Executive Summary

advertisement

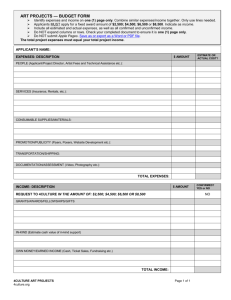

THE PROJECT «CREATION OF ENTERPRISE ON PRODUCTION OF HEAT-INSULATING NEW GENERATION CONSTRUCTION MATERIALS AND ROW MATERIALS FOR METALLURGY FROM INDUSTRIAL WASTE» Executive Summary TOPICALITY OF THE PROJECT. The total quantity of waste, accumulated in Europe, including the Ukraine, is about 25 billions tons, of which 4.7 billions tons are toxic. It equals 40 thousand tons per square meter or 500 tons per inhabitant. Ash-and-slag waste from the thermoelectric power station covers hundreds of thousands of hectares of fertile land and is continuously expanding and polluting aerial and aquatic areas. This has a negative impact on the environment and the health of its people. Suggested technology can be used for the utilization of ash-and-slag waste from industrial and municipal utility plants. Heat production is one of the main environment pollutants. Since the increase in costs of natural gas, the thermoelectric power stations are using solid fuel. This causes an increase in the quantity of solid wastes and will have a negative impact upon the ecological and socio-economical situation in the Ukraine. Also there are numerous unclaimed waste products accumulated in factory dumps and slag storages. These areas have almost turned into man-made ecological environmental problems. Donetsk, Zaporizhzhya, Kryvyi Rih, Mariupol and other regions have become zones of ecological and environmental catastrophes. There are no nickel, chromium, or non-ferrous metal mines in the Ukraine. These metals ores were all imported for refining. This situation has brought forth new interest in reprocessing the waste or slag from previously refined ore slag heaps. Up to now there has been very little interest in reprocessing these waste sites for their ore potentials. Processing this metal scrap has been performed with technologies that allowed only perfunctory extraction. Old technologies were not adequate to reprocess the potentials from this slag. When tested, it was established that 95% by volume of this metal waste slag contained up to 75% oxides, hydrates that had formed compound with chlorine, sulfur and silicon. The absence of updated processing technology does not allow for the proper processing of the waste slag itself. With the help of newly proposed technology, slag-heaps can be processed for metal extraction and simultaneously refining other materials. With the implementation of the new technology, it is now economically advisability and critical for Ukraine to reprocess this waste slag metal for building materials. We would be able to reduce the over-all refining expenses while implement an environmental protection program to solve ecological problems in the region. Taking into account, that all industrial facilities are site specific, it is proposed to organize a separate manufacture program that will specialize in slag-heap processing. This manufacture procedure will process almost any type of industrial metals waste that contains alloys, ferroalloys and building materials. It could be the waste of ferrous and non-ferrous metallurgy, chemical and utility production facilities, etc. DESCRIPTION OF THE TECHNOLOGY: Slag waste treatment technology that is based on the "know-how" to implement a revolutionary metal recovery technology through the application of electroslag re-melting methods that control the processes to obtaining recoverable end products. 1 The first portion of the treated slag is fused in a furnace of special design to melt the fitted flux or finely ground slag (initial phase). In doing so, under the action of a direct current, the high melting temperature mode is set and the formation of two immiscible liquids melt: metal alloyies and slag separation occurs. An introduction of special additives removes the oxygen from the metal oxides and the recovery of the metals take place. Slag is part of the lighter fraction and is located above the metal, this prevents waste and the corrosion of the metals. When the melted metals fill the whole furnace space, slag is discharged through the upper furnace window, and metal alloys are discharged through the lower tap-hole, and the process repeats. This technology provides a high performance furnace unit with a semi-continuous smelting process. Metal alloys are applied during production as an additive for various steel grades. Slag obtained under