EPAPS_VER2 - AIP FTP Server

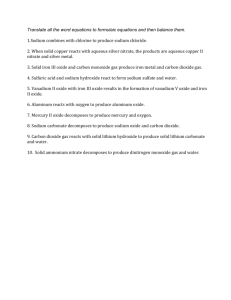

advertisement

I. Generation of amorphous a-Al2O3, a-ZrO2, and a-HfO2 samples. In0.5Ga0.5As substrate. The realistic amorphous a-Al2O3, a-ZrO2, and a-HfO2 samples perfectly matching the In0.5Ga0.5As(4x2)-(100) substrate surface area were generated by hybrid classical– DFT MD “melt and quench” approach. 13-16 Note that in the text the term “samples” refers to models generated by hybrid classical-DFT molecular dynamics simulations, not real experimental samples. The amorphous sample quality was verified via radialdistribution function (RDF) main peak positions and full widths at half maximum (FWHM), average nearest neighbor numbers, nearest neighbor distributions, calculated neutron scattering static structural factors, and DFT calculated band-gaps demonstrating good correlation to available simulated and experimental reference properties.17-24 The generation of a-Al2O3 for the In0.5Ga0.5As(4x2) surface cross-sectional area was described in detail elsewhere.16 EPAPS Table I presents the coordination distribution of the classically annealed a-Al2O3 sample prior to DFT MD annealing vs. reference classical sample distribution demonstrating excellent correlation.17 The simulations by Gutierrez et al were used as one of the reference models because they demonstrated strong correlation to experimentally measured a-Al2O3 properties.17 The generation of the a-HfO2 sample was initiated with an ordered HfO2 structure, which was classically annealed at artificially low density (~3.38 times lower than normal) at 4000K for 200 ps with 1 fs timesteps providing very good melt intermixing; afterwards, the sample was instantaneously rescaled to normal classical density and annealed at 4000K for additional 200 ps. Subsequently, the sample was rescaled to the a- 1 HfO2 DFT density of 9.17 g/cm3 and DFT-MD annealed at 4000K for 8 ps, linearly cooled to 500K for 16 ps with 1.5 fs timesteps producing sample amorphization, and relaxed by conjugate-gradient (CG) algorithm below 0.05 eV/Å force tolerance level. The high-T (4000K) classical annealing stage for HfO2 was performed using the wellestablished classical empirical potential for ZrO2 25 consistent with similar techniques employed by Broqvist et al 26 and J-P Crocombette et al.27 This approach works well due to the chemical similarity between Hf and Zr, and because the classical annealing is followed by very accurate DFT-MD annealing, cooling, and relaxation with Hf pseudopotentials. The normal classical density of the sample at high-T annealing was chosen so that if the Zr mass is employed for the classical sample, the density would be 5.28 g/cm3, within the density range of robust a-ZrO2 sample generation (4.86-5.32 g/cm3).22 Recalculation of the same sample density with Hf mass would give 9.02 g/cm 3. Passing from classical to DFT annealing stage, the sample was rescaled to a final a-HfO2 DFT density of 9.17 g/cm3, determined by previous generations of several sacrificial aHfO2 samples at various initial densities and their final relaxation at variable cell volume. The final a-HfO2 DFT density of 9.17 g/cm3 is close to the density of 9.1 g/cm3 used in DFT simulations of Broqvist et al. and obtained by extrapolation of the linear experimental trend 26 , and a little lower than the final density of 9.39 g/cm3 reported by Ceresoli et al with a-HfO2 amorphous sample generated by the “activation-relaxation” ART technique.22 The coordination distribution of the final sample demonstrated fairly good correlation with results of Ceresoli et al (EPAPS Fig. 1-b).22 The average coordination distribution for Hf and O atoms was calculated by integrating RDF curves up to the first minimum after the first major peak. For the sample employed in the present 2 work, the average coordinations for Hf and O atoms were 6.0 and 3.0 respectively vs. 6.2 and 3.0 of Broqvist et al. 26 The bandgap of the a-HfO2 sample employed in the present work was about 3.2 eV free from defect states, and this bandgap is close to the bandgap of ~3.8 eV in the sample of Ceresoli et al. 22 The limited variation