каскадный метод реакций - новый взгляд на проблему

advertisement

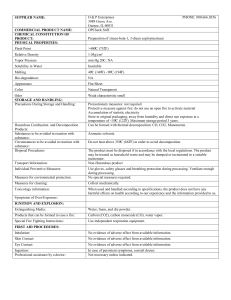

TREATMENT OF APATITE NEPHELINE ORE WASTEENRICHMENT WASTE Abstract The study demonstrated the efficiency of using the cascade reaction method applied to polymineral systems treatment, including technogenic waste of apatite nepheline ore. The conditions for minerals decomposition by sulphuric acid, content, and properties of forming solid phases have been researched. The sequence for carrying out production operations has been defined; the parameters and their operation modes were optimized. The paper demonstrates that cascade reaction method based on serial-parallel reactions allows the products if one reaction to participate as active reagents in the second reaction. This method provides complete use of initial mineral wastes and conversion of components in the form of wide range of useful products. Keywords: mineral waste, nepheline, apatite, titanite, cascade reaction method. 1. Introduction The necessity for the rational use of mineral resources is caused by their scarcity and non-reproducibility. Under the conditions of highly intensive field exploitation, minor part of minable raw material is used. In recent years Mining, Minerals and Sustainable Development project has gained world support (MMSD Project, 2002). In respect to the use of mineral resources, this conception provides disposal of mining waste since under exploitation of natural resources is source of a considerable waste amount having adversely effect on the environment (European Parliament and the Council of the EU, 2002). Waste deposits not only deprive useful area from economic circulation, but also represent the pollution sources of air, soil, underground, and surface water (Branwart, and Malmstrom, 2001, Broadhurst, and Petrie, 2010, Broadhurst, et al., 2007, Moncur, et al., 2005, Tadessa, 1994). In this regard, the researches on waste disposal followed by obtaining the new types of inorganic materials are of current interest. As a rule, flow charts of waste treatment are based on concentrating or chemical methods deriving only one or several components, thus not contributing to the complete waste disposal and slightly decreasing the environmental load. The offered waste treatment processing method is based on the cascade reactions principle, consisting in the fact that a share of products resulting from serial-parallel reactions is a raw material for the subsequent technologic stages and resource for getting new products. It is significant that as far as all or the majority of mineral components being the result of chemical transformations form end products, non-waste and low-waste technologies can be considered. The cascade method can be widely applied for polymineral waste treatment. However, regarding the implementation, it is necessary to conduct a particular complex of physical and chemical researches that includes the following stages: - Determination of amount for each mineral component composing the test material; - Definition of function for each mineral component; - Selection of chemical reactions leading to end product formation; - Study of kinetics and mechanism of end products formation; - Selection of optimum components ratio for targeted synthesis of products with the set properties. The possibility of cascade method application is shown in this work by the example of apatite nepheline ore wastes treatment (Kola peninsula, Russia). This waste is formed during ore flotation concentration with apatite and nepheline concentrate production. They are scarcely treated and, in the form of aqueous suspension, are sent to waste facilities. The new flow scheme of wastes disposal will allow producing a whole series of cheap products used in paint and construction materials industry, and sewage and drinking water purification of suspensions and pernicious contraries, including radioactive nuclides. 2. Material and method Nepheline wastes (fraction 5-150 μm) with composition (weight %): nepheline –30, apatite –5, titanite –25, aegirine –35, feldspar – 5 were used in this study. The bulk of the fine fraction (up to 50 m) consists of apatite and nepheline with traces of titanite, aegirine, and feldspar. The latter is concentrated in the coarser fraction. 