Homogeneous Catalysts for Selective Oxidation of Organic

advertisement

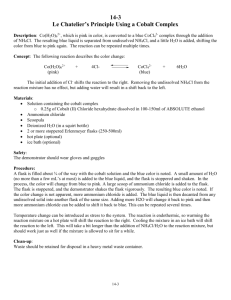

Summitt 1 Homogeneous Catalysts for Selective Oxidation of Organic Compounds with N2O Addie Summitt Faculty Advisor: Megumi Fujita University of West Georgia Chemistry Department Summitt 2 Brief Overview of Project Nitrous oxide is a very destructive greenhouse gas released in industrial processes such as nitric acid production. However, in the presence of a well designed metal catalyst, this gas has the potential to be an oxidation reagent. This potential oxidation by N2O could be exploited in many industrial oxidation processes as an environmentally friendly alternative because the only byproduct of the oxidation would be an environmentally benign N2 gas. The use of such a catalyst in industries would contribute to the reduction of N2O into the environment, which in turn would help reduce the destruction of the Earth’s ozone layer. Our research goal is to develop a transition metal catalyst to activate N2O and mediate in the oxygen atom transfer to an organic substrate. The first step in the N2O activation is n+ LnM to have a ligand with a metal center (our CH3OH catalyst) take the oxygen atom from the N2O. N2O n+ = initial oxidation state L3 = ancillary ligand The catalyst then acts as the oxidizing agent as it transfers the oxygen to a gas like CH4. A initial state M = Metal CH4 N2 (n+2)+ good catalyst would be able to repeat this LnM O "oxo" species cycle over and over again. Hillhouse published a Ni complex that reacted with N2O and activated the O atom. However, the complex resulted in internal oxidation, and was not catalytic. Nickel was selected as a central metal ion because of the previous example by Hillhouse that showed N2O activation by a Ni complex. The proposed catalyst is made up of a bulky tridentate ligand around a metallic center, in this case a Ni center. It was proposed that activation of nitrous oxide requires two coordination Summitt 3 sites next to each other. This ligand allows three available Br coordination sites, two of which may be used for N2O (THF) 1- 2+ N Ni N Br 1- N (THF) activation. (THF) Another advantage is the overall -2 ligand charge, which neutralizes the central metal ion. This will create an overall neutral metal complex which is compatible with organic reaction media. Summitt 4 Work Accomplished This Summer The protonated, neutral form of the ligand (1) was synthesized in four steps (Scheme 1). The procedures were based on those developed by the lab. Various optimizations of the reaction and purification conditions have been made, improving the yields at each step. O O H N O 1. LiHMDS -78oC O NBS/CCl4 N 2.(CH3O)2CO r.t. 94 % 81% N Br Br 1/2 NH2 N Br + Na2CO3 N O CH3CN Br NH2NH2*HCl + KOH 0oC O N N Br MeOH 81% NH Br HN OCH3 OCH3 91% (1) Scheme 1. Ligand synthesis Complexation with Ni(II), still in progress, has been attempeted by the following procedure (Scheme 2). 2NaH N Br NH Br HN Scheme 2. Ni(II) Complexation NiCl2 N Br N Br N / THF "the cataylst" purple species, purification and identification in progress Summitt 5 Experimental Details 1. N-protection of 2-methylindole (6/6/07, I-1) O O H N o LiHMDS/THF -78 C N (CH3O)2CO Name of Compound Formula Formula Mass Amount Other Moles Mole Ratio 2Lithium methylindole bis(trimethsillyl)amide C9H9N ((CH3)3Si)2NLi 131.0 g/mol 167.0g/mol 19.654 g 187.5 mL 0.15 mol 1 0.1875 mol 1.25 Dimethyl carbonate (CH3O)2CO 90.09 g/mol C11H11O2N 189.21 g/mol 16.5 mL d=1.07 g/mL 0.195 mol 1.3 Ref: 1Dhanapoatan Nagarathnam, Synthesis, 1992, 8, 143-5 2 Former Student: Amna Ali’s notebook Procedure: In the glove box, 19.654 g of the 2-methylindole and 220 mL of tetrahydrofuran (THF) were added together in a three neck round bottom flask, and protected from air by a gas adaptor and septa. The air flow was closed off to all mouths of the flask. Once out of the glove box, nitrogen was added and vacuumed three times in the hose using the Schlenkline, and then the mixture was placed under nitrogen. A magnetic stirrer was used to stir the mixture together while the flask was added to a dry ice bath in a bowl