Wind Energy Cost and Feasibility of 2 MW Wind Power Project

Wind Energy Cost and Feasibility of 2 MW Wind Power Project

V. P. Khambalkar

1

, V. N. Madansure

2

S. R. Gadge

3

and S.S. Marawar

4

Department of Unconventional Energy Sources and Electrical Engineering,

Dr Panjabrao Deshmukh Krishi Vidyapeeth, Akola - 444 104, Maharashtra, India

-------------------------------------------------------------------------------------------------------------

Abstract

Present research work has been carried out at 2 MW installed capacity Wind Power Project, Motha

District Amaravati, Maharashtra State, India. The main objectives of this work are to evaluate the various cost involving in the energy production. The cost of energy production per kWh (electrical energy) has been found for the first year of operation. The economics of wind energy and there by the feasibility of the power project was examined by estimating per unit cost of energy, Net Present Value/Worth (NPV), Benefit-Cost ratio (B-C), Internal Rate of Return (IRR), and pay back period of the power system. The discounted cash flow (DCF) method was used to find out the IRR. In wind energy conversion system, three costs were examined for the evaluation of the production cost of energy generated. Installed capital cost, specific capital cost, and life cycle cost of energy was evaluated for the per unit cost. Considering the discount rate on the investment for the project as 11.5 per cent, the B-C ratio comes to 1.36 and IRR comes to 15.10 per cent.

1. Introduction

Electricity plays vital role in the socio-economic development of the nation. India, one of the fast developing countries in the world, which thrives for the energy. The second development stage in the India is on the verge of completion. The commercial energy resources available in the country are limited. Several studies have established that wind energy produces more jobs per capital invested or per kilowatt -hour generated than most conventional resources.

Out of the various renewable energy sources wind is the only renewable energy source that has reached commercial viability stage for large grid connected requirements.

Government of India, in 1952, has initiated an ambitious project to harvest energy from the wind. In December 1952, a Wind Power Sub -committee was constituted under the Council of Scientific and Industrial Research, New Delhi. Wind technology in

India was introduced in the late 1970’s with Danish Development Co -operation (More and Maheshwari, 1984).

The market-oriented approach of the government of India, since the inception of the wind power programme in 1983-84, has resulted in effective commercialization of wind power projects. Wind potential in the country has been assessed at 45,000 MW while in Maharashtra it is 3650 MW, as on today. The potential sites have been identified after study carried out at different wind monitoring stations. The sites having annual mean wind power density more than 150 W/m 2 are considered as potential ones.

While 208 of such sites have been identified in the country. Government of India through Ministry of Non-conventional Energy Sources established 34 demonstration projects in 11 states with the total installation capacity of 62.8 MW. These demonstration projects attached large -scale private sector investment (Sudhirkumar,

2002).

Wind power capacity of 615 MW was added during 2003-04 taking the cumulative capacity to 2483 MW, the fifth largest wind power installed capacity in the world (MNES, 2004).

The demand of energy is increasing day by day in the country. To achieve the targeted demand and satisfy the consumers, the Government of India, decide to increase the wind power generation capacity of the country. In the wind energy harnessing, now, India became the fifth ranked in all over the world.

1. Assistant Professor, 2. Ex- Head of Department, 3. Head of Department and

4. Professor, Department of Economics E-mail address: vivek_khambalkar@yahoo.co.in:

vivek_khambalkar@hotmail.com

The assessed wind power potential in India is nearly 45000 MW, majority of the wind sites have found the wind power density more than 200 W/ m 2 , which is considered proper for the wind power plant installation. The present analysis describe performance and cost involved in the wind power system its first year of operation.

The wind power project is installed at the Motha near the popular hill station, Chilkhaldara situated in the seven-hill range in the Western Vidarbha of the state of Maharashtra, India. The project consists of two-wind turbines of the 1 MW each.

The financial breakdown of the system is studied for the appraisal of project. The working life of the wind turbine has been considered 20 year. This power project is one of the demonstration projects installed by Government of India.

2. Materials and Methods

The wind power generation data have been collected from the station for first year of operation i.e., 2003-04. The gathered data were analyzed for per month wind energy generation and the system reliability. The costs involved in the project were collected from the manufacturing company and the installation company. The agreement between the installation company and the government was for the operation of the wind power project. The company has to serve at least five years from the installation of the wind power project. The installation company has asked Rs

2,00,000 for carrying out the operation and maintenance for the five year (MEDA,2002).

2.1 Theory for the Analysis

One of the main benefits of wind energy is economic gain, both for individuals and for communities. Individuals can save money on their energy bills and even make money, by generating wind power. Communities can diversify their economies and enjoy greater reliance on local resources when their members invest in wind.