1040% sulphuric acid was used in decomposition processes. The results of preliminary studies of individual concentrates were used to prepare a synthetic concentrate mixture similar to industrial wastes. The experiment was carried out in a reactor equipped with a stirrer and a thermometer, under reflux. In the reactor, the calculated amount of sulphuric acid was initially placed and stepwise, under stirring, the corresponding amount of concentrate was added. The obtained suspension was heated (if necessary) and stirred; the mixture was kept for 28h. The liquid phase was filtrated and both solid and liquid products were analysed. The pH of solutions was measured with Orion pH meter 611. Concentrations of metal ions in solutions were determined using AAS-300 atomic absorption spectrometer. Powder X-ray diffraction studies of samples were performed using a Siemens D 5000 diffractometer with a monochromatic Cu Kα radiation (λ = 1.5418 Å). Scanning rate of 2.4º min-1 was used for a 2θ diffraction angle range of 10-60 degrees. 3. Results and discussion The process of polymineral waste separation with synthetic and mineral products production is based on the different solubility of particular minerals in sulphuric medium. Thereby, gradual leaching of components from minerals into liquid state is taking place with their subsequent conversion into compounds, in which they individually or together with other compounds form end products. The alternation of chemical (solid phase interreacting with sulphuric acid) and physical (resulting suspension separation) reactions allows effecting process with preparation of intermediate and end product according to low waste technology. Principal chemical reactions involved in the method are as follows: (NaK)2Al2O32SiO2 +4H2SO4 = (NaK)2SO4 +Al2(SO4)3 +H2SiO3 + 3H2O (1) nepheline Ca5(PO4)3F + 5H2SO4 = 3H3PO4 +HF + 5CaSO4 ↓ (2) apatite Al2(SO4)3 + 2H3PO4 = 2AlPO4 ↓ + 3H2SO4 (3) CaSiTiO5 +2H2SO4 = TiOSO4 + CaSO4 ↓ + SiO2 ↓ + 2H2O (4) titanite TiOSO4 + H3PO4 + H2O = Ti(OН)2(HPO4)↓ + H2SO4 (5) Complexity and instability of system composition under study are the reason for particular challenges when developing technology. That is why an amount of each mineral component that composes waste under study was initially determined. Further interreacting kinetics of each mineral with selected sulphuric acid solution was studied, as well as kinetics and mechanism of mono- or polyphase residues formation based on primary reaction products, their optimum ratio for streamlined synthesis to produce tailor-made end products were defined. 3.1 Nepheline decomposition It has been found that both the type and structure of minerals incorporated in the wastes determine the order and rate of their dissolution. Therefore, nepheline, as the weakest mineral, was leached out at the first stage (Tole, et al., 1986, Hamilton, et al., 2001). When studying the first stage of the process (reaction 1) sulphuric acid solution with a concentration of 50-150 g/l H2SO4 was used. Sulphuric acid consumption made up 50-85% of theoretical necessary for interaction with acid-soluble components of nepheline. Nepheline decomposition reaction is followed by significant amount of heat release, which allows carrying out the process without external power supply. Nepheline adding in sulphurous solution was carried out for 15-20 minutes with the following agitation of reaction suspension for 1 hour. When using sulphuric acid with a concentration of less than 100 g/l H2SO4 leaching of main components proves to be incomplete and their content in liquid phase does not exceed 20 g/l in aluminium and silicium when converted into oxides. Acid strengthening to 150 g/l is accompanied by nearly complete leaching of mineral components. The crystallization process of aluminium sulphates and potassium alum takes place simultaneously. Under these conditions, silicium is prone to hard filterable colloid systems formation. At the consumption of H2SO4, less than 85% of its stereometric amount the degree of nepheline decomposition dips down and suspension tendency to polymerization with producing of colloids increases. Increase in acid consumption more than 85% of stoichiometry contributes to increase in transition degree of main components into solution to 90%, but resultant acid solutions are unusable, for example, as coagulum flocculants, since low рН of such solutions may lead