of acetone to lower the temperature to 78oC. Over the next 48 minutes, 48 mL of LiHMDS was added, followed by another 48.5 mL, followed by another 48 mL, and finished with 43 mL, making a total of 187.5 mL LiHMDS. By the third LiHMDS addition the color had changed from a yellowish-brown color to a blood-red. Temperature was raised to -22oC as the dry ice bath was removed; as the temperature neared Summitt 6 room temperature, the mixture was cooled to -71oC again and16.5 mL of dimeythl carbondate was added over a 15 minute time span. The mixture was allowed to warm to room temperature over night. In a 1600 mL separation funnel flask, 12.5 mL of a 12 M HCl solution was added to a 750 mL ice bath in which the mixture from the 3-neck flask was added to the HCl-ice water mixture. 250 mL of diethyl ether was used to rinse remaining solution from the 3 mouth flask to the separation funnel. The separation funnel was swirled to reveal two distinct layers: the top being a dark red ether layer while the bottom was an aqueous layer of light red. In the separation funnel, the dark red ether layer was extracted from the light red water layer. The ether layer was placed in a separate flask apart from the water layer. 250 mL of diethyl either was poured into the separation funnel with the aqueous layer to extract anymore organic substances. The combined ether layers were washed with brine (120 mL) twice. The remaining ether layer was emptied into a 1600 mL flask and some sodium sulfate was added to remove trace water in the solution; let sit for 20 minutes and was filtered afterwards into a pre-weighted pear-shaped flask. The rotary evaporator was used to evaporate and discard any ether and remaining THF from the contents of the pear-shaped flask. Using a silica TLC, we tested the reaction against the starting material in a 1:1 ratio of chloroform:hexanes showing that a reaction had taken place. Another TLC was taken, but instead of silica, alumina was used in a solution of only chloroform which showed a better result than the silica TLC that a reaction had taken place. The pear-shaped flask was hooked up to a vacuum and was left to vacuum over night. Column 1 test scale: An alumina (neutral) column (10 cm high, 4 cm wide) was assembled; using only 3.004 g of the vacuumed product and an eleunt of only chloroform, 6 fractions were taken. Alumina Summitt 7 TLC was taken with chloroform solvent to show that fractions 1 and 2 contained the product. Using the evaporation machine, fractions 1 and 2 were evaporated in a pre-weighed round bottom flask and then vacuumed. The end result was 3.035 g of a clear liquid product after NMR confirmed the fact that the liquid was pure, free of the starting material, but with residual solvents. The flask was left under vacuum over the weekend. Column 2 big scale (unsuccessful): Another alumina (neutral) column (10 cm high, 5.5 inches wide) was assembled using the remaining mixture from the vacuumed pear-shaped flask and just a chloroform eleunt. Alumina TLC with chloroform solvent was used to confirm that fractions 2 and 3 held our product and were then evaporated in a pre-weighted flask with the evaporator. NMR showed some impurities so another column was needed to purify the product. Column 3 small scale basic alumina trial (a) chloroform: The product was transferred to a pre-weighed 300 mL flask after several washings with dichloromethane and evaporated. A small column (10 cm high, 2 cm wide) with alumina basic was set up and only 1.003 g of product was loaded into the column. Alumina TLC with chloroform solvent was used to determine our product was in fractions 1 and 3; however, fraction 2 was added to fractions 1 and 3. Fractions 1-3 were evaporated in a pre-weighed flask, after evaporation .893 g of material was collected. Column 4 small scale basic alumina trial (b) chloroform:hexanes Another small column (10 cm high, 2 cm wide) was made with alumina basic with a 1:1 chloroform:hexanes in which the .893 g sample was loaded into. Alumina TLC with chloroform solvent showed our product in fractions 1, 2, 4, and 5 which were then evaporated in a preweighed flask. After