Reduced Dissolved Oxygen Fermentation

advertisement

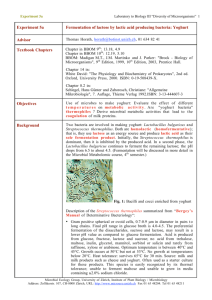

„Reduced Dissolved Oxygen Fermentation”: a New Commercial Method for Rapid, Low Temperature Yoghurt Production, H. Horiuchi, N. Inoue, N. Orii By reducing the dissolved oxygen (DO) content of yoghurt mix, we succeeded in the commercial production of “Bulgarian traditional home-made yoghurt” which is typically prepared in unglazed pots. The favorable features of the Bulgarian traditional home-made yoghurt are related to the following method of production. First, water in the milk is absorbed into the pot and the milk becomes concentrated. Second, the milk in the pot is gradually cooled by vaporization and fermentation proceeds at relatively low temperatures. Thus the yoghurt obtains a thick texture and mild taste. We attempted to mimic these conditions. Thick yoghurt mix could be easily prepared, but as expected the fermentation took much longer time at lower temperatures, making this procedure unsuitable for commercial yoghurt production. We recently found that Lactobacillus bulgaricus and Streptococcus thermophilus remove DO from the yoghurt mix early in the fermentation process. These lactic acid bacteria begin growing actively when the DO of the yoghurt mix is reduced to a certain level. We made use of this observation by reducing the DO content of the yoghurt mix beforehand, by the addition of nitrogen gas using a static mixer. This resulted in shortened fermentation times. We call this “Reduced DO Fermentation”, which is currently used in the production of “Bulgarian traditional home-made yoghurt” in Japan.