COP

advertisement

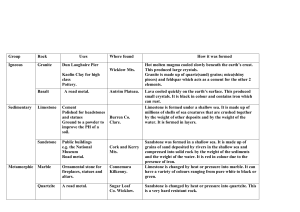

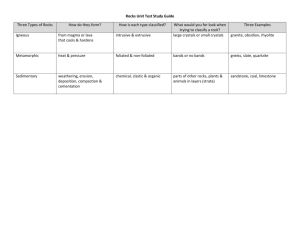

Communication on Progress Year: 2009 P 1/11 STATEMENT OF CONTINUED SUPPORT We have been a proud signatory of the UN Global Compact since 2008 and joined in order to establish more global contacts, share best practices and measure ourselves against rising global expectations, all of which will help us continue to improve sustainability performance. Everything we do at “Quartzite” Ltd is driven by the principle of sustainable development, which takes into account social, environmental and economic considerations in all decision-making. Our commitment to sustainable development requires that we demonstrate care and concern for the environment, that we be seen as a highest-quality employer and valued neighbour, and that we run our business in a way that is both ethical and profitable. Through visible and felt leadership, the Company leadership team supports and ensures adherence to “Quartzite” Ltd’s Health, Safety and Environmental (HSE) policy, believing it central to workforce well-being, operational care and concern for the environment, and the Company's long-range business success. Our management team ensures that all employees are appropriately aware of and trained in all aspects of health, safety and environmental compliance. In particular, all employees are able to implement our comprehensive disaster management and recovery program, which helps us protect against and prepare for potential emergency situations. “Quartzite” Ltd commits to become a model of a socially responsible mining organization through effective implementation of the integrated management system - its standards, programs and procedures. “Quartzite” Ltd commits to high compliance rating in all applicable government laws, regulations and policies, industry standards, in order to uphold a trusting and enduring relationship with all stakeholders. Dimitri Kalandadze General Director “Quartzite” Ltd. December 2009 Contact: Mariam Tabagari, Quality Management Specialist Email: tabagarim@quartzite.ge Phone: 995 32 474343 Fax: 995 32 474447 P 2/11 Brief description of nature of business Quartzite Ltd gold mine is situated in the Bolnisi region of Georgia. The mine site is located within the Madneuli Copper Mine, in the hills between Upper Bolnisi village and Kazreti, approximately 80 km SW from Tbilisi the capital of Georgia. Founding partners of “Quartzite” Ltd are represented by “Madneuli” JSC and company “GeoProMining” with equal share participation. The engineering solution, construction and operation of “Quartzite” Ltd Heap Leach Production Process meet the worldly acknowledged standards of mining operations. Heap Leach method used in the Company implies the application of weak cyanide solution onto a heap of crushed ore within a totally closed production cycle. This is the most cost efficient and environmentally acceptable means of precious metal extraction technique recognized worldwide. The theoretical method of gold extraction from ore by cyanidation was first suggested by a Georgian engineer and scientist Petre Bagrationi, in 1843. Production capacity of the Company has reached 3,200,000 tons of processed ore per annum up to date (75% increase) by implementing of new technologies. Extraction of precious metals involves geodesic, mining, metallurgical, mechanical, technical and other types of works carried out through a continuous 24 hour cycle. The increase of production efficiency is achieved through highly qualified personnel, modern equipment and appropriate infrastructure. At present 542 persons are employed at the “Quartzite” Ltd. It should be mentioned herein that 90% of employees are locals. “Quartzite” Ltd aims to strengthen its leadership position in the global mining and metals industry and its role of a responsible producer and supplier of base and precious metals through: Effective use of unique mineral resources and stability of operating costs; Growth in prospecting, exploration and development of world class mineral deposits; and Support of sustainable development in the regions in which the Company operates. P 3/11 HUMAN RIGHTS PRINCIPLE 1 BUSINESS SHOULD SUPPORT AND RESPECT THE PROTECTION OF INTERNATIONALLY PROCLAIMED HUMAN RIGHTS PRINCIPLE 2 BUSINESS SHOULD ENSURE THAT THEY ARE NOT COMPLICIT IN HUMAN RIGHTS ABUSES ACTION TAKEN & IMPACT ACHIEVED and/or Plans for the upcoming Year Quartzite” Ltd is committed to providing a work environment in which every employee is treated fairly, respected, has the opportunity to contribute to business success and also to realise their full potential as individuals. Mechanisms to protect the human rights of employees and communities covers human rights affecting personal dignity, working conditions, treatment of personnel, freedom of association, forced and child labour, unfair