evaporation 1.95 g of pure product was extracted. Summitt 8 Column 5 big scale neutral alumina hexanes:chloroform The remaining liquid from the 300 mL flask, 1.95 g pure product, and 3.035 g pure product was evaporated then loaded into an alumina (neutral) column (14 cm high, 5 cm wide). Alumina TLC with chloroform solvent confirmed that our product was in fractions 1-7 and was then evaporated in a pre-weighed flask making 30.028 g of pure product. Combined all pure substances together in a pre-weighed 125 mL flask, evaporated methyl chloride, then hooked up to vacuum for 3 hours. NMR confirmed that 26.773 g of pure product had been recovered, making a 94% yield. 2. Double Bromination of N-Protected 2-methylindole (6/14/07, I-15) O O N O O NBS/CCl4 N r.t. Br Br Name of compound Formula Formula Mass Amount Other Moles Mole Ratio C11H11O2N 189.21 g/mol 15.151 g NBromosuccimide C4H4BrNO2 177.99 g/mol 31.326 g 0.08 mol 1 0.176 mol 2.2 Carbon Tetrachloride CCl4 C11H9O2NBr2 347.006 g/mol 250 mL Ref: 3Former Student: Amna Ali’s Fall 2006 Research Paper, pg 15 Procedure: Weighed an empty 1000 mL flask and added 15.151 g of C11H11O2N. Measured out 31.321 g N-Bromosuccimide (NBS). Stirred 250 mL carbon tetrachloride into C11H11O2N. When NBS was added to the mixture, the mixture turned a lemonade-yellow color and was stirred over night. Summitt 9 The next day, the mixture was a cloudy, orange juice color and TLC on alumina with a 2:1 hexanes:chloroform solvent was used to test if the reaction was complete. A sample was taken from the mixture, evaporated under air, and used for NMR. NMR showed some impurities so the sample was added back to the original mixture by using methlyene chloride. The mixture was then filtered and rinsed with carbon tetrachloride. An orange liquid was collected in a flask and an alumina TLC with was taken the same 2:1 hexanes:chloroform solvent. The orange liquid was then evaporated in the evaporation machine; as a result, a white powder formed after evaporation which was then refrigerated over the weekend. The filtered powder, presumable the byproduct succimide, still contained the product after doing TLC, therefore was added to the mixture for the first column. A silica column (12 cm high, 7 cm wide) was assembled and a 1:1 chloroform:hexanes eleunt was used as the refrigerated, filtered white powder was loaded into the column. A silica TLC was taken of the first 6 fractions with a 1:1 chloroform:hexanes solvent. In a pre-weighed pear-shaped 1000 mL flask, fractions 1-4 were combined, evaporated, re-weighed (17.583 g pure product), and refrigerated. Column was continued to fraction 8 where the eleunt was changed to just chloroform and was continued to fraction 13. The more impure fractions 5-12 were combined, evaporated, and refrigerated over night. Fractions 5-12 were taken from the refrigerator and loaded into a silica column with 2:1 hexanes:chloroform eleunt. Silica TLC with 1:1 chloroform:hexanes showed that fractions 3-7 contained the product; fractions were evaporated in a pre-weighed flask. After evaporation, 4.948 g pure product was collected and added to the 17.583 g of pure product from the day before making a total of 22.531 g of product; a 81.1% yield. Summitt 10 3. Coupling using n-Butylamine (6/22/07, I-23) O O 1/2 N NH2 Br + Na2CO3 Br Name of Compound Formula Formula Mass Amount Other Moles Mole Ratio CH3CN 68oC 6.007 g Sodium Carbonate Na2CO3 82.999 g/mol 7.179 g 0.0173 mol 0.0865 mol 2 10 C11H9O2NBr2 347.00 g/mol N Br Acetonitrile CH3CN 41.053 g/mol 500 mL N O Br O N OCH3 OCH3 NButylamine C4H11N C26H27Br2N3O4 73.13 g/mol 605.32 g/mol 0.855 mL d = 0.74 0.00865 mol 1 Ref: Former Student: Amna Ali’s notebook 2 Procedure: 6.007 g C11H9O2NBr2 and 7.179 g sodium carbonate were mixed with 500 mL acetonitrile in a 1000 mL flask. Silicon oil bath was heated to 68oC. N-Butylamine was then added to the flask and placed into the oil bath and the contents was stirred over night. 1 H NMR of a small aliquant, evaporated and dissolved in acetone-d6 showed a very clear product; however, TLC on silica with 1:1 chloroform:hexanes, showed a little impurity. About 500 mL of distilled water was added to reaction mixture in the separation funnel. 