to acidification of purifying water. According to findings, optimum conditions for nepheline decomposition are as follows: H2SO4 concentration - 100 g/l at the rate of 85% of stoichiometric rate (Table 1). Table 1. Nepheline decomposition by sulphuric acid H2SO4, concentration, g·l-1 50 100 150 H2SO4, consumption, % of stoichiometric value 50 85 100 50 85 100 50 85 100 Content of components in suspension, % Leaching to solution, % Al2O3 SiO2 Al2O3 SiO2 11.8 21.2 50.2 51.1 10.9 18.8 79.0 76.8 10.0 17.2 84.3 82.5 29.5 50.3 62.3 60.5 24.9 44.2 89.7 90.4 21.8 39.4 92.2 94.7 52.0 88.2 73.4 70.7 33.3 56.3 79.8 76.6 Polymerization in the process of preparation Solution stability, h 48 48 6 3 18 8 1 2 Тhe pH of the resulting solution was 1.9-2.0. These conditions ensure only the nepheline decomposition and release of the elements into the solution (Reaction 1). The mixture was stirred for one hour, and the pH was increased up to 2.1-2.3. When the reaction was completed, the solid products were isolated by filtration to obtain stable colloid products (Goto, et al., 1992, Otterstedt, et al., 1987). The concentrations of all elements in the resulting liquid phase (in terms of oxides) are gl1 : Al2O3 –25, SiO2 –44, Na2O –15, K2O –5, Fe2O3–1.5. The degree of nepheline decomposition, calculated from the quantity of aluminium and silicate oxides extracted to liquid phase, is about 90%. Because colloidal hydrosilicic acid coagulates in aqueous solutions, it can be used as a coagulating-flocculating agent (Zakharov, et al., 1996). The colloidal silica particles of a polymeric structure have a high surface area and facilitate the sorbent of dissolved impurities, increasing the degree of wastewater purification. 3.2 Apatite decomposition The second stage is interaction of apatite with sulphuric acid solution. The process of sulphuric decomposition of apatite results in phosphoric acid with a concentration of 28-50% in P2O5 and in calcium sulphate in the form of gypsum (Evenchik and Brodskii, 1987, Pozin, 1974). Sulphuric acid concentration impact and rate have been studied, as well as process time impact on apatite decomposition degree and structural features of calcareous phase. For this purpose when agitating concentrated sulphuric acid in amount of 110% of its stoichiometric amount necessary for calcium banding in the form of gypsum was slowly added (30 min) into aqueous suspension of apatite. Resulting concentration of H2SO4 in suspension liquid phase is 15-40%. Reaction mixture was heated to 80оС, and held when agitating for 2-6 hours. Calcium sulphate structure and fluorine recovery, which is evolved in the form of hydrofluosilicic acid with gas-vapour phase (SiO2+6HFH2SiF6+2H2O) and decreases medium aggressivity, depends on hold-up time and temperature. Resulting gypsum is separated by filtrating and washed with water at S:L=1:3. Apatite decomposition data is shown in Table 2. Table 2. The effect of the time of apatite decomposition and H2SO4 consumption on the liquid phase composition Decomposing conditions H2SO4, % , h 15 2 40 2 40 4 15 4 15 6 Liquid phase composition, g·l-1 P 2O 5 SO3 FSO2 The filtrates are unstable, precipitating immediately after filtration. 205.4 3.14 0.95 0.51 162.6 3.87 0.83 0.48 226.7 2.28 0.45 0.30 Solid phase composition, % P2O5 SO3 SiO2 - - - 1.89 1.87 1.97 1.56 40.8 41.5 42.7 35.0 1.58 0.64 0.47 0.25 Sulphuric suspension holding for 2 hours at a temperature of 80оС regardless of H2SO4 concentration is insufficient for complete solid phase precipitation. With increase of reacting mass holding time to 4 h the system is close to equilibrium and calcium precipitates almost completely. The higher sulphuric acid concentration, the more phosphorus content in the liquid phase. In the case of process time of 6 h, 2 ultimate recovery of phosphorus from apatite is reached (Fig. 1). S P2O5, gl-1 200 150 100 50 0 1 2 , h 3 4 5 Figure 1. Phosphorus (V) recovery from apatite during its decomposition by H2SO4, %(▲-10,●-20, ■-40) X-ray fluorescence analysis shows that main phase in all samples is gypsum CaSO42H2O, according to crystal optical analysis its particles is of needle prismatic form from 4-28 µm to 5-64 µm, are prone to aggregation (Fig. 6c). Impurity phase is anhydrite, the amount of which increases with increase in sulphuric acid concentration. The studies has proved that