this process contains no metals or metal alloys and is ready for the production of bricks, paving , clinker for production of cement and other construction materials (e.g. heat insulation). Furthermore, metal alloys obtained during the initial refining process will contain no less than 85% metals, which may be nickel, chromium or copper, depending on the treated slag. Metal alloys obtained during the galvanic treatment, results in the production of highly purified electro-technical metals. Particular qualities of the proposed technology are as follows: In the course of re-smelting, the entire process creates little to no wastes, except for the metal alloys extraction. The materials are of the quality utilized in construction and other needed areas. There are provisions for securing various metal alloys to fulfill specific requests. This technology is able to separate metals and silicates from the smelting process during the silicates foaming process. The process receives a solid, porous, nonflammable and an insulation material (foam-silicate) from different fractions. It is used to as a covering to thermal insulation, overlaps, roofs, floors and filling materials as described in the production of thermal isolation articles (slabs, building and facing blocks, brick, etc.), with an apparent density from 50 to 300 kg/m 3. Also, the technology also manufactures as an end product, high-purity glassware made from the foam-silicate based adsorbents which may be used in industrial waste purification, burial and so on. Thus, the integrated products range is not limited only to slag’s or galvano-slag’s chemical composition, but has the technology for utilizing additional additives and fluxes. The universality of the electric arc direct-current furnace’s design allows the treatment of practically any production waste. The implementation of this proposed technology allows for additional products to be received: foam-silicate (solid, porous, nonflammable, insulation and soundproof materials based on their make-up) high-performance fillings for pavement and building construction for use in high work loads (“doorsill”) iron based with a high percentage of alloys that contains up to 30-80% of nickel, chromium and other expensive metals. 2 SCHEME OF CREATED PLANT MANUFACTURING IS SHOWN BELOW THE PLANT, PRODUCES TWO BASIC GROUPS OF PRODUCTS: FOAM-SILICATE AND METALS. MAIN MANUFACTURING WORKSHOP THE PROCESS OF ASH-AND-SLAG WASTE PROCESSING AND OUTWARD OF FOAM-SILICATE 6 BRIEF TECHNICAL INDICES. A foam-silicate brick is 1.5 - 2 times lighter than usual (silicates). Life expectancy is 75 years (versus 50 years for normal production brick). The cost of foam-silicate brick is 50% lower while it’s insulation quality is 10 times more effective. The insulation and mechanical characteristics of foamsilicate production exceeds all similar building materials. The comparison of all technical and consumer characteristics show that foam-silicate construction materials surpass all of the parameters of the traditional construction materials currently in use in the Ukraine. Costs of the new energy-efficient materials are important. Comparison of the Ukrainian construction markets shows that foam-silicate materials surpass greatly the currently used materials in every area, including Cost. It is significant that the foam-silicate is pollution-free, it breaths and is nonflammable. In the manufacturing process of the foam-silicate, no toxic substances are produced during the production. The foam-silicate compared to wood: the ecological coefficient of wood is 1, brick is 10, and haydite blocks are 20. Heat resistance insulation of foam-silicate is 1000 оС. Foam-silicate is fire resistant and satisfies the first level of refractoriness. Another road constructional material, obtained through use of the new technology is “DoorSill”. This material surpasses any foreign replacement and road mixes, of natural products, by all operating characteristics. Asphalt and concrete composite pavement filled with “DoorSill” filling when compared with traditional pavement made with granite rock, as a filling, has a 2-3 times longer maintenance cycle (especially in arduous climatic conditions and high mechanical loads), better adherence between tire and the pavement (shorter stopping distance), the capability to scatter light widely during night time driving to create better visibility. According to cost and for