150 mL of diethyl ether was added (x3) and extracted material. The material was also filtered by a vacuum filtration to remove excess carbontates. The combined organic layers were a yellow liquid. The liquid was then dried with sodium sulfate. The organic layer was filtered into a pre-weighed 500 mL flask, evaporated, and refrigerated over night. Summitt 11 NMR was taken and 4.787 g of pure product was recorded making a 91.4% yield. 4. Deprotection (small scale) (6/29/07, I-28) N Br N O Br O N NH2NH2*HCl + KOH 0oC N Br Br MeOH NH HN OCH3 OCH3 Name of Compound Formula Formula Mass Amount Other Moles Mole Ratio C26H27Br2N3O4 605.32 g/mol 0.5 g Hydrazinium Chloride N2H5Cl 68.5061 g/mol 0.908 g Potassium Hydroxide KOH 56.108 g/mol 1.856 g 0.826 mmol 1 13.21 mmol 16 33.04 mmol 40 C22H23Br2N3 489.25 g/mol Procedure: In a pre-weighed 100 mL round bottom flask, 0.5 C26H27Br2N3O4, 0.908 g hydrazinium chloride, and 10 mL methanol were combined and set in an ice bath of 0oC. 1.856 g potassium hydroxide was dissolved in 10 mL methanol and added drop wise to the ice-bath mixture while stirring. The mixture was then taken off the ice bath and continued to stir at room temperature. An hour later, a silica TLC with 1:1 chloroform:hexanes solvent confirmed that the reaction was making progress. The mixture continued to stir over the weekend. Reaction mixture was poured into 70 mL brine in a separation funnel which was then rinsed with 40 mL methylene chloride. The funnel was shaken and the two layers were separated, the bottom methylene chloride layer (a peach color) was collected and saved. Separation was repeated two more times using fresh 40 mL methylene chloride everytime. The Summitt 12 methylene chloride layer was dried with sodium sulfate for 15 minutes, filtered into a preweighed 125 mL flask, and evaporated. The result was an amber colored oil. NMR showed some impurities, so an alumina (basic) column was assembled with a chloroform eleunt and fractions 1-9 were collected and tested on alumina TLC with chloroform solvent. Fractions 2-7 were combined and evaporated in a pre-weighed 1000 mL flask. The brown oil was vacuumed for 4 hours; NMR confirmed that 0.354 g of pure product was collected making a 87.6% yield. 5. Deprotection (large scale) (7/3/07, I-33) N Br N O Br O N NH2NH2*HCl + KOH 0oC N Br Br MeOH NH HN OCH3 OCH3 Name of Compound Formula Formula Mass Amount Other Moles Mole Ratio C26H27Br2N3O4 605.32 g/mol 2.501 g Hydrazinium Chloride N2H5Cl 68.5061 g/mol 4.527 g Potassium Hydroxide KOH 56.108 g/mol 9.268 g 4.13 mmol 1 66.08 mmol 16 165.2 mmol 40 C22H23Br2N3 489.25 g/mol Procedure: In a pre-weighed round bottom flask, 2.501 g of C26H27Br2N3O4, 4.527 g of hydrazinium chloride, and 50 mL methanol were combined and cooled by an ice bath to 0oC. 9.268 g of potassium hydroxide was dissolved in 50 mL methanol and added drop wise to the ice bath mixture while stirring. After all potassium hydroxide/methanol mixture was added, ice bath was removed, and mixture was allowed to stir at room temperature for 24 hours. Summitt 13 TLC was done on alumina with 1:1 chloroform:hexanes to show that the reaction was complete. In a 1000 mL separation funnel, 350 mL brine was added to reaction mixture. The flask rinsed with 200 mL methylene chloride, shaken, and drained methylene chloride layer. 50 mL of distilled water was added to the flask to dissolve the white-powdery substance. Fresh 200 mL methylene chloride was added to the flask, shaken, and the methylene chloride layer was drained; repeated a second time. All methylene chloride layers were combined and dried over sodium sulfate. In a pre-weighed 500 mL flask, the methylene chloride layer was evaporated and hooked up to vacuum for two hours. The column chromatography was carried out by Amna Ali. An alumina (neutral) column (11.5 inches high, 4.5 cm wide) was assembled; the following eleunts were used: Fractions Eleunt 1-11 1:1 chloroform:hexanes 12-15 2:1 chloroform:hexanes 16-35 Pure chloroform 36-43 98% chloroform 2% ethyl acetate 44-51 95% chloroform 5% ethyl acetate 52-59 