sulphuric acid concentration increase for more than 20% in H2SO4 is unfeasible since during real wastes processing titanite will be composed together with apatite (Fig. 2). For that reason the optimum conditions for apatite decomposition are as follows: sulphuric acid concentration 15-20%, temperature 80о С; time 5-6 h. Gypsum precipitation is well aggregated, low-level in relation to the mother solution. TiO2, gl-1 80 60 40 20 0 1 2 3 4 h 5 6 7 Figure 2. Titanium (IV) release from titanite during its decomposition (Tboil) by H2SO4, %(■-15,●-40) 3.3 Titanite decomposition Choosing conditions for titanite decomposition is based on the necessity of titanium (IV) conversion into liquid phase. Previously it had been established that this process proceeds under rigid conditions: sulphuric acid high concentration – 10001700 g/l Н2SO4, elevated temperature – 140-200оС (Goryachev, and Dvegubskii, 1990). At a low concentration of sulphuric acid to 300 g/l, H2SO4 titanium (IV) in liquid is unstable and precipitates in the form of titanium hydroxide. Herewith, mineral decomposition degree does not exceed 50% (Motov and Maksimova, 1983). For the research, sulphuric acid with a concentration of 400-600 g/l H2SO4 was chosen. Such choice provides high stability of titanium (IV) in liquid and leads to preparation of all-purpose titaniferous precursor (as solution), which acts as a basis for subsequent syntheses of various titaniferous products (Lazareva, et al., 2006). Fine-grained titanium (TiO2 – 35-37%) was used as a test object. Decomposition process was carried out at a boiling temperature (108-115оС), mass ratio of titanite and acid - Т:VL= 1:3. Resultant suspension was held when boiling and agitated for 7 hours. At that point leaching of sphene components takes place into liquid sulphuric phase with the later formation of reaction solid products – calcium sulphate and amorphous silica. Owing to high solubility, titanium (IV) is concentrated in liquid. Since decomposition process belongs to heterogeneous and proceeds at the interface of liquid (sulphuric acid) and solid phases (mineral particles), its speed depends on not only sulphuric acid concentration and temperature, but also on particles’ dispersion degree. Fig. 3 shows titanium (IV) content change in liquid suspension in the process of heating at the chosen concentration of sulphuric acid. The first stage of the process is a chemical reaction that proceeds at the surface of mineral particles with components leaching in liquid phase and early producing reaction solid products . -1 TiO2, gl 80 60 40 20 0 0 200 400 600 800 1000 1200 1400 1600 min Figure 3. Titanium (IV) release from titanite during its decomposition (Tboil) by H2SO4, г/л (▲-400,●-500, ■-600) Temperature rise and concentration of H2SO4 have a positive effect on reaction speed. This stage time is about 60 minutes. According to X-ray phase analysis, there is mainly titanite in solid phase and anhydrite in fewer amounts. With increase in reaction products in reaction mass, the process slows down. According to SEM reaction, products are formed in the form of individual phases, and forms porous shell at the surface of undecomposed sphene particles as well (Fig. 4). Figure 4. SEM image of titanite particle. Further decomposition process reaches the second stage related to reagent diffusion through that shell. The reaction speed at this stage is much lower than at the first one. Approximately, in 5 h decomposition speed is so low that one can consider pseudoequilibrium state of the system that can be tilted by external influence only. Sulphuric acid optimal concentration should be considered to be 600 g/l H2SO4, whereby titanium (IV) content in liquid phase is not less than 80g/l in TiO2 4. Description of the flow sheet, target product composition, and properties Flow chart of mineral wastes treatment with end products obtaining is shown in Fig. 5. Figure 5. Schematic flow chart of nepheline waste recovery The process proceeds in a periodic mode. At the first stage of decomposition wastes composed of minerals mixture (Fig. 6а) are treated with sulphuric acid with a concentration of 100 g/l at the solid-liquid stage ratio of S:L=1:8. o – titanite; ∆ – nepheline; ◊ – apatite; х – aegirine; s – СaSO4 Figure 6. XRD powder patterns for (a)-initial mineral waste, (b)-after nepheline