Community Concerns About Dust and Noise

advertisement

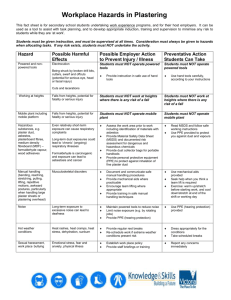

Answering Community Concerns about Dust and Noise A How-to Guide for the Aggregates Industry as proposed by Aspasa Introduction The public’s perception of the aggregates industry can be a help or a hindrance to obtaining zoning and other permit approval for Greenfield sites and existing plant expansions. Public opinion of the industry often based on an assessment, whether or not deserved, of a “lowest common denominator: type of plant that neighbours feel is unattractive, dusty, noisy or may have a management team that is irresponsible to public concerns. By pursuing a leadership role in the control of dust and noise and confirming results through monitoring and documentation, a conscientious operator may be able to minimise community concerns about these issues. Noise is one of the most commonly cited community concerns regarding aggregates operations. And, it is associated with a great number of common activities at aggregates operations, including blasting, loading, crushing, screening, washing, and hauling. As a first step towards dealing with community concerns, aggregates producers should work not only to identify noise point sources, but also implement Best Management Practice (BMPs) in order to minimise noise, and have a plan in place to work with neighbours who have concerns or complaints. In both urban and rural environments neighbours of aggregates operations commonly voice concerns about dust. The disturbance of fine soils by extraction and processing activities at sand and gravel pits and rock quarries can increase the potential for dust creation, and dust control should be part of the ongoing operations. Again, producers should work to identify dust generating activities, situations where dust can be an issue, which people and facilities are sensitive to dust, and what BMPs and other measures can be used to control dust. The Aspasa About Face environmental program looks at the above impacts and ensures that Aspasa members comply to the legislation. Educate Yourself and Your Employees: Understanding noise…. Noise sources at aggregates operations can include equipment, back-up alarms, drills, power generators (“gensets”), crushers, screens ,material falling into empty metal box of haul truck, the “body slap” of tailgates, squealing of vehicles on tracks, such as bulldozers, and even the rattle of loose hitches on trucks travelling through the neighbourhood. Noise control can include rescheduling hours of operation, selecting appropriate equipment (e.g. does it have a proper muffler?), constructing sound barriers and berms to contain noise, relocating noisy operations to remote parts of the plant and other options. The effects of aggregate operational noise on neighbours can vary, but may cause annoyance, disturbance and even a sense of interference with quality of life. Impacts to the community will vary depending on the frequency of vehicle traffic on local roads and, of course, the proximity of the operation to neighbouring houses. Understanding dust…. Dust has a wide variety of manmade and natural origins, including vehicle exhaust, agriculture, tire wear, natural and domestic fires and sea salt. Dust can become airborne when wind blows over exposed surfaces or by mechanical disturbances such as rolling truck tires. Smaller sized dust particles travel farther and are perceived as a greater health concern than larger particle. The most difficult type of dust to control is “fugitive dust” which is generated by unstable non-point sources (like movement of equipment} and the effects of wind on stockpiles and areas stripped of vegetation. Fugitive dust is the most common cause of dust complaints at aggregate operations, as it commonly settles on cars and houses in adjacent areas. Answering Community Concerns About Dust and Noise At an aggregates operation, dust can be generated from numerous sources, including wind blowing over exposed soil or stockpiled material (which includes materials travelling in trucks or on conveyors, where the material is moving versus the air moving); falling material, such as in loading ground abrasion, where wheels and tracked vehicles kick up dust; handling, as in extraction, crushing and sizing, drilling and blasting. Who is most likely to complain…? Defend yourself effectively. Get to know your neighbours. But also identify the likely opposing organisations, citizens’ groups and special interest groups. Find out where they are “coming from” – and what the real issues are, because those openly argued, may not be the ones actually espoused. Educate the Community: Make community education a priority… A proactive approach to the concerns of your community establishes you as a good neighbour from the start – and a little bit of education goes a long way. If possible, lay the groundwork early with your neighbours. It is important for the public to sense you are committed to mitigation or avoidance of noise and dust impacts. Opportunities should be taken to discuss the results of noise monitoring with local communities and take time to explain why, when and for how long particularly noisy events are likely to occur. Meet and develop a rapport with the community leaders, regulators, citizens’ groups, homeowners’ associations and individuals. Establish