Investigation of the Flow and Pressure Characteristics Around a

advertisement

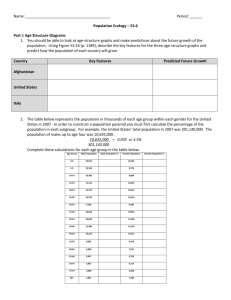

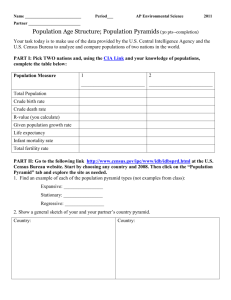

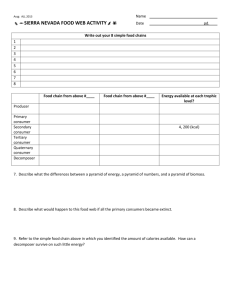

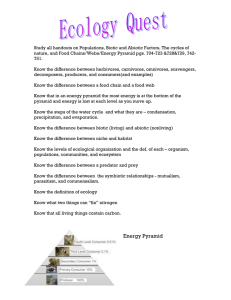

Investigation of the Flow and Pressure Characteristics Around a Pyramidal Shape Building1 M. Ikhwan & B. Ruck Laboratory of Building- and Environmental Aerodynamics Institute for Hydromechanics, University of Karlsruhe, Kaiserstr.12, 76128 Karlsruhe, Germany Abstract An experimental investigation of the flow and pressure characteristics around a pyramidal shape building is presented. The experiments were conducted in an atmospheric boundary layer wind tunnel. The velocities of the flow around the pyramid were measured using 2D Laser Doppler Anemometry (LDA). The pressure distribution on the pyramid surface were measured using standard pressure tapping technique enabling the generation of pressure coefficient surface map on the pyramid with different wind direction. This study focuses on shallow pyramid structures (height to length ratio < 0.5, height to boundary layer ratio < 0.2). The results show different trends compared to the one from rectangular bluff body buildings and moderate-high pyramidal shape buildings. I. Introduction Pyramid comes from the Greek word “Pyre” which means fire. It has been the symbol of the Devine fire, Devine light, the symbol of the main principle of life for all the living. For millennia the shape of the four-side pyramid has been the subject of pondering for the curious-minded. Many historical buildings or monuments have been found in the shape of pyramid. The Cheops pyramid in Egypt which have been built thousands of years ago is famous as one of the Seven Wonders of the World. In today’s architectural design, the pyramid shape building is undergoing a renaissance. Building as a whole for various purposes such as hotels, offices, houses, museums, halls as well as building component like roof, or entrance hall are constructed in a pyramidal shape. From the aerodynamic engineering point of view, the pyramidal shape building has its own interesting characteristics. The pyramid geometry has a diagnostic value relative to the rectangular, sharp-edged configurations mainly due to the modifying effect of the vertical wall taper, which has important implication to environmental and industrial aerodynamics. Although the surface flow topology for the pyramid and the cube bear some similarity, the pattern on the leeward face indicates that the mean structure of the recirculation wakes are very different. Also, the aerodynamic loading of the structures is distinct for pyramids, since the wall taper results in different surface pressure distributions than for rectangular buildings [1]. Despite its distinction to rectangular buildings, the technical layout with respect to the wind load assumption for the pyramidal shape is usually not listed in standard tables. These considerations show the importance of this study to investigate the flow and pressure on the pyramidal shape building. Full Paper, 10. GALA-Fachtagung “Lasermethoden in der Strömungsmesstechnik“ 10-12 September 2002, Universität Rostock 1 Ruck & Roth [4] carried out an investigation which involved 2 types of pyramids. They were able to show interesting characteristics of pyramidal shape buildings, however, more detail information is required to produce a standardization of flow and pressure characteristic around pyramidal shape building since the shape of the pyramid itself might have several different configurations (e.g H/L, ). This study focuses on relatively shallow pyramid in order to observe whether the distinguished characteristics shown in Ruck and Roth [4] still occur. II. Experimental Set-up The experiments were carried out in a closed-circuit 29 m long atmospheric boundary layer wind tunnel of the Institute for Hydromechanics, University of Karlsruhe. The tunnel has a 1.5 m octagonal cross-section, with 50 cm boundary layer height. The atmospheric boundary layer was developed along 2.6 m roughness elements combine with two types of vortex generators, 65 cm and 50 cm height. This combination produce an exponent of = 0.26 in the exponential velocity law U / U = (z /). See figure 1 for detail boundary layer set up. Flow Measurement Horizontal and vertical velocities were measured with the aid of a twocomponent Laser Doppler Anemometry (LDA) forward light scattering system. The system consists of an argon-ion laser (1.4 watts) and two bragg cells for frequency shifting. The LDA signals were detected with photomultipliers and evaluated by counter-based signal processing (2 x TSI IFA 550). 