ACTIVATED CARBON

advertisement

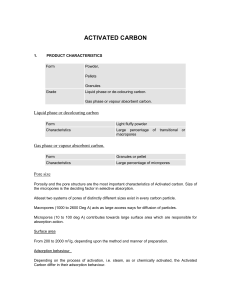

ACTIVATED CARBON 1. PRODUCT CHARACTERISTICS Form Powder, Pellets Granules Grade Liquid phase or de-colouring carbon. Gas phase or vapour absorbent carbon. Liquid phase or decolouring carbon Form Light fluffy powder Characteristics Large percentage macropores of transitional or Gas phase or vapour absorbent carbon. Form Granules or pellet Characteristics Large percentage of micropores Pore size Porosity and the pore structure are the most important characteristics of Activated carbon. Size of the micropores is the deciding factor in selective absorption. Atleast two systems of pores of distinctly different sizes exist in every carbon particle. Macropores (1000 to 2600 Deg A) acts as large access ways for diffusion of particles. Micropores (10 to 100 deg A) contributes towards large surface area which are responsible for absorption action. Surface area From 200 to 2000 m2/g, depending upon the method and manner of preparation. Adsorption behaviour Depending on the process of activation, i.e. steam, as or chemically activated, the Activated Carbon differ in their adsorption behaviour. Product specifications 2. Chemical parameters Acid washed Unwashed Moisture(%) max. 10 10 Methylene value(min) 270 280 KmnO4(min) 60 60 Iodine value 1100 1100 Ash(%) max. 3 NA Fe ppm 200 1000 pH 6.5 to 7.2 Adjustable Chlorine(%) max 0.4 NA Sulphate(%) max 0.4 NA Phosphate Nil Nil Acid soluble matter(%) 1.5 5 Water soluble(%) 0.5 4 Bulk density 4 to 6 gm/cc 4-6 gm/cc PRODUCT APPLICATIONS Activated carbon is a unique and effective agent for purification and for isolation and recovery of trace materials. During the last two to three decades, treatment with active carbon has become an important unit process for separations and purifications in the food, pharmaceuticals, sugar, chemical and other processing industries. Nature of applications For the removal of colour or odour, oxidising chemicals, compounds responsible for foaming, metallic ions which constitute impurity and invisible impurities, to improve product stability and to provide better cystallisation. For recovery of valuable materials, to enhance purity, to improve the appearance of product and to act as barrier to prevent migration of colour bodies. Gradewise application Grade Sector Powdered Activated carbon Vegetable oils, fats, sugar, treatment, pharmaceuticals, chemicals and food products. Granular Activated carbon Automotive canisters, air purification, chemical and pharmaceutical industry. Pelletised Activated carbon Solvent recovery, catalyst application etc 3. IMPORTS Around 1000 tonnes per annum 4. EXPORTS Around 2500 tonnes per annum water fine 5. INDIAN MANUFACTURERS There are around 50 producers of Activated Carbon in the country, mostly in Medium and SSI sector. The Indian producers of Activated Carbon include the following. Indian Manufacturers * Active Carbon India Ltd , Hyderabad * Bleachaid Minerals Mehdipatnam * Unichar International, Goa * Anil Starch Products Ltd.,Gujarat * Amar Carbon , Rajpipla * Baroda Carbons Limited,Baroda * J.C.Chemical Industries, Surat * Mahavir Industrial Corporation,Ahmedabad * Nikhil Intermediates Pvt. Ltd , Gujarat * Raj Carbons Pvt.Ltd.,Gujarat * Shri Rajpipla Amar Carbon & Chemical Industries,Dist.Bharuch * Unique Carbon and Chemicals, Gujarat * Industrial Carbons Pvt. Ltd.,Ankleshwar * Shreema Chemicals P.Ltd.,Himachal Pradesh * **Indo German Carbons Ltd., Alwaye, Kerala * Balaji Chemicals,Karnataka * Gowrishankar Chemicals,Karnataka * Key-Sun Enterprises,Mumbai * Kemie Industries, Mumbai * Advance Agro-Tech, Mumbai * Chandra Chemical Industries,Thane * Daisy Industries,Thane * Eurofine Chemicals, Mumbai * Kan-Carbon (P) Ltd.,Delhi * United Active Chars (P) Ltd.,Delhi * Amar Indl. & Fine Chemicals, Punjab * Brilex Chemicals,Amritsar * Century Absorbents, Punjab * Hindustan Indl.Carbon Products,Punjab * Hosch Industrial Absorbents,Punjab * Shriram Carbon Sales P.Ltd.,Dist.Hoshiarpur * Barium International, Rajasthan * Beta Gama Chemicals (P) Ltd.,Jaipur * Rajeshwari Industries, Rajasthan * Coco Shell Carbon (P) Ltd., Coimbatore * Core Carbons P. Ltd., Coimbatore * Fermi Chemicals, Chennai * Metroblue Industries, Madurai * Southern Agro Chemicals (P) Ltd.,Chennai * Shell Carb, Vellore * VVD Crops and Chems Ltd, Tuticorin * Sri Balaji & Co.,Tamilnadu * Dass Rasayanik Carbo Udyog, Uttar Pradesh * Jains Carbons (P) Ltd.,U.P * Unicarbons & Chemicals, Ghaziabad * Arunodaya Industrial Corpn.,Calcutta * Global Enterprises, Calcutta * International Chemical Agenices, Calcutta * The Smitaja Chemicals P.Ltd., West Bengal ** Indo German Carbon Ltd., has put up a joint venture with Kerala State Industrial Development Corporation Ltd., (KSIDC), for 2500 tonnes per annum Activated carbon plant with technology from Carbo Consult, Germany at a project cost of around Rs.15 crores at Kochi in Kerala. The company is promoted by Galfar India Group and KSIDC. 6. DEMAND SUPPLY TRENDS Sectorwise demand Sector Demand annum Pharmaceutical 2630 Plasticisers 1750 Glucose/Dextrose Monohydrate/Sorbitol 1550 Vegetable Oil 32500 Miscellaneous sector 6100 Export Sector 400 Total 44930 in tonnes per Indian demand is partly met by imports. Likely growth rate in demand : 9 to 10% per annum 7. MANUFACTURING PROCESS AND TECHNOLOGY DEVELOPMENT Activated carbon can be produced from any carbonaceous material, which on activation attain porous structure and consequently a large surface area. Raw materials such as wool, lignite, woods, coconut-shells, agricultural waste like bagasse, rice husk are generally used for the manufacture of Activated carbons. Raw materials having high carbon and low ash content are preferred. Coconut shell has been found to be most suitable raw material for making gas adsorption grade Activated carbon. >Activated carbon from Coconut shells Carbon Resources LLC, Oceanside, California, USA, is to market coconut shell Activated Carbon products throughout North America on behalf of Sri Lankan company, JB Carbon Activators. Under the agreement, JB Carbon Activators will manufacture coconut shell granular and powder Activated Carbons under Carbon Resource's quality control standards. According to Carbon Resources, the demand for coconut shell carbon in water purification will grow because of proposed stricter limits on the levels of Arsenic and Methyl tertiary butyl ether (MTBE) in water. Earlier, Carbon Resources signed an agreement to distribute natural char Activated Carbon to the water filteration market in the USA on behalf of Tate and Lyle Process Technology, which is based in Greenock, UK. 8. GLOBAL SCENARIO Demand for Activated Carbon: Around 0.50 million tonnes per annum Raw material The wood based Activated Carbon accounts for around 40% of the total world production. Major Producing Countries The Philippines and Sri Lanka are the major producers and exporters of Activated Carbon. Sri Lanka has increased its export volume of Activated Carbon to around 10,000 tonnes per annum. Global growth rate in demand 2 to 3% per annum 9. RECOMMENDATIONS Activated Carbon manufacturers are increasingly looking to securing production bases in Asia, where cost advantages can be obtained for both coconut shell and coal-based Activated Carbon. Tamil Nadu is an ideal location for the project in view of the abundant availability of coconut farms. Recommended capacity Estimated project cost 600 tonnes per annum Rs.500 lakh