cargo/transport aircraft and general aviation aircraft estimates. There

were also some components (installed APU, hydraulics, etc.) that were listed in the

cargo/transport category that did not appear in the general aviation aircraft category. The

weights for these components were taken directly from the cargo/transport aircraft

component weight equations; no averaging or adjustments were made. Lastly, the

weights of components such as the pilot seats, passenger seats, refreshment center,

lavatory, and appliances, and other furnishings were taken from historical data and

estimations.

The weights for the passengers, pilots, and baggage were originally based on FAA

passenger weight requirements, but were changed based on an adjusted view of the

typical C.E.O. type passenger that would utilize this aircraft. The weight for each

passenger was set at 200 pounds and the average weight of luggage for each passenger

was set at 35 pounds. The total weight for each pilot was set at 200 pounds (this weight

includes any luggage brought by the pilots). The complete weight breakdown is shown

on the next page in Table 15.

Table 15: Aircraft component weight breakdown

Structures

Forward wing

Aft Wing

Fuselage

Nose gear

Main landing gear

Tail

Nacelles

Weight (lbs)

1231.8

1025.6

2224.5

115.7

609.5

815.8

146.7

Propulsion

Installed Engines

Engine Starter

Engine Controls

Fuel System/Tanks

3004.7

48.8

41.2

90.2

Equipment

Flight Controls

Avionics

Instruments

APU Installed

Electrical

Air Conditioning

Hydraulics

581.6

1982.7

134.4

220

676

471.9

125.6

Accommodations

Seats (6 total)

Lavatory

Refreshment center

Appliances (Fridge,

Microwave, Coffee Pot)

Other Furnishings

300

45

300

110

105.1

Based on the estimations described above the manufacturing empty weight of the

aircraft is 14,137 pounds. The fuel weight required to complete the max range, max

payload mission with the necessary reserves, was determined using FLOPS. Based on

this FLOPS analysis the aircraft will need to carry 10,000 pounds of fuel. This fuel will

be stored entirely in the wings of the aircraft with 6,000 pounds being housed in the

forward wing and 4,000 pounds being housed in the rear wing. With the addition of the

fuel the maximum gross take-off weight of the aircraft is estimated at 26,147 pounds.

Assuming that 3% of the fuel in each tank cannot be used zero-fuel weight will be 16,447

pounds. This includes the weight of the flight crew and 6 passengers with baggage in the

aircraft

These weight estimates correlate well with the output from FLOPS. This

correlation serves to validate the data received from FLOPS and therefore validates the

input used to reach this gross take-off weight. Another purpose for estimating these

various weights is to determine the location of the center of gravity (CG) of the aircraft,

and this data will in-turn be used to determine the static stability of the aircraft.

12 Cost Analysis

12.1 Direct Operating Cost

The direct operating cost of an aircraft is one of the most important points to a

potential buyer. Calculating the direct operating cost can be more difficult then it sounds.

Different companies use different criteria for what is included in a direct operating cost.

Some companies factor in costs of engine overhauls and of repainting basic surfaces.

Upgrades and aircraft inspections are two more examples of costs that may be considered

into the direct operating cost. The direct operating cost for the EcoJet alternatively fueled

aircraft is based off of the variable cost estimates done by AMSTAT Corporation. Three

different aircraft were used as a baseline in order to properly estimate the cost of the

EcoJet aircraft. The breakdown used by AMSTAT of the variable operating cost is based

off of four main categories. The fuel expense is calculated by multiplying the average

hourly aircraft fuel consumption by the current average nationwide fuel price. The hourly

fuel consumption is found from actual operator experience and includes fuel burn

throughout the entire flight operation. The maintenance labor expense represents the

combined costs of internal and contractor labor and includes both scheduled and

nonscheduled maintenance. This figure is also based off of operator experience. The parts

expense includes costs for all the replacement parts for the airframe, avionics, and

engines if the aircraft is not enrolled in an engine maintenance plan. Finally the

miscellaneous trip expense includes all trip-related expenses including crew overnight

expenses, catering, cabin supplies, and landing / parking fees. This expense is the same

for all aircraft in a particular category or class. Table 23 shows the operating cost of three

baseline aircraft in comparison with the EcoJet aircraft. The data on the three baseline

aircraft is directly from the AMSTAT Corporation’s database.