1,2-propandiol droplets were generated with a condensation-type particle generator, producing the seeding particles of 1.5 µm mean diameter [4]. Fig. 1: Experimental set up and pyramid geometry Pressure Measurement A total of 46 pressure taps with 1.5 mm diameter were distributed systematically on the half of the pyramid surface. In order to bring the pressure taps sufficiently near to the edges, the model is manufactured from a thin (4 mm) but strong Plexiglas. In this way, a distance of 6.5 mm to the edges was not exceeded. However, the relative small basis angle, = 20°, produces a distance of 12 mm between the pressure taps and the bottom of the pyramid (see figure 2). Dimensionless pressure coefficient value Cp was calculated by dividing the measured differential pressure with the dynamic pressure of the flow at the 27.5 cm reference height. Cp p p surface p stat. q 2U ref 2 Fig. 2: Distribution of tapping positions on the pyramid surface III. Experimental Results Flow Measurement The flow fields were investigated for square-based (L x L =: 20 x 20 cm), sharp-edge surface-mounted pyramid with basis angle = 20° and with wind direction of = 0° (normal to the front face, see fig.1). The boundary layer was charaterized by a Reynolds number Re=12.000 based on the pyramid height h=36.4 mm and a free stream velocity, U = 5m/s. The flow field was measured ranging from 2.5 x L downstream to 1.5 x L upstream of the pyramid, and 5 H (height) over the pyramid. The flow characteristics are presented in parallel planes at y direction each spaced by l/8 x L, as can bee seen in figure 3. z/H U0 Planes x/L z/H y/L y/L=0 y/L=0.125 y/L=0.25 y/L=0.375 y/L=0.5 x/L y/L Fig. 3: Parallel measuring planes Planes Fig. 4: Isolines of mean horizontal velocity around the pyramid in parallel planes. From the top to bottom: y/L =0 (centre plane), y/L = 0.25, y/L = 0.5 Fig. 5: Isolines of mean vertical velocity around the pyramid in parallel planes. From the top to bottom: y/L =0 (centre plane), y/L = 0.25, y/L = 0.5 Isolines of horizontal and vertical mean velocities at selected cross-sections, y/L =0 (centre line), y/L = 0.25 and y/L = 0.5, are shown in Figure 4 and 5. From these figures, no recirculation zone in the lee of the pyramid can be found even though the pattern shows that the velocity in the lee of the pyramids is decreasing. For steeper pyramids, the horseshoe vortex, the separation bubble and the reattachment point should be detectable, see Figure 7 [1], however, in this case of a shallow pyramidal structure none of them can be identified. Ruck & Roth [4] and Abuomar & Martinuzzi [1] found that the recirculation zone in the lee of a pyramid is comparably much shorter in length (streamwise direction) than that of a rectangular bluff body of the same height (and of almost every width). The latter seems due to the fact that the recirculating mass and the recirculation velocity are decreased significantly with structures tapered in height. The present study shows that if the pyramid is too shallow (base angle is too small), then, no flow separation will occur. This might be trivial at the first sight, but it is not. The separation of the flow behind a pyramidal structure cannot be predicted or inferred from well-known step-type or nozzle- and diffusor-type flow theory since it has to be assessed in combination with the specific and complex 3-dimensional pressure field around this pyramidal structure. Thus, there must be a certain H/L and y/H ratio of the pyramid building which starts generating recirculation zone. Another variable that should be take into account is the upstream surface roughness which is a significant factor influencing the