2.2 Wind energy costs

The costs of these (wind, solar etc.) renewable energy systems have decreased significantly over the past 15 years. The three methods customarily used to measure the costs and economic performance of wind turbine systems. The measures begin with the installed capital cost, continue with the specific capital cost (the installed capital cost to generate one unit of energy per year), and end with the cost of energy (NWCC,1997).

Installed capital cost: The simplest of the three measures of cost for wind turbine systems is the installed capital cost. This measure includes all planning, equipment purchase, construction and installation costs for a turnkey wind system, ready to operate. As such this cost will include the wind turbine and tower delivered and installed at the site together with all electrical, maintenance and other supporting infrastructure (NWCC, 1997 and Deb 2002).

Specific capital cost: The second measure of cost combines the installed cost, the strength of the wind resource and the matching of the wind resource to the wind turbine power curve. This cost measure is called the specific capital cost or the unit of energy capital cost (NWCC,1997 and

Deb,2002). The specific capital cost is the installed cost to obtain a Kilowatt-hour of energy per year. That is, the cost to procure, install and make ready generating capacity that will generate a kilowatt-hour per year.

Installed capital cost

C= --------------------------- Rs./(kWh/yr.)

Energy production per year

This second cost measure, the specific capital cost, still is not all-inclusive. It does not include the cost of operation and maintenance over the lifetime of the facility, the costs of frequent major overhauls or the cost of capital.

Life-cycle cost of energy: The third and most comprehensive measure of wind energy cost is the life-cycle cost of energy (CoE). This measure incorporates all elements of cost i.e., installed

capital cost, cost of capital, cost of operations and maintenance over the life the installation and cost of major overhauls and subsystem replacement.

ICC + FCR + O&M + (LRC)

CoE = ------------------------------------------

Energy production / year

Where, ICC = Installed capital cost, FCR = Annual fixed charge rate ,O&M= Annual operation and maintenance cost and LRC= Levelized replacement cost

2.3 Economic feasibility of wind farm

The project evaluation technique (discounted cash flow) was used to measure the economic feasibility of wind farm. This technique measure the productivity of capital invested and for which the flows of costs and returns over the life period of the wind farm required. These costs and be brought to refer to the particular point of time i.e., present period by discount/ compounding them.

Comparative picture of different measures of capital productivity used in economic evaluation of investment in wind farm were use are net present value, benefit cost ratio, internal rate of return and payback period (Aktar,1996; Burton et at ., 2001; Gittenger,1982; and

Varadarajan and Jeya Kumar,1991).

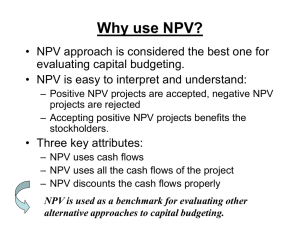

Net present value: In this method, generally the discount rate/compound rate, which reflects the price of the investment funds, is used to arrive at costs and returns to a common point of time.

These costs are subtracted from the return to get the net present values of the project. The positive net present values indicate that the investment is worthwhile and the size of the net present value

(NPV) indicates how worthwhile the project is in utilizing the resources to maximize income.

Following expressing is used to work out the net present value.

NPV =

N R.t-C.t

----------------------- t=1 (1+i) t

Where R is the returns in year t, C is the costs in year t, N is the project life, i is the discount rate in per cent

The decision for profitability criteria are:

If NPV >0 Investment is worthwhile

NPV<0 Investment is not worthwhile

NPV=0 Indifferent case

Benefit cost ratio: The benefit cost ratio measures the returns or benefit per unit of cost of investment. ........

N R.t

----------

t=1 (1+i) t

Benefit cost ratio = ------------------------------

N C.t

-----------

t=1 (1+i) t

The decision criteria are:

If B-C>1 Investment is worthwhile

B-C<1 Investment is not worthwhile

B-C=1 Indifferent case

Internal rate of return (IRR): The internal rate of returns means the discount/ compound rate at which the present value of returns equals that of costs. According the derived discount rate (IRR-r) is compared with the price of the investment funds to the know the worthiness of the project.