discrimination and training. The Company employees are provided with personal protection wear and equipment. All employees are insured and each of them has a pension fund. Territory of the gold mine contains an additional medical facility. Employees travelling to work, receive compensatory travel money. Vacancies at “Quartzite” Ltd are announced as open competition. After theoretical and practical testing and interview, suitable applicant is chosen for the position. Candidate later attends work safety instructions course and is enrolled in the company, for trial period of work. Trade union, taking into consideration social circumstances of the employees, provides assistance and organizes different social events at the “Quartzite” Ltd. Significant resources are invested in the training and development of current and potential employees. With the aim of prompt implementation of the latest scientific, technical and economic ideas in the production, the Company is planning to introduce continuous staff re-training and qualification improvement schemes in close cooperation with UNDP Georgia. There are no records of human rights abuse against the Company. “Quartzite” Ltd will continue to conduct activities in a manner that minimizes risk to public health and safety. Further, “Quartzite” Ltd believes that natural resources can be developed and utilized in a manner consistent with proper stewardship for the environment. Therefore, recognizing that all activities associated with the development of our mineral resources impact the environment, all our future projects will be designed and managed to reasonably minimize risk and mitigate negative impacts to the environment. “Quartzite” Ltd will strive to assure that its activities are conducted in compliance with the applicable laws and regulations which will help us in obtaining the necessary social license to operate. P 4/11 LABOUR STANDARDS PRINCIPLE 3 BUSINESS SHOULD UPHOLD THE FREEDOM OF ASSOCIATION AND THE EFFECTIVE RECOGNITION OF THE RIGHT TO COLLECTIVE BARGAINING PRINCIPLE 4 BUSINESS SHOULD SUPPORT THE ELIMINATION OF ALL FORMS OF FORCED AND COMPULSORY LABOUR PRINCIPLE 5 BUSINESS SHOULD SUPPORT THE EFFECTIVE ABOLITION OF CHILD LABOUR PRINCIPLE 6 BUSINESS SHOULD SUPPORT THE ELIMINATION OF DISCRIMINATION IN RESPECT OF EMPLOYMENT AND OCCUPATION ACTION TAKEN & IMPACT ACHIEVED and/or Plans for the upcoming Year Quartzite” Ltd is committed to upholding the Fundamental Labor Standards. All undertakings set out the standards which guide the company and its employees in the overall conduct of its business. The Company commits to developing motivated, competent and experienced teams of employees through appropriate recruitment, retention and development initiatives. An emphasis is placed on the identification of potential talent, mentoring and personal development planning. Each employee (including contractors) is held accountable for ensuring that those employees, equipment, facilities and resources within his or her area of responsibility are managed to comply with the Company Labor policy and to minimise environmental risk. The Company aim is to have a positive impact on the people, cultures and communities in which it operates. “Quartzite” Ltd strives to ensure that surrounding communities are informed of, and where possible, involved in, developments which affect them, throughout the life cycle of our operations. The Company undertakes social investment initiatives in the areas of need where it can make a practical and meaningful contribution. In particular, “Quartzite” Ltd contributes to those areas of education and health care which are relevant to its business activities, and those most likely to be sustainable once company’s operations have come to a conclusion in that community. “Quartzite” Ltd seeks to ensure the implementation of fair employment practices by prohibiting forced, compulsory or child labour. Employees, both potential and active, will be treated in a way that will be free of bias on the grounds of race, color, religion, sex, age, disability, marital status, citizenship, or any other characteristic protected by Company policies. Ernst &Young Audit LLS annually carry out the auditing of financial statements of “Quartzite” Ltd. The export share of “Quartzite” Ltd makes up 10% of the total export of the country. The Company is actively involved in charitable activities providing grants and disburses funds for educational and charitable purposes. P 5/11 ENVIRONMENT PRINCIPLE 7 BUSINESS SHOULD SUPPORT A PRECAUTIONARY APPROACH TO ENVIRONMENTAL CHALLENGES PRINCIPLE 8 BUSINESS SHOULD UNDERTAKE INITIATIVES TO PROMOTE GREATER ENVIRONMENTAL RESPONSIBILITY PRINCIPLE 9 BUSINESS SHOULD ENCOURAGE THE DEVELOPMENT AND DIFFUSION OF ENVIRONMENTALLY FRIENDLY TECHNOLOGIES ACTION TAKEN & IMPACT ACHIEVED and/or Plans for the upcoming Year “Quartzite” Ltd Environmental Management