separation and reattachment length [3]. These are important factors to be investigated in near future since the relatively small dimensions of recirculation zones behind pyramidal structures are interesting not only in building aerodynamics or architecture. They are as well of interest in technical processes, where an optimum mixing or heat transfer behind low energy consuming surface mounted structures is desired. Fig. 6: Mean velocity vector representation in plan y/H = 0 (centre plane), = 20°, = 0° ; (please note that the horizontal and vertical axis scale with multiples of pyramid height -> pyramid shape is not realistic) Fig. 7: Mean vector representation in plan y/H (centre plane), = 60°, = 0° [1] Pressure Measurement The pressure measurements were carried out with a flow velocity of 12 m/s in order to obtain measurable and reliable pressure differences. Two positions of the pyramid, = 0° and = 45° with respect to the flow direction were investigated. Figure 8 shows the pressure (Cp) distribution on the surface of the investigated shallow pyramid. For the 00 flow direction as shown in figure 8–a, the maximum pressure coefficient was found on the front side at the bottom of the pyramid with a maximum value of 0.02. On the downstream surface, suction is measured near the top whereas positive Cp-value are found near the base. As well as on the upstream side, also on the downstream side pressure coefficients are observed to be more or less evenly distributed. The maximum suction Cp-value occurs near the upstream edges of the pyramid on the side surfaces. They are peaked in the upper third of the pyramid. Symmetrically pressure coefficient distributions were found for the 450 flow direction as shown in figure 8-b. There are no high levels of suction values anymore as illustrated in figure 8-b and the maximum positive pressure coefficient are found near the baseline of the pyramid. The previous study [4] indicates that the maximum pressure on the upstream side occur at a height of 53 % of the total pyramid height and maximum suction values occur at the upstream edges near the baseline (see also [1] ). On the other hand, this study shows that the maximum pressure occurs at the baseline and the upper edges are exposed to high suction, which is more similar to rectangular bluff body flow. This results indicate that the base angle of the pyramid influences significantly the pressure distribution on the pyramid walls. As a trend, it seems that a steepening of the pyramid shifts down the point of maximum suction (minimum pressure) on the side walls towards the baseline and shifts up the point of maximum pressure on the front side. Further systematic investigations have to be carried out in order to discretize any flow and pressure characteristics in the shape range between shallow and steep pyramidal structures. At the end, the measured results shall be plotted and combined to an animation from which all relevant load characteristics can be inferred for rectangular pyramids with increasing steepness in boundary layer flow. a. Wind Direction: 0° b. Wind Direction: 45° Fig. 8: The pressure (Cp) distribution on the surface of the pyramid Acknowledgement The financial support of the Deutsche Forschungsgemeinschaft DFG/Bonn within the project No. Ru 345/25 is gratefully acknowledged by the authors. References: 1. Abuomar, M.M., Martinuzzi, R.J., 2000. An Experimental Investigation of the flow around a Surface Mounted Pyramid. 6th Triennal Intermational symposium on Fluid Control, Measurement and Visualization, August, 13-17, 2000, Sherbroke, Canada. 2. Heist, D.K., Gouldin, F.C., 1997. Turbulent Flow Normal to Triangular Cylinder. Journal of Fluid Mechanics, vol.331, pp. 107-125. 3. Peterka, J.A., Meroney, R.N., Kothari, K.M., 1985. Wind Flow Patterns About Buildings. Journal of Wind Engineering and Industrial Aerodynamics, 21 (1985) 21-38. 4. Ruck, B., Roth, M., 1997. The Flow and Pressure Distribution Around Pyramids. Laser Anemometry Advances and Applications, Proceedings of the 7th International Conference, September 8-11, pp.761-769. 5. Tom Lawson, 2001. Building Aerodynamics. Imperial College Press, London ISBN 1-86094-1 87-7.