fast introduction of the foam-silicate ware into the market, it is possible to establish a price that is 30-60% lower than existing products. Existing Products _ _ _ New Technology Prices poured foam-silicate $47 per m3cost price $17 per m3 insulation board $72 each cost price $27 thermo-insulating building blocks 1 thousand standard units - $70 cost price $30 Average for Ukraine cost prices of building materials by January 2007: keramzite blocks $78-89 per 1 m³ lime-sand brick $88 per 1 m³ red clay burnt brick $250 per 1 m³. It is significant that cost of building material is rising constantly. The costs of “DoorSill” is lower than the cost of the natural granite rock and at least 2 times lower than the price of the foreign product “Sinopal”. The quantity of raw materials (ash-and-slag waste) for the proposed technology is unlimited in Ukraine. For example there are more than 30 millions tons of ash-and-slag waste at the Trypilska thermoelectric power station. The location of the power station is situated i 40 km away from Kyiv. Annual program of production output for manufacture is: - Technical foam-silicate – 3,500,000 m3 - Metals – 35,000 tons. Prices of production (dated March 1st 2008): foam-silicate and wares - $47 per 1 m3 metals (high alloy on basis of iron or half for it producing, that contains up to 30-80% of nickel, chromium) - $3 500 per ton. Annual gross revenue from manufacture reaching productive capacity is $287 millions. The customers’s letter of guaranty the manufactured products, will be present on demand. 7 Economic indicators under the Project Table 1. Expense of investment capital on production development № 1. 1.1 1.2. 1.3. Cost, US Dollars Name and work types Technology, formation, management Purchase of waste recycling technology Developing WCD specialized melting facility Developing of power supply systems and technological process control Тотal: 2. Planning works 2.1 Project of the waste recycling complex stage of technical and economic 2.2. assessment. Development of the Environmental Project 3.2. 3.2.1. 3.2.2. 4. 4.1 4.2 4.3 4.4 4.5 4.6 4.7. 4.8. Main technological equipment Melting facility – the set consisting two electric arc furnaces of direct current, capacity – 12 t. , new development with production and supply. Electric power equipment 2 580.000,00 The sources set – two standard transformers 9,0 МVА 1 800.000,00 2 300.000,00 Current-limiting inductors (reactors), transducers, heat-exchanging unit, control systems with producing of control box and desk – new development and producing. Total: 6 680 000.00 Supporting facilities. Low voltage circuit (copper bus with compensators, cable set) Outside furnace equipment (casting molds, slag pots, tools etc.) Gas treatment complex with exhauster on the base of two ФРИР- 1000 Watercooling (cooling stacks, pumping equipment) Laboratory rapid analysis ( equipment) Preparing of burden material (grinders, blending machines, weigher) Cranage crampon desiccator, The set of equipment for foam-silicates production. Total: Total technological equipment: 5. 5.1. 5.2. 5.3. 5.4. 5.5. 5.6. 5.7. 5.8. 5.9. 5.10. 5.11. 840 000.00 60 000.00 900 000.00 Total: 3. 3.1. 1 200 000.00 240 000.00 320 000.00 1 760.000.00 600.000,00 960.000,00 1 200.000,00 800.000,00 140.000,00 960.000,00 1200.000,00 600.000,00 6 460 000.00 13 140 000.00 Building and assembly works. Production building of melting facility Firing substation buildings Understructure of equipment and furnace working platform Assembly of technological, crane and electric equipment of furnace Construction and assembly of gas treatment equipment Construction and assembly of cooling stacks equipment. Laboratory area Construction of the site for preparing of burden material Start-up work Administration building (complex0 Gas treatment system 1 960.000,00 76 000,00 900.000,00 1 600.000,00 600.000,00 300.000,00 200.000,00 150.000,00 1 900.000,00 850 000.00 450 000.00 8 5.12. 5.13. 5.14. 5.15. 