solution

advertisement

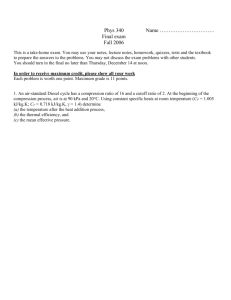

Chem E 260 HW #7 (Due: Friday - 11/16) 7-63 A cylinder is initially filled with saturated water vapor mixture at a specified temperature. Steam undergoes a reversible heat addition and an isentropic process. The processes are to be sketched and heat transfer for the first process and work done during the second process are to be determined. Assumptions 1 The kinetic and potential energy changes are negligible. 2 The thermal energy stored in the cylinder itself is negligible. 3 Both processes are reversible. Analysis (b) From the steam tables (Tables A-4 through A-6), T1 100 C h1 h f xh fg 419 .17 (0.5)( 2256 .4) 1547 .4 kJ/kg x 0.5 h h g 2675.6 kJ/kg T2 100 C 2 u 2 u g 2506.0 kJ/kg x2 1 s 7.3542 kJ/kg K 2 P3 15 kPa u 3 2247.9 kJ/kg s3 s 2 H2 O 100C x = 0.5 Q We take the contents of the cylinder as the system. This is a closed system since no mass enters or leaves. The energy balance for this closed system can be expressed as E Eout in Net energy transfer by heat, work, and mass Esystem Change in internal,kinetic, potential,etc. energies Qin Wb,out U m(u2 u1 ) For process 1-2, it reduces to Q12,in m(h2 h1 ) (5 kg)(2675.6 - 1547.4)kJ/ kg 5641 kJ (c) For process 2-3, it reduces to W23,b,out m(u2 u3 ) (5 kg)(2506.0 - 2247.9)kJ/ kg 1291 kJ SteamIAPWS 700 600 T [°C] 500 400 101.42 kPa 300 200 15 kPa 2 1 100 0 0.0 3 1.1 2.2 3.3 4.4 5.5 6.6 7.7 8.8 9.9 11.0 s [kJ/kg-K] 7-67 A hot copper block is dropped into water in an insulated tank. The final equilibrium temperature of the tank and the total entropy change are to be determined. Assumptions 1 Both the water and the copper block are incompressible substances with constant specific heats at room temperature. 2 The system is stationary and thus the kinetic and potential energies are negligible. 3 The tank is well-insulated and thus there is no heat transfer. Properties The density and specific heat of water at 25C are = 997 kg/m3 and cp = 4.18 kJ/kg.C. The specific heat of copper at 27C is cp = 0.386 kJ/kg.C (Table A-3). Analysis We take the entire contents of the tank, water + copper block, as the system. This is a closed system since no mass crosses the system boundary during the process. The energy balance for this system can be expressed as E Eout in Net energy transfer by heat, work, and mass Esystem Change in internal,kinetic, potential,etc. energies WATER 0 U or, U Cu U water 0 [mc (T2 T1)]Cu [mc (T2 T1)]water 0 Coppe r 50 kg 120 L where mwater V (997 kg/m3 )(0.120 m3 ) 119.6 kg Using specific heat values for copper and liquid water at room temperature and substituting, (50 kg)(0.386 kJ/kg C) (T2 80) C (119.6 kg)(4.18 kJ/kg C) (T2 25) C 0 T2 = 27.0C The entropy generated during this process is determined from T 300.0 K 3.140 kJ/K Scopper mcavg ln 2 50 kg 0.386 kJ/kg K ln 353 K T1 T 300.0 K 3.344 kJ/K S water mcavg ln 2 119.6 kg 4.18 kJ/kg K ln T 298 K 1 Thus, Stotal Scopper Swater 3.140 3.344 0.204 kJ/K 7-75C For an ideal gas, dh = cp dT and v = RT/P. From the second Tds relation, ds dh vdP c p dP RT dP dT dP cp R T T T P T T P Integrating, T P s 2 s1 c p ln 2 R ln 2 T1 P1 Since cp is assumed to be constant. 