90% chloroform 10% ethyl acetate 60-63 80% chloroform 20% ethyl acetate 64-71 1:1 chloroform: ethyl acetate Alumina TLC with pure chloroform solvent showed that fractions 52-70 contained the pure products. Fractions 52-70 were combined in a pre-weighed flask, evaporated, vacuumed, and re-weighed. NMR showed that 1.665 g of pure product was collected, making a 81.89 % yield. *Crystallization* After scraping out as much pure product from the deprotection (large scale) and refrigerated, we did a crystallization test with the remaining material. In four separate vials eleunts hexanes, diethyl ether, ether, and acetonitrile were tested on .001 g of product. After adding heat, hexanes appeared to have low solubility at room temperature, but higher at near Summitt 14 boiling point, so did ethyl acetate. In an empty pre-weighed flask, transferred remaining solid from the hexanes crystallization to a beaker by washing with hexanes and heating. The hot plate was used to heat the mixture in the beaker and filtered into a separate vial. Removed the vial from heating plate and let cool with top slightly open; after a few hours, nothing happened, so mixture was put in the freezer over night. The next morning, crystals still had not formed so air was blown on hexanes until dry, then added a few drops ethyl acetate and, immediately, crystals formed! The excess liquid was removed, then cooled crystals and some ethyl acetate in an ice bath. Crystals were then washed with the cool ethyl acetate. The excess liquid also grew crystals, so it was put in the ice bath as well and air was blown on it and let crystals grow in the ice bath. Crystals were washed with cool ethyl acetate three times to remove red liquid and leave white crystals, then dried carefully. The elemental analysis of the crystals showed the good match to a 1:1 co-crystal of the product with ethyl acetate. 6. Nickel Complexation (small scale) (7/10/07, I-40) 2NaH N Br NH Name of Compound Formula Formula Mass Amount Other Moles Mole Ratio Br 1 day HN C22H23Br2N3 489.253 g/mol 0.0306 g 0.0625 mmol 1 N Sodium Hydride NaH 23.998 g/mol 0.0030 g 0.125 mmol 2 NiCl2 N Br Acetonitrile CH3CH 41.053 g/mol Br / THF "the catalyst" “brown species” 1 day N Nickel Chloride NiCl2 129.596 g/mol 0.0081 g 0.0625 mmol 1 ? Summitt 15 Procedure: (In the glove box) In a pre-weighed flask 0.0306 g of C22H23Br2N3 and in a separate vial 0.0030 g sodium hydride were weighed. About 5 mL acetonitrile was added to C22H23Br2N3, then transferred to sodium hydride and stirred the pale yellow liquid. About an hour later, the color changed to a brown color; left stirring over night. Using about 5 mL acetonnitrile, 0.0081 g nickel chloride was added to the mixture, and continued to stir over night, a cloudier brown color appeared. Mixture was heated and turned black. Heat was removed and color changed back to brown color. Stir was stopped and a white precipitate appeared at the bottom of the brown liquid. Liquid was filtered and vacuumed. 1H NMR CD3CN showed something that looked like a mixture of two species, one of which seemed like the sodium salt. 7. Nickel Complexation (attempt 2) (small scale) (7/12/07, I-42) 2NaH N Br NH Name of Compound Formula Formula Mass Amount Other Moles Mole Ratio Br NiCl2 N Br Br 1 day HN N C22H23Br2N3 489.253 g/mol 0.0306 g 0.0625 mmol 1 Sodium Hydride NaH 23.998 g/mol 0.0030 g 0.125 mmol 2 Acetonitrile CH3CH 41.053 g/mol / THF "the catalyst" “purple species” 3 days N Nickel Chloride NiCl2 129.596 g/mol 0.0081 g 0.0625 mmol 1 ? Summitt 16 Procedure: (In the glove box) In a pre-weighed flask 0.0306 g of C22H23Br2N3 and in a separate vial 0.0030 g sodium hydride were weighed. About 5 mL acetonitrile was added to C22H23Br2N3, then transferred to sodium hydride and stirred the pale yellow liquid over night. The color changed to a dark brownish color. A small sample was taken, evaporated, and did NMR in CD3CN to record the spectrum of the sodium salt. NMR mixture was added back to the original mixture. Using about 5 mL acetonitrile, 0.0081 g nickel chloride was added to the mixture, and let stir over the weekend. The reaction had turned a dark