Computer/Hardware Engineer

advertisement

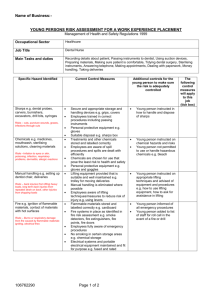

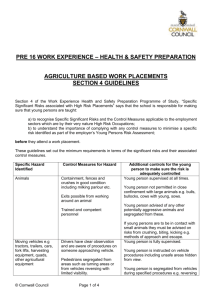

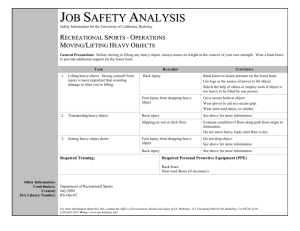

Name of Business:- YOUNG PERSONS RISK ASSESSMENT FOR A WORK EXPERIENCE PLACEMENT Management of Health and Safety Regulations 1999 Occupational Sector Engineering Job Title Computer Hardware Engineer Main Tasks and duties Designing and developing computers, Designing, manufacturing or programming microchips and circuit boards, Testing, Installation of new PC’s or circuit boards, General hardware advice, Taking deliveries Specific Hazard Identified Display Screen Equipment e.g. use of monitors, keyboards, other screens Risks – Work Related Upper Limb Disorders, Headaches, Other aches and pains, Eye discomfort Current Control Measures Electricity e.g. Use of electrical equipment, leads, testers, electrical systems Risks – Electrocution, burns Soldering e.g. manufacturing circuit boards, minor repairs Risks –Burns, flux fumes, asphyxiation, skin damage, asthma, dermatitis 533564978 Employees advised on correct posture and use of display screen equipment Suitable workstation set up e.g. adjustable chair, sufficient workspace, adequate upper limb support Suitable lighting or anti-glare devices e.g. anti glare screens Regular breaks or job rotation in place Health surveillance e.g. regular eye tests Electrical systems in good condition Repair work carried out by competent person Portable appliance leads etc in good condition Residual current and/or surge devices used Portable equipment regularly inspected and correctly fused and rated Protective clothing or other devices used as necessary to reduce static Adequate ventilation and lighting in workplace Employees trained in appropriate soldering techniques and precautions including suitable storage Soldering equipment maintained in good condition and inspected before use Personal Protective Equipment e.g. gloves, eye protection, suitable clothing, respirators Health surveillance e.g. skin checks Page 1 of 3 Additional controls for the young person to make sure the risk is adequately controlled Young persons advised of necessary precautions to reduce risk of injury or discomfort when using display screen equipment Regular breaks Suitable workspace set up for work or observation e.g. suitable chair Young persons not permitted to undertake electrical repairs or maintenance on live systems Young person advised of risks e.g. when observing work in a server room or near a control panel Young person instructed in risks associated with soldering and appropriate procedures Young person only performs light, simple tasks under supervision once a level of competency reached through instruction Personal Protective Equipment The following control measures will apply to this job (tick box) Fire e.g. hot equipment and flammable materials – cardboard boxes Risks – Burns or respiratory damage from fire caused by flammable materials igniting, electrical fires Manual Handling e.g. moving monitors, other computing components, boxed supplies on delivery Risks – back injuries from lifting heavy monitors or other loads, long term back injuries from repeated strain on back, other injuries from dropping loads Equipment or machinery e.g. pliers, wire strippers, other tools, testers Risks –cutting injuries from contact with equipment, trapped skin, electrocution from faulty electrical equipment Work environment e.g. floors, ventilation, lighting, temperature Risks – Slips, trips and falls resulting in fractures, bruises, grazes or cuts from contact with sharp edges, respiratory difficulties, dehydration Chemicals e.g. inks, glues, cleaning materials, paints Risks – skin or respiratory damage from contact, damage to eyes, poisoning Driving e.g. driving to customers premises, transporting goods Risks – road traffic accident resulting in fracture injuries or other to driver, passenger or pedestrians People/ home visits e.g. visits to domestic premises Risks – Stress or risk of attack if working alone 533564978 Flammable materials stored and labelled correctly e.g. cardboard Fire systems in place as identified in fire risk assessment e.g. smoke detectors, fire extinguishers, fire points, fire doors Employees fully aware of emergency procedures No smoking in certain storage areas e.g. cardboard storage Electrical systems and portable electrical equipment maintained and fit for purpose e.g. fused and rated Lifting equipment provided that is suitable and well maintained e.g. trolley for moving monitors Manual handling is eliminated where possible Employees aware of lifting techniques/measures to reduce risk of injury e.g. secure loads, not bending or twisting back Large items requiring assistance to move are identified or labelled Equipment maintained in good condition and fit for purpose Equipment has ergonomic features allowing ease of use and reduced risk e.g. suitable grips, clear controls Suitable storage e.g. protection on blades so can be handled Workplace is generally clean and tidy Adequate lighting, heating and ventilation is provided Workplace and fittings are well maintained Young person advised on housekeeping procedures Chemicals stored and labelled correctly Employees are aware of spill procedures and spills are dealt with efficiently Chemicals are chosen for use that pose the least risk to health and safety e.g. non solvent glues Personal protective equipment e.g. gloves and goggles Trained and competent drivers Suitable seating and seat belts Segregation of passengers and driver and equipment e.g. by proper storage, by a screen or storage in boot of car Employees have coordinated visits and where necessary phone in ‘call outs’ to main office Employees instructed on appropriate conduct and behaviour Mobile phone provided for home visits Young person instructed on chemical hazards Young person not permitted to use or handle hazardous chemicals e.g. aerosols Page 2 of 3 Young person informed of all emergency procedures Young person added to list of staff for roll call in the event of a fire or drill Young person instructed on appropriate lifting techniques and advised of equipment and procedures e.g. how to use lifting equipment, how to ask for assistance in lifting Consideration given of some lifting tasks that may be unsuitable for young person e.g. carrying light but bulky items that would restrict visibility of path to young person Young person is fully trained and instructed on use and equipment is suitable e.g. technical expertise Young person is fully supervised Young person not permitted to drive whilst on block work experience If riding as a passenger, young person has a safe and secure passenger seat with seat belt Young person supervised at all times, not permitted to work alone Confined spaces e.g. small server rooms, running cables Risks – Asphyxiation due to lack of oxygen Access/ Egress considered and retrieval possible Suitable temperature or ventilation levels or personal protective equipment provided Time spent working in confined space limited Young persons not permitted in confined spaces Young persons risk assessment completed by:- ________________________ Date:- __________ Name of student:- ___________________________________________________________________ Copy of risk assessment sent to:- ____________________________________ A copy of the risk assessment will be send to the parents via the school/college 533564978 Page 3 of 3 Date:- __________