The Structural Optimum Design of Erected Circular Medicine

advertisement

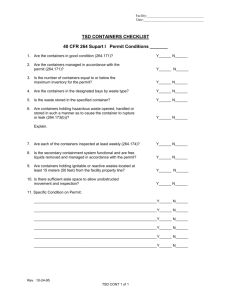

The Structural Optimum Design of Erected Circular Medicine-Chest Based on Non-intervention Motion Zhi-qiang Zhang 1,2, Chao Yun 1, Xiang-quan Liu 2,Li-yong Wang 2 1 2 .Institute of Robotics, Beijing University of Aeronautics & Astronautics, Beijing 100191 . School of Mechanical & Electrical Engineering, Beijing Information Science & Technology University, Beijing 100192 (zzqbj@sohu.com) Abstract: In this paper, the following studies are completed, including the analysis of the mechanical structure of the erected circular medicine-chest as well as its working principle, discussion of the non-intervention motion conditions of drug containers according to their different motion phases, establishment of the optimum functions of the chain transmission based on the conditions of the nonintervention motion of the containers, obtention of the minimum circular radius of drug containers by application of Matlab as well as the obtention of the design parameters of chain transmission, the simulation model building with UG and ADAMS, and the accomplishment of the motion simulation to prove the success of optimum design based on the non-intervention motion condition of drug containers. Key words: erected circular medicine-chest, optimum functions, non-intervention motion conditions, motion simulation I. supplementary equipment to the drug dispensing machine for box-packed drugs as effective assisting[4]. II. THE WORKING PRINCIPLE OF THE ERECTED CIRCULAR MEDICINE-CHEST In operation, after two rate reductions, one by reducer, the other by the first chain transmission, the motor of the erected circular medicine-chest drives the two driving chain wheels on the synchronizing shaft, connected to which are two driven wheels fixed on the two half axles accordingly. Driven by the chains, the support rods and balance bars fixed on them make all the drug containers move circularly. Drugs in the movable containers, after receiving the dispensing order, are conveyed along the shortest path and reached the outlets within the shortest time. INTRODUCTION Currently, with the limitation regarding technology, the drug storing system in a hospital pharmacy mainly consists of ordinary shelves, unable to realize the dense storage. In most of the hospital pharmacy, the facilities are old, working environment poor and pharmacists’ working intensity high. In addition, there are other problems such as storage complexity, space waste, low working efficiency, etc. The introduction of automated pharmacy system may help to make a better overall plan for the pharmacy, including reducing the drug storage area, effectively carrying out the standardized and automated management of the pharmacy, thus improving drug dispensing and reducing patients’ waiting time. The automated pharmacy system may be connected to HIS, putting all the working process of the working staff under the supervision[1-3]. The typical equipment is erected circular Medicinechest, which is originated from the digital-controlled erected circular inventory for the management and storage of accessories and tools in large factories. Basing on the stereoscopic inventory, when adding safety security, humanization design and connecting with the HIS system of hospital, it can be sued for the pharmacy management in the hospital. This is a semi-automatic system, in which the drug dispensary works should be done artificially. This type of automatic system is adaptable to the package of drugs, and can be used as the III. THE ANALYSIS OF THE CONDITIONS IN REGARD TO NONINTERVENTION MOTION OF NEIGHBOURING DRUG CONTAINERS As shown in Figure 1, the pitch of chain 084A: 12.7 mm; the span between the two support rods connected to the same container: 18 pitches; the span between the support rods respectively Figure 1. The structure of the erected circular medicine-chest connected to the neighbouring containers:4 pitches; the number of containers(evenly arranged along the chains):12. The pitch radiuses of both driving wheels and driven wheels: r; the overhang of the support rods: c; the width and height of the containers: w and h , respectively; the space between the centers of the pivots of the two neighbouring drug containers: H; the fixation range for the connection beam: A; the safety space between the connection beam and the drug container: s. As shown in Figure 2, with the center of driven wheel as the origin of coordinate, the reference coordinate is O O O O built; 1 、 2 、 3 、 4 are, respectively, the joint points of the transmission chain with the Supporting Rods A 1 A 2 , whose No. 1, 2, 3 and 4 for the Drug Containers , x1, y1 x2 , y2 x3, y3 coordinates are 、 、 、 x4, y4 A accordingly. 