The fuel expense is dependant on two factors as mentioned before, the cost of fuel

and the consumption rate. To calculate the fuel consumption of EcoJet the SFC was used

at cruise as the average fuel consumption. A majority of the time spent is at cruise in

comparison with the 30 to 40 min it may require to takeoff, climb, and land. Due to the

different type of fuel and the variety of results from studies done on the fuel consumption

of bio-diesel based fuels this number is a rough estimate. Just as important in the fuel

expense is the cost of bio-diesel. The cost of bio-diesel can be almost a dollar less then

Jet-A. Marin Biofuels sells B100 bio-diesel for $3.62 per gallon in Los Angeles. To try

and account for the estimate of the fuel consumption rate of the EcoJet aircraft, the higher

cost of bio-diesel in California was used instead of a national average. The fuel expense

is about $500 for the EcoJet aircraft which is significantly less then the Jet-A fueled

aircraft. Again, the cheaper cost of fuel is a large part of this cost. With more testing

results could show that the fuel consumption may actually be less then expected or could

show the opposite. In either respect the fuel expense of EcoJet will be less then the

aircraft that use Jet-A fuel.

The maintenance expense was a hard expense to estimate. Estimating this cost

from the weight is not possible due to the costs shown in the baseline. The Learjet 45

weighs in the over 20,000lbs category but has the cheapest maintenance labor expense.

This cost was overestimated to be more expensive then all of the baseline aircraft.

Maintenance is going to be more costly due to the new technology involved in this

aircraft as well as the lack of methods to perform labor on a diamond wing aircraft.

The parts expense for the EcoJet was grossly overestimated in comparison with

the baseline aircraft. Bio-diesel is known to corrode rubber fuel lines in automobiles as

well as test aircraft that have used bio-diesel (Soy-Diesel blends use in aviation turbine

engines, Purdue Ave-Tech Department). This effect will require different types of hosing

to be used which may cost more then the standard fuel lines. The effect that the bio-diesel

has on the engine is also a young science. Some testing has shown that due to the

lubricity improvements of bio-diesel the wear of some critical engine components could

be reduced, thus increasing the life and time between overhaul of the engine (The Use of

Bio-Fuels as additives and extenders for aviation turbine fuels, The American Society of

Mechanical Engineers). More research could show that parts last longer then the baseline

aircraft which could drive this parts expense down.

The miscellaneous trip expense for EcoJet was calculated based on the class of

the aircraft. The EcoJet aircraft is more similar to the Citation Excel and the Learjet 45

baseline aircraft therefore the design aircraft would be a class three aircraft. Class three

aircraft have a miscellaneous trip expense of about $165. The EcoJet cost was rounded up

to $170 for this section, to include the possibility of forgotten factors in this section.

Overall the total operating cost of the EcoJet aircraft is about $1062 per hour.

This is comparable to all three of the baseline aircraft. It is neither the cheapest nor the

most expensive, but as mentioned above this value is very flexible once more research is

done on using bio-diesel in aircraft turbine engines. Ideally this cost could be driven

down but even if the cost were to increase due to inaccurate fuel consumption value or an

underestimate of one of the expenses the direct operating cost would still be competitive

in comparison with the three baseline aircraft, especially the citation excel which is the

most similar aircraft to EcoJet.

12.2 Acquisition Cost

The final acquisition cost of the aircraft was estimated to be 14.5 million dollars.

This was still within the threshold limit established in the design criteria, but still

relatively high in terms of making this design competitive with current aircraft on the

market. This acquisition cost was determined based on adjusted predictions from FLOPS

which included a set offset that was determined in the calibration. This was then

validated by calculating an acquisition cost from a linear regression curve that predicted

acquisition cost as a function of gross take off weight. The equation for this curve was

found by plotting the acquisition cost of current BA aircraft against their gross take off

weight and then curve fitting the data. This value compared well with the estimate from

FLOPS. Finally a research and development factor was included for the use of the joined

wing concept that accounted for approximately an extra $2.5M in the acquisition cost.

13 Conclusion

Of the seven design objectives created in the initial research phase of the project

only one was not met within the created design thresholds: the maximum gross takeoff

weight design target was set at 20,000 lbs with a threshold value of 25,000lbs. The

calculated gross takeoff weight was a little over 26,100lbs, exceeding the threshold limit

by 1,100 lbs. Even though the GTOW threshold was exceeded, the take off length and the

cruise Mach number targets were met. The excessive gross takeoff is not considered a

failure of the design since all other design parameters were within the specified

thresholds. The gross takeoff weight is linked to the large acquisition cost which is a

critical aspect of marketing the aircraft.

