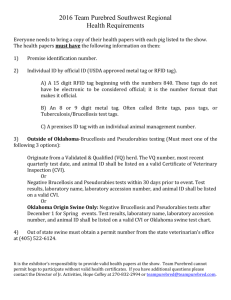

RFID - Computer Science and Computer Engineering

advertisement