1 is the center of the pivot of A Container 1 and Supporting Rods No. 1 & 2, while 2 is the center of the pivot of Container 2 and Supporting A A Rods No. 3 & 4. The coordinates of 1 、 2 are X1,Y1 、 X2,Y2 respectively. The wheels do counterclockwise rotation. Suppose located in the pitch circle is Point B, which is on the same horizontal line with Center O of the O O O O chain wheel, coinciding with 1 , 2 , 3 , 4 are on the same vertical line. At the beginning of the container O motion, 1 moves unclockwise along the circle with r as the radius, while O When and O 2 2 O 2 , O 3 , O 4 move upward vertically. reaches the same height as that of Point O , move along the same circle. OO OO 0 1 and 2 when angle between along the same circle simultaneously; between OB and X axis; included 2 between OO3 is O 1 is the included O 1 1 O 、 2 move is the angle OO2 and O O space and the vertical space of the Centers of Pivots A. The mathematical model of the optimum design of chain transmission 1) The idea of the optimum design of chain transmission. The floor area of the erected circular medicine-chest refers to the projected area of the outline of the steelwork, whose length is affected by such factors as the length of the drug containers, while whose width by such factors as the turning radius and the width of the drug containers. After the design of the drug containers, the following references may be given, including the width wand height h of the container, as well as the pitch of the chain. In the design of the chain transmission, available are the best overhang of the support rods c and the pitch radius of the chain wheel r based on the optimum design, thus also available is the minimum turning radius of the container, whose outline of the steelwork is smallest in width. If the length remains the same, the floor area will be reduced, also reduced will be the mechanical deformation of the steelwork. 2) The design variables and objective functions Based on the analysis of the condition of nonintervention motion, 1 is a independent variable, if ,then the coefficient is introduced,and and will be variables, so: X x r1 1 xx 2 3 T T Lcr r 1 Y are the horizontal A THE OPTIMUM DESIGN OF CHAIN TRANSMISSION BASED ON NON-INTERVENTION MOTION () Based on the above, the expression of the objective function of the optimum design is: f x x 1 x 2 1 3) Constraints ① The vertical nonintervention motion of the containers on the left and those on the right: 2 L w A 2 s In the practical design, selected are the following data: X and and 2 , the condition of nonintervention motion is[5]: Xw if 0 , IV. To make available the smallest width of the outline of the steelwork, the Turning Radius L is taken as the objective function, then: the angle 2 , 3 when move along the same circle simultaneously. Suppose, at the motion of Containers 1 and 2, Xw, there must be no intervention When between the two drug containers. A 1 Figure2. The motion initial positions of the two neighbouring drug containers Y h w 4 2 0 m m , A 3 0 m m , s 8 7 m m ∵ Lcr r 1 , r 1 0 .3 1 2 m ∴ ②Since the container forces on the support rods, the overhang of the support rod should not be too long in order to ensure the enough strength of the chain. In the design: 0 . 1 5 m c 0 . 2 5 m . 1 5 m r 0 . 2 5 m 0 ③The diameter of the chain pitch circle: p d 180 sin z 1 2 .7 m m :the pitch of the chain, here p , z :40~60, p 60, . 0 8 1 m r 0 . 1 2 1 m 0 ④The space between the centers of the pivots of the two neighbouring drug containers: 1 2 .7 m m ∵ p , H ∴ (the space between the centers of the pivots of the two neighbouring drug containers moving vertically) must meet the following condition: Hhh0 h 0 : the gap between the two neighbouring drug h 3mm. containers moving vertically, generally 0 Then, according to the structure of the chain, H np . n :the number of the pitches whose total length amounts to h , i.e. the height of the container. 2 7 5 m m Here h ,and it may be calculated: n 22. n 22 If ,the total number of the pitches will be 264. H 2 7 9 . 4 m m ∴ ⑤ 0 , 2 n 3 6 0 6 .3 5 1 3 6 a r c s i n 0 (6) n 3 6 0 6 .3 5 2 8 a r c s i n 2 n1 (7) : the number of the pitches whose total length O n amounts to the distance between 1 and 2 ; 2 : the number of the pitches whose total length amounts to the O O distance between 2 、 3 . ⑥ Based on Formulae (3) and (4), it may be deduced: 1 . 