leaching, (c)- gypsum, (d)- after apatite leaching, (e)-titanium adsorbent, (f)- the residue after third stage Under the chosen conditions nepheline decomposition degree exceeds 90% . When рН reaches 2.1-2.3, liquid phase is separated by filtrating or decantation. The filtrate is a colloid solution aluminium and silicium, which is watered to 10 gl-1 of SiO2 in order to increase aggregative stability. Efficiency of this colloid solution usage as a coagulum flocculants (Product I) is shown in Table 3. Table 3. The efficiency of alumosilicium coagulant for purification of industrial wastewater, pH-7.2 Impurities Before purification, mg·l-1 After purification, mg·l-1 Oil Suspensions Nitrate Sulphate Chloride Phosphate Ferrum 0.53 87.60 1.41 69.81 17.20 2.93 3.50 0.27 14.20 1.00 63.62 14.61 0.89 0.99 Purification efficiency, % 49.0 83.8 29.1 8.9 15.1 69.6 71.7 Represented data allows recommending aluminosilicic coagulum flocculants for cleaning industrial waste of suspensions and oil (Zouboulis and Tzoupanos, 2009, Pacheco and Rodriguez, 2000, Tzoupanos, et al., 2008, Morgunov, et al., 2006) At the second stage of decomposition mineral residue (Fig. 6б) is treated with 15% H2SO4 at S:L=1:1. The suspension is heated to 80оС and stirred for 6 h. In the process of heating decomposition of the residual quantity of nepheline and apatite with the formation of phosphoric solution containing aluminium and silicium takes place. Calcium sulphate is crystallized in the form of gypsum and transits in residue (Fig. 6с), which is separated from the solution by filtrating and sent to the third stage of decomposition. Phosphoric acid is added into the solution to precipitate aluminium and silica gel phosphates. Resultant residues wash off mother solution and heattreated (Product II). Washing degree and heat treatment temperature depend on requirements to the end product (Table 4) (Kalendova, 2002., Kalendova, 2003, Latishev, et al., 1997, Tolmachev, 1998). Table 4.Characteristic features of Product II Heat treatment, oС Up to 50 pH of extract 1.0-1.5 Up to 100 5.5-7.0 450-500 6.0-7.0 aqueous Components Areas of application Acidicaluminiumhydrophosphate, silica gel, water Basic aluminiumhydrophosphate, silica gel Basic aluminium phosphate, amorphous silica Anticorrosion paint primers, underpaint putty Water-based paints (dull) Water- and organic-based paints (gloss) After the second stage of decomposition solid residue, consisting of titanite, aegerite, and calcium sulphate, (Fig. 6d) is treated with sulphuric acid with a concentration of 600g/l H2SO4 at S:L=1:3. Reaction mass is heated to boiling temperature and held for 7 h and the suspension is filtered. Sulphuric filtrate with a concentration of titanium (IV) when converted into TiO2 – 70-80 g/l and 450 gl-1 H2SO4 is used for titaniferous compositions synthesis, in particular hydrated titanium phosphate (Product III) (Bortun, et al., 1997, Clearfield, 1995, Nilchi, et al., 2004). For this purpose the solution was heated up to 70 oС and the corresponding amount of phosphate agent (molar ratio of TiO2 : P2O5 = 1:0.5-5 ) was slowly added to it, leading to solid phase formation, titanium phosphate (Reaction 5). Evaporated filtrate after the second stage of decomposition is used as a phosphoric reagent. The suspension was stirred at this temperature for 8 h, the solid then filtered and washed firstly with 5% H3PO4 (to remove the excess of H2SO4) and secondly with water (till pH 2.8-3.2). The solid products were dried initially on air and then at 60оС. Precipitation degree of titanium (IV) when producing titanium phosphate is 95-99%. The final material is amorphous titanium hydroxyphosphate (TiP) with formula Ti(OH)2·(HPO4) ∙ 2H2O can be used as an ion-exchanger (fig.6e) ((Maslova, et al., 2008). Resultant adsorbent can be successfully used to clean liquid radioactive wastes of radionuclides and industrial wastes of heavy nonferrous and toxic metals. This adsorbent use efficiency is shown in Fig. 7. 