375 000.00 295 000.00 175 000.00 955 000.00 Complex of circulating water supply cycle Electrical substation Compressor room Storage houses TOTAL: 10 786 000.00 26 586 000.00 Total value Additional expenses 1 109 000.00 2 745 000.00 Social city development 10% Total value of the complex 30 440 000.00 ECONOMICS OF PRODUCTION Table 2. Nessesary investment capital № Cost items Cost, US Dollars 4 274 400,00 1. Planning work and technology 2. Equipment cost «ready-to-operate» 13 140 000,00 3. Construction and reconstruction cost including extraordinary expenses 9 067 0000,00 4. Funds for enterprise organization 300 400,00 5. Funds for initial production needs 913 200,00 6. Socials services 2 745 000,00 Total: 30 4400 000,00 Including construction of administrative building, gas cleaning, water supply complex, electric substation, compressor unit and workshop premises. Calculating of economic results of melting complex on base of ДСППТ-12 ИР. Enter data (period of works - year): 1. 2. 3. 4. Productivity of melting complex makes 20 000 tones per year. Final product - foam-silicates: 18 000 tones. At density of 150-160 kg/cub.m. the volume of produced foam-silicates will make 120 000 cub.m Quantity of workers): 135 persons 5. * Power consumption at full capacity of enterprise operation. Operation Name Quantity of electric power on 1 ton of metal in melting Quantity tones of metal in melting Melting 1350 kW/h 1.86 Quantity of Quantity of electric Quantity of electric melting per power per day power per year, day 350 day 8 30 900 kW/h 10 800 800 kW/h 9 Table 3. Cost of consumable row materials, materials and energy resourses at full capacity of enterprise operation during 1 year. № Expenses name Expenditure Price per unit, US Dollars Total sum, US Dollars Initial materials 1. Industrial waste 20 000,00 t 10,00 200 000.00 2. Regenerator 16 000.00 t 250,00 4 000 000.00 3. Lime-stone 24 000,00 t 25.00 600 000.00 Total 60 000,00 t 4 800 000.00 Energy recourses and others 6. Electric power* 10 800 800 kWt/h 0,1 1 080 000.00 7. Furnace electrodes 80 t 2.600.00 208 000.00 8. Covering material 40 t 300,00 12 000.00 9. Worker’s salary fund 94 persons 11 371,00 1 068 640.00 Total 2 368 640,00 All expenses 7 168 640,00 Production cost Table 4. Cost of equipment service at full capacity of enterprise operation during 1 year. № Name of cost items Sum of expenses, US Dollars 1. Wages of production workers 740 000,00 2. Charge on payroll 275 295,00 3 Current equipment repair 409 169,00 Total: 1 015 295,00 Table 6. Workshop expenses at full capacity of enterprise operation during 1 year. № 1. 2. 3. 4. Name of cost items Wages of engineers and administration Charge on payroll (40%) Buildings and constructions services Work safety expenses Total: Sum of expenses, US Dollars 322 800,00 122 315,00 650 714,00 335 463,00 1 431 292,00 10 Summary Table 7. Income and expenditure at full capacity of enterprise operation № Name of cost items Per month, US Dollars Per year, UA Dollars Production expenses 1. Variable (row materials, energy recourses etc.) -698 303,00 -8 379 638,00 2. Fixed (building and equipment services, etc.) -204 945,00 -2 459 340,00 Total expenses -903 248,00 -10 838 978,00 5. Income from sales of foam-silicate and metal row (net of VAT) +2 566 042,00 +30 792 500,00 6. Income +1 662 794,00 +19 953 522,00 7. Profit tax (25%) -415 699,00 - 4 988 381,00 +1 247 095,00 +14 965 141,00 Profit after tax payment CONCLUSION: Total investment sum makes 30 440 000 US Dollars Annual profit after tax payment will make 14 965 141 US Dollars 11 Schedule of project investing ГРАФИК ИНВЕСТИРОВАНИЯ ПРОЕКТА 3 500 000 3 000 000 2 500 000 2 000 000 1 500 000 1 000 000 500 000 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 месяцы проекта Credit term, months Period of grace, months 16 17 18 19 20 21 22 23 сумма, дол. США Project months Credit sum, $$ 15 Sum, US Dollars 30 440 000 156 36 Annual % rate 12,50% % due for payment 12,50% 4,43% 1,00% 12 Schedule of disbursement and credit repayment 1 Compensation for granting of credit 4,44% Commission for Agency contract services 1% 14 000 000 620 894 140 000 760 894 0 30 440 000 729 106 164 400 893 506 3-12 0 30 440 000 0 0 0 13-24 0 30 440 000 0 0 0 25-36 0 30 440 000 0 37-48 3 044 004 30 440 000 3 037 500 3 037 500 3 037 500 Months of the project 1 2 Credit disbursement 14 000 000 16 440 000 Repayment of loan principal 0 The sum of undercharged loan Credit payments (total) Credit payments (%%) 49-60 3 044 004 27 396 000 3 037 500 61-72 3 044 004 24 352 000 3 037 500 3 037 500 73-84 3 044 004 21 308 000 3 037 500 3 037 500 18 264 000 3 037 500 3 037 500 15 220 000 3 037 500 3 037 500 12 176 000 3 037 500 3 037 500 9 132 000 3 037 500 3 037 500 6 088 000 3 037 500 3 037 500 3 044 000 3 037 500 3 037 500 32 029 400 30 375 000 3 044 004 85-96 3 044 004 97-108 3 044 004 109-120 3 044 004 121-132 3 044 004 