N Rt-Ct

IRR=

------------------

t=1 (1+i) t

Solve this equation to find the value of IRR-r

The decision profitability criteria are:

If r >1 Investment is worthwhile

r<1 Investment is not worthwhile

r=1 indifferent case

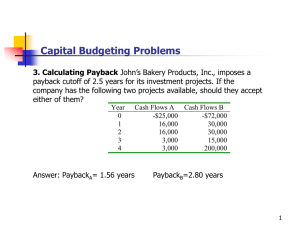

Payback period: This is the simplest of the techniques for evaluating an investment proposal. It is defined as the time period within which the initial investment of the project is recovered in the form of benefits. In other words, this is the length of time between the starting time of the project and the time when the initial investment is recoupled in the form of yearly benefits.

Expressing it in notation:

I

P = ------

C

Where, P is the payback period, I is the initial investment, and C is the yearly net cash flow.

3 Results and Discussion

3.1 Economics of Wind Power Project

The economics of wind energy and feasibility of the project is examined by estimating per unit cost of energy and by estimating NPV, B-C ratio, IRR and pay back period Table 1 shows information gathered from station regarding capital cost and energy production of 2 mw wind farm for one year. the annual capacity factor was calculated from the energy data collected per month for the station.

3.2 Wind energy cost per unit electrical energy generation

In wind energy conversion system, three costs were examined for the evaluation of the production cost of the wind energy conversion system. They are namely : i) installed capital cost, ii) specific capital cost and iii) life cycle cost of energy.

Installed capital cost : This cost includes all planning equipment purchase, construction and installation costs for a turn-key wind power system, ready to operate. Total installation cost for the

2000 kW capacity of wind power project comes to Rs. 972 lakh. Installed capital cost per kilowatt was worked out to be Rs.48600.

Specific Capital Cost : The second measure of cost, combines the installed cost, strength of the wind resource and the matching of the wind resource to the wind turbine power curve. The installed capital cost per kW was Rs. 48600 and the annual wind energy production of the site for

Table 1 Capital statement and energy production of 2MW wind farm

Sr.

No.

Particular Parameter

1 Wind farm capacity

2 MW

2 Installed Capital Cost

Rs.972 lakhs

3 Annual Capacity Factor

23 % (From initial year of operation)

4 Annual O & M cost

Rs.200000

5 Sale price of electricity (MSEB)

3.50 Rs./kWh

6 Discount rate

11.5 %

7 Project life time

20 Year (NWCC)

8 The annual energy yield 37.3 lakhs units

9 The gross annual income for first year

Rs.130.55 lakhs

10 Levelised Replacement Cost

25% on the annual O & M cost for the first year

11 Annual Fixed Charge Rate (FCR) 11.5 % this year under consideration was 37.3 lakh of electrical unit. Using the annual energy production as 40 lakh unit (estimated considering 23 per cent capacity factor for the future) and the installed capital cost value of Rs. 972 lakhs the specific capital cost was calculated to be (972/37.3) i.e.,

26.05 Rs./(kWh/yr) on the basis of first year.

Life-cycle cost of energy

The third and most comprehensive measure of wind energy cost is the life-cycle cost, which incorporates capital cost component, annual operation and maintenance cost, and cost of replacement occurred in the operation of the wind power project. Capital cost component is calculated using specific capital cost (26.05 Rs./(kWh/yr)) and fixed charge rate of 11.5 per cent which comes to 3.0 Rs/kWh. Annual operation and maintenance cost was Rs. 2 lakh for the wind power project and this was 0.05 Rs./kWh for the one year. Cost of levelized replacement was examined by considering the 25 per cent of the wind farm operation and maintenance cost, which comes to 0.0125 Rs/kWh (NWCC, 1997).

The cost of energy is equal to sum of three components which are mentioned above i.e., capital cost component i.e., 3.0 Rs per kWh, operation and maintenance cost i.e., 0.05 Rs per kWh and cost of replacement i.e., 0.0125 Rs per kWh which comes to 3.06 Rs per kWh. The relative magnitudes of these estimated cost values (Table 2) provide insight into where the overall economics of this system may be impacted. From Table 2 it is seen that the leading component of cost of energy is the capital cost component followed by the cost of operation and maintenance.

The capital cost component represents 98 per cent of the total cost of energy. This is true because all renewable energy systems required very high initial investment and operation maintenance and replacement cost are meagre i.e., 1.60 per cent only.

Profit statement of wind power project at Motha: Information presented in the Table.3 shows the profit statement for 2MW wind power project. The profit for per kWh of energy production was worked out to be Rs 0.44 in the first year of operation. Considering electrical energy production of 37.3 lakh and selling price of 3.5 Rs / kWh, the gross annual income comes to Rs.

130.55 lakhs. The production cost comes to (Rs 2.66 X 37.3 Lakh) Rs 114.13 lakhs and so profit for the first year of operation is Rs 16.41 lakhs.