7-92 One side of a partitioned insulated rigid tank contains an ideal gas at a specified temperature and pressure while the other side is evacuated. The partition is removed, and the gas fills the entire tank. The total entropy change during this process is to be determined. Assumptions The gas in the tank is given to be an ideal gas, and thus ideal gas relations apply. Analysis Taking the entire rigid tank as the system, the energy balance can be expressed as E Eout in Net energy transfer by heat, work, and mass Esystem Change in internal,kinetic, potential,etc. energies 0 U m(u2 u1 ) u2 u1 T2 T1 IDEA L GAS 5 kmol 40C since u = u(T) for an ideal gas. Then the entropy change of the gas becomes T 0 V V S N cv ,avg ln 2 Ru ln 2 NRu ln 2 T1 V1 V1 5 kmol 8.314 kJ/kmol K ln 2 28.81 kJ/K This also represents the total entropy change since the tank does not contain anything else, and there are no interactions with the surroundings. 7-100 Oxygen is expanded in an adiabatic nozzle. The maximum velocity at the exit is to be determined. Assumptions 1 This is a steady-flow process since there is no change with time. 2 The process is adiabatic, and thus there is no heat transfer. 3 Oxygen is an ideal gas with constant specific heats. Properties The properties of oxygen at room temperature are cp = 0.918 kJ/kg·K and k = 1.395 (Table A-2a). Analysis For the maximum velocity at the exit, the process must be reversible as well as adiabatic (i.e., isentropic). This being the case, the exit temperature will be P T2 T1 2 P1 ( k 1) / k 120 kPa (363 K) 300 kPa 0.395 / 1.395 280.0 K There is only one inlet and one exit, and thus m1 m 2 m . We take nozzle as the system, which is a control volume since mass crosses the boundary. The energy balance for this steady-flow system can be expressed in the rate form as E E inout E system0 (steady) Rate of net energy transfer by heat, work, and mass Rate of change in internal,kinetic, potential,etc. energies E in E out V2 m h1 1 2 h1 0 300 kPa 90C 3 m/s 2 m h2 V2 ) 2 Solving for the exit velocity, V 2 1 0.5 2c p (T1 T2 ) 120 kPa T V12 V2 h2 + 2 2 2 V 2 V12 2(h1 h2 ) O2 300 kPa 1 120 kPa 2 s 0.5 1000 m 2 /s 2 (3 m/s) 2 2(0.918 kJ/kg K)(363 280 )K 1 kJ/kg 390 m/s 0.5 7-106 An ideal gas is compressed in an isentropic compressor. 10% of gas is compressed to 400 kPa and 90% is compressed to 600 kPa. The compression process is to be sketched, and the exit temperatures at the two exits, and the mass flow rate into the compressor are to be determined. Assumptions 1 The compressor operates steadily. 2 The process is reversible-adiabatic (isentropic) Properties The properties of ideal gas are given to be cp = 1.1 kJ/kg.K and cv = 0.8 kJ/kg.K. Analysis (b) The specific heat ratio of the gas is k cp cv 1.1 1.375 0.8 P3 = 600 kPa COMPRESSO R 32 kW P2 = 400 kPa P1 = 100 kPa T1 = 300 K The exit temperatures are determined from ideal gas isentropic relations to be, P T2 T1 2 P1 P T3 T1 3 P1 ( k 1) / k ( k 1) / k 400 kPa 27 273 K 100 kPa 600 kPa 27 273 K 100 kPa 0.375/1.375 437.8 K 0.375/1.375 489.0 K (c) A mass balance on the control volume gives 1 m 2 m 3 m where m 2 0.1m 1 m 3 0.9m 1 T We take the compressor as the system, which is a control volume. The energy balance for this steady-flow system can be expressed in the rate form as E E out in Rate of net energy transfer by heat, work, and mass E system0 (steady) 0 Solving for the inlet mass flow rate, we obtain Win c p 0.1(T2 T1 ) 0.9(T3 T1 ) 32 kW (1.1 kJ/kg K) 0.1(437.8 - 300) 0.9(489.0 - 300) 0.158 kg/s P2 P1 Rate of change in internal,kinetic, potential,etc. energies E in E out m 1h1 Win m 2 h2 m 3h3 m 1c pT1 Win 0.1m 1c pT2 0.9m 1c pT3 m 1 P3 s