133-144 3 044 000 145-156 TOTAL 30 440 000 30 440 000 1 350 000 304 400 13 Pro forma statement of movement of funds 1-st year, $$ Cash flow from operational activity 1 2 3 4 5 6 7 8 9 10 11 12 TOTAL Sales income 0 0 0 0 0 0 0 0 0 0 0 0 0 Variable 0 0 0 0 0 0 0 0 0 0 0 0 0 Fixed -41 088 -48 539 -54 050 -57 495 -60 893 -64 245 -67 069 -69 855 -72 603 -76 550 -78 822 -81 063 -772 273 Payments into the budget -12 194 -9 607 -9 483 -8 808 -8 233 -7 667 -7 108 -6 638 -6 174 -6 230 -5 715 -5 336 -93 194 0 0 0 0 0 0 0 0 0 0 0 0 0 3 461 4 460 5 135 5 709 6 276 6 834 7 305 7 769 8 227 8 742 9 121 9 495 82 536 0 -3 461 -7 921 -13 056 -18 765 -25 041 -31 876 -39 181 -46 950 -55 178 -63 920 -63 920 0 -3 461 -4 460 -5 135 -5 709 -6 276 -6 834 -7 305 -7 769 -8 227 -8 742 -9 121 -8 742 -760 894 -893 506 0 0 0 0 0 0 0 0 0 0 -1 654 400 -814 176 -951 653 -63 533 -66 303 -69 127 -71 912 -74 178 -76 493 -78 776 -82 780 -84 537 -86 399 -2 519 867 0 0 0 0 0 0 0 0 0 0 0 0 0 -2 932 683 -1 363 439 -798 961 -1 098 406 -1 098 406 -1 098 406 -953 683 -953 683 -953 683 -831 850 -831 850 -831 850 -13 746 900 -2 932 683 -1 363 439 -798 961 -1 098 406 -1 098 406 -1 098 406 -953 683 -953 683 -953 683 -831 850 -831 850 -831 850 -13 746 900 14 000 000 16 440 000 0 0 0 0 0 0 0 0 0 0 30 440 000 0 0 0 0 0 0 0 0 0 0 0 0 0 14 000 000 16 440 000 0 0 0 0 0 0 0 0 0 0 30 440 000 Months of the project Credit VAT Debit VAT VAT reclaimed progressive total VAT Payments into the budget Interests and commissions (credit №1) The outcome from operational activity Cash flow from investment activity Founders contribution Fixed asset acquisition The outcome from investment activity Cash flow from financial activity Credit entry 1 Credit repayment 1 The outcome from financial activity Funds At the beginning of period At the end of period Cash flow 0 10 253 141 24 378 050 23 515 555 22 350 847 21 183 315 20 012 997 18 985 136 17 954 960 16 922 500 16 007 870 15 091 483 0 10 253 141 24 378 050 23 515 555 22 350 847 21 183 315 20 012 997 18 985 136 17 954 960 16 922 500 16 007 870 15 091 483 14 173 233 14 173 233 10 253 141 14 124 909 -862 494 -1 164 708 -1 167 532 -1 170 318 -1 027 861 -1 030 176 -1 032 460 -914 630 -916 387 -918 249 14 173 233 14 Pro forma statement of movement of funds, $$ Months of the project Sales income Variable 2 3 4 5 6 7 8 9 10 11 12 13 1 year year year year year year year year year year year year год TOTAL 0 0 33 710 925 36 951 000 36 951 000 36 951 000 36 951 000 36 951 000 36 951 000 36 951 000 36 951 000 36 951 000 36 951 000 403 220 925 0 -63 585 -3 374 312 -3 488 765 -3 641 369 -3 809 233 -3 993 884 -4 197 000 -4 420 428 -4 666 198 -4 936 545 -5 233 927 -5 561 047 -47 386 294 Fixed -772 273 -1 194 299 -3 454 582 -3 662 577 -3 680 699 -3 700 633 -3 722 560 -3 746 680 -3 773 212 -3 802 398 -3 834 501 -3 869 815 -3 908 661 -43 122 891 Payments into the budget -93 194 24 913 -5 473 695 -6 705 277 -10 184 210 -10 306 722 -10 381 800 -10 418 043 -10 421 794 -10 397 665 -10 348 926 -10 277 800 -10 185 680 -105 169 892 Interests and commissions (credit №1)) -1 654 400 0 0 -3 037 500 -3 037 500 -3 037 500 -3 037 500 -3 037 500 -3 037 500 -3 037 500 -3 037 500 -3 037 500 -3 037 500 -32 029 400 The outcome from operational activity -2 519 867 -1 232 971 21 408 336 20 056 880 16 407 222 16 096 912 15 815 256 15 551 777 15 298 066 15 047 239 14 793 527 14 531 958 14 258 111 175 512 448 Cash flow from investment activity 0 Founders contribution 0 0 0 0 0 0 0 0 0 0 0 0 0 0 -13 746 900 -16 693 100 0 0 0 0 0 0 0 0 0 0 0 -30 440 000 -13 746 900 -16 693 100 0 0 0 0 0 0 0 0 0 0 0 -30 440 000 0 Fixed asset acquisition The outcome from investment activity Cash flow from financial activity Credit entry 1 Credit repayment 1 The outcome from financial activity Funds At the beginning of period At the end of period Cash flow 0 0 30 440 000 0 0 0 0 0 0 0 0 -3 044 000 -3 044 000 -3 044 000 -3 044 000 -3 044 000 -3 044 000 -3 044 000 -3 044 000 -3 044 000 -3 044 000 -30 440 000 30 440 000 30 440 000 0 0 -3 044 000 -3 044 000 -3 044 000 -3 044 000 -3 044 000 -3 044 000 -3 044 000 -3 044 000 -3 044 000 -3 044 000 0 0 0 0 14 173 233 -3 752 837 17 655 499 34 668 379 48 031 601 61 084 513 73 855 769 86 363 546 98 617 612 110 620 851 122 370 379 133 858 337 797 546 883 14 173 233 -3 752 837 17 655 499 34 668 379 48 031 601 61 084 513 73 855 769 86 363 546 98 617 612 110 620 851 122 370 379 133 858 337 145 072 448 942 619 