of the band gap value can be assigned to the different sample densities, 9.17 g/cm3 (present work) vs. 9.39 g/cm3 (Ref 22) and the different generation procedure, DFT-MD in the present work and “activation-relaxation” technique.22 These a-HfO2 DFT-calculated bandgap values were lower than reported experimental values of 5.5 eV (Ref 28) and 5.7 eV (Ref 29) due to the standard DFT band-gap underestimation coming from the exchange interaction approximation. Broqvist et al. reported a band-gap of 5.3 eV using PBE0 technique which includes a Hartee-Fock contribution to the standard DFT interaction model thereby mitigating the standard DFT bang-gap underestimation problem for many materials.26 The a-ZrO2 sample matching InGaAs(4x2)(100) substrate area was generated using similar hybrid classical-DFT MD technique but with different timing and density values. Since previous DFT simulations reported realistic amorphous a-ZrO2 structures for a density range between 4.86 - 5.32 g/cm3 (Ref 20-22), a relatively low DFT sample density value (4.90 g/cm3) was selected to minimize the risk of sample recrystallization. The so-called “normal” classical amorphous density was calculated from the DFT amorphous density (4.90 g/cm3) and classical-to-DFT density correction ratio, obtained by DFT annealing and relaxation of the classical a-ZrO2 test samples at variable cell volume.14 The high-T (4000K) classical annealing stage was performed using wellestablished empirical potential for ZrO2.25 The a-ZrO2 sample generation was started from an ordered ZrO2 system at artificially low density (~3.38 times lower than normal 3 classical density 4.71 g/cm3) by annealing at 4000K for 125 ps with 1 fs timesteps providing very good melt intermixing; after instantaneous rescaling to a “normal” classical density of 4.71 g/cm3, the sample was annealed at 4000K for additional 200 ps. Afterwards, the sample was rescaled to a-ZrO2 DFT density of 4.90 g/cm3, transferred to DFT code, and DFT-MD annealed at 4000K for 8 ps, linearly cooled to 500K for 16 ps with 1.5 fs timesteps producing sample amorphization, and relaxed by conjugate-gradient (CG) algorithm below 0.05 eV/Å force tolerance level. The coordination distribution of the obtained sample demonstrated strong similarity both to coordination distributions of the Vanderbilt et al sample and our previous sample generated for Ge(100)(2x1) substrate by slightly different simulation approach (EPAPS Fig. 1-a).14,21 The present a-ZrO2 sample had a bandgap of ~2.77 eV free from defect states; the calculated bandgap for the amorphous oxide is similar to previously reported calculated bandgap for amorphous aZrO2 of ~2.7 eV (DFT, =4.90 g/cm3) (Ref 14), ~3.2 eV (DFT, ρ=5.32 g/cm3) (Ref 22), ~3.4 eV (DFT, ρ=4.86 g/cm3) (Ref 21) and the experimental 4.7 eV value measured by EELS on amorphous a-ZrO2 samples (Ref 23, 24). Note, that amorphous ZrO2 has a lower experimental bandgap than crystalline polymorphs of ZrO2 which have bandgaps of 5.0-5.8 eV.30-36 The discrepancy with experiment is mainly due to the standard DFT bandgap underestimation. The In0.5Ga0.5As(100) substrate was relaxed to form the In/Ga rich 4x2 surface reconstruction with 3 bottom atomic layers fixed in their bulk positions.37 The bottom layer As atoms were passivated by H atoms with a fractional 3/4 |e| charge to mimic continuous bulk according to Ref 38. The preliminary In0.5Ga0.5As bulk unit cell was formed from GaAs unit cell by substituting half of Ga atoms by In following 4 checkerboard pattern and DFT optimizing the lattice constant of the alloy to equilibrium value. The present study employs the model of the In/Ga-rich InGaAs(001)-4x2 described by Shen et al. to interpret the low temperature (77K) and 300K reconstructions of MBE grown and decapped InGaAs(001)-c(8x2) samples 37. The model is dominated by group III dimers and tricoordinated As atoms. In the present study, a regular polymorph is employed in which the In and Ga atoms have alternating positions in the lattice. Shen et al investigated different polymorphs and found that it did not change the relative stability of different reconstructions 