Table 2 Comparison of calculated cost of energy (CoE) component

CoE component

Value

(Rs./kWh)

Basic of estimate

Capital cost 3.00 Used FCR = 10% per year

Percent total CoE

98.00 of

Operation and maintenance 0.05

As planned by MEDA Rs.

200000 per year

1.60 cost

Levelized replacement cost

Total CoE

0.0125

3.06

25 % on the operation and maintenance cost

0.40

Total of all cost component 100

Table 3 Profit per unit of wind energy generation

Sr, No. Particular

Per unit

(Rs.)

1 Total cost of Energy (a+ b+ c) a) Capital cost component

3.06

3.0

2 b) Annual O & M Cost c) Levelised replacement cost

Return per unit

0.05

0.0125

3.5

3 Net profit (2-1) 0.44

3.3 Economic feasibility of wind power project

For initial project appraisal some form of discounted cash flow is normally required and the non-discounted indicators are not used. The discounted rate chosen reflects the values of the lender places on the money and the risk that are anticipated in the project.

In economic term the discount rate is an indication of the opportunity cost of capital to the organization. Opportunity cost is the return on the next best investment and so is the rate below it is not worthwhile to invest in the project. In the India at present discount rate of 11.5 per cent

(MNES, 2004) would not be uncommon for commercial power projects reflecting the value placed on capital and the perceived level of risks.

While working out the costs and returns from wind power project in the above analysis which was carried out for year of installation and first year working, the time factor was not considered. To bring the past and future costs to present worth compounding and discounting technique was used and it was done at 11.5 per cent discount rate. The economic feasibility of wind power project was examined by working out the net present value (NPV), benefit-cost ratio

(B-C ratio), internal rate of return (IRR) payback period, considering operation and maintenance cost for first five year as 2 lakh, from 6 to 10 year 3 lakh from 11 to 15 year 3.5 lakh and 1-16 to

20 year 4 lakh. For the income calculations, the sale price of wind energy generated per kWh is taken as Rs 3.5 in the first year of operation and small escalator from the next year as 15 piase

(Rs. 0.15) per kWh every year for a period of thirteen year (Chaudhari, 2003). The present worth of cost and present worth of benefits at 11.5 per cent discount rate are Rs 99580814 and Rs

136408658 respectively.

Net present value : The information presented in Table 4 reveals that the net present value (NPV) is positive and so the project is feasible and suitable for further consideration. The net present worth for wind power project was worked out to be Rs.26897294 with the 11.5 per cent discount rate and the discount factor for the year 20 as 0.1133. This discount factor indicates that the present value of income stream in that year is only 11.33 per cent of its cash value.

Benefit-cost ratio : The project is insensitive to operation and maintenance costs at the level of each year (as only 2 lakh to 5 lakh per year range is considered for O&M cost). The B-C ratio of wind power project was found out by taking ratio of present worth of benefit and present worth of cost which comes to 1.36. Since the ratio is greater than unity, the investment is financially justified. However, the capital investment of one rupee in wind power project shows a profit of

Rs.0.36.

Internal rate of return : The internal rate of return of the wind power project for the 20 years life period was worked out from the trial and error method of calculation. The internal rate of return means the rate at which the present worth of benefit minus the present worth of cost comes to zero i.e., the net present value becomes zero at that IRR. The IRR in the present case is worked out to be 15.10 per cent.

Table 4 Financial outlay for wind power project, Motha

Sr.No.

1

2

3

4

5

Particular

Present worth of cost

Present worth of benefit

Net present value (NPV)

Benefit-cost ratio (B-C)

Internal rate of return

(IRR)

Amount and Per cent

99580814

136408658

26897294

1.36

15.10 %

Figure in rupees

Pay Back period : Payback period discriminates whether the project is feasible or not for the threshold lifetime. The net cash flow is calculated by deducting yearly operation and maintenance cost from the gross annual income of the wind power project. Then cumulative net cash flow is calculated for different years (Table 5). Payback period of the wind power project was worked out to be six years nine months and four days (6.76 year), where the cumulative net cash flow becomes equal to the initial investment at the beginning.

It means that after nearly seven years the operation of the project it will be giving net profit and as its life of the wind energy conversion system is nearly 20 years, the project is found economically feasible. Not only the system (Wind Energy Conversion System) generates ample electrical energy but at the same time keeps the environment very clean and so its name as “ Green

Power” is justified.