330 14 173 233 -17 926 071 21 408 336 17 012 880 13 363 222 13 052 912 12 771 256 12 507 777 12 254 066 12 003 239 11 749 527 11 487 958 11 214 111 145 072 448 15 Calculating of debt service ratio, $$ 1 год Amortization 36 659 53 877 64 883 78 959 92 828 106 493 117 985 129 305 140 458 150 125 159 644 169 018 1 300 233 Net profit for the period -847 373 -1 851 904 -1 979 645 -2 124 332 -2 285 721 -2 463 568 -2 655 259 -2 860 593 -3 079 369 -3 311 759 -3 555 562 -3 810 605 -3 810 605 Credit Interests payments 760 894 893 506 0 0 0 0 0 0 0 0 0 0 1 654 400 0 0 0 0 0 0 0 0 0 0 0 0 0 All expenses -49 821 -904 520 -1 914 761 -2 045 373 -2 192 893 -2 357 074 -2 537 275 -2 731 288 -2 938 911 -3 161 634 -3 395 917 -3 641 587 -855 972 All repayments for the period 760 894 893 506 0 0 0 0 0 0 0 0 0 0 1 654 400 Credit repayment Debt service ratio -0,52 Calculating of debt service ratio, $$ 1 year 2 year 3 4 5 6 7 8 9 10 11 12 13 ВСЕГО Amortization 1 300 233 3 695 010 4 760 526 3 791 400 3 033 886 2 439 360 1 970 753 1 599 747 1 304 662 1 068 858 879 527 726 783 602 969 27 173 715 Net profit for the period -3 810 605 -13 666 566 2 235 933 12 758 094 13 219 525 13 548 046 13 770 389 13 906 621 13 971 709 13 976 714 13 929 679 13 836 302 13 700 433 121 376 273 Credit Interests payments 1 654 400 0 0 3 037 500 3 037 500 3 037 500 3 037 500 3 037 500 3 037 500 3 037 500 3 037 500 3 037 500 3 037 500 32 029 400 0 0 0 3 044 000 3 044 000 3 044 000 3 044 000 3 044 000 3 044 000 3 044 000 3 044 000 3 044 000 3 044 000 30 440 000 All expenses -855 972 -9 971 556 6 996 459 19 586 993 19 290 912 19 024 906 18 778 642 18 543 868 18 313 871 18 083 072 17 846 707 17 600 585 17 340 902 180 579 388 All repayments for the period 1 654 400 0 0 6 081 500 6 081 500 6 081 500 6 081 500 6 081 500 6 081 500 6 081 500 6 081 500 6 081 500 6 081 500 62 469 400 -0,52 #ДЕЛ/0! #ДЕЛ/0! 3,22 3,17 3,13 3,09 3,05 3,01 2,97 2,93 2,89 2,85 2,89 Credit repayment Debt service ratio 16 Project months 1 2 3 4 5 6 7 8 9 10 11 12 1 год Calendar month of the project 1 2 3 4 5 6 7 8 9 10 11 12 ВСЕГО Gross income 0 0 0 0 0 0 0 0 0 0 0 0 0 VAT 0 0 0 0 0 0 0 0 0 0 0 0 0 Updated Gross Income 0 0 0 0 0 0 0 0 0 0 0 0 0 Fuel 0 0 0 0 0 0 0 0 0 0 0 0 0 POL 0 0 0 0 0 0 0 0 0 0 0 0 0 Tiers 0 0 0 0 0 0 0 0 0 0 0 0 0 Accumulator storage battery 0 0 0 0 0 0 0 0 0 0 0 0 0 Electric power 0 0 0 0 0 0 0 0 0 0 0 0 0 Wages of main personnel 0 0 0 0 0 0 0 0 0 0 0 0 0 Transport rent 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 Administrative personnel wages 32 516 34 849 37 181 37 181 37 181 37 181 37 181 37 181 37 181 38 553 38 553 38 553 443 293 Communication and community facilities 1 458 1 667 1 875 1 875 1 875 1 875 1 875 1 875 1 875 1 979 1 979 1 979 22 188 Business trips 2 100 2 400 2 700 2 700 2 700 2 700 2 700 2 700 2 700 2 850 2 850 2 850 31 950 Operational expenses VARIABLE: FIXED: Service and repair of fixed assets 175 200 225 225 225 225 225 225 225 238 238 238 2 663 Transport 1 458 1 667 1 875 1 875 1 875 1 875 1 875 1 875 1 875 1 979 1 979 1 979 22 188 Security 1 633 1 867 2 100 2 100 2 100 2 100 2 100 2 100 2 100 2 217 2 217 2 217 24 850 Clerical and other expenses 10 480 14 499 16 902 19 772 22 604 25 397 27 751 30 072 32 362 34 449 36 343 38 210 308 841 Total operational expenses 49 821 57 147 62 858 65 729 68 560 71 354 73 707 76 028 78 318 82 265 84 159 86 026 855 972 Amortization 36 659 53 877 64 883 78 959 92 828 106 493 117 985 129 305 140 458 150 125 159 644 169 018 1 300 233 Electric power Credit interests and commissions 760 894 893 506 0 0 0 0 0 0 0 0 0 0 1 654 400 Profit before-tax income (for period) -847 373 -1 004 530 -127 741 -144 688 -161 388 -177 847 -191 692 -205 333 -218 776 -232 390 -243 803 -255 044 -3 810 605 0 -847 373 -1 851 904 -1 979 645 -2 124 332 -2 285 721 -2 463 568 -2 655 259 -2 860 593 -3 079 369 -3 311 759 -3 555 562 -3 810 605 -847 373 -1 851 904 -1 979 645 -2 124 332 -2 285 721 -2 463 568 -2 655 259 -2 860 593 -3 079 369 -3 311 759 -3 555 562 -3 810 605 -3 810 605 Net operating loss carry-back (at rising ) Assessable incomes/losses 17 Income tax Net profit / losses 0 0 0 0 0 0 0 0 0 0 0 0 0 -847 373 -1 851 904 -1 979 645 -2 124 332 -2 285 721 -2 463 568 -2 655 259 -2 860 593 -3 079 369 -3 311 759 -3 555 562 -3 810 605 -3 810 605 Profit and material losses pro forma statement for 1-13-th years, $$ Project months Calendar month of the project 1 2 3 4 5 6 7 8 9 10 11 12 13 year