yourself a good neighbour; support local organisations and causes; attend community events and activities. Join your local Chamber of Commerce; it’s often a good way to meet key people in your community. Invite ASPASA to assist you with your promotion. Establish a community liaison committee… It is a good idea to establish a dedicated committee, the members of which will be responsible for proactively educating the community and dealing with neighbour complaints. Assign one or two people from this committee to be community contacts for questions. And make sure your neighbours know who the contacts are that they can call with their questions and concerns. This will speed up the response process and as a result, allay concerns more quickly. Ways to “Get the Word Out”… Hold an open house. By inviting neighbours to come and see who you are and what you do, you may help to change many unflattering opinions and perceptions. Make sure your presentation includes your efforts towards noise and dust control. Use the ASPASA Health and Safety Audits and Environmental Audits done on your site. Best Management Practices (BMPs) Be a leader in the control of dust and noise… Noise and dust control limits are set by a state, local or provincial regulatory agency and language about compliance is generally included in local ordinances as well as your facility operating permits. If possible, hire consultants to conduct noise level studies at your facility. Send your reports to the townships as part of a license submission. Regularly conduct your own environmental and employee exposure monitoring. Confirm compliance through government data. Provide for good noise reduction practices through site planning… A general site plan layout map is usually required for permitting purposes. Your plan for noise and dust can be incorporated in such a facility plan. A site control plan could contain the following noise components; noisegenerating activities; offsite facilities (i.e. residences, schools, etc,) that are noise-sensitive; potential noise reflectors (mine faces, hillsides, hard ground and water), topographic hollows and noise absorbing areas (wood lots, shrub areas, grasses) placement of berms, stockpiles and tree buffers to create or enhance noise-damping locations for the site or act as noise barriers; plans to locate noise-generating activities and hail roads in suppressing locations and away from noise-sensitive facilities; procedures to avoid noise generation and contain noise; and designation of existing trees and shrubs as perimeter barriers on noise sensitive sides of the operation. Provide for good noise reduction through equipment purchases… When= buying equipment, do so with an ear to its noise reduction capabilities. Do not purchase noisy equipment and establish that as company policy. Answering Community Concerns About Dust and Noise Provide for good noise reduction practices through operational procedures… Table 1: Site layout, operations and interception noise control options Management Options SITE LAYOUT Containment & Damping OPERATIONS Source Prevention Escape & INTERCEPTION Ambient Reduction Noise Management and Control Methods Locate haul-roads away from ridge tops and in topographic lows Place processing equipment within natural or excavated hollows, such as the pit or quarry floor Minimise the fall height of material Construct stockpiles to intercept point of source and ambient noise Use crushing and screening plants within their design capacity Plan orientation of working faces to reflect noise into damping areas Use first stage operations o act as screening for noise sensitive areas and receptors Group and position buildings to act as an acoustic barrier Restrict noise generating activities to sheltered areas Create ‘sensitive zones’ within which activities are limited. Select low noise emission equipment Ensure smooth road running surfaces Start plant engines one at a time Maintain, repair and lubricate equipment Alert and train staff to reduce noise emissions Limit drop heights during handling Fit acoustic barriers to processing equipment Minimise mobile equipment speeds Use alternative non-audible back-up alarms Vegetate exposed surfaces such as overburden mounds with quick growing ground cover and plants Use rubber linings in chutes, dumpers and transfer points to reduce the noise of rock falling onto metal surfaces Use simple baffles around washing drums and rubber mats around screening, crushing and coating plants Switch off equipment when not in use Avoid unnecessary revving of engines Direct noise away from sensitive areas whenever possible, if the noise source is highly directional Enclose sources of significant noise, such as conveyors and process plants Keep truck tailgates closed where possible Retain and plant trees or shrubs around the site Place treed berms near noise generation activities (source), receptors or at the perimeter of the site Install acoustic fencing Ensure there are no gaps in acoustic barriers, as noise will leak out BMPs and Measures Berm Drop height Fences Vegetative Cover Straw Bale Wall Treed Windbreaks Drop Height Equipment Selection Fences Vegetative Cover Water Spray Speed Limits Berm Fences Planting Vegetative Cover Provide for good dust reduction practice through site planning… A site layout map could also contain the following dust components, dust