37. Recently Goryl et al have reported upon the structure of similar c(8x2) reconstructions of sputter annealed InAs(100)-c(8x2) imaged by AFM at low temperature and room temperature 39. Goryl et al report that a small variation of the Kumpf et al model is the most consistent with the data 39,40. The Kumpf et al c(8x2) model has some similarities to Shen et al model (no As-As dimers, tricoordinated As atoms, group III dimers) but has no trough sites 37, 40. It is likely lower interfacial defects would be modeled for the amorphous oxides on the Goryl et al model surface since this model surface is flatter 39. However, the greatest effect of reconstruction would be switching to the As-rich 2x4 reconstruction since it is dominated by As-As dimers. II. Computational Details. Classical MD simulations were performed by a Large-Scale Atomic/Molecular Massively Parallel Simulator (LAMMPS) 41, expanded by well-tested empirical potentials for Al2O3 and ZrO2 (Ref 25, 42). All DFT simulations were performed with the 5 Vienna Ab-Initio Simulation Package (VASP) 43,44 using projector augmented-wave (PAW) pseudopotentials (PP) 45,46 and the PBE (Perdew-Burke-Ernzerhof) exchangecorrelation functional 47,48. The choice of PBE functional and PAW PP’s was validated by parametrization runs demonstrating good reproducibility of experimental lattice constants, bulk moduli, and formation energies for bulk crystalline Al2O3, ZrO2, HfO2, Al, Zr, Hf, GaAs, and InAs. III. Stack Formation and Annealing Procedure. The DFT-MD annealed, cooled and relaxed a-Al2O3, a-ZrO2, and a-HfO2 samples were cleaved in X-Y plane parallel to the interface breaking periodic boundary conditions by introducing ~12-15 Å of vacuum over the samples. To get better statistics, two different oxide cuts in X-Y plane were used to provide different oxide initial geometry at interface with InGaAs (EPAPS Fig. 2). This resulted in two different initial interfaces for each oxide type, which were annealed independently. Since the InGaAs(100)-(4x2) experimental surface has a row-trough topography, the corresponding oxide samples were cleaved to form a groove of ~ 7.5 Å x 1.7 Å to match the substrate row / trough step-like structure. The oxide cleavage planes were chosen to get a roughly equal number of metal and oxygen atoms on the oxide surface in contact with the substrate to avoid any pre-determined bias in initial conditions. The amorphous samples were placed on the relaxed InGaAs substrate at a height such that the initial interfacial bond lengths were approximately equal to 0.70-0.75 of their empirical equilibrium distance. There were values close to 0.5-0.6 for a few bonds 6 since the horizontal cut of an amorphous sample usually produces a very non-planar oxide surface topography which creates a corrugated interface to the planar parts of semiconductor surface. The initial interfacial distance was chosen to be on the repulsive rather than on attractive portion of the potential to prevent the oxide from relaxing into an oxide/vacuum interface structure on the fresh-cut surface. Furthermore, the initial partial relaxation with a fixed semiconductor substrate quickly equilibrates the interfacial bond lengths. The dangling bonds on the oxide upper surface were passivated by H atoms having ~12-15 Å of vacuum to avoid spurious interaction through periodic boundary conditions. The oxide samples were not relaxed after surface cleavage prior to stacking on InGaAs to provide a chemically reactive surface with dangling bonds in contact with the substrate. In contrast to other published DFT-MD oxide/semiconductor studies, all stacks employed one oxide/semiconductor interface and a vacuum spacer since the supercell model with two oxide/semiconductor interfaces and no vacuum could unphysically restrict atomic migration to/from the oxide/semiconductor interface in the thin oxide film (~10 Å). More importantly, the presence of a vacuum spacer over the oxide provides complete relaxation of the interfacial oxide-semiconductor height and any possible residual stresses in the system induced by mutual bonding. To compensate for spurious electric fields induced by PBC for this type of system, a dipole correction was applied. 