160 140 120 A, mg/g 100 80 60 40 20 0 Cs 1 + Sr 2 2+ Fe 3+ 3 Cu 4 2+ Co 5 cations 2+ 2+ Ni Zn 6 7 2+ 3+ Cr 8 Figure 7. Sorption capacity (A) of some cations by titanium phosphate Residue from the third stage of decomposition (Fig. 6f) is divided into two factions by means of hydraulic classification. Light fraction, collected in catchers, includes phosphogypsum, calcium sulphate in anhydrite form and amorphous silica. Upon filtrating, the residue is heat treated at a temperature not more than 3000С. Resulting Product IV is a white or ecru powder, which can be used for dry construction mixtures preparation (Olmez, and Erden, 1989., Singh, and Garg. 2000., Singh, 1988, Singh, and Garg. 1992). Mineral part mainly consisting of aegerite (Product V) is dried and used for weatherproof fillers of paint and construction materials production (Table 5). Table 5. Characteristics of the products obtained from mineral waste Product Product I Components Colloidal solution of aluminium and silicium—a coagulating-flocculating agent Product II Acid aluminium phosphate, silica gel Product III Titanium hydrophosphate or its composite with silica gel Calcium sulphate, amorphous silica, titanium dioxide Sphene and aegirine concentrates Product IV Product V Field of use Thickening of suspensions with a finely divided solid phase. Water purification from oil, suspensions, iron, etc. Anticorrosion compounds on the organic and water bases Sorbent purification of toxic liquid effluents Dry building composites for whitewashing In the production of pigments, weather-resistant paints and paint primers Conclusions The composition of apatite-nepheline ore wastes has been studied. The chemical processing stages parameters in the cascade reactions method has been established. During the kinetic studies, the operation sequence and conditions of interaction between the waste components and H2SO4 were determined. The mechanism of the formation of mono- and polyphase residues based on primary reaction products has been established. Optimal parameters for directed synthesis of target products with tailored properties and the area of their application have been determined. The new process of nepheline wastes recovery is technologically attractive, considering that all steps are inter-connected and all by-products are utilized. This technology will make it possible to reduce the amount of dumped wastes by 70-80%. It has been shown that in order to obtain efficient nepheline removal from the wastes it is necessary to introduce the process of its interrelation with sulphuric acid in the mode providing for mineral dissolution rate not exceeding 90%. Moreover, aggregative non-stable system formation being accompanied by silica gel formation is excluded. The correct choice of titanium decomposition is based on the analysis of kinetic aspects of the process thus providing the high degree of titanium conversion (IV) into solution – 92% in TiO2; by adding phosphoric solution, the product is precipitated out of it. This product is a precursor for obtaining titanium-phosphatic sorbent capable to purify low-medium LRW as well as effluents containing cations of nonferrous heavy metals. References 1. Bortun, A.I., Bortun, L.N., Clearfield, A., (1997). Synthesis and characterization of ion exchange properties of spherically granulated titanium phosphate. Solvent extraction and ion exchange 15, (3), 515-532. 2. Branwart, S.A., Malmstrom, M.E., (2001). Hydrochemical modeling for preliminary assessment of mine water pollution. J. Geochemical Exploration 74, 73-97. 3. Broadhurst, J.L., Hansen, Y., Petrie, J.G, (2007). Waste characterization and water-related impact predictions for solid mineral wastes: a new approach. Water Research Commission Report, N 1550/1/07. 4. Broadhurst, J.L., Petrie, J.G., (2010). Ranking and scoring potential environmental risks from solid mineral wastes. Minerals Engineering 23, 182191. 5. Clearfield, A., (1995). Inorganic ion exchangers: a technology ripe for development. Ind. Engineering Chemistry Research 34, 2865-2872. 6. European Parliament and the Council of the EU, (2002) Decision no1666/2002/EC of the European Parliament and the Council of 22 July 2002 laying down the Sixth Community Environment Action Program. Official Journal of the European Communities, 10.09.2002 7. Evenchik, E.L., Brodsky, A.A., (1987). Technology of phosphate and complex fertilizers. Moscow, Nauka. 8. Goryachev, A.A., Dvegubskii, N.S., (1990). Sulphuric acid processing of sphene concentrate. Rus. J. Paint –and- lacquer materials and their application 4, 30-34. 9. Goto, S., Akazawa, K., Diamon, M., (1992). Solubility of silica-alumina gels in different pH solutions. Discussion on the hydration og slags and fly ashes in cement. Cement and Concrete Research 22, (6), 1216-1223. 