purple, almost black. After filtering and vacuuming, a 1H NMR in CD3CN was taken; the results showed a mixture of at least two, one of them was very similar to the original ligand, which was not a good thing (where did the protons come from?). The mixture was filtered again using a filtering aid after returning the sample used for NMR and vacuumed. The filtrate was condensed to half volume to do a preliminary crystallization test. Diethyl ether was added; the solubility of the purple species did not seem to drop by ether addition, thus not suitable for re-crystallization medium). The mixture was then evaporated and left a little bit wet; 1.5 mL of toluene was added and put in the refrigerator. *Crystallization Test* The purple compound was tested with different solvents for the best conditions during the crystallization test. At room temperature, toluene seemed to dissolve well, while diethyl ether proved to be fairly soluble, and hexanes was a very poor solvent at both low and high temperatures. Therefore, crystallization was done with toluene and hexanes. The mixture was dissolved in toluene and then filtered to remove the undissolved solid. Hexanes was added to the top and allowed for a slow diffusion. After a couple of hours, there were some solids observed Summitt 17 but they were not crystalline. The mother liquor was transferred to another vial and the remaining solid was dried under vacuum. An NMR was done of the evaporated solid in CD3CN. NMR showed a very dilute sample, but when the picture was blown up, the results showed that crystallization seemed to have gotten rid of any of the starting ligand. 8. Drying of Nickel Chloride As anhydrous NiCl2 was suspected as the proton source, we decided to further dry under vacuum and heat. A round bottom flask and stopcock was heated in the oven and then pumped into the glove box. Poured a small amount of nickel chloride was added to the round bottom flask and heated in a heating mantle while hooked up to the vacuum for 3 hours. The nickel chloride was occasionally stirred to open up power and evaporated any excess liquid. The color changed from yellow to orange which showed that there may have been a presence of water in the nickel chloride. 9. Nickel Complexation (attempt 3) (small scale) (7/18/07, I-45) 2NaH N Br NH Br 1 day HN Name of Compound Formula Formula Mass Amount Other Moles Mole Ratio C22H23Br2N3 489.253 g/mol 0.0306 g 0.0625 mmol 1 N Sodium Hydride NaH 23.998 g/mol 0.0030 g 0.125 mmol 2 NiCl2 N Br Br N Acetonitrile CH3CH 41.053 g/mol / THF "the catalyst" “purple species” 4 days Nickel Chloride NiCl2 129.596 g/mol 0.0081 g 0.0625 mmol 1 ? Summitt 18 Procedure: (In the glove box) In a pre-weighed flask 0.0306 g of C22H23Br2N3 and in a separate vial 0.0030 g sodium hydride were weighed. About 5 mL acetonitrile was added to C22H23Br2N3, then transferred to sodium hydride and stirred the pale yellow liquid over night. The color had once again changed to a dark brown color; using about 5 mL acetonitrile, 0.0081 g nickel chloride was added to the mixture, and let stir over the weekend. After evaporation of the purple mixture, the 1H NMR showed no peaks resembly the original ligand, but showed different peaks from the attempt 2 purple species. 10. Nickel Complexation (large scale) 2NaH N Br NH Br Name of Compound Formula Formula Mass Amount Other Moles Mole Ratio Br 1 day HN C22H23Br2N3 489.253 g/mol 0.0918 g 0.1875 mmol 1 Procedure: (In the glove box) N Sodium Hydride NaH 23.998 g/mol 0.0090 g 0.375 mmol 2 NiCl2 N Br N Acetonitrile CH3CH 41.053 g/mol / THF "the catalyst" “purple species” 2 days Nickel Chloride NiCl2 129.596 g/mol 0.2430 g 0.1875 mmol 1 ? Summitt 19 Conclusion The yield of each step has been improved by optimizing the reaction, workup, and purification conditions. This is the first time our lab produced this ligand in a large (2 g) scale, which allows us to explore metal complexation chemistry. The synthesis reactions conducted thus far have been very successful. Future work includes having a successful reaction between the tridentate ligand and nickel chloride, and then testing the catalyst for catalytic behavior.