Table 5 Computation of payback period of the wind farm of 2MW capacity

Year

0

1

Initial

Investment

(Rs)

97200000

200000

Income

Rs/year

-

12950000

Net Cash

Flow

Rs/year

-

12750000

Cumulative Net

Cash Flow Rs/year

-

13800000

2

3

4

5

6

200000

200000

200000

200000

300000

13505000

14060000

14615000

15170000

15725000

13305000

13860000

14415000

14970000

15425000

27105000

40965000

55380000

70350000

85775000

7*

8

9

300000

300000

300000

16280000

16835000

17390000

15980000

16535000

17090000

Payback period = 6.75 year i. e., 6 year 9 month and four day

* shows year in which the installed capital cost recoupled i.e., 972 lakhs.

101755000

118290000

135380000

4.

Conclusions

Wind energy cost was determined for the energy production in terms of Rs per kWh. A very simple technique was used for finding the cost of energy generation. The cost of energy of the wind generation includes the three cost component. It was realize that installation cost is the leading factor in the wind energy cost. Economic feasibility of the wind power project was determined over the life of the system. The result obtained from this method, project is feasible and which is acceptable from the net present value (NPV). Pay back period of the wind farm comes within the early few years. Internal rate of return of the wind form was also more than the discount factor taken for the cash flow analysis.

Wind energy costs of the power project were worked for the installation capital cost, specific capital cost and the life -cycle cost of the energy. Installation cost per kW was found more, which implies on the cost of energy of t he WECS.

Specific capital cost gives the strength value of the resource and the matching to the wind turbine power curve. This cost was found by the energy production of the system to the total installation cost of the WECS.

In the cost of energy of energy generation capital cost component was found the leading which directly reflect the production cost of the energy.

The net present value of the wind power project was found positive for the life time of the project.

In the year on 20 the discount factor indicates that the present value of income stream in that year is only 11.33 per cent of its cash value.

The B-C ratio of wind power project was found out by taking ratio of present worth of benefit and present worth of cost which comes to 1.36. Since the ratio is greater than unity, the investment is financially justified.

The internal rate of return (IRR) means the rate at which the present worth of benefit minus the present worth of cost comes to zero i.e., the net present value becomes zero at that IRR.

The IRR in the present case is worked out to be 15.10 per cent.

Payback period of the wind power project was worked out to be six years nine months and four days (6.76 year), where the cumulative net cash flow becomes equal to the initial investment at the beginning.

5. References

Atkar R.B. 1996. Economic of production of important crops grown on farmers field in Akola

District. unpublished Master of Science thesis in agriculture Dr. PDKV, Akola (MS).

Barish,N.N. 1962. Economic Analysis. New York McGraw-Hill.

Chaudari S.R. 2001. Salient Features of Tariff Order by MERC for Wind Power Projects.

Future

Energy ,MEDA,Pune:37-39

Deb. M. K. 2002. Wind Power Generation. The Sunrise Sector. In MEDA Foundation day Seminar on “Future Energy” Organized by Maharashtra Energy Development Agency, Pune 25-27,

July 2002: 30-36.

Fabrycky W.J. and G.J.Thuesen. 1975 Economic Decision Analysis. New Jersey Prentice-

Hall,Inc.

,Englewood Cliffs.

Gittenger J.P.1982 Economic analysis of agricultural projects. London ,The Johns Hopkins

University Press.

MEDA 2002. News and Events: 2 MW Demonstration Power Project at Motha Commissioned.

Future Energy . Maharashtra Energy Development Agency, 1(2): 31.

MNES 2004. Renewable Energy in India, Business Opportunities, Ministry of Non-Conventional

Energy Sources, GoI,New Delhi.

NWCC 1997.Wind Energy Costs. NWCC Wind Energy Series No.11, Nation Wind Coordination

Committee, at www.nationalwind.org

RERL 2003. Wind Power : Performance and Economics. Wind Power on the Community Scale,

Renewable Energy Research Laboratory, University of Massachusetts, Amherst, at www.ceere.org/rerl/

Sudhir Kumar, 2002. Future Perfect; A Background Paper on “ Future Energy” In proceeding on

MEDA Foundation day Seminar on “ Future Energy”. Organized by Maharashtra Energy

Development Agency, Pune. 25-275, July, 200 2: 9-12.

Suzlon 2004. 1 MW Wind Turbine System and Power Curve. Suzlon Energy Ltd at www.suzlon.com

Varadarajan,D.B. and K.R.Jeya Kumar 1991. Economics of Wind Energy. New Delhi Ashish

Pbulication House :40-50

6. Acknowledgements

We would like to thank Maharashtra Energy Development Agency (MEDA), Pune and

SUZLON Wind Farm Developers, Pune (India) for providing us with valuable information and data of installation and energy generation in first year of operation wind farm.