generating activities, offsite facilities that are sensitive to dust (i.e. homes and schools, etc.), prevailing wind direction(s) and onsite wind patterns, placement of berms, stockpiles and tree buffers to create or enhance wind shadows; possible location of dustgenerating activities and hail roads in calm locations and far from dust sensitive facilities; and location of existing trees and shrubs to create a wind breaks. Provide for good dust reduction practices through operational procedures… One of the best ways to reduce dust in your operation is through the use of water. Provide spray systems for feeds and discharges on crushers, screens, transfer points for conveyers, stockpiles and non-covered trucks ready for departure. Wet down or clean roads onsite and fronting the site entrance/exit. Use wheel washer systems between the scale and the property exit, and/or spray the truck wheels and /or the entire truck with water to reduce the amount of dust that is deposited on public roadways. Where feasible, recycle and reuse processing water and make sure any water discharged meets or surpasses government, provincial and local water quality standards. Answering Community Concerns About Dust and Noise Provide for good dust reduction practices through equipment purchases… When buying equipment do so with the idea of controlling dust. Covered conveyors, impact idlers at the belt transfer points, conveyors that automatically adjust their height to the stockpile are all examples of equipment designed to help control dust. Do not purchase equipment that lacks modern dust controls and establish as company policy that this is the only kind of equipment you will purchase at your properties. Additional operation procedures for dust control… Table 2: Control options for dust at aggregate sites Control Strategies Dust Control Options SITE LAYOUT Minimise Creation OPERATIONS Control Escapes AIR QUALITY Dust Removal CESSATION Locate haul-roads, dumpsites and stockpiles away and down-wind from neighbours Minimise the height from which materials falls Surface roads with dust-free material Lay out and construct stockpiles to minimise dust creation, use gentle slopes and avoid sharp changes of shape Use crushing and screening plants within design capacity Use conveyors rather than haul-roads Restrict dust generating activities to sheltered areas Create ‘sensitive zones’ within which dust activities are limited Limit spillage by not overloading trucks Enclose or provide wind protection for conveyors, chutes, process plant, stockpiles Install a dust removal system (bag system) for the plant Use sprays and mist at dust sources Fit outlets with cyclones, wet-scrubbers and filters Insist on good maintenance and housekeeping Compact and grade, surfaces and maintain haul-roads Fit dust extractors, filters and collectors on drilling rigs Use mats when blasting Use wind-breaks/netting screens/semi-permeable fences Limit drop heights Fit wind-boards/hoods at conveyor/transfer points Reduce sped and limit movement of vehicles, use upswept exhausts Spray exposed surfaces (haul-roads, dormant faces and stockpiles)with binders Vegetate exposed surfaces, such as overburden stockpiles, with quick growing plants Pave and sweep haul-roads and other high use semi-permanent dusty surfaces Shake dirt off trucks with rumble bars and provide vehicle washing facilities Provide a surfaced road between vehicle washing facilities and site exit Use closed or sheeted vehicles to carry dry material Use trees or shrubs around the site as coarse air filters Place treed berms near dust generators, receptors or at the perimeter of the site Use sprinklers, sprayer or mist with or without additives Shut down the operation if, due to unique weather conditions, the extended dispersion of dust cannot be avoided BMPs & Measures Berm Drop Height Tarps Vegetation Cover Wind Protection Drop height Tarps Vegetation Cover Water Spray Wind Protection Wheel Washers Hydro seeding Speed Limit Telescopic chutes Berm Vegetation Cover Water Spray Document all noise and dust reduction measures… Have this documentation prepared in advance so that when community concerns arise, you can produce it quickly as proof of your noise and dust reduction efforts, and your proactive attention to your neighbours’ concerns. Respond quickly to complaints… A community response system can address noise-related complaints in a fair and expedient manner. A record of complaints, the action taken, outstanding follow-up actions and subsequent dialogue with complaints are some measures that have been practiced with success. Whether you receive your complaint directly from a resident or through a local government office, respond promptly. Listen and be concerned. Make sure neighbours know you understand and empathize; repeat their concern to let them know you heard and understood. Meet them on an emotional level with your response. Be open and honest, emphasizing positives Answering Community Concerns About Dust and Noise in your language, not negatives, Say things such as, “We are committed to being a good neighbour because…” and repeat the phrase with your reasons. Follow up after your initial response. Continue to follow up if the neighbours feel their concerns have not been resolved. www.aspasa.co.za P O Box 1983 Ruimsig email: office@aspasa.co.za Tel: 011 791 3327 August 2012