43,44,49 After initial formation of the oxide/InGaAs(4x2)(100) stacks, the stacks were annealed. Initially, the entire InGaAs substrate was fixed in space while the oxide was partially relaxed for ~20-30 conjugate-gradient (CG) relaxation steps. The duration of 7 this initial relaxation was systematically determined by performing longer (~150 CG steps) relaxation runs, which demonstrated that ~20-30 CG steps were sufficient to reach the optimal interface height, releasing initial artificial interface stresses and allowing the oxide to conform to the non-planar reconstructed substrate topography. After the initial partial relaxation with frozen semiconductor substrate, the substrate atoms were unfixed except for the three bottom layers, and the whole system was annealed at 800K for 1000 fs with 1.0 fs timesteps, cooled to 0K for 200 fs, and finally relaxed below a 0.05 eV/Å force tolerance level. Due to high computational cost of these DFT-MD runs (~250 atoms and ~2500 CG/MD steps) and the large PBC box size, the initial relaxation, annealing, cooling and final relaxation were performed with a 2 Κ-point irreducible set. After the final relaxation the Κ-point set was expanded to a 4x8x1 Gamma-centered mesh with 18 irreducible K-points, and the system was tuned by another relaxation run. Although expansion of the K-point set had no visible effect on the system geometry and required only ~30-50 CG steps to relax below the 0.05 eV/Å force tolerance level, it improved the electronic structure. After stack final relaxation, additional steps are required to passivate the upper oxide-vacuum interface. The oxygen atoms at oxide-vacuum interface usually have the same coordination as in amorphous oxide bulk and don’t need additional passivation. However, coordination of some metal atoms at the upper oxide-vacuum interface can be lower than their coordination in amorphous oxide bulk. This occasional metal atom undercoordination at the oxide/vacuum interface can potentially create several problems, such as midgap pinning states and artificial surface stresses, which can propagate down to the oxide/InGaAs interface due to the small oxide thickness. To eliminate these 8 occasional problems after stack final relaxation, coordination of metal atoms on the oxide upper surface was analyzed and those atoms which were found to be undercoordinated were passivated by additional OH groups to restore corresponding in-bulk metal coordination (4 for Al, 6 for Hf and Zr). The minimum required number of 5-8 OH groups was added per stack to passivate all undercoordinated metal atoms on the upper oxide surfaces. To avoid too much mechanical shock due to simultaneous addition of all OH groups, they were added gradually in 2-3 steps relaxing the system after every addition step at 4x8x1 Gamma-centered K-point mesh below 0.05 eV/Å force tolerance level. In real devices such undercoordinated metal atoms at upper oxide surface are readily passivated by bonding to electrode material. 9 Figure Captions EPAPS Figure 1. Nearest neighbor distribution of: a) our a-ZrO2 sample for InGaAs vs. our a-ZrO2 sample for Ge (Ref 14) and a-ZrO2 of Ref 21. b) our a-HfO2 sample vs. sample of Ref 22. Cutoff radius for all samples is 3.0 Å. EPAPS Figure 2. Cutting of an amorphous oxide sample to create Cut I and Cut II surfaces. Grey area- oxide sample. a) Initial amorphous oxide sample with periodic boundary conditions. b) The sample with the Cut I surface and vacuum layer. c) The sample with the Cut II surface and vacuum layer. d) a-Al2O3 /InGaAs (Cut I) system before oxide/semiconductor merging. e) a-Al2O3/InGaAs (Cut I) system after oxide/semiconductor merging. PBC Box - Periodic Boundary Condition Box. A,B,Cdifferent parts of the oxide sample. 10 Nearest Neighbor Distribution O(2) O(3) O(4) Al(3) Al(4) Al(5) Al(6) Our Sample Ref 17 18% 20% 79% 78% 3% 2% 0.0% 0.3% 75% 76% 23% 22% 2.0% 1.7% EPAPS Table I. Nearest neighbor distribution of our classical a-Al2O3 sample prior to DFT-MD annealing vs. classical sample of Ref 17. Cutoff radius-2.2 A. 11