System includes responsibilities, budget allocation, monitoring plans, training, reporting. More responsibility is being transferred to operational staff for sampling, maintaining monitoring sites and taking appropriate case of non-conforming events. All results are held in hard copy and catalogued on computer for interpretation and reporting. The Ministry of Environment will be informed of any controlled and uncontrolled discharges. There are four main objectives of the Environmental Management Plan: To assess and quantify the nature, extent and environmental significance of any environmental impacts from the “Quartzite” heap leach operations To minimize environmental impacts and continually improve environmental performance To comply with requirements of the Ministry of Environment To ensure that measures described in the Environmental Report and summarized in this EAP are undertaken Quartzite produces gaseous emissions, including airborne particulates, aqueous discharges and solid wastes. Those that are assessed by the Ministry of Environment as the most critical are: Dust (and its mineral components) Cyanide as HCN gas Cyanide in solution Dust is generated from stockpile activities, vehicular movements, crushing and wind erosion. Prevailing winds would tend to distribute fine dust towards population aggregate, and for this reason dust suppression is a high priority, however only 9% of the time do winds blow in a north easterly direction towards population aggregate. From a work place point of view, the area of dust P 6/11 generation is the crushing circuit where there is the potential for the greatest concentration of dust and the greatest number of operating personnel. Typically the moisture content of the material being crushed is the most critical variable in controlling the amount of dust generated around the crushing plant. The use of lime in the gold extraction process has two purposes. It is used to create alkaline conditions for the safe use of the cyanide for gold dissolution and it also acts as a binding agent. When the lime is mixed with the crushed ore with the moisture content of 8-10%, the fine particles bind together and agglomerates. Once stacked on the heap leach pad the crushed ore is irrigated with the leach solution. It has the effect of almost immediately washing the near surface fines well within the heap. When the stacked ore undergoes periods of no irrigation and the ore dries out on the surface, there is little potential for dust generation from winds, due to the lack of fine and unagglomerated particles at the surface. Revegetation reduces fugitive dust to a minimal level upon project completion. Haul road dust suppression is most easily maintained with the use of water tankers and sprinkler systems. At present air emission is assumed from standard literature based on rates of emission and linked to rates of production and operating hours. Air quality impacts appear to be minimal during current operations and no change is anticipated. The environmental department is carrying out monthly water quality sampling in nearby water courses. The main purpose of this monitoring program is to verify that no free cyanide (CN-) or any of the various metal-complexes are detectable in the water. Four sample locations have been identified around the open pit that has the potential to be in hydraulic continuity with water from the open pit. In the unlikely event that there is extreme rainfall event whereby the storm water pond overflowed the only concern environmentally would be the cyanide in solution. If this water were to overflow into the environment the degradation of the free cyanide ion in an acid environment and the dilution effect of the water around the site would further reduce the cyanide concentration to such a level that it would pose no threat to fish or wildlife upon entering streams and rivers. However, the heap leach facility has been designed with sufficient solution storage capacity to ensure the likelihood of such an occurrence to be minimal. P 7/11 The potentially most significant environmental issue associated with the “Quartzite” heap leach operation is a major chemical spill resulting in an emergency or crisis situation due to the potential environmental degradation that might result. The Emergency Response Plan is the umbrella document which documents the way “Quartzite” would react to any crisis event. A chemical spill is one particular crisis event. The company ensures that environmental guidelines and procedures are periodically reviewed to ensure that they remain current and effective. The HSE Coordinator has the sole authority to issue new, or amends existing, guidelines and procedures. The HSE Coordinator has primary responsibility for tracking regulations and international standards, as well as the identification and monitoring of environmental permission