year year year year year year year year year year year 36 951 000 36 951 000 36 951 000 36 951 000 36 951 000 36 951 000 36 951 000 36 951 000 36 951 000 year 36 951 000 TOTAL 403 220 925 6 158 500 30 792 500 6 158 500 30 792 500 6 158 500 30 792 500 6 158 500 30 792 499 6 158 500 30 792 498 6 158 500 30 792 497 6 158 500 30 792 496 6 158 500 30 792 495 6 158 500 30 792 494 6 158 500 30 792 493 67 203 488 336 017 410 Gross income 0 0 33 710 925 VAT 0 0 5 618 488 Updated Gross Income 0 0 28 092 438 Operational expenses 0 VARIABLE: FIXED: Fuel 0 45 000 999 000 1 080 000 1 188 000 1 306 800 1 437 480 1 581 228 1 739 351 1 913 286 2 104 614 2 315 076 2 546 584 18 256 419 POL 0 6 750 149 850 162 000 178 200 196 020 215 622 237 184 260 903 286 993 315 692 347 261 381 988 2 738 463 Tiers 0 1 013 22 478 24 300 26 730 29 403 32 343 35 578 39 135 43 049 47 354 52 089 57 298 410 769 Accumulator storage battery 0 225 4 995 5 400 5 940 6 534 7 187 7 906 8 697 9 566 10 523 11 575 12 733 91 282 Electric power 0 0 173 333 173 333 173 333 173 333 173 333 173 333 173 333 173 333 173 333 173 333 173 333 1 906 667 Wages of main personnel 0 0 1 687 560 1 687 560 1 687 560 1 687 560 1 687 560 1 687 560 1 687 560 1 687 560 1 687 560 1 687 560 1 687 560 18 563 160 Transport rent 0 0 83 333 83 333 83 333 83 333 83 333 83 333 83 333 83 333 83 333 83 333 83 333 916 667 Utilization service (ground) Service and repair of fixed 0 0 500 000 500 000 500 000 500 000 500 000 500 000 500 000 500 000 500 000 500 000 500 000 5 500 000 assets 0 6 292 139 688 151 014 166 116 182 727 201 000 221 100 243 210 267 531 294 284 323 713 356 084 2 552 761 Administrative personnel wages 443 293 385 532 385 532 385 532 385 532 385 532 385 532 385 532 385 532 385 532 385 532 385 532 385 532 5 069 677 Communication and community facilities 22 188 35 000 99 627 99 627 99 627 99 627 99 627 99 627 99 627 99 627 99 627 99 627 99 627 1 153 081 Business trips 31 950 50 400 50 400 50 400 50 400 50 400 50 400 50 400 50 400 50 400 50 400 50 400 50 400 636 750 Electric power 2 663 4 200 4 200 4 200 4 200 4 200 4 200 4 200 4 200 4 200 4 200 4 200 4 200 53 063 Transport Consulting services 22 188 35 000 35 000 35 000 35 000 35 000 35 000 35 000 35 000 35 000 35 000 35 000 35 000 442 188 0 0 1 685 546 1 847 550 1 847 550 1 847 550 1 847 550 1 847 550 1 847 550 1 847 550 1 847 550 1 847 550 1 847 550 20 161 046 Security 24 850 39 200 39 200 39 200 39 200 39 200 39 200 39 200 39 200 39 200 39 200 39 200 39 200 495 250 Clerical and other expenses 308 841 624 359 624 359 624 359 624 359 624 359 624 359 624 359 624 359 624 359 624 359 624 359 624 359 7 801 147 855 972 1 232 971 6 684 101 6 952 809 7 095 080 7 251 579 7 423 727 7 613 090 7 821 390 8 050 519 8 302 562 8 579 809 8 884 780 86 748 389 1 300 233 3 695 010 4 760 526 3 791 400 3 033 886 2 439 360 1 970 753 1 599 747 1 304 662 1 068 858 879 527 726 783 602 969 27 173 715 1 654 400 -3 810 605 0 0 -4 927 980 16 647 810 3 037 500 17 010 792 3 037 500 17 626 034 3 037 500 18 064 061 3 037 500 18 360 519 3 037 500 18 542 161 3 037 500 18 628 945 3 037 500 18 635 618 3 037 500 18 572 906 3 037 500 18 448 402 3 037 500 18 267 244 32 029 400 190 065 906 Total operational expenses Amortization Credit interests and commissions Profit before-tax income (for 18 period) Net operating loss carry-back (at rising ) Assessable incomes/losses Income tax Net profit / losses -3 810 605 -3 810 605 -8 738 585 -13 666 566 0 -3 810 605 0 -13 666 566 -13 666 566 2 981 245 745 311 2 235 933 0 17 010 792 0 17 626 034 0 18 064 061 0 18 360 519 0 18 542 161 0 18 628 945 0 18 635 618 0 18 572 906 0 18 448 402 0 18 267 244 -26 215 756 167 660 755 4 252 698 12 758 094 4 406 508 13 219 525 4 516 015 13 548 046 4 590 130 13 770 389 4 635 540 13 906 621 4 657 236 13 971 709 4 658 905 13 976 714 4 643 226 13 929 679 4 612 101 13 836 302 4 566 811 13 700 433 46 284 481 121 376 273 Calculation of index of the project effectiveness Calculation of indexes of project effectiveness 1 2 3 4 5 6 7 8 9 10 11 12 13 Expected economic effect: 0 0 28 092 438 30 792 500 30 792 500 30 792 500 30 792 499 30 792 498 30 792 497 30 792 496 30 792 495 30 792 494 30 792 493 Variable expenses 0 51 654 7 185 157 7 278 134 7 402 104 7 538 471 7 688 475 7 853 479 8 034 984 8 234 639 8 454 259 8 695 842 8 961 583 Fixed expenses 851 146 1 460 523 1 742 286 2 175 429 2 209 605 1 839 688 2 288 552 2 334 041 1 976 568 2 439 120 2 