The excessive weight was a driving factor in the acquisition cost of the aircraft and

drove this value up significantly. The target cost was set during preliminary design to $10

million with a threshold value of $15 million. The cost calculated was found at $14.5

million, which is within the threshold value but is slightly out of a competitive cost range

for aircraft of this size. The low direct operating cost of about $1100 per hour will

become a good selling point for the aircraft due to its very competitive nature in

comparison to other aircraft.

The excessive gross take off weight is driven primarily by the large fuselage and

the cruise speed of the aircraft, both of which substantially exceed the performance of

current BA aircraft in this class. The lack of optimization of the aerodynamics and the

structure also is a significant factor that drove the gross take off weight outside the

threshold. Given more time for analysis, an optimization code could have been

developed for the structure and aerodynamics of the aircraft which most likely would

have led to a reduced GTOW. The predicted extra weight of fuel needed for using biodiesel instead of Jet-A also contributed to the increased weight of the aircraft. If future

research proves bio-diesel to burn with the same efficiency as Jet-A the amount of biodiesel needed will decrease.

Overall this design was considered to successfully meet the requirements of the

design project. With the exception of the gross take off weight and acquisition cost, all

other performance parameters of the aircraft met or exceeded the design specifications

established. The estimated direct operating cost is competitive with existing aircraft and

will be even more competitive as the price of petroleum fuels rises. A reduction in the

gross take off weight would lead to a reduction in the acquisition cost making it more

attractive to fractional operators wishing to recover their expenses as soon as possible.

14 References

1. Raymer, Daniel P. “Aircraft Design: A Conceptual Approach”, Third Edition,

AIAA Inc. Reston, Virginia 1999.

2. investor.textron.com/downloads/03-08-2006_Citigroup.pdf

3. Samuels, Mary F. Structural Weight Comparison of a Joined Wing and a

ConventionalWing. AIAA paper 81-0366R, Vol. 19 No. 6 June, 1982

4. Mattingly, J., On-Design analysis of gas turbine engines V3.23

5. www.Aircraftenginedesign.com

6. Renewable Aviation Fuels Development Center (RAFDC), Baylor University

7. http://www.baylor.edu/bias/

8. Lopp Denver, Stanley Dave., “Soy-Diesel blends use in aviation turbine engines”

9. Purdue University School of Technology, 1995

10. Kimble-Thom, M., Cholis, J., Stanley, D., Lopp., D. “The use of bio-fuels as

additives and extenders for aviation turbine fuels.” The American Society of

Mechanical Engineers 1999.

11. http://www.biodiesel.org, “Energy Content,” National Biodiesel Board

12. “Cessna, Citation Excel, CE-560-XL Aircraft Operating Cost Report”

13. AMSTAT Corporation, January 13th, 2006

14. “Hawker 400XP, Model 400A Aircraft Operating Cost Report”

15. AMSTAT Corporation, January 13th, 2006

16. “Learjet 45, Model 45 Aircraft Operating Cost Report”

17. AMSTAT Corporation, January 13th, 2006

18. Wolkovitch, J., “The Joined Wing: An Overview” AIAA -45285-385

19. Samuels, M., “Structural Weight Comparison of a Joined Wing and a

Conventional Wing.” AIAA-81-0366R, Journal of Aircraft. Vol. 19, No. 6, June

1982

20. Gallman, John W., Kroo, Ilan M., Smith, Stephen C., “Design Synthesis and

Optimization of Joined-Wing Transports,” AIAA-90-3197, Sept. 17-19, 1990.

21. Burkhalter, John E., Spring, Donald, J., Kent, M., “Downwash for Joined-Wing

Airframe with Control Surface Deflections,” Journal of Aircraft. Vol. 29, No. 3,

May-June 1992.

22. Wolkovitch, Julian, “Joined-Wing Research Airplane Feasibility Study.” AIAA84-2471, Oct 31-Nov2, 1984.

23. Smith, S. C., Cliff, S. E., “The Design of a Joined-Wing Flight Demonstrator