requirements, issued by regulators. The HSE Coordinator, with assistance of senior management, are responsible for identifying environmental monitoring and to develop comprehensive, documented guidelines and/or procedures to implement these requirements. These guidelines and procedures are reviewed and updated at least annually or when operations and/or external circumstances change significantly. Similarly, HSE Coordinator is responsible for reviewing company’s regulatory commitments, which are then disseminated to management who ensure physical and/or management controls are implemented to ensure compliance. “Quartzite” plan applies to significant spills of stored chemicals and petroleum products. The containment and mop-up operation will consist of the following: In the event that spilled process fluids, chemicals or petroleum products have escaped from existing containment moats, earthen dykes will be pushed up with heavy equipment to contain the spill Pumps and absorbent materials will be used to remove the spilled fluid from the contained area Waste rock material contaminated by petroleum products will be excavated and placed in a designated area of the waste rock dump then covered with compacted material. All other contaminated material will be treated, excavated and placed on the waste rock dump to be covered by subsequent dumping The person discovering a chemical or petroleum product spill, or an accidental discharge from any component of the process water management system, will immediately notify their P 8/11 Supervisor, or designated alternate. The Supervisor will then be responsible for notifying all other appropriate individuals and coordinating the emergency response. A detailed Environmental Risk Assessment (ERA) is currently being undertaken examining the probability of an incident occurring which might result in the unplanned release of toxic chemicals into environment. Potential types of incident that are considered to be have the greatest impact on Quartzite operations include: Delivery truck accident with spillage Rupture of a liner of pad or pond Rupture of a main header pipe joint with major spray off the liner Failure of a holding tank or mixing tank Rupture of a process pipe Flood with pond system overflow to natural drainage (likely harmlessly diluted by then) Accidental acidification of cyanide solution in plant (pipe failures) and HCN gas emission. A seismic event could cause the dump to settle and hence potentially caused the integrity of the pond and pad liner to fail. The liner however, is designed to withstand considerable extension and failure is considered unlikely. The significant impact that could result from the “Quartzite” operation is an accident involving the release of chemicals during transportation, especially by road. The company recognizes that this is an area requiring greater attention and that contingency plans must be drawn up to enable a swift response to a potential incident. Accidental releases of chemicals or fuels constitute the prime environmental threat relating to the “Quartzite” heap leach operation. Although the probability of an incident is highly unlikely, a prudent operator develops management procedures to ensure a swift and effective response minimizes any impact to the environment. “Quartzite” is committed to providing a safe and healthy work place for all employees and contractors. Accomplishing this goal requires constant attention and the cooperation of every person at the work site. Keeping the importance of health and safety in the front of everyone's mind takes individual dedication and ongoing training, along with frequent safety and health reminders. Employees and contractors attend weekly departmental safety meetings as well as "tool box" meetings for individual crews. These meetings provide the opportunity for open communication and training on Health and safety topics in addition to timely updates of response to issues or concerns raised. P 9/11 ANTI - CORRUPTION PRINCIPLE 10 BUSINESS SHOULD WORK AGAINST CORRUPTION IN ALL ITS FORMS, INCLUDING EXTORTION AND BRIBERY ACTION TAKEN & IMPACT ACHIEVED and/or Plans for the upcoming Year “Quartzite” Ltd is committed to the highest standards in all aspects of its business. The Code of Business Conduct and Ethics, which emphasizes integrity, ethics, and fairness, elaborates on many of the legal and ethical principles to which we must all adhere. The Company expects its directors, officers and employees to comply in every respect with all applicable laws and regulations and to conduct the Company’s business in a way that protects and promotes our valuable reputation. P 10/11 How do you intend to make this COP available to your stakeholders? The COP will be posted on the Company’s website. Any feedback from “Quartzite” Ltd stakeholders is appreciated trough an e-mail and personal conversation. P 11/11