499 665 2 158 754 2 639 525 Expected expenses 851 146 1 512 177 8 927 442 9 453 563 9 611 710 9 378 160 9 977 028 10 187 520 10 011 552 10 673 759 10 953 925 10 854 596 11 601 108 -851 146 -1 512 177 19 164 995 21 338 937 21 180 790 21 414 340 20 815 471 20 604 978 20 780 945 20 118 737 19 838 570 19 937 898 19 191 385 1 300 233 3 695 010 4 760 526 3 791 400 3 033 886 2 439 360 1 970 753 1 599 747 1 304 662 1 068 858 879 527 726 783 602 969 ДВПНА Amortization expenses Credit interests 1 654 400 0 0 3 037 500 3 037 500 3 037 500 3 037 500 3 037 500 3 037 500 3 037 500 3 037 500 3 037 500 3 037 500 Profit before tax -3 805 779 -5 207 187 14 404 469 14 510 037 15 109 404 15 937 480 15 807 218 15 967 730 16 438 783 16 012 379 15 921 543 16 173 615 15 550 916 Minus: income tax 0 0 745 311 4 252 698 4 406 508 4 516 015 4 590 130 4 635 540 4 657 236 4 658 905 4 643 226 4 612 101 4 566 811 -3 805 779 -5 207 187 13 659 158 10 257 339 10 702 896 11 421 465 11 217 089 11 332 190 11 781 547 11 353 474 11 278 316 11 561 514 10 984 105 Plus amortization 1 300 233 3 695 010 2 757 332 2 067 999 1 550 999 1 163 249 872 437 654 328 490 746 368 059 276 045 207 033 155 275 Minus: investment 30 440 000 0 0 0 0 0 0 0 0 0 0 0 0 Net cash flow -32 945 546 -1 512 177 16 416 490 12 325 338 12 253 895 12 584 714 12 089 526 11 986 518 12 272 293 11 721 534 11 554 361 11 768 547 11 139 380 Cumulative net cash flow -32 945 546 -34 457 723 -18 041 234 -5 715 895 6 538 000 19 122 714 31 212 239 43 198 758 55 471 050 67 192 584 78 746 945 90 515 492 101 654 872 Net profit Payback period without discount: 4,46 Average deposit rate for legal person 12,0% Discount rate: 12,0% Discount cash flow Cumulative discount cash flow 10 465 655 -1 205 499 11 684 933 7 832 975 6 953 189 6 375 808 5 468 687 4 841 154 4 425 512 3 774 020 3 321 603 3 020 693 2 552 858 -29 415 666 -1 205 499 11 684 933 7 832 975 6 953 189 6 375 808 5 468 687 4 841 154 4 425 512 3 774 020 3 321 603 3 020 693 2 552 858 -29 415 666 -30 621 165 -18 936 231 -11 103 256 -4 150 067 2 225 741 7 694 428 12 535 582 16 961 094 20 735 114 24 056 716 27 077 409 29 630 268 19 Discounted payback period: 5,42 Net present value: 29 630 268 Internal rate of return: 0,2815 Profit index: 1,97 1,00 Services cost 1,00 Variable expenses 1,00 объем услуг 1,00 1,00 1,00 1,00 1,00 1,00 1,00 Services volume 20 NET PRESENT VALUE (NPV) Discount factor Year (Initial cost) Net cash flow 13% Real value of net cash flow 30 440 000 1,0000 -30 440 000 1 -2 510 372 0,8889 -2 231 442 2 -9 971 556 0,7901 -7 878 760 3 6 996 459 0,7023 4 913 837 4 16 549 493 0,6243 10 331 767 5 16 253 412 0,5549 9 019 489 6 15 987 406 0,4933 7 886 111 7 15 741 142 0,4385 6 901 899 8 15 506 368 0,3897 6 043 519 9 15 276 371 0,3464 5 292 337 10 15 045 572 0,3079 4 633 226 11 17 014 214 0,2737 4 657 299 12 6 081 500 0,2433 1 479 723 13 21 127 072 0,2163 4 569 372 Disposal value 15 045 572 0,2163 3 254 063 NPV 28 432 439 INTERNAL RATE OF RETURN (IRR) IRR Year Net cash flow 18,8% 1,0000 13 30 440 000 -2 510 372 -9 971 556 6 996 459 16 549 493 16 253 412 15 987 406 15 741 142 15 506 368 15 276 371 15 045 572 17 014 214 6 081 500 21 127 072 Disposal value 15 045 572 0,1067 (Initial cost) 1 2 3 4 5 6 7 8 9 10 11 12 0,8419 0,7088 0,5967 0,5023 0,4229 0,3560 0,2997 0,2523 0,2124 0,1788 0,1506 0,1268 0,1067 NPV Real value of net cash flow -30 440 000 -2 113 422 -7 067 389 4 174 673 8 313 365 6 873 607 5 692 017 4 718 158 3 912 860 3 245 283 2 690 847 2 561 771 770 881 2 254 570 1 605 584 7 192 806 21 Payback period, months 80,7 Projected period of credit repayment, months 156 Net Present Value-NP 28 432 439 Profitability index of investment (PI) for discount of 13% 1,93 Rate of gross profit margins 99% Rate of operating profit margins 78% Rate of net profit margins 30% Cumulative of project’s Коммулятивный profile профиль рисков по проектуrisks Cumulating NPV, $$ $$ Кумулятива NPV, 7 000 000 6 000 000 5 000 000 4 000 000 3 000 000 2 000 000 1 000 000 0 -1 000 0001,000 3,000 5,000 7,000 9,000 11,000 Рис. - Кумулятивный показатель событий Pic1 1. Cumulative indexвероятности of event наступления probability 22 Indicator PI Project sensibility to variable expenses changing Level of variable expenses, % to the planning Indicator PI Project sensibility to product cost changing Cost service level Indicator PI Project sensibility to the planning production volume changing 23 Rendering service volume 24