10. Hamilton, J.P., Brantley, S.L., Pantano, C.G., Criscenti, L.J., Kubicki, J.D., (2001). Dissolution of nepheline, Jadeite and albite glasses: Toward better models for aluminosolicate dissolution. Geochimica et Cosmochimica Acta 65, (21), 3683-3702. 11. Kalendova, A., (2002). Comparison of the efficiencies of anticorrosive pigments based on chemically modified phosphates. Anti-Corrosion Methods and Materials 49, (5), 364-372. 12. Kalendova, A., (2003). Comparison of the anticorrosion efficiencies of pigments based on condensed phosphates and polyphosphosilicates. AntiCorrosion Methods and Materials 50, (2), 82-90. 13. Latishev, U.V., Lenev, A.M., Semenov N.F., (1997). Anticorrosive pigments. Rus. J. Paint-and-varnish materials and their application 2, 14-18. 14. Lazareva I.V., Gerasimova L.G., Okhrimenko R.F., Maslova M.V., (2006). Reaction of shene with sulphuric acid solutions. Rus. J. Applied Chemistry, 79,(1), 16-19. 15. Maslova, M.V., Rusanova, D, Naidenov, V, Antzutkin, O.N., Gerasimova, L.G., (2008). Synthesis, characterization and sorption properties of amorphous titanium phosphate and silica-modified titanium phosphates. Inorganic Chemistry 47, (23), 11351-11360. 16. MMSD (Mining, Minerals and Sustainable Development) Project, (2002). Mining for the future. Appendix A: Large Volume Waste Working Paper. N.31. 17. Moncur, M.C., Ptacek, C.L., Blowes, D.W., Jambor, J.L., (2005). Release, transport and attenuation of metals from an old wastes impoundment. Applied Geochemistry, 20, 639-659. 18. Morgunov, A.F., Kruchinina, N.E., Timasheva, N.E., Morgunov, P.A., (2006). Colloid-chemical regularities of water purification using an alumino-silicate flocculating-coagulating agent. Izvestiya VUZ. Chemistry and chemical technology 49, (4), 20-24. 19. Motov, D.L., Maksimova, G.K., (1983). Sphene and its chemical processing for titanium pigments and fillers. Leningrad, Nauka 20. Nilchi, A, Maragheh, M.G., Khanchi, A., Farajzadeh, M.A., Aghaei, A.A., (2004). Synthesis and ion-exchange properties of crystalline titanium and zirconium phosphates. J.Radioanal. Nuclear Chem., 261, (2), 393-400. 21. Olmez, H., Erden, E., (1989). The effect of phosphogypsum on the setting and mechanical properties of Portland cement and trass cement. Cement and Concrete Research 19, 377-384. 22. Otterstedt, J-E. A., Ghuzel, M., Sterte, J.P, (1987). Colloidal components in solutions of alkali silicates. J. Colloid Interface Sci. 115, (1), 95-103. 23. Pacheco, S., Rodriguez, R., (2000). Flocculation process of alumino-silicate particles using different metal ions in aqueous and alcoholic solution. J. Noncrystalline solids, 277, 30-38. 24.Pozin, M.E., (1974). Technology of mineral salts. Part 1. Chemistry, Leningrad. 25. Singh, M., (1988). Utilization of by-product phosphogypsum for building materials. Building Research Note 9. CBRI Publication, Roorkee, India. 26. Singh, M., Garg.M., (1992). Investigation of durable gypsum binder for building materials. Construction Building Materials 6, 52-56. 27. Singh, M., Garg.M., (2000). Making of anhydrite cement from waste gypsum. Cement and Concrete Research 30, 571-577. 28. Tadessa, B, Donaldson, J.D., Grimes, S.M., (1994). Contaminated and polluted land: a general review of decontamination management and control. J. Chemical Technology & Biotechnology 60, 227-240. 29. Tole, M. P , Lasagaa, A.C., Pantanoa, C., Whitea, W. B., (1986). The kinetics of dissolution of nepheline (NaAlSiO4). Geochimica et Cosmochimica Acta 50, (3), 379-392. 30. Tolmachev, I.A., (1998). Anticorrosive water-based paints. Rus. J. Paint-andvarnish materials and their application 1, 23-28. 31.Tzoupanos, N.D., Zouboulis, A.I., Zhao, Y.-C., (2008). The application of novel coagulant reagent (polyaluminium silicate chloride) for the post-treatment of landfill leachates. Chemosphere, 73, (5), 729-736. 32. Zakharov, V.I., Matveev, V.A., Maiorov, D.V., (1996). Effect of process parameters of acid decomposition of nepheline on the filterability of silica sediments. Russ. J. Applied Chemistry 69, (3), 322-326. 33. Zouboulis, A.I., Tzoupanos, N.D., (2009). Polyaluminium silicate chloride – a systematic study for the preparation and application of an efficient coagulant for water or wastewater treatment. J. Hazardous Materials 162, (2-3), 13791389.