2 4 3 . 0 8 0 2 1 0 2 ⑦The scope of : 4) The mathematical model Omitted here are the track equations of the centers of Pivots and that of the guide rail of the balance bars. From the above, Variables x1 , x2 and x3 may be 1 gx x x 0 . 2 5 3 21 0 1 0, When g x X 4 1 gx X 2 0 5 1 4 g x 2 7 5 Y x x 9 3 . 7 6 1 2 33 g x x R c o s x / 2 4 2 0 When 0 1 0 2, g x x R c o s x / 2 4 2 3 0 5 2 30 gx 2 7 5 R s i n /2 x 6 2 0 x x 3 9 3 .7 23 , When 0 2 1 g x X 4 3 gx X 2 0 5 3 4 g x 2 7 5 Y 6 3 2 2 1 0 When , g x X 4 4 gx X 4 2 0 5 4 gx 2 7 5 Y 6 4 2 0 2 , g x 2 7 5 Y 6 5 g 1 .2 4 x x 7 1 r O gx 0 . 1 5 x x 2 2 1 gx X 2 0 5 5 4 r z s .t g x 0 . 3 1 2 x 1 x 1 2 1 1 When g x X 4 5 : z the conditions of the Non-intervention Motion of the containers may be expressed as follows[6-8]: m i n fx x 1 x 2 1 substituted in the formula, then the optimum mathematical model of the chain transmission based on g x 3 .0 8 x 8 1 gx 0 . 0 8 1 x 9 2 g x x 0 . 1 2 1 1 0 2 g x3 1 1x gx x 2 1 2 3 0 2 B. The optimization based on Matlab It may be seen from the mathematical model, the optimum design belongs to that of the constrained nonlinear optimization[9]. The Matlab functions to solve the above problem of the constrained nonlinear optimization are FMINCON. The calculation results based on Matlab are: Lin 3 1 2 m m 1 .7 6 0 9 1 1 3 m m , r , m . 5 .8 8, rounded for According to formula(8), z5 z 56,then p d 226.5m m 180 sin z 1 1 3 . 2 5 m m i.e. r According to Formula ( 2 ) , if c 1 9 9 . 5 m m , the turning radius of the L 3 1 2 . 7 5 m m container . The results of the optimum design include the pitch of the chain: ,the overhang of the support rod: ,the number of the pitches whose total length amounts to the height of the container: ,the total number of the pitches: ,the diameter of the pitch: ,the teeth number of the chain wheel:56, the length of the chain: ,the theoretical center distance: the above mentioned structural optimum design is established by the analysis based on modeling and simulation. ACKNOWLEDGEMENT This work was completed with the support of the project of national natural science foundation of china (No. 51105041) REFERENCES [1] [2] [3] V. THE SIMULATION ANALYSIS BASED ON UG AND ADAMS [4] According to the results of the optimum design, by applying UG/Model, built up are the models of the chain wheels, chain, containers and support rods etc. The solid model for the analysis of the container motion is built up as shown in Figure 3[10]. According to the test results of the motion simulation intervention, based on the conditions of the Nonintervention Motion of the containers, feasible are the results that the turning radius of the container L 3 1 2 . 7 5 m m and the horizontal overhang of the c 1 9 9 . 5 m m support rods . [5] [6] [7] [8] [9] [10] Figure 3 The solid model for the analysis of the container motion VI. CONCLUSION The analysis is made on the working principle of the erected circular medicine-chest, built up are the conditions in regard to non-intervention motion of neighbouring drug containers, structure optimization is implemented by the application of Matlab, feasibility of Zhao Taoli, “hospital pharmacy automation is the inevitable trend of pharmacy development,”Capital Medicine. China, 2009, 16(24). Li Chengqun, Wang Wei, and Yun Chao, “Status quo and new development of automated pharmacy,”Robot Technology and Application. China, 2007(5). Liu Xiangquan, Yun Chao, Zhao Xuefeng, Wang Wei, and Ma Yongbo, “Research and Design on Automated Pharmacy,” Chinese Journal of Machine Design, Vol. 26 No. 7, 2009. Zhao Xuefeng, Yun Chao, Liu Xiangquan, Wang We, and Gao Zhihui, “Research on the automated pharmacy system,” Chinese Journal of Scientific Instrument, Vol.29 No.4, Apr. 2008. Zheng Zhifeng, Chain Transmission Design and the Application, Beijing:China Machine Press,1992. Liu Wenliang, , Design of Vertical Carousel Automation Based on SolidWorks, Jinan:Shandong University,2005. Wang Jizhong, Non-intervention Motion Conditions for Vertical Circulation of Parking Equipment Carrier, Machinery, 2005,32(3)::P22-23. Guo Peng, Study & Design of Vertical Circulation Cubic Garage Based on CAE, Jinan: Shandong University, 2007. Su Jinming, Zhang Lianhua, Liu Bo, MATLAB Toolbox Application, Beijing: Electronic Industry Press,2004. Lijun, Xing Junwen , Qin Wenhao, ADAMS Tutorial Example,Beijing: Beijing Institute of Technology Press,,2002.